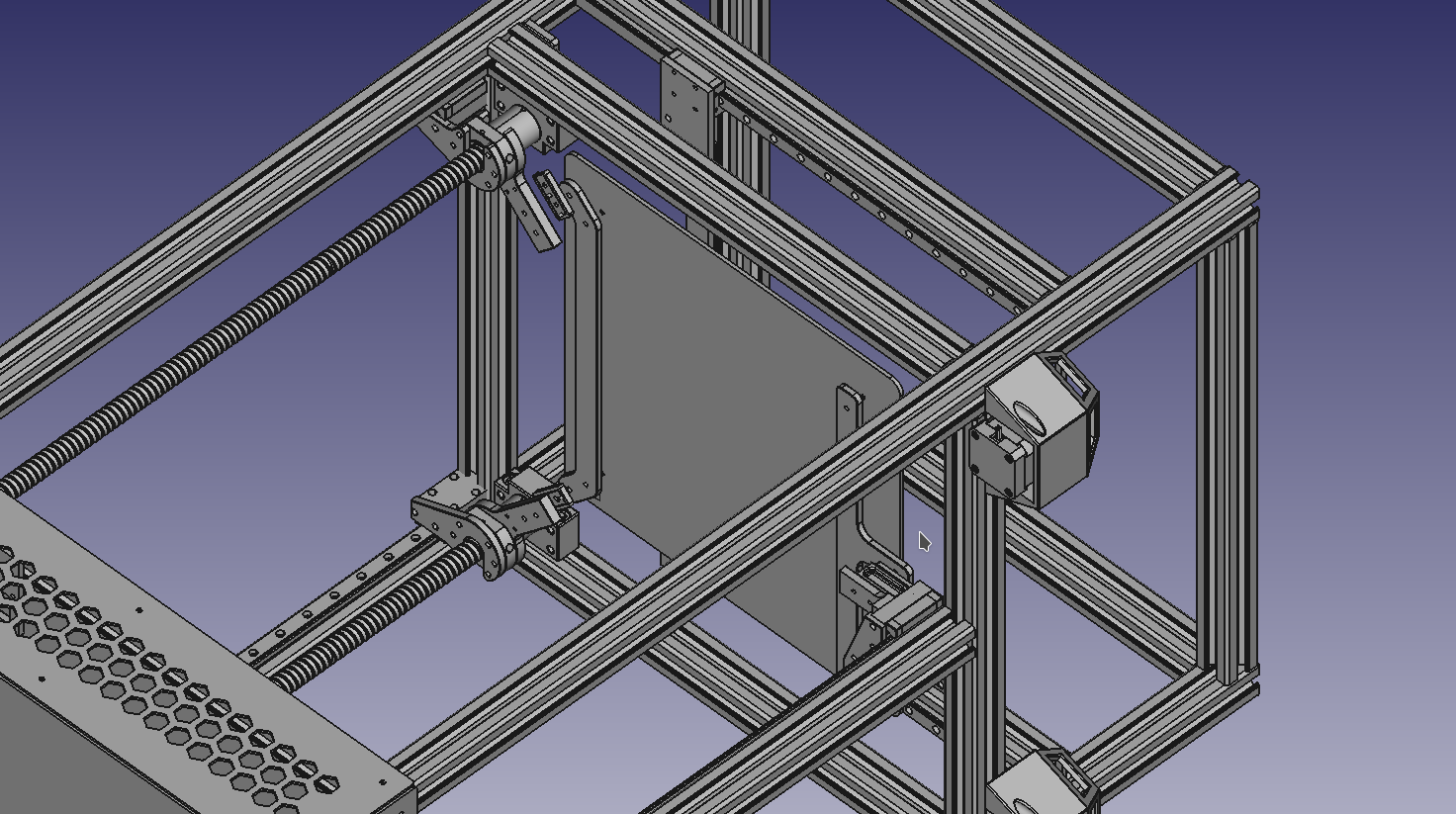

HEVO triple kinematic bed configuration

-

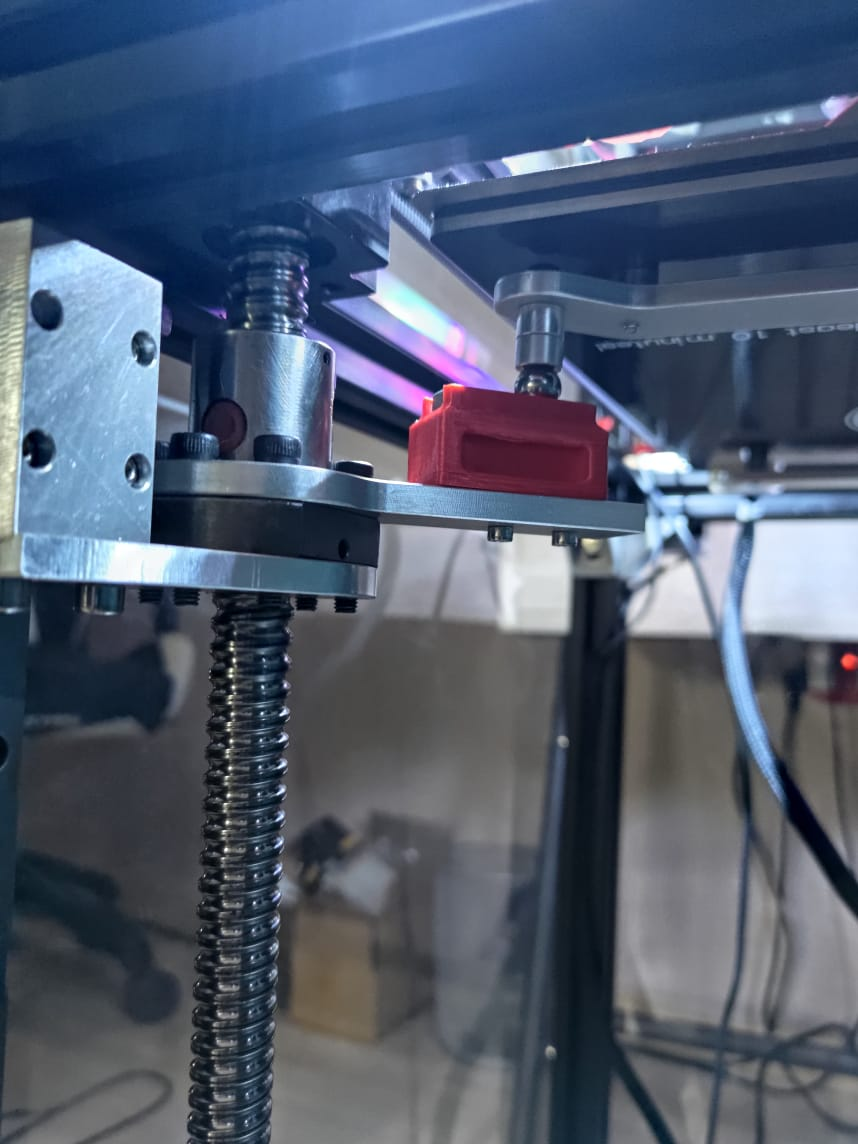

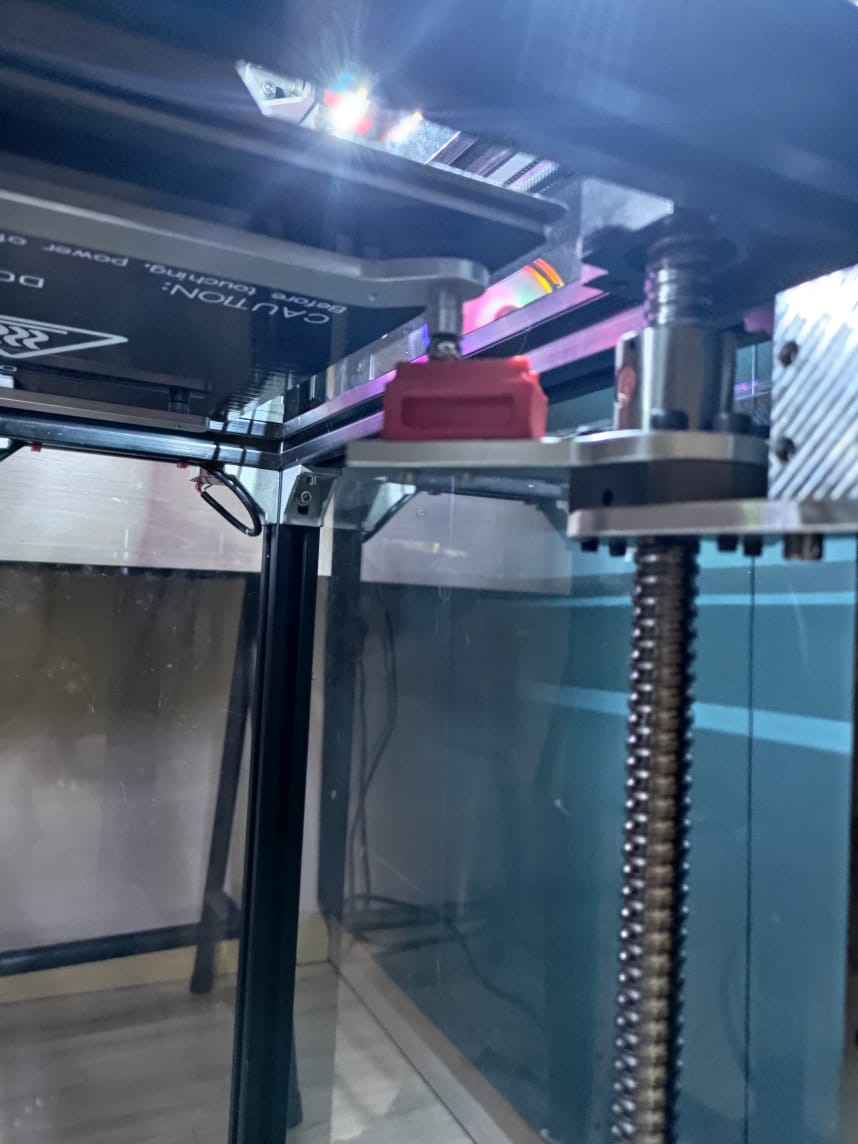

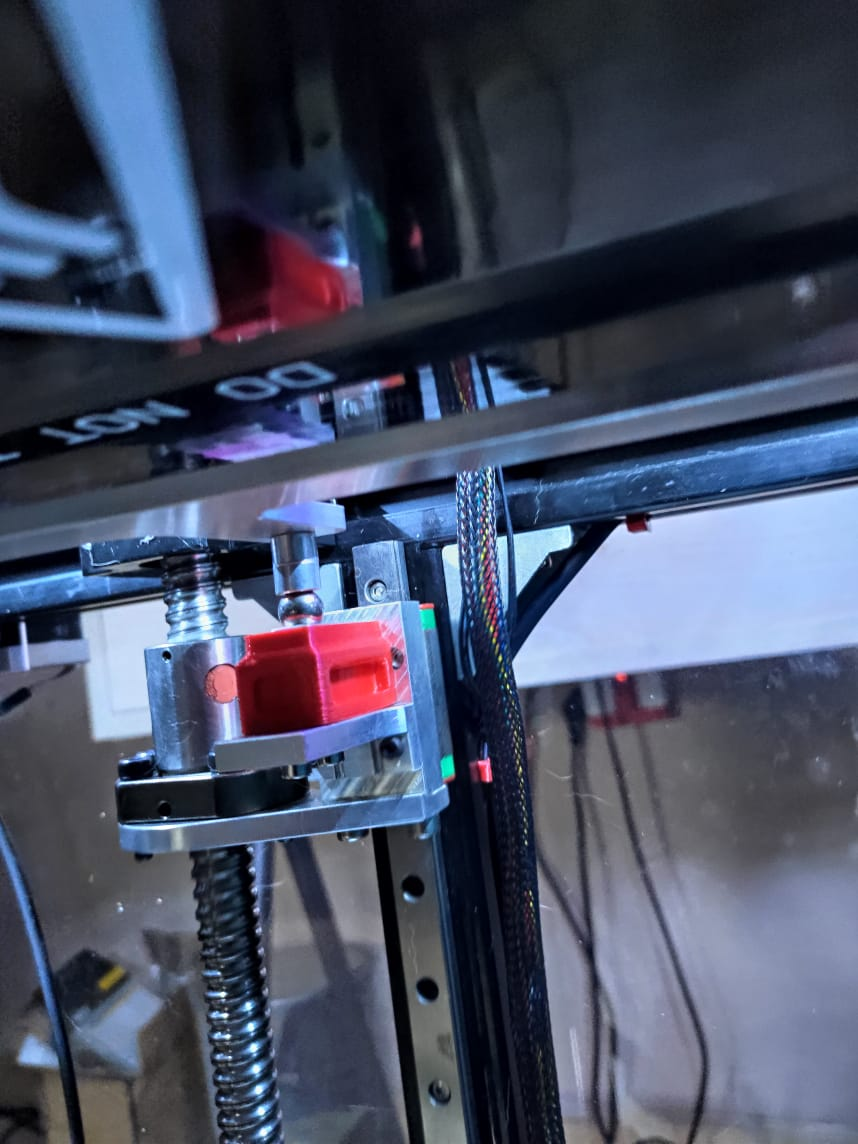

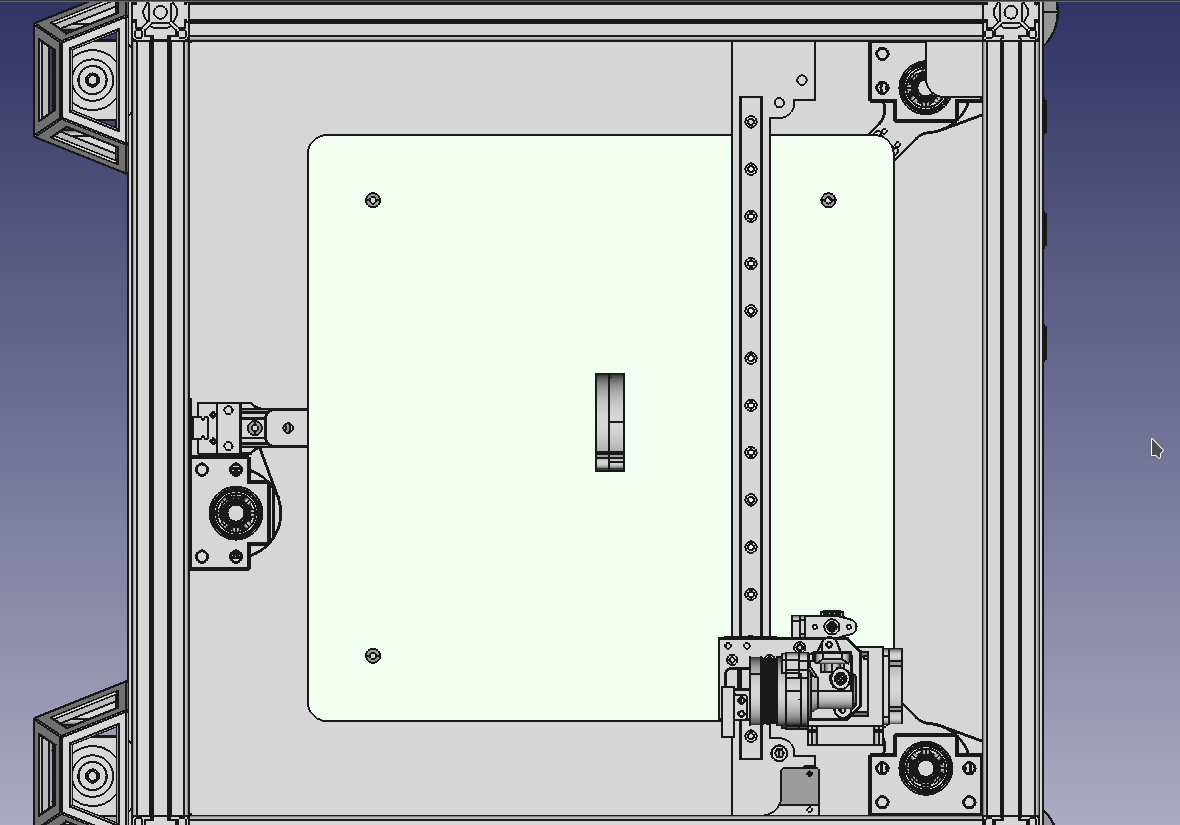

great are those cordinate defined as where the lead screw physically is, or where it mounts to the bed, as there are ball screws under the hot bed, these are extended a bit inwards by the mount from the lead screws, basically we followed the HEVO triple Z axis design, tough its modified a bit.

Front Left

Center rear

However notice the screw is offset and the rear is actually mounted at the rail

