First layer issues-Extrusion volume dropping on first layer?

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

@fcwilt Yes, in bed.g, at the end, there is a G30 at the center on the bed. The mesh leveling happens after bed.g is run.

Have you tried upping the extrusion multiplier using M221 or the DWC slider control?

Frederick

-

Calibrate your extruder and tune your extrusion multiplier.

https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40

I wouldn't use hilbert curve as an indicator of first layer quality. It's not really a suitable pattern for first layer with all the direction changes. The extrusion could become so slow that the filament starts to cook in the hotend.

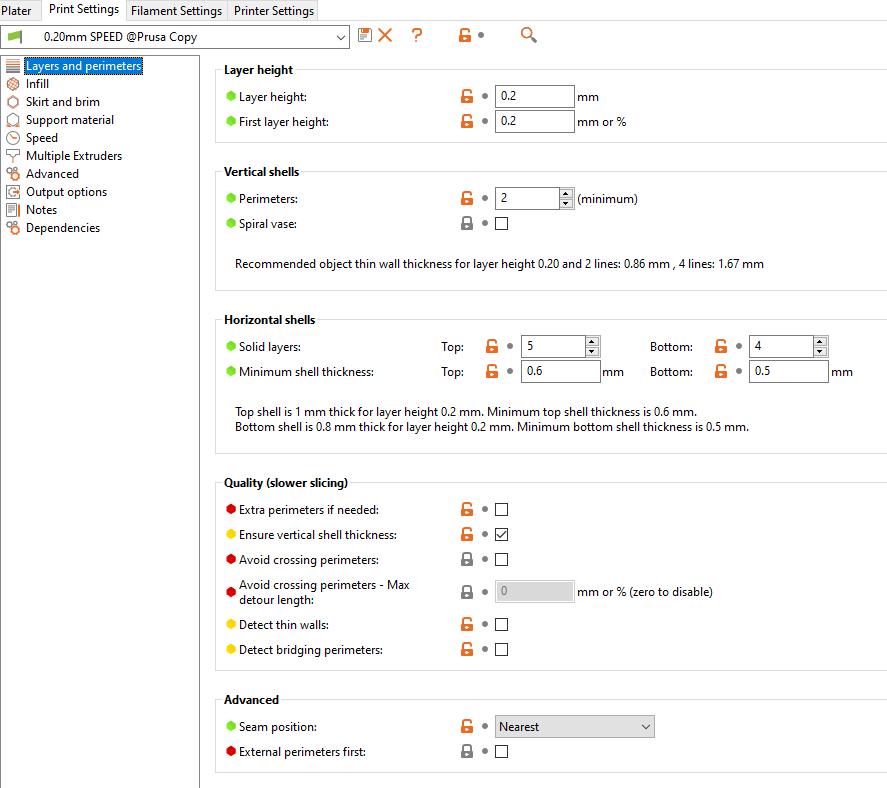

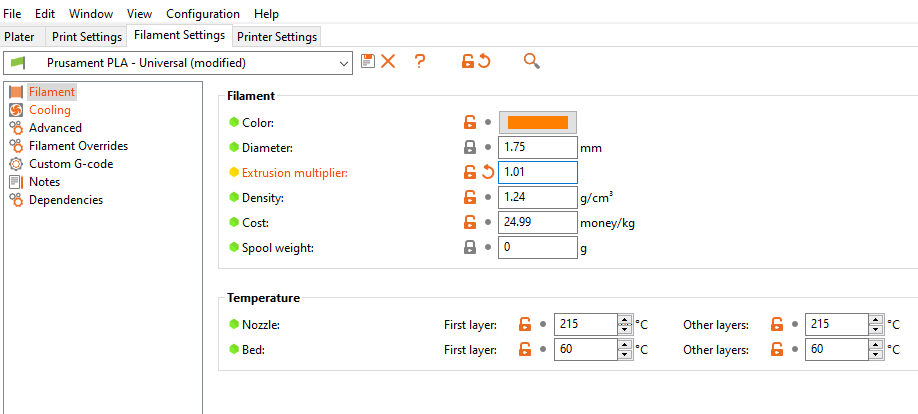

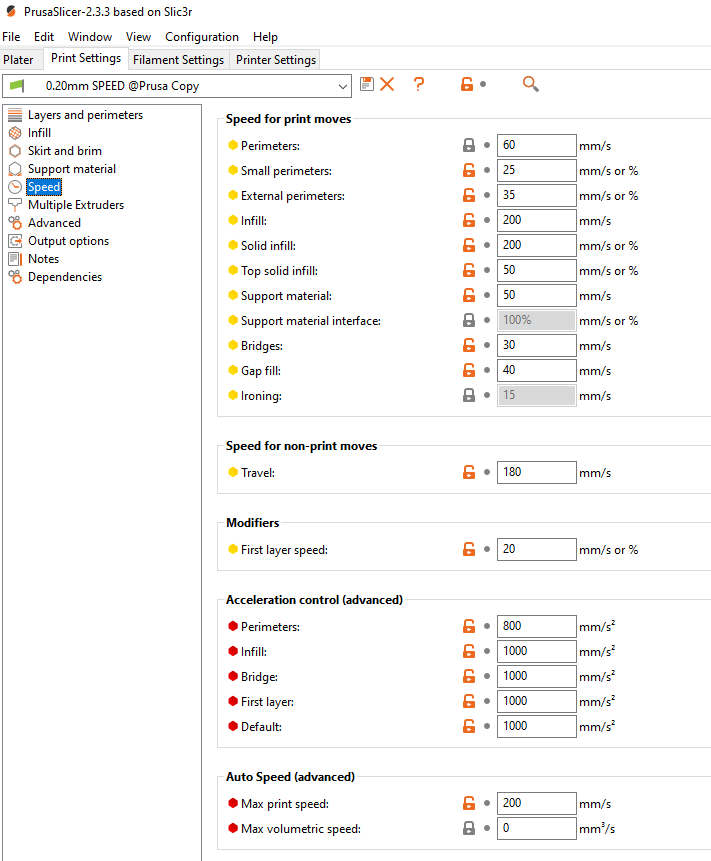

Show us your slicer settings. Upload a sliced gcode file.

-

@phaedrux Calibrated the Esteps and extrusion multiplier. ESteps did not change, the extrusion multiplier changed by 0.01, so went from 1 -> 1.01.

Still the issue persists.

Running a few more tests it looks like an issue with Z distance between bed and nozzle increasing as the first layer progresses.

