Cooling solution for Bondtech BGM + Pancake + 50mm fan

-

Hi dear folk of this amazing community

This is not a problem report but instead a solution for some that use delta printers that use a FLY system for suspend the block (motor-extruder).

Because I'm working on the enclosure of my delta I'm facing now all the sort of problem for keep some part hot and other cooled.

With the 50 degree inside the chamber the stepper became so damn hot that it was able to transfer the heat to the BGM keeping biting the filament all the times . Probably the filament came too hot and during retraction it came consumed...

So I putted the most powerful fan that I found for cooling the necessary parts. For now it seems to work.

I was not able to find a smaller fan more powerful than those HK Fan AB5020H12 , and the motor is a LDO-42STH25-1404MAC.

https://www.amazon.it/gp/product/B06X6MHGSR/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Those are 50mm x 20mm for near 6500rpm.

Now the work , it don't need screw (apart for block the fan and the flying belt support) but work at interlocking. For the fan the holes are small just for give the sign , they must be drilled with the right tip depending on the diameter of the screws.

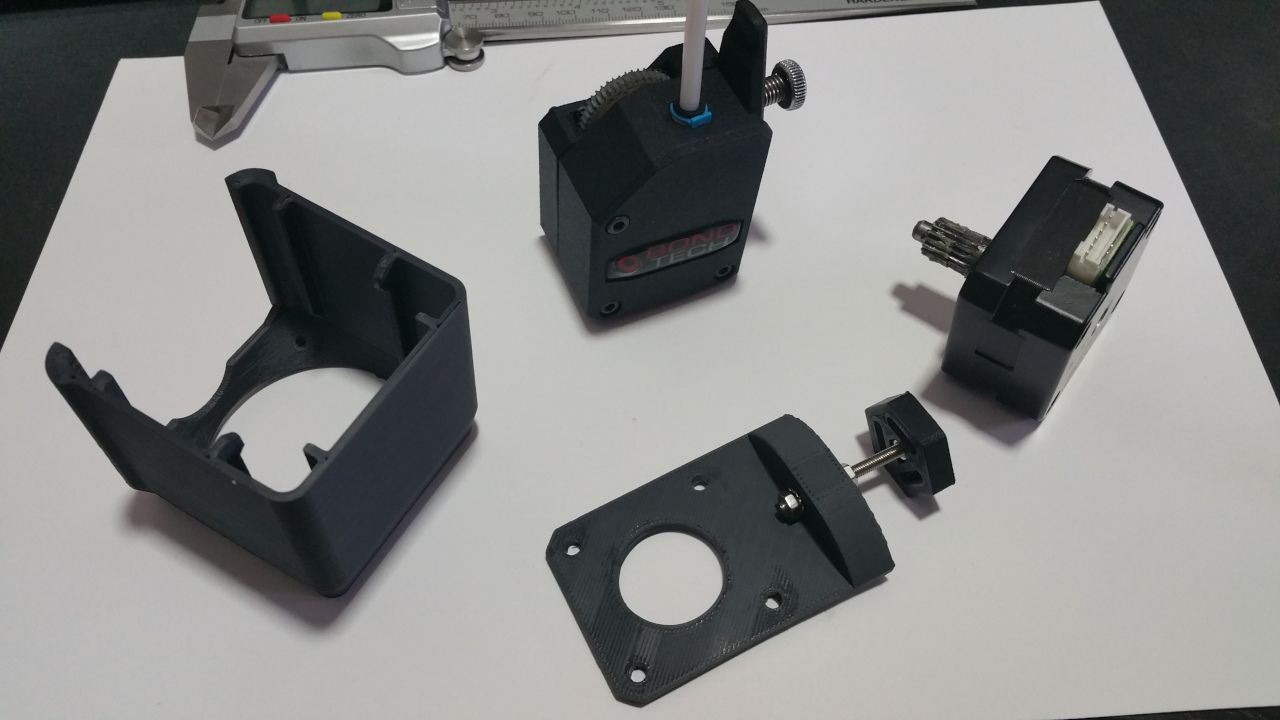

All the parts:

The support between the motor and the extruder (the long screw is 3mm diameter):