ill look around for an example bed.g

-

@dingo007 said in HEVO triple kinematic bed configuration:

ill look around for an example bed.g

Did you look here?

If it's a triple lead screw with 3 motors then this should apply: https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

Specifically: https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors#Section_Example_for_3_motors

-

3 Z Screws will ball mounts at X:Y 20:20, 125:290 and 230:20

So Im pretty sure im not understanding the M671 Logic i read in that guide. Ive tried from the guide however12/3/2021, 7:35:22 AM Error: Some computed corrections exceed configured limit of 0.50mm: 2.467 -0.039 0.029

12/3/2021, 7:34:42 AM G32

110 points probed, min error -1.395, max error 2.579, mean 0.493, deviation 0.962

Height map saved to file 0:/sys/heightmap.csvconfig.g

; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S0 ; physical drive 0.3 goes forwards

M569 P0.4 S0 ; physical drive 0.4 goes forwards

M569 P0.5 S1 ; physical drive 0.5 goes forwards

M584 X0.4 Y0.3 Z0.0:0.1:0.2 E0.5 ; set drive mapping

M350 X16 Y16 Z116:16:16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z1280.00:1280.00:1280.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00:60:60 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00:180.00:180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00:20.00:20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800:800:800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Screws

M671 X20:20:230 Y190:10:125 S0.5 ; leadscrews at rear left, front middle and rear rightconfig-overide.g

; config-override.g file generated in response to M500 at 2021-12-02 20:40

; This is a system-generated file - do not edit

; Heater model parameters

M307 H0 R0.206 C393.800:393.800 D2.19 S1.00 V23.3 B0 I0

M307 H1 R1.679 C247.000:247.000 D7.08 S1.00 V23.7 B0 I0

; Workplace coordinates

G10 L2 P1 X0.00 Y0.00 Z0.00

G10 L2 P2 X0.00 Y0.00 Z0.00

G10 L2 P3 X0.00 Y0.00 Z0.00

G10 L2 P4 X0.00 Y0.00 Z0.00

G10 L2 P5 X0.00 Y0.00 Z0.00

G10 L2 P6 X0.00 Y0.00 Z0.00

G10 L2 P7 X0.00 Y0.00 Z0.00

G10 L2 P8 X0.00 Y0.00 Z0.00

G10 L2 P9 X0.00 Y0.00 Z0.00and bed.g

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Tue Nov 30 2021 22:33:03 GMT+0700 (Indochina Time)

M561 ; clear any bed transform

G29 ; probe the bed and enable compensationG28 ; home

G30 P0 X20 Y20 Z-99999 ; probe near a leadscrew

G30 P1 X125 Y290 Z-99999 ; probe near a leadscrew

G30 P2 X230 Y20 Z-99999 S3 ; probe near a leadscrew and calibrate 3 motors -

You don't want to do a G29 in bed.g - that file is just for auto-leveling of the bed.

The file mesh.g is for creating the height map needed for mesh bed compensation.

