A delta with colourful lights

-

Back in early 2020 I started building a new 3D printer (I already had a Prusa Mk2) and I've just finished all the things I had in mind when I started, so while I hesitate to say it's finished, here it is.

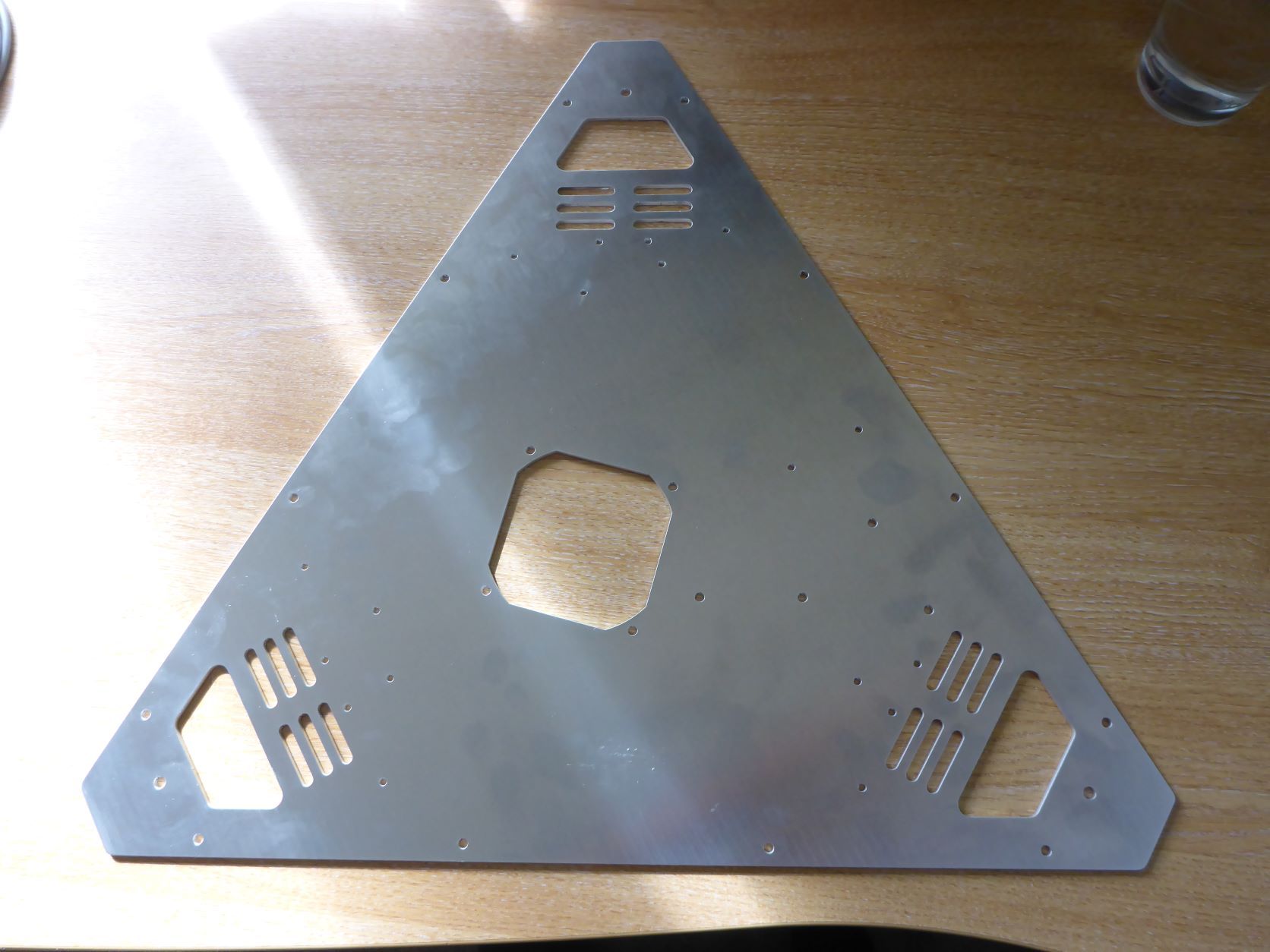

In essence it's a fairly standard delta, though built with genuine brand components from the 'good' end of the range, so it's Duet MB6HC plus smart effector (I ordered that just before the mini 5+ was announced!), Hiwin rails, Gates 9mm belts, Haydn Huntley carbon rods, Bondtech BMG, Meanwell PSUs, E3D V6 (copper block, titanium heatbreak), magnetic bed. Suppliers are from among the usual suspects (RobotDigg, Ooznest, E3D, Farnell, Digikey) plus www.lasermaster.co.uk (no relationship other than happy customer) who did all the aluminium laser cutting - I've used them for mild steel, stainless and aluminium in all sorts of sizes and thicknesses (including some very small orders) and always been happy.