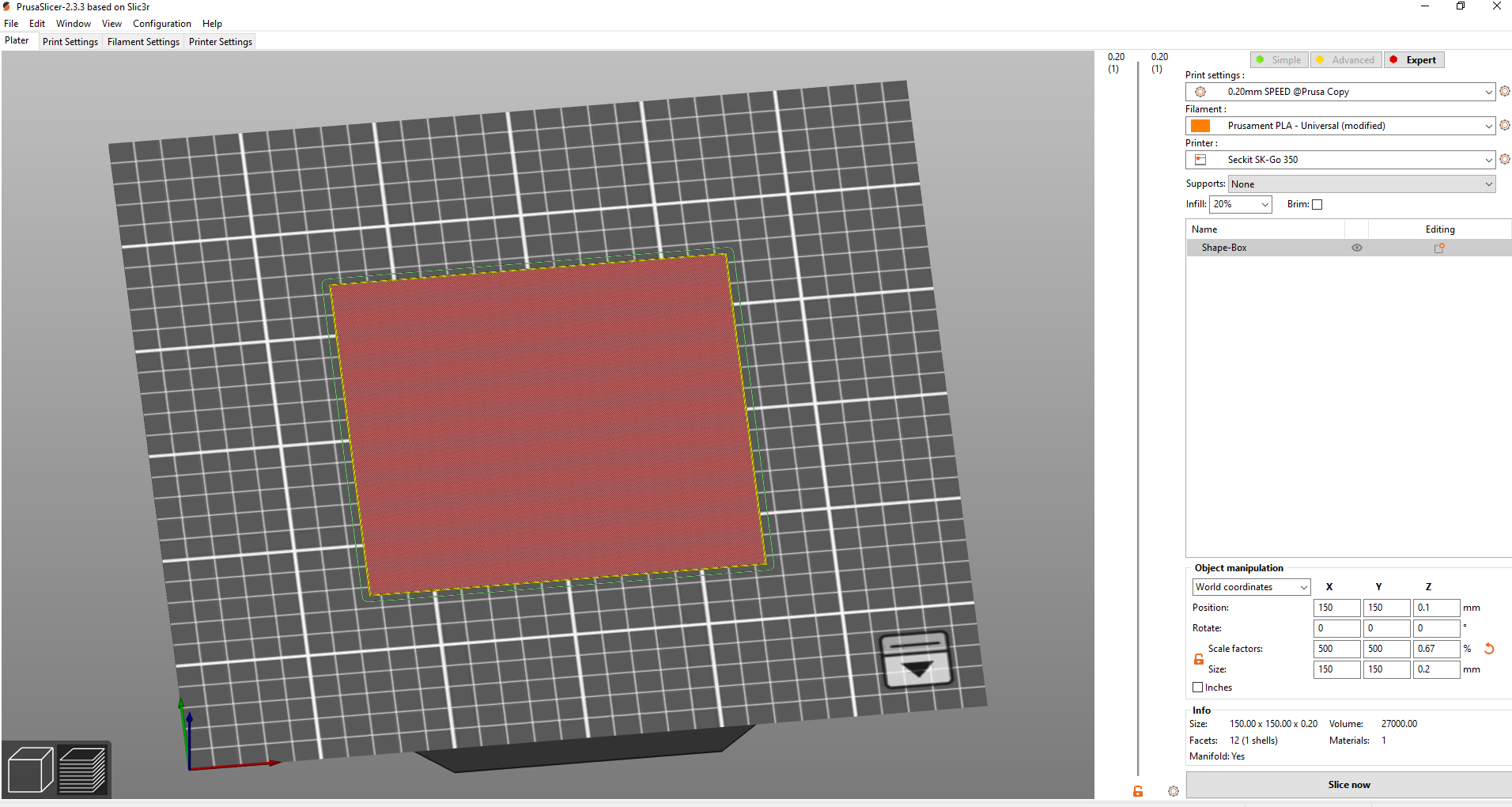

On a 150x150mm square print with reclinear infill the layer stops sticking halfway through the layer, I then reduced the distance using baby step, and kept doing that as the print stops sticking again. At the end of the layer I had to move the nozzle closer by 0.2mm (-0.2)!!!. That is a lot.

I tried heating bed for 15 min before starting print/probing to see if thermal expansion is somehow involved. But that did not help and the print still did not stick halfway through.

Next heated the bed for a while and then ran mesh bed leveling. Then moved the head to various points on the bed with a piece of paper under it to see if the nozzle is close to the bed. And the paper is being gripped by the nozzle correctly. If I raise the bed by 0.2mm the paper does not grip. So the moving the bed using the bed using the Dashboard is maintaining the nozzle distance correctly.

Attaching the gcode of the file I used, and slicer settings.

150x150_center_0.2mm_PLA__50m.gcodeAlso adding the height map, it is pretty level in the middle of the bed.

-

Instead of a large flat full infill print try something like this STL instead.

-

@rkaronde

Do you see skipped steps for the Z-axis?

That's the only explanation, why it keeps gripping the paper when moved manually, but building up a gap when it does mesh levelling -

Printed without an issue.

The lines are pretty well stuck to the bed, and I could see the Z motors move when printing near the bump in the front part of the bed. -

@o_lampe I have not heard any skipping, not sure if there is any way to measure the skipping.

