Duet 3 MH6HC with Duet expansion 1XD, configuration issue

-

Hii,

I have Duet 3 Main board with Pannel due7", currently i am using small stepper motors, that works fine,

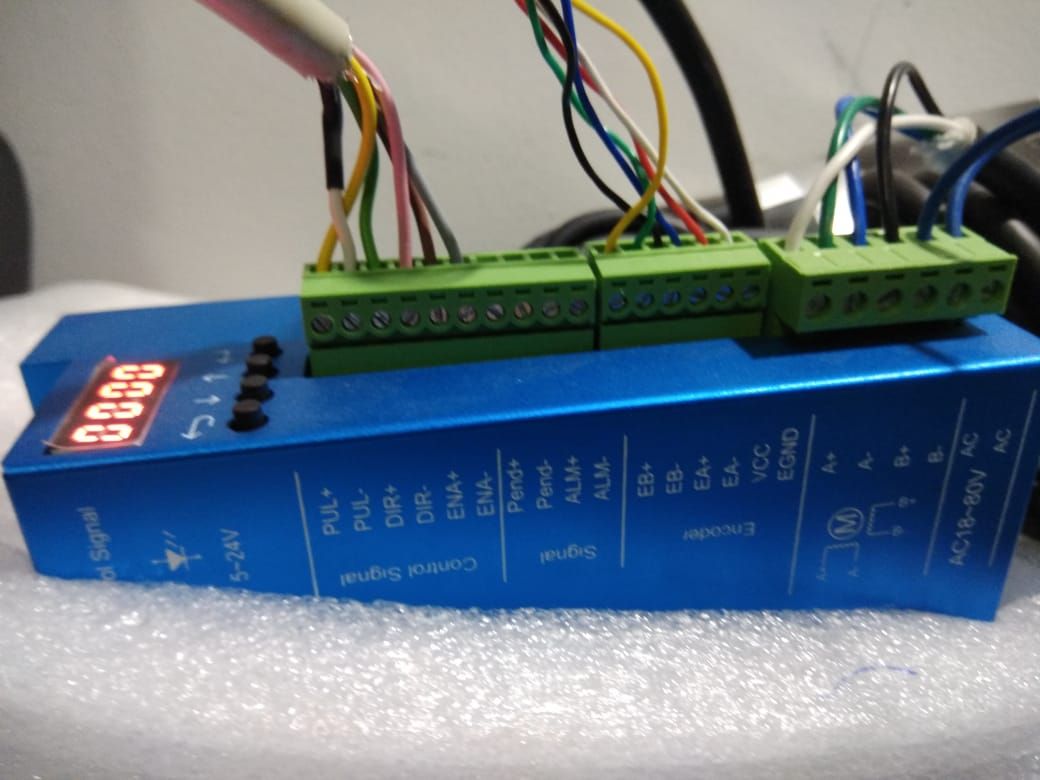

now we purchase "NEMA34 12Nm motor 86EBP181ALC and driver ZDM-2HA865 closed loop stepper motor drive", and also purchase "Duet3Expansion1XD" for 4 external stepper drive.

but in Rip Rap configuration not showing any option to configure the Duet3Expansion1XD. so how can be configured. if anyone have config file for external 1xd running Cartesian printer.

Please check the attachment........ -

Have you seen this?

-

We're still working on the configtool to add support for the 1XD. In the meantime you'll probably be able to choose tool boards as a replacement but the CAN addresses will be off (121 vs 122).

Please follow the EXP1XD documentation for further information.

