600 PPR 5v rotary encoder filament monitor help

-

Hi All,

Just trying to get my DIY filament monitor running but I'm getting a no calibration data statement. I've used these encoders on several Arduino projects and haven't had a single hiccup until now.This is my config file entry:-

M591 D0 P7 C"io4.in" S1 R1:1000 L0.0523 E0.1

L0.0523 = 10mm drive wheel, at 600ppr = 10 x 3.14 / 600

Prior to extrusion (200mm)

23/05/2021, 14:34:51 m591 d0

Pulse-type filament monitor on pin io4.in, enabled, sensitivity 0.052mm/pulse, allowed movement 1% to 1000%, check every 0.1mm, no data receivedAfter 200m extrusion

23/05/2021, 14:35:30 m591 d0

Pulse-type filament monitor on pin io4.in, enabled, sensitivity 0.052mm/pulse, allowed movement 1% to 1000%, check every 0.1mm, no calibration dataThis is the encoder:-

https://www.amazon.co.uk/gp/product/B015GYY7XU/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1Output

AB two -phase quadrature output rectangular pulse ,the circuit output is NPN open collector output type ,the output of this type can and with internal pull-up resistor is directly connected MCU or PLC ,such as 51 single or Mitsubishi PLC (PLC input mode should be connected to 0V switch function).The Encoder is connected on IO_4 as follows:

5V_Ext - Enc Vcc

GND - Enc V0

io4.in - Enc Phase AFrom the encoder output description above do I need a pullup resistor on io4.in?