Also in the middle of the bed the Z motors don't actually have to move since the bed is pretty flat. I also marked the Z motor pulley with a Sharpie and it does not move from the initial position printing infill in the center of the bed.

This is a CoreXY with bed moving up/down, so if Z is stable then I would think the X gantry is somehow moving up (not sure how that can happen). I also did the bedlevel_nozzel print suggested by Phaedrux and that stuck well all through.

The reason I am trying large flat full infill print as test is because I ran into this issue when printing large footprint models/STLs and got into debugging.

I am going to recheck for any mechanical issues.

-

@rkaronde silly question time... you don't have any PLA parts supporting your hot bed that are warping under heat/load during the print are you? When I first started printing ABS on my printer I spent days trying to figure out why my z offset ket changing before realised my bed supports had basically melted...

-

@engikeneer Fair question.

Except for the cooling duct and PINDA holder this printer does not use any plastic parts, it is all metal.

https://seckit3dp.design/kit/sk-go2-essential

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

The reason I am trying large flat full infill print as test is because I ran into this issue when printing large footprint models/STLs and got into debugging.

This may be more of an extrusion or cooling issue then.

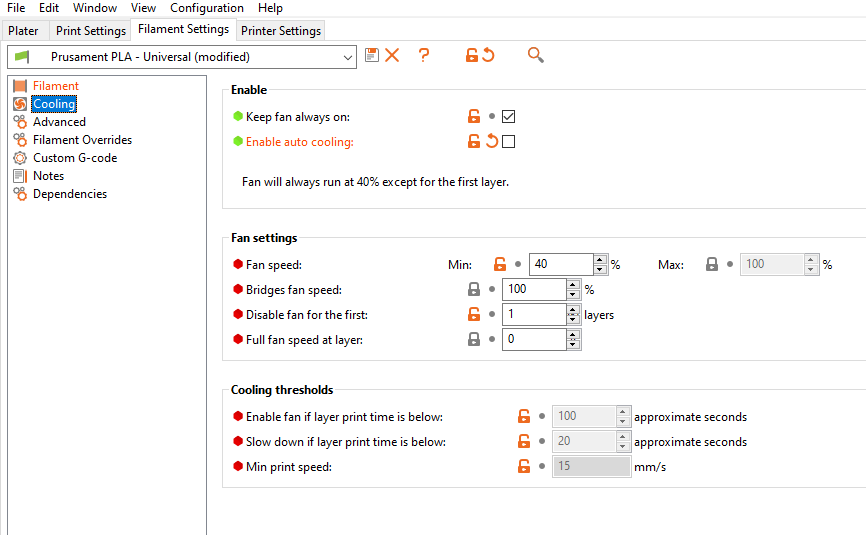

Can you confirm the fan is off for the first layer?

