spontaneous horrible print quality

-

Does anyone know what might be going on here:

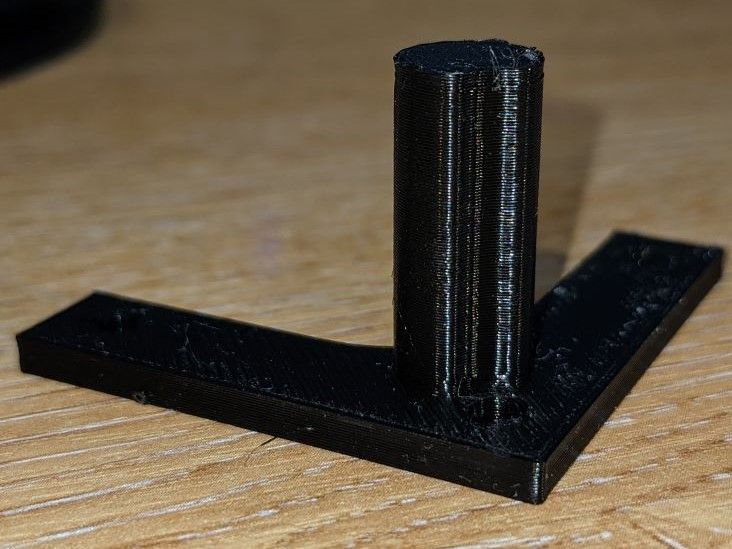

It's supposed to be a small right-angle plate, with a 10mm diameter post sticking out of it, with a notch on the back face of the post. The base plate is OK, but the post is berserk:

In fact, the first two layers of post are OK, then there are five or six berserk layers, then it reverts to OK for about 25 layers, then goes berserk again.

It's a delta, PLA, RRF3.3 firmware, 0.4mm nozzle, 0.2mm layer height, sliced on PusaSlicer-2.3.0 and it has never done anything like this to me before. Is this a printer problem or a slicing problem? This is the second attempt (after re-slicing and re-printing) the first time I didn't get any good layers in the post (those are M3 screws, for an idea of scale):

-

@achrn my guess is poor cooling. The long layer times on the flats leave enough time for the plastic to cool. The relatively short layer times for the cylinder result in more cooling needed otherwise it goes blobby, like what you have

-

@achrn Can you point us to a location with the GCODE so we can do test prints?

-

@alankilian +1 on the cooling did the cooling fan have some sort of failure (bearing jam up or whatever?)

-

Thanks all for your comments.

The gcode is not too huge:stepperstop_Delta 0.2_Delta PLA_Delta0.4.gcode

That is the second one, and has archimedian chords as first layer (I wanted something to cause the slicing to slice differently but not change the vicinity of where it was going wrong).I don't know that cooling fan did or did not stop - I guess that would explain why quality swaps to and fro, if it was an intermittent fan stopping problem. That has caused me to notice that where I've relocated the printer over the weekend just gone I can't see whether the print cooling fan is spinning. I might have to rethink that location (or fit a mirror).

I've resliced and reprinted on a different (much slower, not RRF) printer and that has gone OK, but the 'main' printer is currently doing something different so I'll try printing slower and monitoring the fan tomorrow (evening).

-

@achrn At layer #15 the speed does drop dramatically to around 10mm/second.

However, it's printing fine for me.

-

With such small single items, I guess you need a minimum layer printing time in your slicer or some extra objects. Sometimes, I just place a little tower a bit away from main main part so it takes a while to transport to and from it.

But, check your min layer time in the slicer or add more fan cooling

-

@achrn It printed fine for me even after I turned off the cooling fans AND increased the temp to 220C for the top 6 layers or so.

It really looks like MASSIVE overextrusion to me.

But I cannot think how that would happen just in the tower area.

-

@alankilian thanks, that's what it's supposed to look like.

The slicer has a 10 seconds minimum layer time set, which presumably causes the speed drop. I think 10mm/s is the abolute minimum print speed settting (i.e. it slows printing to try and achieve a minimum of 10 seconds layer time, but not at the expense of dropping below 10mm/s).

I might try printing two of them at opposite sides of the bed.

In the next print jobI kept an eye on the part cooling fan and it behaved fine - no sign of any tendency to stop, and it's running at 100% the whole time (from second layer onwards).

-

So I've looked again at my part cooling fan, and it generates a good breeze around the nozzle, and no sign of it stopping or sticking.

Then I've printed two at once, one on each side of the bed, and that's gone fine:

Thanks all for your input. I'll keep an eye on the fan . I could go back and try printing just one again, but I already have three of the part now, and I only wanted one for something temporarily in the first place!