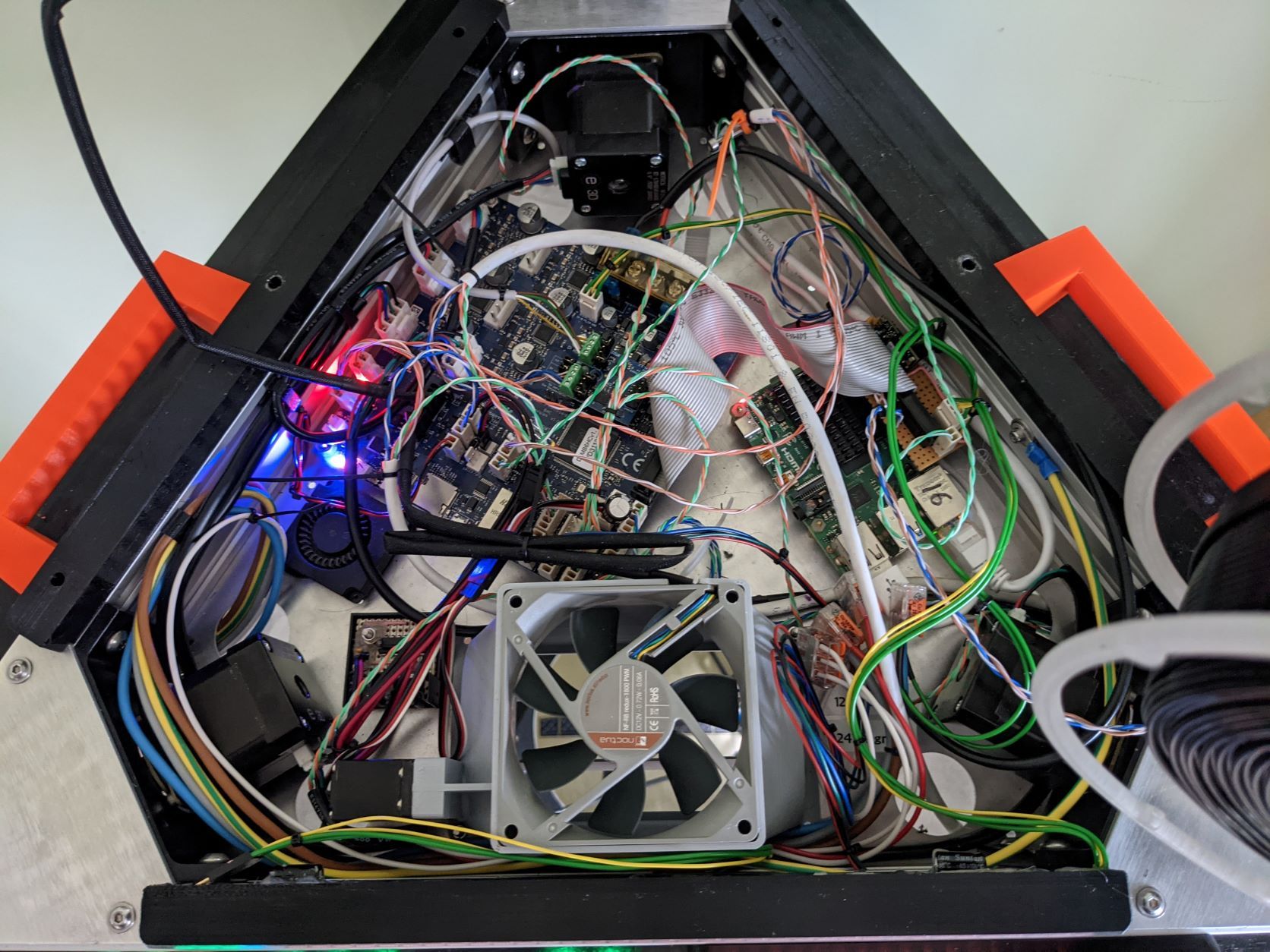

PSUs are in base, along with SSR for the mains heated bed. I have a 350W 24V and a 200W 12V - the latter drives a 5A POL DC-DC convertor at the Raspberry Pi to generate 5V for the Pi, the Duet board and the LEDs. The 24V PSU is powered via a real relay (I don't like putting PSUs on SSRs - but that's just a superstition of mine). Both PSUs are fanless, but the bottom aluminium plate is deliberately chunky (as a heatsink) and there's an arduino (actually a teensy) with thermistors on each of the PSUs which runs a fan if required. There's a spare SSR in case I heat the enclosure in future.

