please help me blv setting

-

Due to the size of my bed, I use 2 thermistors. 1 in the heat mat, Keenovo and I have a slot in the top of the bed to take a second.

For safety I use the thermistor in the heatmat, but the one in the top to give me a better idea of what the heat on the bed is.

Regardless what material I am printing, I let the bed and printer warm up for 50mins to an hour. My bed is 8mm thick

All Z tweaks are done at temp. ie Z Offset. Bed at 100 nozzle at 150.As @oliof mentioned, 80 degress is way to hot for PLA.

If you use SuperSlicer, there is a lot of calibration tools in it, to help get your bed level, extrusion rates, bridging speeds etc.

Has helped me a lot. -

@paulhew hello indeed it works well after heating 1 hour to 60 of the rooms are glued to the bed thank you for your advice. But the cubes are full of lines as before.

-

I have looked, but what printer is it please?

Picture also? -

@paulhew hello blv mgn cube

-

3 things that could be an issue.

Has the gantry been de-racked?

Do the Z rods move smoothly, no untoward noise? Bed securely fixed.

How old is the PLA? and is it a good quality?I keep my PLA and PETG in a sealed box when not in use. Has a rechargeable silica box in it.

And before use, I throw it in the de-humidifier for an hour. -

@paulhew hello yes my z it's sfu 1204

yes it moves noiselessly well oiled it pla ila 2 months but I use it on my cr10s and the parts are perfect the bed well fixed nothing abnormal -

@sgk Has the gantry been de-racked? what does it want? racked

-

@sgk I changed my hotend dragon hf plus extrudezr orbitor and my rods slide perfectly

-

@paulhew

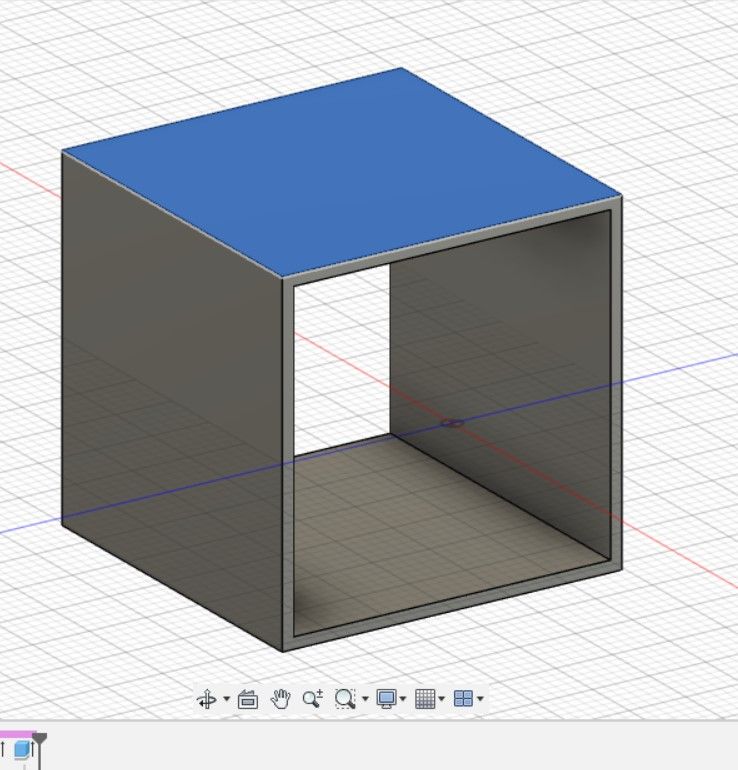

I made another cube to see I did the pid hotend again -

@sgk

-

@sgk From All the writings and photos If I was in your shoes, I would do the following

- Both bed and hotend temp check with external measurement and then calibration

- SFU are stiff, so some kind of anti-wobble device for the nut, it can be nylock nuts or some printed set

- Flow calibration and E steps

- finally X/Y stage, belts tensioning check

-

-

@martin7404 the hotend before I had e3dv6 and a different probe the z of t8 metal and extruder bmg changed to extruder orbitor and I had the same problem and when I touch the adjustment of the belt I have not much difference