So first get auto-leveling working and then work on mesh bed compensation.

Frederick

-

I removed the G29 And still thats whats giving me the error, so im not sure im measuring the probe points right. is it where the physical screws actually are? or where the ball mounts are under the board??

G32

Error: Some computed corrections exceed configured limit of 0.50mm: 0.026 3.362 -1.291config.g

; Configuration file for Duet 3 (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Tue Nov 30 2021 22:33:03 GMT+0700 (Indochina Time); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"300" ; set printer name

M669 K1 ; select CoreXY mode; Network

M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet ; Set idle timeout; Drives

M569 P0.0 S1 ; physical drive 0.0 goes forwards

M569 P0.1 S1 ; physical drive 0.1 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S0 ; physical drive 0.3 goes forwards

M569 P0.4 S0 ; physical drive 0.4 goes forwards

M569 P0.5 S1 ; physical drive 0.5 goes forwards

M584 X0.4 Y0.3 Z0.0:0.1:0.2 E0.5 ; set drive mapping

M350 X16 Y16 Z116:16:16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z1280.00:1280.00:1280.00 E420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00:60:60 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00:180.00:180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00:20.00:20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800:800:800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Screws

M671 X20:125:230 Y20:300:20 S0.5 ; leadscrews at rear left, front middle and rear right; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X250 Y320 Z480 S0 ; set axis maximabed.g

; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Tue Nov 30 2021 22:33:03 GMT+0700 (Indochina Time)

M561 ; clear any bed transform

;G29 ; probe the bed and enable compensationG28 ; home

G30 P0 X20 Y20 Z-99999 ; probe near a leadscrew

G30 P1 X125 Y300 Z-99999 ; probe near a leadscrew

G30 P2 X230 Y20 Z-99999 S3 ; probe near a leadscrew and calibrate 3 motors -

Well that is not really an error, more of an informational message.

You have the S parameter in your M671 set to 0.5 which limits the correct for a single pass to 0.5 mm which is not very much. The default value is 1.0.

You see that one of the adjustments required was going to be 3.362.

So as a test change the S parameter to 4.0 and see what happens.

Frederick

-

@fcwilt

G32

Leadscrew adjustments made: 0.167 0.270 -0.504, points used 3, (mean, deviation) before (-0.022, 0.343) after (0.000, 0.000)mmm think i nailed it now...

-

@dingo007 said in HEVO triple kinematic bed configuration:

@fcwilt

G32

Leadscrew adjustments made: 0.167 0.270 -0.504, points used 3, (mean, deviation) before (-0.022, 0.343) after (0.000, 0.000)mmm think i nailed it now...

You can if you wish put those three G30 command inside while loop with a few other commands and it will run multiple passes until an acceptable degree of levelness (is that word) is reached.

Here is an example:

; start of bed.g while true G30 P0 X-145 Y-65 Z-99999 ; probe near ball stud #1 G30 P1 X0 Y100 Z-99999 ; probe near ball stud #2 G30 P2 X145 Y-65 Z-99999 S3 ; probe near ball stud #3 ; check results - exit loop if results are good if move.calibration.initial.deviation < 0.02 break ; check pass limit - abort if pass limit reached if iterations = 5 M291 P"Bed Leveling Aborted" R"Pass Limit Reached" abort "Bed Leveling Aborted - Pass Limit Reached" ; end of bed .gYou would just need to put your own G30 commands in there.