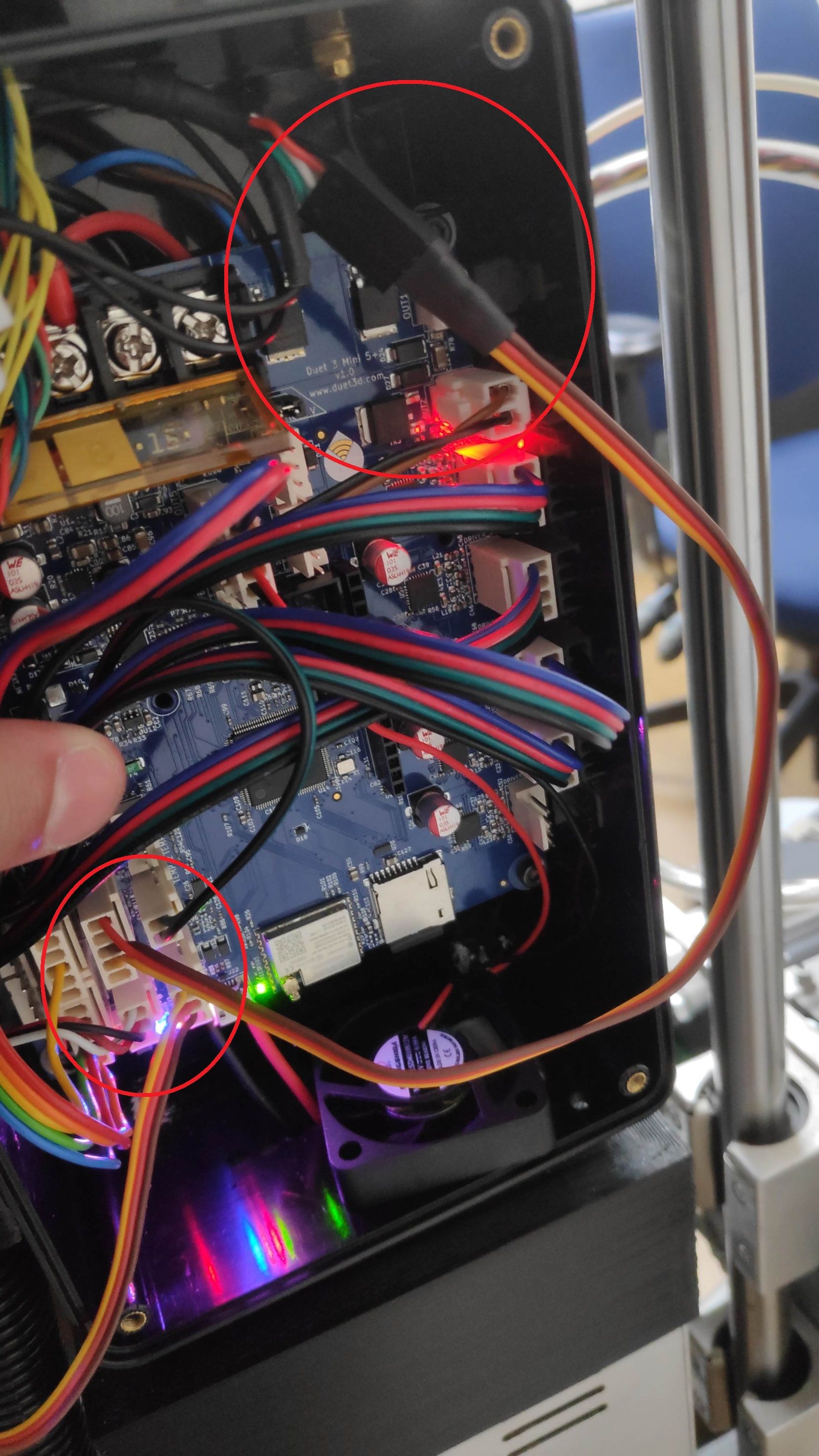

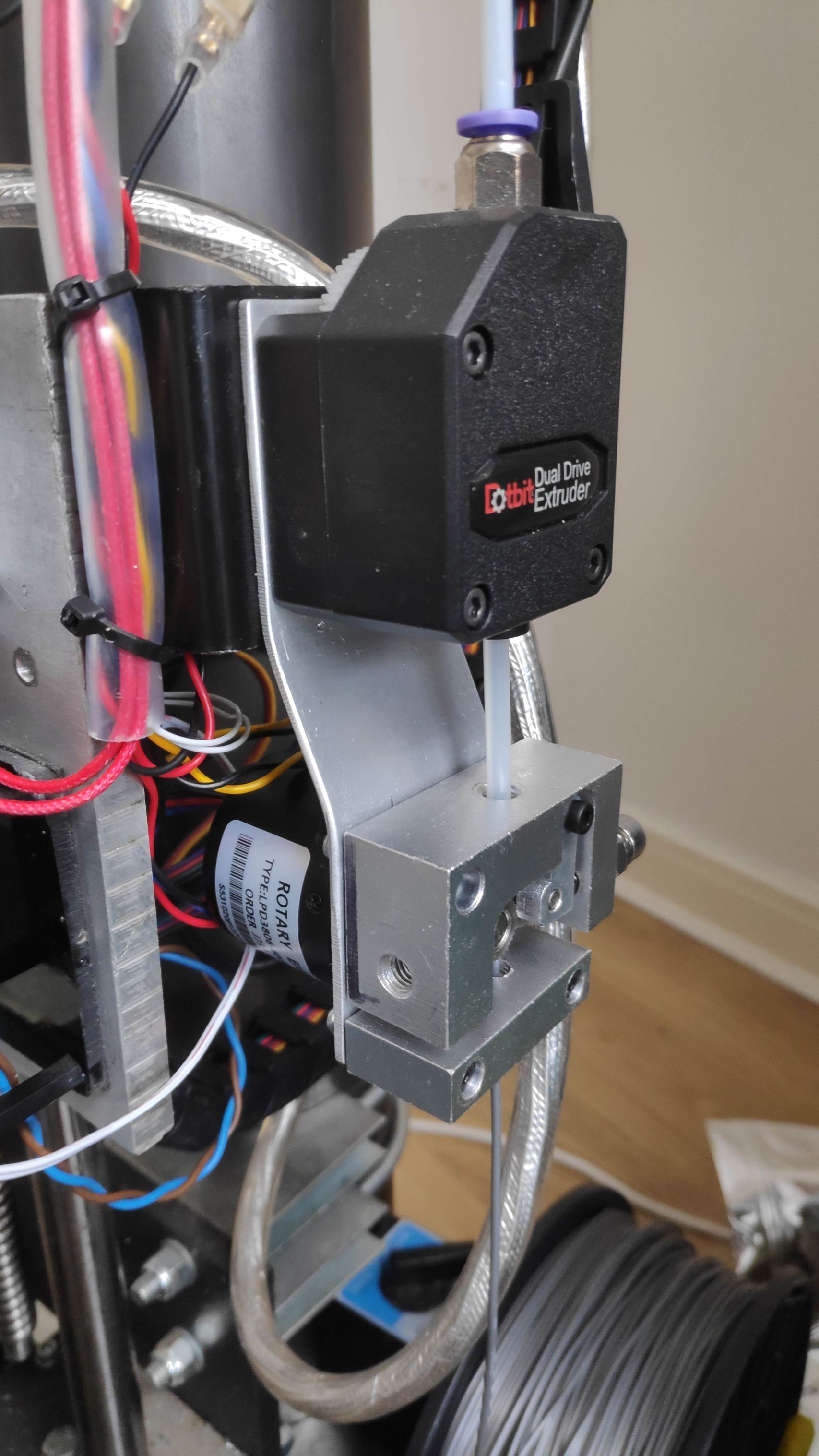

General Arrangements

Any constructive thoughts would be much appreciated.