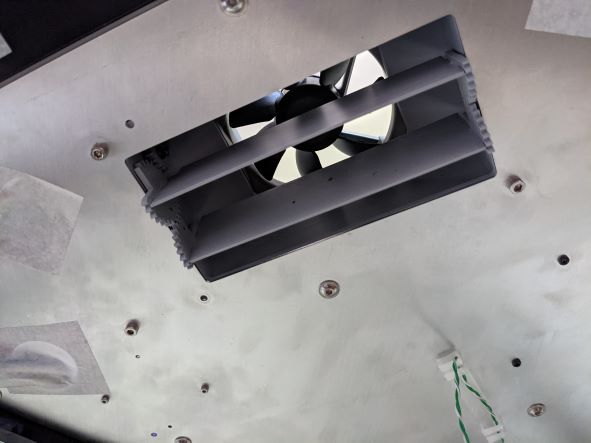

Duet, Pi, steppers and a vent for the enclosure are in the top. The top enclosure has a single cooling fan blowing air in direct onto the stepper drivers, and a small centrifugal fan blowing air across the underside of the MB6HC. I thought the Pi might want a fan, but it hasn't - there's a largish heatsink on the processor, but it doesn't get much above 55C. My wiring will probably give the voron crowd conniptions, but I'm working on the basis that parallel wires risk cross-talk (honest).

The vent for the enclosure has some servo-driven blades. Daemon.g opens and closes it just below the temperature when the fan cuts in.

There's a spool holder with built-in weighing load cell so I get a report of how much filament remains - I've posted about that recently at https://forum.duet3d.com/topic/25419/another-weighing-filament-holder

There are two rows of LEDs (actually, one row of 40x SK9822 and a row of 12x APA102, and they are joined end-to-end as one string) to provide status information from across the room. One row gives me a progress bar (showing heater 0 and 1 when they are heating and file progress when the heaters are at temperature) and the other row gives me status of heaters, fans and power. Heater lights slide from blue if the heater is more than a few degrees below set-point through green at set-point to red if it's more than a few degrees above set-point. Fan lights are just on green if the fan is on (but I can set them to show varying colour with PWM duty). The power lights likewise change colour if the voltage deviates by more than 0.5V from where it's supposed to be.

Heater progress bars grow form each side to meet in the middle, so this tells me the nozzle is about a third of the way to temperature and the bed is two-thirds. Reading across the second row I see that two heaters are cold (blue), one is OK (the enclosure is always OK if it's not too hot), there's one fan on, the 24V is good and the system is on:

File progress is just one left-to-right bar, so here it is having barely started on a file (actually about 3.5% - green is a 'full' slot and blue is a fractional, sliding from dim dark blue through bright cyan to green), and here nozzle and bed heaters are OK, the enclosure is hotter than it should be, three fans are running (print cooling, hot end, electronics enclosure), the 24V is good and the system is on:

The lights script is set up as a systemd service, so runs automatically on boot.

If I'm not across the other side of the room, there's also a PanelDue 5i, as you can see.

The enclosure is illuminated by white LEDs down the back side of the left and right legs (so flood the interior when on), but it doesn't really need them. They are just switched by the rocker switch you can see near the LEDs. The front door is on a magnetic catch and opens to 120 degrees, but can also just lift off the hinges.

-

Very nice build. Don't recall seeing an enclosed delta before. Is this for ABS? What kind of chamber temperature do you get?

-

@zapta said in A delta with colourful lights:

Very nice build. Don't recall seeing an enclosed delta before. Is this for ABS? What kind of chamber temperature do you get?

It's not really for ABS, though I have a coupel of spools of that I keep meaning to use up. Honestly, there's probably no very good functional reason.

I did find that my Prusa became much more just-print-on-demand and much less aggro and fiddling when I put it in an enclosure, but I suspect that might be because before it was in an enclosure it was just sat out on the side in a family room and got moved around and so on. When it went into an enclosure it did so in a less boisterous room, and never gets moved, so it might be the not getting disturbed that made the real difference. A metre-high 20kg delta doesn't get just moved here and there, so possibly wouldn't suffer the same.