-

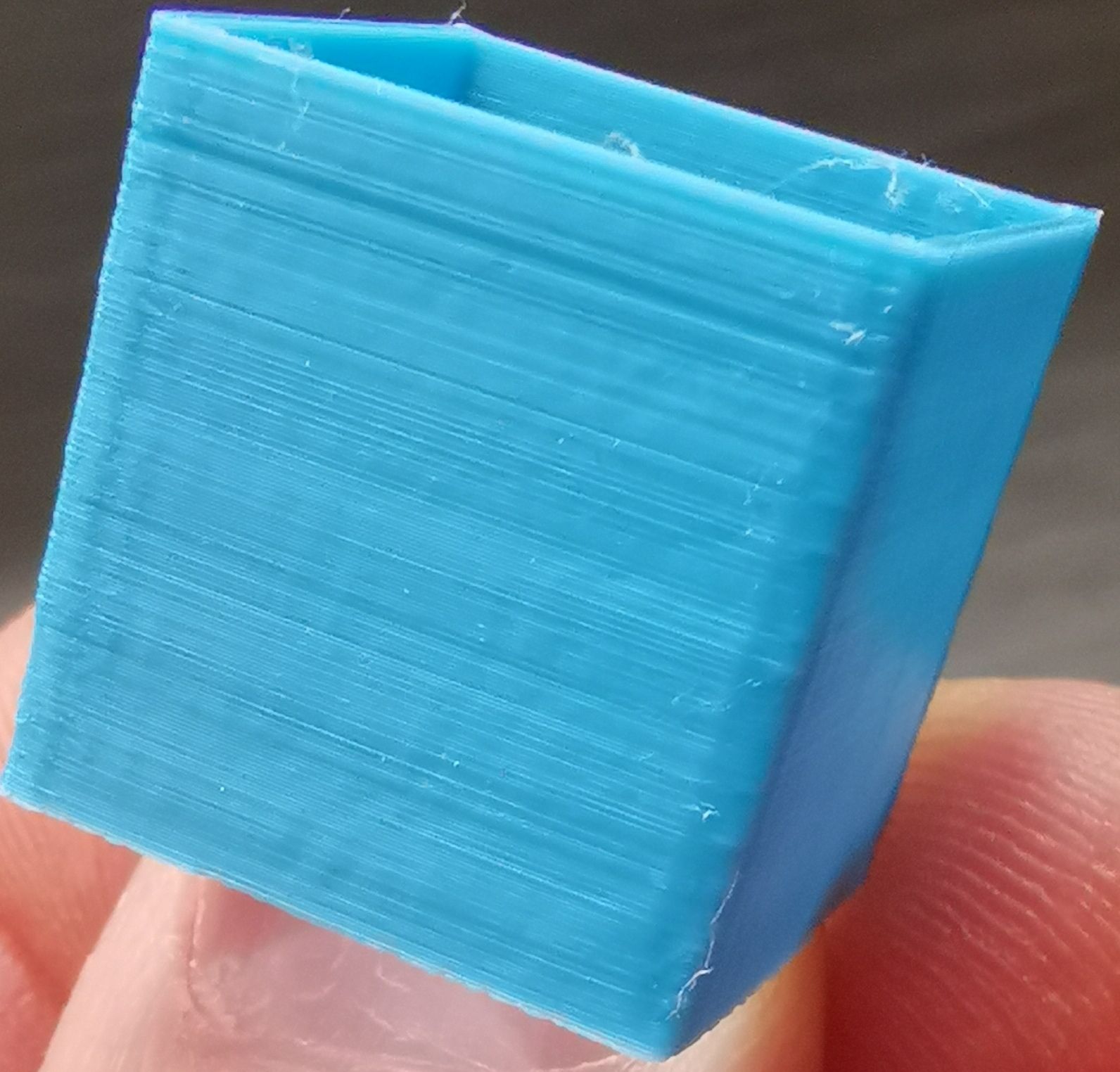

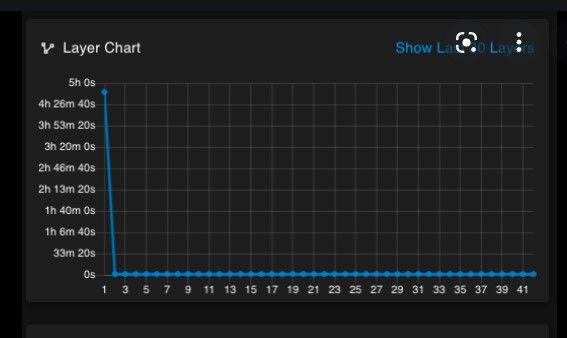

@martin7404 I wonder if the problem is not related to that because I print a 20x20x20 cube all the dimensions full and on the graphics it is not going

-

@martin7404

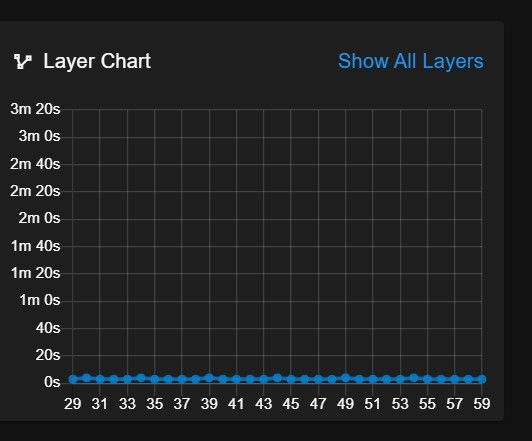

here it is a graphic of someone who printed the same cube as me, we see that the lines are always the same