-

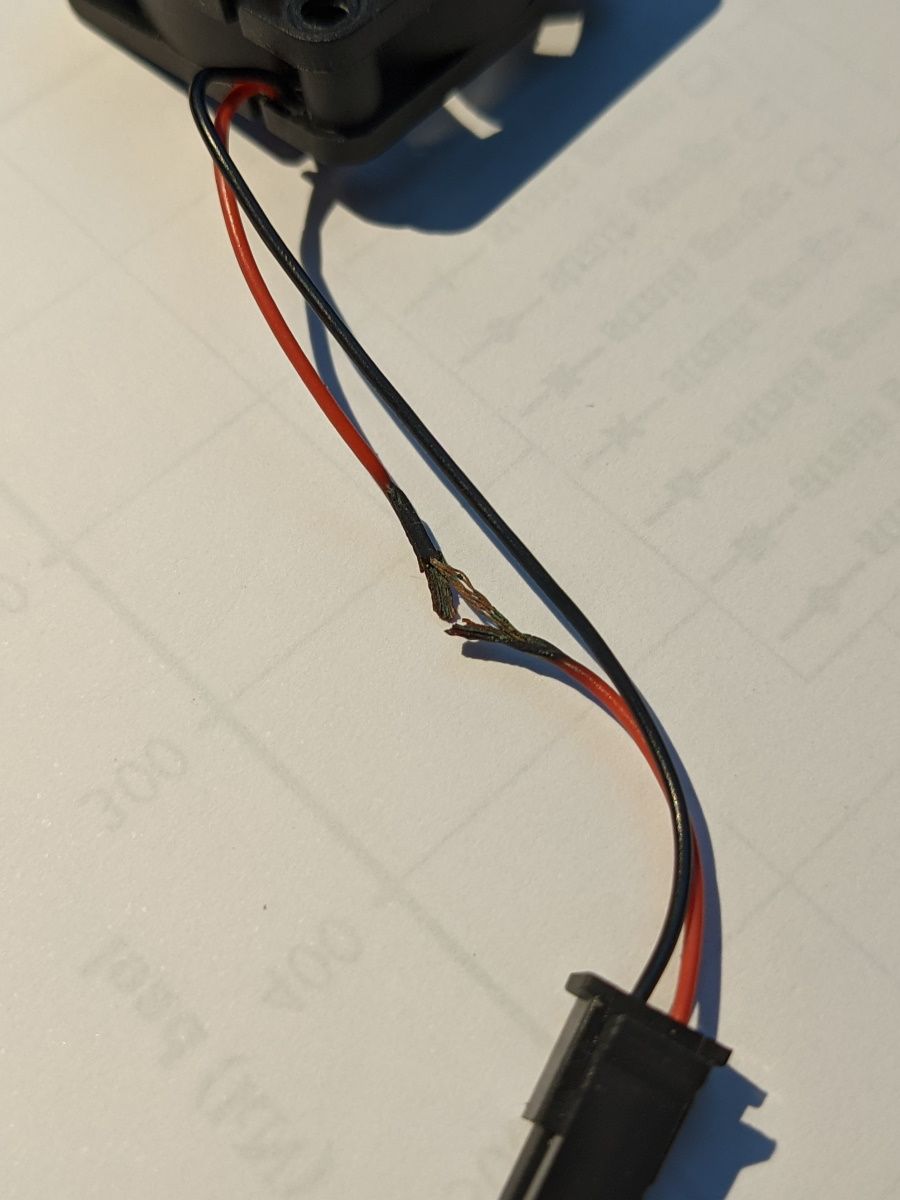

So, I still have some problems with this, and still looking for some input. I have an interesting new symptom though (I think).

First, in poking around I found this on my hot end fan. I'm not sure if this is relevant, because it was the print cooling fan that was under suspicion. I don't know if this is a 'melted in contact with the heater block' case, or a short, or both:

But on with the print woes. Last night's 8-hour print managed about 75% and the last 25% was knotted spaghetti.

Looking at what I had under the knotted spaghetti, there's a layer shift, and I suspect this is actually the print head snagging and pulling the magnetic sheet out of place (I had that once before, so I know a snagged head can overpower my magnets).

When I look at the remnant, there are several places where I have a glossy band, and at the edge of the glossy band a rough ridge. The ridge is typically about 0.5 to 0.7mm high, though one was about 1.1mm high. The ridge is two to three nozzle passes wide. This occurs 6 times across the print, on two different layers (the print was to be 3ish mm high in some parts, 5ish mm in others, and higher elsewhere, I have glossy bands both where 3mm is the top and where 5mm is the top). The edge of a glossy band always aligns with a discontinuity (ie edge of a hole through the print) but sometimes it's the ridged edge that aligns, and sometimes the flat edge.

Here (above) the lower-left glossy band is aligned on the non-ridge edge to the big hole at bottom left corner (which is in the middle of the print - it's a big cog), but the rightmost glossy band the ridged edge aligns with the edge of the small hole above.

If I look closely, the glossy band is shocking under-extruded (extrusion about half the width it should be), to the extent that the line of extrusion isn't even continuous. I can see the layer beneath between the extrusions.

These photos are me holding a magnifying eyepiece in front of my phone camera lens, so quality isn't great, but this is the middle and lower end of the top glossy band in the photo above.

So it looks to me like I get dramatic under-extrusion for a few passes (ten or so in the detail photos case), then massive over-extrusion for a couple of passes - almost as if the extruder is passing the right amount of filament, but it's bunching up somewhere, then coming out in a rush. I do have a bowden extruder, with about 650mm 'capricorn' bowden tube. I could probably shave about 20mm off that length.

Has anyone got any possible explanations, or more importantly any possible remedies for this?

-

that looks like the Bowden gap issue where a tiny gap between the bowden tube and the nozzle in hotend designs where the tube goes down to the nozzle (I.e., the default ones on cheap printer kits like the ender3). That'll cause soft pla to go in there especially during retracts and causes partial clogs which sometimes will cause weird sponge like behavior resulting in uneven extrusion ....

-

@oliof thanks for that pointer.

Having replaced the hotend fan, I've repeated the same print and done a couple more largish (10 hour plus) prints with no similar problem, so it seems that fan was somehow to blame. The best I can come up with is that if the hot end fan was fluctuating in power (maybe even going off) the the length of melt zone would have been varying and that could cause something similar to the 'bowden gap issue' by altering the 'springiness' of the melt zone?

I have not tested whether this was also contributing to the small-tower case. I have my suspicion there that although my cooling air flow is generally OK, it might be aimed at slightly the wrong angle, and with a small tower rather than get deflected across the newly-placed material, it misses and gets deflected down the side of the tower.

-

@achrn yes, lack of/inconsistent heatsink cooling could cause the same issue. air flow deflection on small features certainly qualifies as another possible factor, especially close to the print surface.