-

@chrishamm tommarow we need to start the printing then how can we map X,Y,Z axis of external stepper motor

-

@chrishamm [0_1606676388351_config (20).zip](Uploading 100%)

-

can you send config. file then we edit manually 1xd expansion board mapping.config.json

-

@Phaedrux can you send sample config. with mapping of 1-X axis, 2-Y axis and 2-Z axis using EXP1XD .config.json

-

You're going to have to do some reading.

https://duet3d.dozuki.com/Wiki/Duet_3_Expansion_1XD#Section_Sample_configuration_examples

-

We have configured the 1XD external driver: But showing following errors:

30/11/2020, 12:07:39 M32 "0:/gcodes/config.g"

File 0:/gcodes/config.g selected for printing

Error: Setting not available for external drivers

Setting not available for external drivers

Ethernet is enabled, configured IP address: 0.0.0.0, actual IP address: 192.168.0.120

Finished printing file 0:/gcodes/config.g, print time was 0h 0m

30/11/2020, 12:07:38 Upload of config.g successful after 0sConfig .g code here:

; Configuration file for Duet 3 (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.8 on Fri Nov 20 2020 11:43:55 GMT+0530 (India Standard Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name; Drives

M569 P40.0 S1 R1 ; change enable polarity, active = disable drive

M569 P41.0 S1 R1 ; change enable polarity, active = disable drive

;M569 P42.0 S1 R1 ; change enable polarity, active = disable driveM584 X40.0 Y41.0 Z0.2 E0.3

;M584 X40.0 Y41.0 Z42.0 E0.3 ; set X, Y, Z, Extruder drivers

;M569 P0.0 S1 ; physical drive 0.0 goes forwards

;M569 P0.1 S1 ; physical drive 0.1 goes forwards

;M569 P0.2 S1 ; physical drive 0.2 goes forwards

;M569 P0.3 S0 ; physical drive 0.3 goes backwards

;M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E90.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E900.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z600.00 E6000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E500.00 ; set accelerations (mm/s^2)

M906 X2000 Y2000 Z2000 E2000 ; set motor currents (mA)

M84 S0 ; Disable motor idle current reduction; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y230 Z230 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!^io3.in" ; configure active-high endstop for low end on X via pin !^io3.in

M574 Y1 S1 P"!^io1.in" ; configure active-high endstop for low end on Y via pin !^io1.in

M574 Z1 S1 P"!^io2.in" ; configure active-high endstop for low end on Z via pin !^io2.in; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:220 Y15:220 S20 ; define mesh grid; Heaters

M308 S0 P"temp1" Y"thermistor" T100000 B5000 ; configure sensor 0 as thermistor on pin temp1

M950 H0 C"out2" T0 ; create bed heater output on out2 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp0" Y"thermistor" T100000 B5000 ; configure sensor 1 as thermistor on pin temp0

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S230 ; set temperature limit for heater 1 to 230C; Fans

M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency

M106 P0 S0.8 H-1 ; set fan 0 value. Thermostatic control is turned off; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings

M575 P1 S1 B57600

M570 H0 P999 S240

M552 S1

M552 192.168.0.132; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue -

M350 and M906 are not needed for the drives which use the external drivers, because microstepping and current setting are done in the external drivers (either by switches or by firmware setting of the external driver).

You've defined 2 drivers (40.0, 41.0, missing 0.2 and 0.3), but using 4 (XYZE).

-

@JoergS5 can you modify code for our requirement is:

- X axis stepper-01 nos

- Y axis stepper-02 nos

- Z axis stepper-02 nos

- internal extruder

-

@dkraja42 said in Duet 3 MH6HC with Duet expansion 1XD, configuration issue:

; Drives

M569 P40.0 S1 R1 ; change enable polarity, active = disable drive

M569 P41.0 S1 R1 ; change enable polarity, active = disable drive

;M569 P42.0 S1 R1 ; change enable polarity, active = disable drive

M584 X40.0 Y41.0 Z0.2 E0.3

;M584 X40.0 Y41.0 Z42.0 E0.3 ; set X, Y, Z, Extruder drivers

;M569 P0.0 S1 ; physical drive 0.0 goes forwards

;M569 P0.1 S1 ; physical drive 0.1 goes forwards

;M569 P0.2 S1 ; physical drive 0.2 goes forwards

;M569 P0.3 S0 ; physical drive 0.3 goes backwards

;M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mappingshould be changed to

M569 P40.0 S1 R1 ; change enable polarity, active = disable drive

M569 P41.0 S1 R1 ; change enable polarity, active = disable drive

M569 P42.0 S1 R1 ; change enable polarity, active = disable drive

M569 P0.0 S1 ; physical drive 0.0 goes forwardsand then in the M584:

M584 X40.0 Y41.0 Z42.0 E0.0 ; set X, Y, Z, Extruder drivers

so here you map your M569 P numbers to the letters of the drives.And remove X, Y and Z from M350 and M906.