Frederick

-

This post is deleted! -

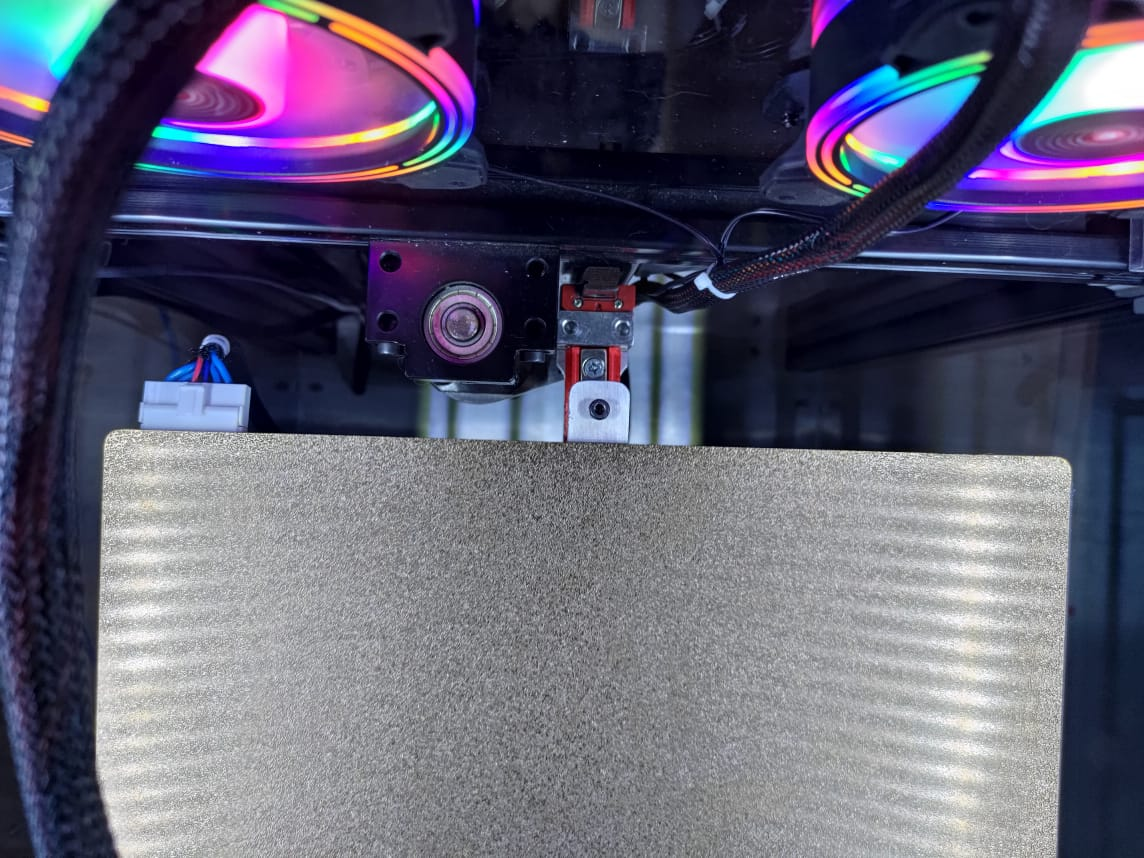

ok here is the top and bottom side cad of the bed, plus the photos of it above, im literally not sure what/where to measure. Am I measuring at the screws, or the ball studs, which align under the board and offset slightly with a bracket, am i measuring at the screws, or the ball studs, also do i include the offset from the board to the ball stud? and you will also notice on the rear screw it has a mount from the Z rail with a ball screw, the board sits on it centered.

for M671 ... I tried the below thinking i would measure at the ball screws, yet when i run the G32 leveling the right and read go way out of whack.

; Screws

M671 X20:125:230 Y20:280:20 S4.5 ; leadscrews at rear left, front middle and rear rightand in bed.g

G30 P0 X20 Y20 Z-99999 ; probe near a ball stud

G30 P1 X125 Y280 Z-99999 ; probe near a ballstud

G30 P2 X230 Y20 Z-99999 S3 ; probe near a ballstud and calibrate 3 motors

-

@dingo007 measure at the pivot point, i.e. the ball studs.

so the ball stud locations should go in M671

the M671 order should be the same order as the motors are defined in M584

so Z0.0:0.1:0.2 and M671 should be the location for the ball studs in that order -

ok and this is compared to the machine home position X0Y0 including the probe offset ?? so im measuring from that point to the pivots i take it.

-

@dingo007 yep

-

The measurement doesn't need to be 100% exact to work either. The closer the better, but don't fret over half a mm.