Have you tried upping the first layer hotend and bed temp a bit? Maybe 65c bed, 225c nozzle?

What is your first layer extrusion width?

-

@phaedrux Yes the cooling fan is OFF for the first layer

The first layer extrusion width is 0.42mm (nozzle is 0.4mm), should I try a different extrusion width?

I will try upping the temps.

Thanks

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

@phaedrux Yes the cooling fan is OFF for the first layer

The first layer extrusion width is 0.42mm (nozzle is 0.4mm), should I try a different extrusion width?

I will try upping the temps.

Thanks

What is your first layer speed

What is the first layer height as opposed to the normal layer height?

Thanks.

Frederick

-

@fcwilt First layer speed is 20mm/sec

First Layer height is 0.2mmIn a post above I have attached screenshots of most of the slicer settings.

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

@fcwilt First layer speed is 20mm/sec

First Layer height is 0.2mmIn a post above I have attached screenshots of most of the slicer settings.

Thanks.

Those settings seem good.

Frederick

-

@rkaronde Maybe another silly question but have you tried cleaning your bed? I regularly clean my bed with isopropyl alcohol but once in a while I have to clean it with hot water and washing-up liquid and that can be the difference between night and day sometimes. Even though I never ever touch my bed and it looks squeaky clean there can be some residue on it.

-

@tmicke Yes, the bed is clean.

The bed has PEI steel sheet on it.

With all the tweaking to solve this I do sometimes get finger prints/oil on the bed.

I normally just wash with soap and water. -

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

not sure if there is any way to measure the skipping.

Some people can read a lot from the M122 diagnose output. Issue a diagnose right after the first layer (pause and diag) and post it here.

Let the first layer run without babystepping, we want to provoke the errors... -

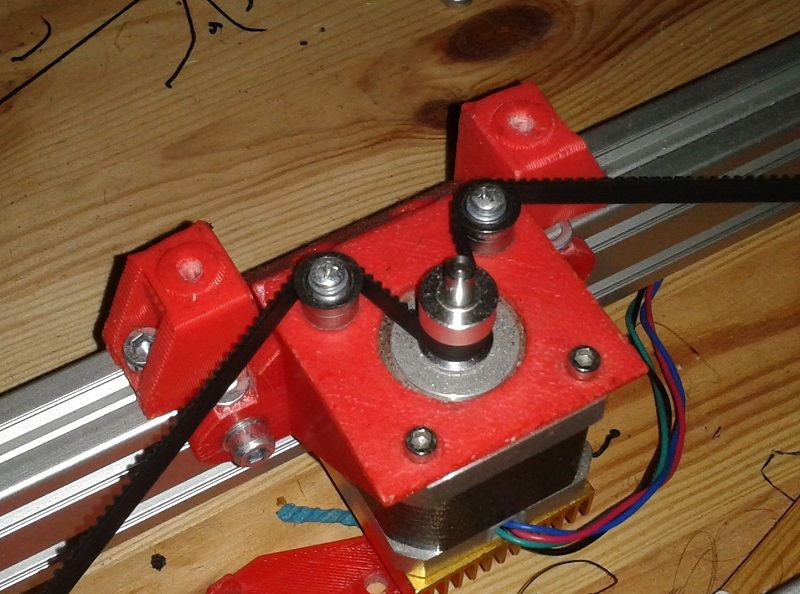

Loose grub screw on a lead screw or z motor that's letting it walk up during mesh compensation adjustments but then binding enough to keep it from walking back down?

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

Back to the subject:

I had a closer look on your Z-axis and saw anti-backlash nuts and springs around the bed adjuster. Just wondering, if the extruder pressure adds enough counterforce to the bed to provoke the skipped steps we discussed earlier?There's also room for improvement regarding belt-wrap around the drive pulleys. I simply added a few flanged bearings on mine.

They run on two of the stepper mounting screws, so you could easily add them too. Maybe have to turn all pulleys around with the belt-side facing downwards to run the belt closer to the stepper bracket. (reducing load on the bearings)

-

@rkaronde I can see two likely reasons:

-

The bed and hot end temperatures are not stable between when you probe the bed to set up mesh compensation and when you print the end of the first layer. Don't just heat the bed, heat the hot end too.

-

Your Z probe does not have a constant trigger height across the bed. So although your height map looks flat, it isn't really. At several XY positions on the bed, use G30 S-1 to lower the nozzle until the probe triggers, then measure the height of the nozzle above the bed using feeler gauges.

-