-

@sgk

do you know why the time of each layer is not the same while the cube is the same everywhere -

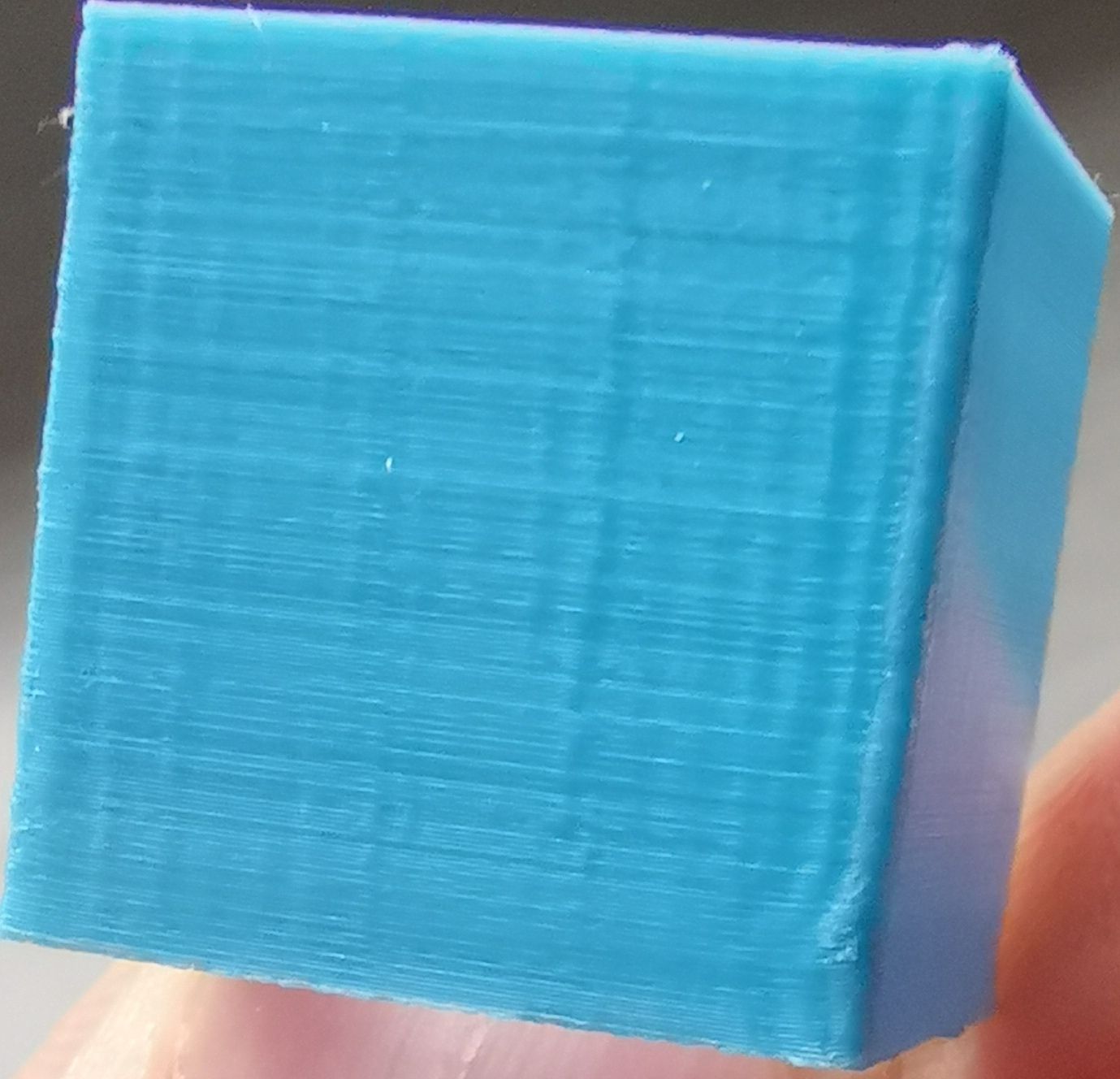

@sgk this is my cube

-

@sgk If you are sure Your bed is level and there is no wobble in the Z axis

then it is extrusion calibration and temperatures -

@martin7404

I do before each print g29 -

@sgk ok can you share your bed graph