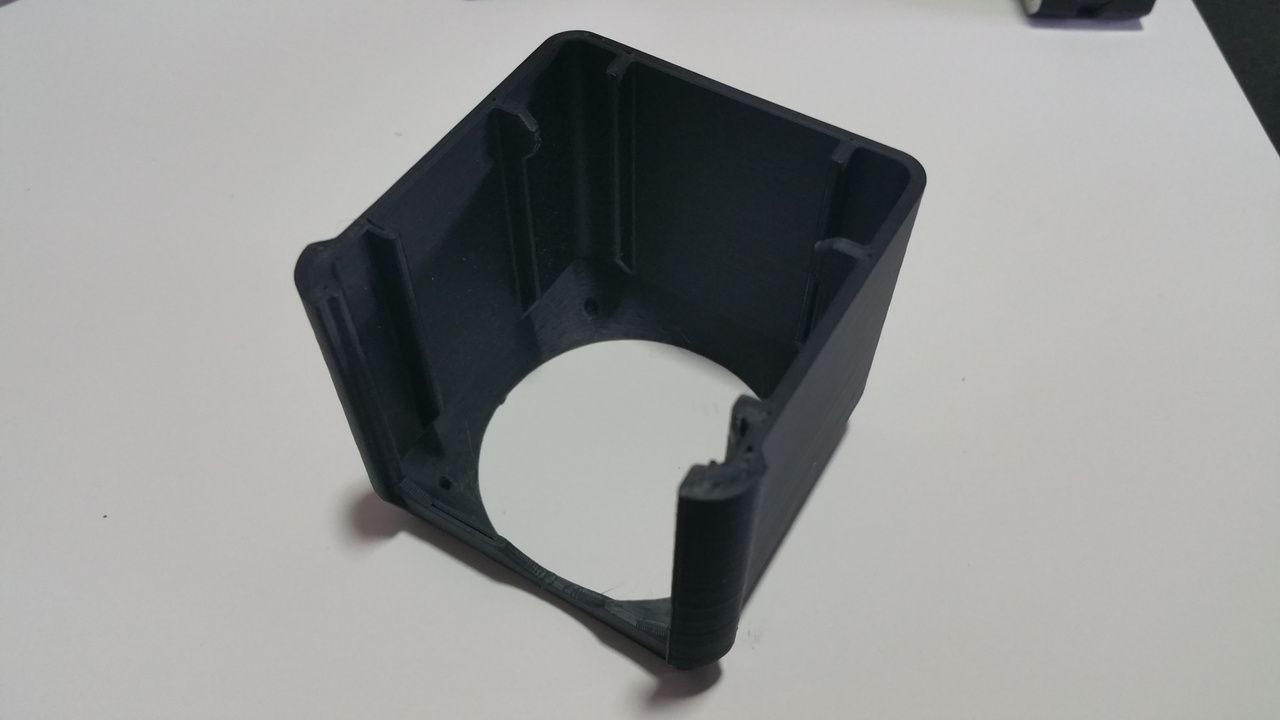

The cover alone:

All assembled:

I also make a small hole for keep a little cooled also the aluminium cylinder:

With the fan:

Some thermal images after 5 hours of printing with 52 degree inside the chamber:

And the aluminium cylinder:

Here the STL:

The part between the motor and the extruder:

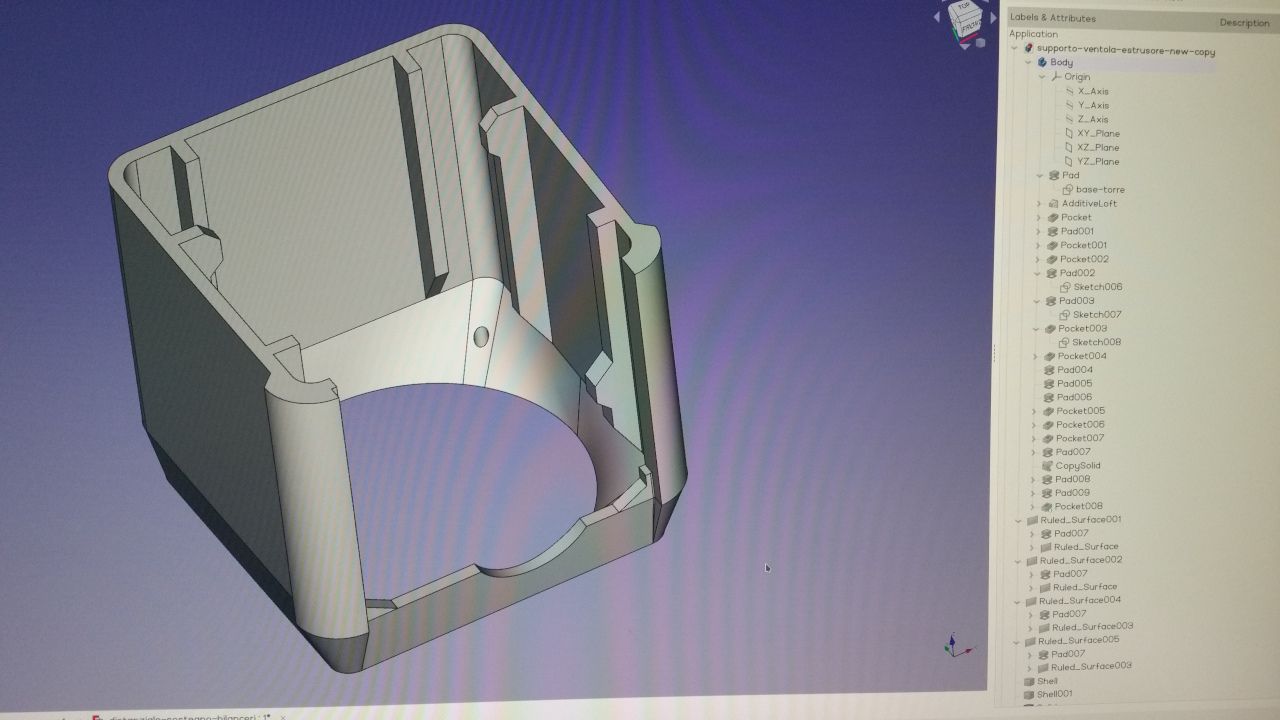

supporto-estrusore.stlThe cover:

supporto-ventola-estrusore-new.stlThe belt support (3mm hole):

https://www.thingiverse.com/thing:2867612/commentsThe same post on thingiverse:

https://www.thingiverse.com/thing:4903778The solution could be a liquid system but for this printer maybe is not worth the effort.

The LDO motor is rated for max 80 degree So I'm at the limit. -

@giostark What is the purpose of the part that goes between the motor and extruder body? The screw/thumbwheel doesn't appear to do anything.

-

@mrehorstdmd looks like it's used to mount the extruder so it's "flying"

-

@mrehorstdmd

Sorry I didn't specified the flying system good enough.

An other guy make this system for the Tevo Little Monster but it was too delicate so I modified his part adding a new one.

Despite seems for regulate the height between the belt and the block the purpose is an other.

What I noticed using a 35cm bed glass was that putting the right tension to the suspender belts , depending on the far perimeter zone , happens some little torsion / tension during the movements. The small screw is not tied hard so the part can rotate a little. The entire block like this stay always in line rotating a little depending where the mass during the movement goes.

Is not a super refined solution and I have no idea if this will make a difference in long term but it looked a small improvement respect a static solution.

Hope my poor english was able to explain the thing. I added a picture of the installation. -

@giostark OK, I see. Thanks!

-

@giostark

just wondering if an 'all metall' BMG housing would be better or worse for your printer? -

@o_lampe

Hi lampe , I have one for the next coreXY full metal I'll be mounting. But for this system I'm a little concerned because the internal temps.

The glass transition for the ASA is rated (as I can read around) at 105 degree. All the times I removed a small part from the hot bed even at the temp of 100 degree the part was almost soft. The cause of my last bite of filament by the extruder I can suppose was because of this. Now , before this system I realized, I had the original metal part of the Tevo , that is an aluminium plate. That part , as the small cylinder of the extruder, came so damn hot during the print. I'm not competent in this area so empirically I just noticed that the metal is far more capable to accumulate heat despite the ASA that I was using for the rest of internal part I printed. Seems the plastic is more insulator and cooler material.

So for the ASA filament or in general those softer material I would stay with the plastic version of the extruder in this delta printer, for the coreXY and polycarbonate and PEEK I'll use the full metal version.

This is my idea , can be right?