Cheers

Barry M -

@cncmodeller Yes, you can try just turning on the built-in pullup by adding a '^' character when you define the pin used.

Pin configuration documentation

M591 D0 P7 C"^io4.in" S1 R1:1000 L0.0523 E0.1 -

@alankilian said in 600 PPR 5v rotary encoder filament monitor help:

@cncmodeller Yes, you can try just turning on the built-in pullup by adding a '^' character when you define the pin used.

Pin configuration documentation

M591 D0 P7 C"^io4.in" S1 R1:1000 L0.0523 E0.1Thanks @alankilian, unfortunately no change after setting the pullup resistor as you suggested... bugger lol

Not sure where to go from here...

Will put my thinking cap on...

Many thanks

Barry M -

5V_Ext - Enc Vcc5V_Ext is not a sourse of 5 Volts. It's an INPUT for external 5 Volt power supply. There's a diode in the way so you cannot power the encoder from that pin.

Try a different source of 5 Volts.

-

There's definitely 5v on that pin, I've just checked with my multimeter.

And the documentation says the IO 0 thru 4 supply 5v.

Or am I missing something here?

-

@cncmodeller Oh, I see, I was thinking you had connected to 5V_EXT_IN.

Sorry.

I'm out of ideas.

Can you connect an LED or something to the encoder output and see if it blinks when you turn the encoder? That would verify it's getting power and producing a signal.

-

@alankilian said in 600 PPR 5v rotary encoder filament monitor help:

@cncmodeller Oh, I see, I was thinking you had connected to 5V_EXT_IN.

Sorry.

I'm out of ideas.

Can you connect an LED or something to the encoder output and see if it blinks when you turn the encoder? That would verify it's getting power and producing a signal.

Good idea, I'll give it a go tomorrow evening.

-

@cncmodeller how did you perform your 200 mm extrusion to test the encoder? It sounds like you just commanded the extruder move manually.

The filament monitor code only works when running a job through the SD card. If you haven’t, try running a print and when you are a few layers in check with M591 as you did before.

-

@alex-cr thanks, I'll check it out.

The monitor may have been working as I had a print pause last night, but unfortunately I don't know why as DWC stopped working too. I have another thread following that up.

Many thanks

Barry M -

@cncmodeller said in 600 PPR 5v rotary encoder filament monitor help:

M591 D0 P7 C"io4.in" S1 R1:1000 L0.0523 E0.1

The Wiki doesn't specify if it expects a positive or negative pulse for a P7 sensor?

Did you try to invert the pin with "!"?

The default value for 'E' is 3mm, are you sure it accepts 0.1mm? Maybe the polling frequency is too high then?

OTOH your R-values are pretty 'generous', this doesn't make sense with the fine E-polling.Another thing I'm worried about is the L-value. It's already truncated to 0.052. How can you calibrate it, when the last digit is already cut off?

-

@o_lampe said in 600 PPR 5v rotary encoder filament monitor help:

@cncmodeller said in 600 PPR 5v rotary encoder filament monitor help:

M591 D0 P7 C"io4.in" S1 R1:1000 L0.0523 E0.1

The Wiki doesn't specify if it expects a positive or negative pulse for a P7 sensor?

Did you try to invert the pin with "!"?

The default value for 'E' is 3mm, are you sure it accepts 0.1mm? Maybe the polling frequency is too high then?

OTOH your R-values are pretty 'generous', this doesn't make sense with the fine E-polling.Another thing I'm worried about is the L-value. It's already truncated to 0.052. How can you calibrate it, when the last digit is already cut off?

@o_lampe I'm now getting the following response which is great:

24/05/2021, 13:15:01 m591 d0

Pulse-type filament monitor on pin io4.in, enabled, sensitivity 0.052mm/pulse, allowed movement 1% to 1000%, check every 0.1mm, measured sensitivity 0.058mm/pulse, measured minimum 63%, maximum 150% over 441.9mmI get where you are coming from, a couple of more decimal places for the calibration value may be necessary given the resolution of the encoder.

I'm going to set the sensitivity to 0.058mm/pulse and see how far out it is on my next test print.

Many thanks folks, glad this is working now

All the best

Barry M -

@alex-cr said in 600 PPR 5v rotary encoder filament monitor help:

@cncmodeller how did you perform your 200 mm extrusion to test the encoder? It sounds like you just commanded the extruder move manually.

The filament monitor code only works when running a job through the SD card. If you haven’t, try running a print and when you are a few layers in check with M591 as you did before.

@Alex-cr you were right... its responding now I've tried it during a test print. Thanks very much for your input, very helpful!

Barry M

-

@cncmodeller GREAT NEWS Barry!

I was stumped. It seemed like you had everything right (which you did) and I learned something new from this thread.