-

@JoergS5 ok. thanks. i will try

-

@JoergS5

M32 "0:/gcodes/config.g"

File 0:/gcodes/config.g selected for printing

Error: Bad command: 584 X40.0 Y41.0 Z42.0 E0.0

Ethernet is enabled, configured IP address: 0.0.0.0, actual IP address: 192.168.0.120

Finished printing file 0:/gcodes/config.g, print time was 0h 0m; Drives

M569 P40.0 S1 R1 ; change enable polarity, active = disable drive

M569 P41.0 S1 R1 ; change enable polarity, active = disable drive

M569 P42.0 S1 R1 ; change enable polarity, active = disable drive

M569 P0.0 S1 ; physical drive 0.0 goes forwards584 X40.0 Y41.0 Z42.0 E0.0 ; set X, Y, Z, Extruder drivers

M92 X100.00 Y100.00 Z400.00 E90.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E900.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z600.00 E6000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E500.00 ; set accelerations (mm/s^2)

M84 S0 ; Disable motor idle current reduction

Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X230 Y230 Z230 S0 ; set axis maxima; Endstops

M574 X1 S1 P"!^io3.in" ; configure active-high endstop for low end on X via pin !^io3.in

M574 Y1 S1 P"!^io1.in" ; configure active-high endstop for low end on Y via pin !^io1.in

M574 Z1 S1 P"!^io2.in" ; configure active-high endstop for low end on Z via pin !^io2.in; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M557 X15:220 Y15:220 S20 ; define mesh grid; Heaters

M308 S0 P"temp1" Y"thermistor" T100000 B5000 ; configure sensor 0 as thermistor on pin temp1

M950 H0 C"out2" T0 ; create bed heater output on out2 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp0" Y"thermistor" T100000 B5000 ; configure sensor 1 as thermistor on pin temp0

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S230 ; set temperature limit for heater 1 to 230C; Fans

M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency

M106 P0 S0.8 H-1 ; set fan 0 value. Thermostatic control is turned off; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Custom settings

M575 P1 S1 B57600

M570 H0 P999 S240

M552 S1

M552 192.168.0.132; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue -

You appear to have lost the M at the start of the M584 line.

-

@dc42 yes we corrected M584 command line. but not able to move any axis.

30/11/2020, 13:04:11 M32 "0:/gcodes/homex.g"

File 0:/gcodes/homex.g selected for printing

30/11/2020, 13:04:10 Upload of homex.g successful after 0s

30/11/2020, 13:03:59 M32 "0:/gcodes/config.g"

File 0:/gcodes/config.g selected for printing

Ethernet is enabled, configured IP address: 0.0.0.0, actual IP address: 192.168.0.120

Finished printing file 0:/gcodes/config.g, print time was 0h 0m

30/11/2020, 13:03:58 Upload of config.g successful after 0s -

-

Are the red status LEDs on the expansion boards all blinking in sync with the one on the main board?

-

Have you tested the axis motors individually, using G91 followed by G1 H2 moves, e.g. G91 G1 H2 X10 ?

-

-

@dkraja42 all your config files are in the folder gcodes rather than the folder sys.

until you move them, they won't work correctly -

@dc42 said in Duet 3 MH6HC with Duet expansion 1XD, configuration issue:

ed stat

We have check all the manually G91 code but not able to move.

We have attached Video link and some images. please check ..

https://drive.google.com/file/d/1bjjLoMsEUapcxTMKrXVd_gO4B-17KvXU/view?usp=sharing

-

@dkraja42 and you removed M350 and M906 completely. Please remove XYZ values for it only, not the command completely. For E you still need the settings:

M350 E16 I1 ; configure microstepping with interpolation

M906 E2000 ; set motor currents (mA)