Which frame design can scale best?

-

@mikeabuilder said in Which frame design can scale best?:

Mostly a limitation I've imposed on myself trying to stick with only the Duet3 and having enough drivers for a multi-extruder head.

What board are you thinking of using?

I'm planning some custom code during bed.g to measure some bed heights and tell me how much to adjust each of the front Kinematic balls under the bed.

You don't need custom code - that feature, Manual Bed Leveling, is part of the firmware.

Frederick

-

I'm also in agreement on the math. Engineering is about understanding and you can't really understand without math.

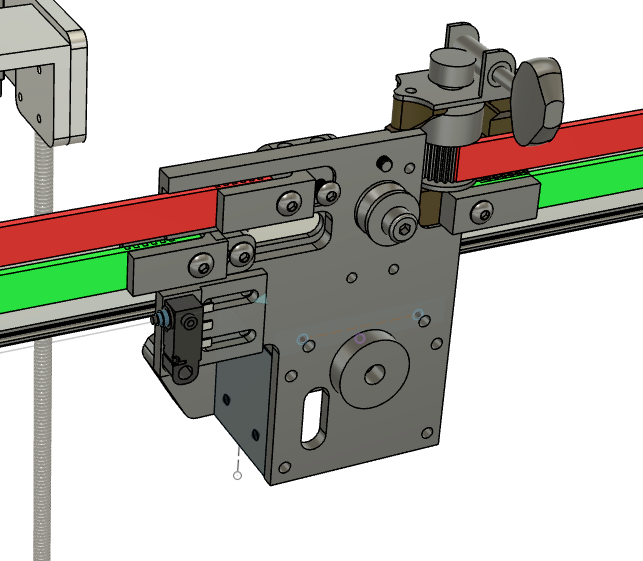

But I also approach a lot of the engineering problems by trying to design to minimize undesirable forces even if I don't calculate their magnitude. For example, on a coreXY, there is a lot of talk about how to set the two belt tensions to be equal. Lots of phone apps and acoustic measurements. My coreXY designs (1.5, so far) use mechanisms to allow the two belts to be connected during tensioning so that they are naturally equalized. Then I lock the belts in place. This way, I avoid having to worry about the effects of unequal belt tension. Here's the overly complicated mechanism we're using on the printer at my maker-space, using a guitar tuning machine to allow us to "crank up the tension"

.

.I also over-design where the cost is not high to do so. I use 10mm belts because it's not that much more expensive. 2040 vs 2020 extrusion, NEMA23 vs 17. This works because my printer design is just for me and I'm OK with the added costs. Other designers will have their own priorities.

-

@fcwilt, I've got a Duet3 6HC on hand. I'm using the 6 drivers for X,Y, Z, E0, E1, and one unused.

For leveling, I'll check out the process for assisted manual leveling. But I'm also thinking of coding up something just for fun with some constraints I want to place on myself. I don't want to adjust the rear support because it's hard to reach, and I'll have big thumb wheels on the two front bed supports. I thinking of code that I can use to calibrate the thumb-wheels (I know, it can be calculated, but where's the fun in that?), then the leveling code will tell me to turn each one right or left by a specific amount of rotation.

This is what happens when engineers retire...

-

Just to summarize a bit what I learned or confirmed in this thread:

- Always do the math, for belt stretch, beam deflection...

- No design is perfect and it's always tradeoffs.

- MarkdForge kinematic is a nice alternative to CoreXY

- Cross gantry might work with proper design (I will try it for fun (at least a CAD drawing, maybe not the construction))

- Ballscrews are overkill for 3d printer

- Belts can work on Z with gear/brake (or maybe even just 4 big steppers)

- Belt stretch can be smaller than we think, do the math

- There are some 1.75mm bowden drive (nimble)

- This forum is great

-

@mikeabuilder said in Which frame design can scale best?:

For leveling, I'll check out the process for assisted manual leveling. But I'm also thinking of coding up something just for fun with some constraints I want to place on myself. I don't want to adjust the rear support because it's hard to reach, and I'll have big thumb wheels on the two front bed supports. I thinking of code that I can use to calibrate the thumb-wheels (I know, it can be calculated, but where's the fun in that?), then the leveling code will tell me to turn each one right or left by a specific amount of rotation.

If you design the bed support with just 3 points (left front, rear center, right front) then you could use the firmware feature because it uses the first point probed as the reference and only computes the needed adjustments for the other two points probed. So you would probe rear center, left front, right front.

And three points do determine a plane.

Frederick

-

-

@engikeneer said in Which frame design can scale best?:

@fcwilt to be correct, you can probe as many points in whichever order you want. You just need to define the back adjustment screw as number one

True but having tried varying numbers of points 3 seemed to work fine BUT I am using bed plates known to be flat within a certain spec.

Frederick

-

Side question, does anybody know were to source genuine epdm gates belts in europe?

-

@fcwilt, thanks for the description of how the manual bed level assist works. I also read the wiki page and it's clear there too - the first probe point is not moved in the adjustment. This brings me to an interesting topic (somewhat off topic for scaling), and that is the concept of "leveling". When discussed, people usually assume, without stating, that the surface described by the Z probe (or nozzle) is perfectly planar and this is rarely the case. There can be humps or bends in the rails, and on a gantry supported by rails on either end, those rails might be skewed (back end up on one and down on the other). The point is that there are a lot of places that tolerances and alignment errors can impact getting a "really level" bed and the mesh compensation is really the final feature that covers up most of these. Getting each of the other elements as close to right as practical is a good thing, but be practical and have faith in the mesh.

-

A large printer doesn't necessarily need the same bed flatness that a smaller printer needs. If you're building a large printer, there's a good chance you're going to use it to print large objects with a large nozzle and thick layers. A thick first layer is much more tolerant of variation in bed surface flatness than the thin first layer typically used in smaller printers.

-

@mrehorstdmd

sounds reasonable, but there's also more shrinkage on bigger parts and a first layer with uneven squish-factor is prone to lift off the bed. -

@mrehorstdmd said in Which frame design can scale best?:

If you're building a large printer, there's a good chance you're going to use it to print large objects with a large nozzle and thick layers.

There's also a good change you'd want to print a large batch of many small objects. Having worked on a 1 square meter printer recently I can say that leveling and mesh is critical for both though.

-

@o_lampe In my experience with printing ABS in a heated chamber (even at only 50C), relatively large prints (280 mm) don't warp off the bed. What's more likely to be a problem is getting the print to let go of the bed when it's finished. You have much wider lines and so much larger surface area where the plastic contacts the bed surface, even if the surface isn't perfectly flat. I find that a little IPA at the base of the print, combined with prying with a sharp scraper, does the job reliably and with minimal damage to either the print or the bed surface.