How to get rid of these bumps

-

How to get rid of these bumps

Hi All - I've been doing a few test prints now that I've got it running reasonably well while this has been an experience, it's been a good experience as I've really gotten to know my printer a lot more than I did with Marlin.

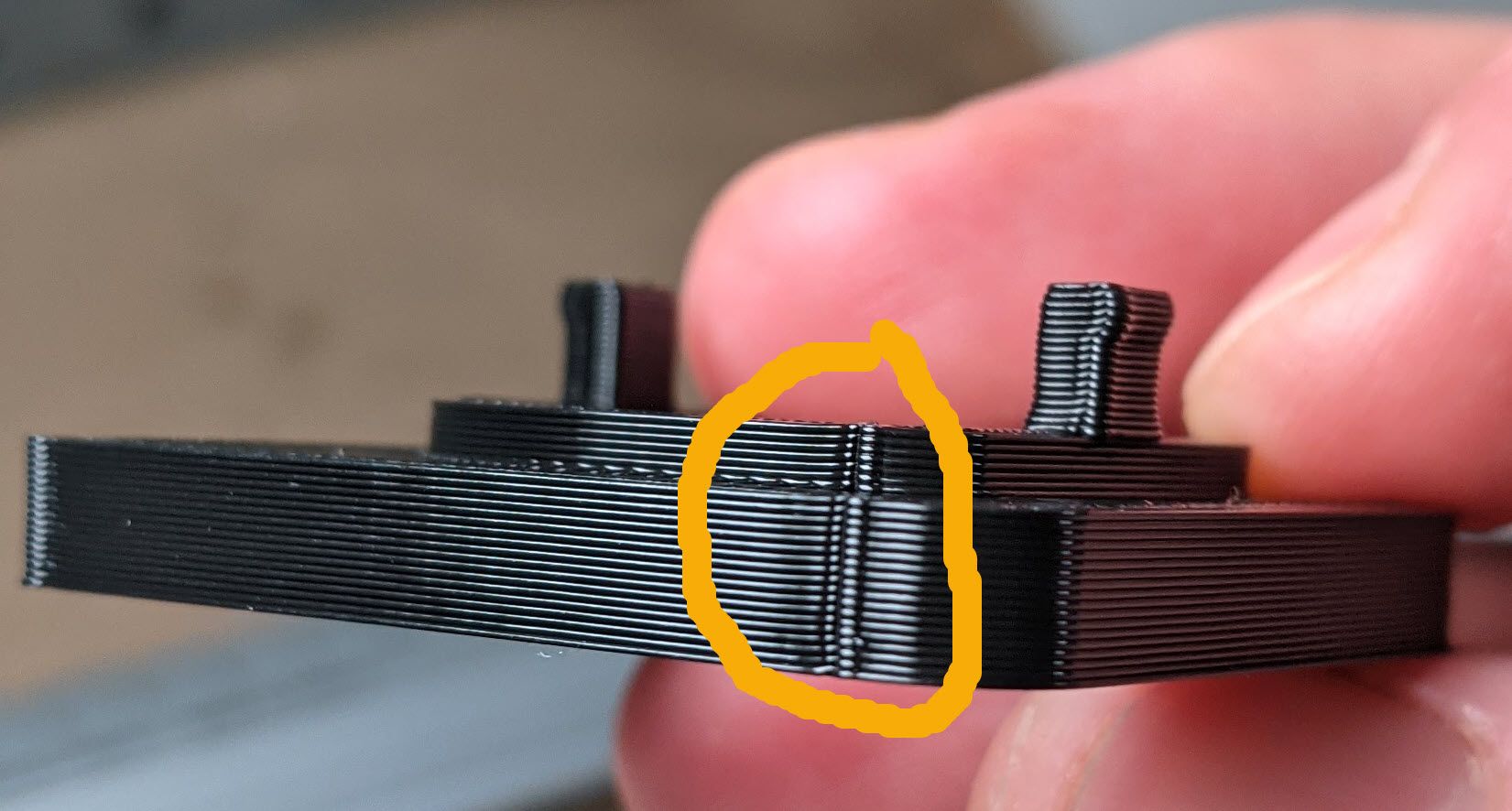

Now as I start to fine tune things, I noticed these bumps when I, what looks like, change walls and it creates a small bump in my print on each layer, which ends up causing problems when I have pieces connected to each other.

Is there a specific setting, article I can read to help redice this bump?

Thanks for all the support to date!

-

@infidelprops

Slicer settings. In Cura there are several that can provide a better seam. But because all the printer/materials/parts to be printed are different you have to try several time to find the right mix.

https://forum.duet3d.com/topic/24451/what-tricks-have-you-found-to-reduce-seam-bumps/4

https://mattshub.com/blogs/blog/layer-seams

Pressure advance (for some parts is good).

The better is understand very well the own printer. If all is well calibrated (and belts well tied and of good quality) then is just matter of slicer setting (or firmware functions enabled/disabled).

ps:

looking at your corners (all of them) the speed could be a little too hight

For the test use an empty cube (no base and top) with 2mm wall thickness. There you will find the right combo for a good seam.

More the layer height is high the more difficult is to manage the quantity of material that come extruded. So the settings will not be the same by layer height (also if really similar) -

Search the forum for "pressure advance."

-

You may find some tips here: https://forum.duet3d.com/topic/24451/what-tricks-have-you-found-to-reduce-seam-bumps?_=1629236301281

-

-

Just as an FYI, I have not been able to eliminate the seam completely but what you can do is to hide it in plain sight by having the slicer put the seam at a corner. It won't help on a smooth corner like your example but if you have sharp corners it can hide a multitude of sins.