The enclosure kills a bit of the whine from the little E3D fan (I'm looking forward to the Revo hotend, but fear the even smaller fan will be even whinier).

The enclosure has no active heating (just the effect of bed and hotend). I generally set the vent to run its fan from 35C, and I've never tried (yet) to see what it could / would get to. There is an SSR in the base with half a mind to put enclosure heating in it in future, but I'm mostly happy with PLA and PETG!

-

@achrn said in A delta with colourful lights:

The enclosure kills a bit of the whine from the little E3D fan

That's also my experience with Vonron V2.4. The panels edges are sealed with 1x5mm adhesive foam and I think that also helps. I am getting about 40C chamber temperature with 105C bed temp and never had any ABS adhesion, warping or lamination issues.

It seems that you are using UHP power supplies, they are compact, efficient, fanless and stay cool, I like them. You could eliminate the high power one by running the bed heater of mains voltage (the bed is static so less safety concerns).

-

@zapta said in A delta with colourful lights:

It seems that you are using UHP power supplies, they are compact, efficient, fanless and stay cool, I like them. You could eliminate the high power one by running the bed heater of mains voltage (the bed is static so less safety concerns).

Yes a UHP-350-24 and a UHP-200-12. The bed is already on 240V. The power supplies are probably overkill, but

1: I wasn't 100% sure where I was headed when I started building, and I bought them early for testing electronics so they were chosen more as as-big-as-would-fit rather than careful consideration of ratings

2: As previosuly noted I'm superstitous about PSUs - in addition to not putting them on SSRs and making sure they have lots of heatsinking I like them to have a good amount of headroom. -

@achrn Nice build! Any lights inside to light up the print? White lights make seeing and photographing the print easier, and UV makes fluorescent prints look really nice as they are printing.

In my experience, once you can print ABS reliably, there's no reason to print PLA, unless someone in the house complains about the smell. In that case, PETG will work for many prints. Of course all may be hazardous to your health, whether you can smell something or not.

-

@mrehorstdmd said in A delta with colourful lights:

@achrn Nice build! Any lights inside to light up the print? White lights make seeing and photographing the print easier, and UV makes fluorescent prints look really nice as they are printing.

Yes, a run of cool white LEDs (60/m) full height behind both the front two extrusions (actually fixed to the 'glazing bar' at the corner between two panes). There's lots of light when they are on.

They do make it easier to see detail when it's printing. Interestingly with my (fairly new) mobile phone the photos taken with them on are almost indistinguishable to those with them off - the exposure / colour balance / whatever in the phone tunes them out.

-

@zapta

That 40 degree is not enough for the ABS , at least for big parts. In my delta I started with that too... a single plexy layer and the result was poor. Then I doubled the plexy separated with foam and still the dispersion of so big surface was too much for rise the inner temp at decent level. Now applying a full surface of 3-5cm of foam for all the inner faces I can get good result over 60 degree ... and finally this damn ABS didn't bend anymore. -

@giostark said in A delta with colourful lights:

That 40 degree is not enough for the ABS , at least for big parts.

It seems to work well for me. Haven't had a problem yet. If in doubt I add brim. Here is an example of a part I printed the other day, 4 hours, no warping, no lamination issues, added brim just in case because the base is hollow. Same results for a long part I printed a few weeks ago diagonally from corner to corner.

I also heard that ABS+ is every easier to print but haven't had a reason to try it.

I am using a Voron V2.4 250mm and didn't work too hard to seal it, for example, the panels are help only at the four corner without the mid-length screws. I also don't pre-heat it, just let the bed and nozzle reach their respective temperatures and starts printing immedietly.

-

@zapta

Yea , I'm aware that some part can be printed also if big but those part benefit of "good" or very regular design that don't allow too much inner tension of the material.

Ex: In this part on the left there was a circle (it is a conveyor) . The vertical left and right side adjacent the circle , at 40 degree were bended toward the inside. Resulting in a non vertical strait line.

The only way to make them strait was reach an higher chamber temp.

My task in building the chamber was be free to print without the warp or bending agony despite an non optimal design of the part.

-

@giostark said in A delta with colourful lights:

Yea , I'm aware that some part can be printed also if big but those part benefit of "good" or very regular design..

Yea, I'm aware that some parts may benefit from chamber temp of 60C over 40C.

That's a nice print in the picture you posted.

-

undefined achrn referenced this topic

undefined achrn referenced this topic

-

undefined achrn referenced this topic

undefined achrn referenced this topic