please help me blv setting

-

@sgk p.s speed, accel , jerk ?

-

@martin7404

I can't find where the graphics are -

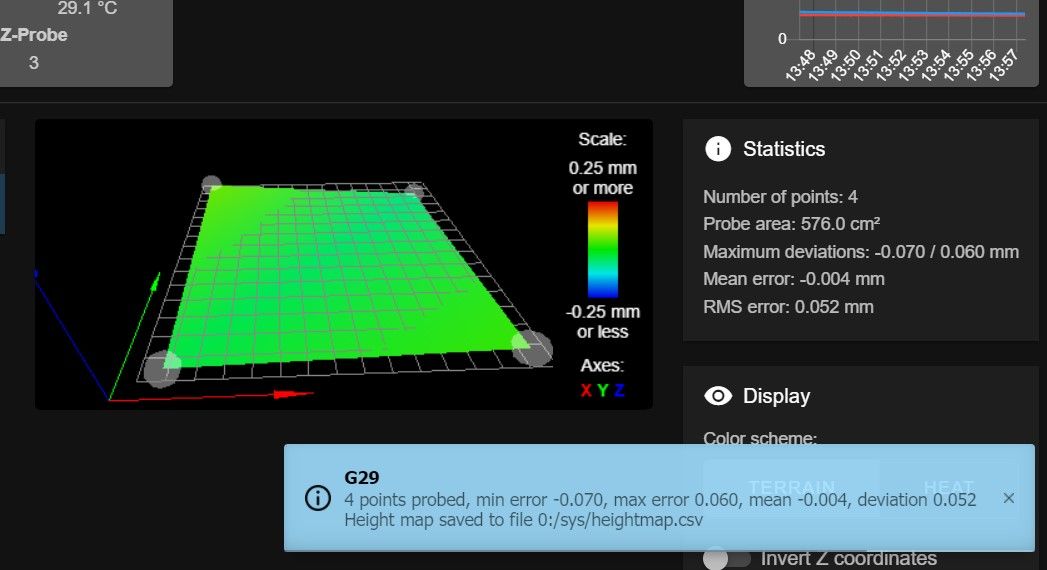

@sgk On DWC heightmap

-

@martin7404

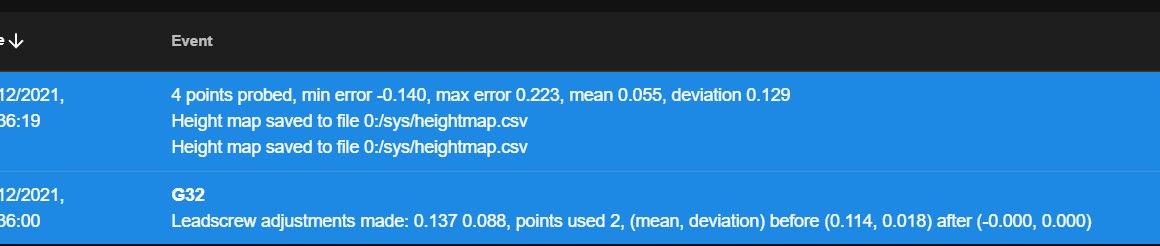

RepRapFirmware height map file v2 generated at 2021-12-17 13:36, min error -0.140, max error 0.223, mean 0.055, deviation 0.129

RepRapFirmware height map file v2 generated at 2021-12-17 13:36, min error -0.140, max error 0.223, mean 0.055, deviation 0.129

axis0,axis1,min0,max0,min1,max1,radius,spacing0,spacing1,num0,num1

X,Y,20.00,270.00,20.00,270.00,-1.00,240.00,240.00,2,2

0.076, 0.223

0.062, -0.140 -

@sgk

-

@sgk it is ok, but I will suggest you do at least 16 points map

-

@martin7404 ok 16

-

@martin7404 how do you manage to put in 16?

-

@sgk ; bed.g

; called to perform automatic bed compensation via G32

;

; generated by RepRapFirmware Configuration Tool on Tue Oct 09 2018 13:27:56 GMT+0300

M291 P"Probing mesh grid process started" R"Probing.." S1 T2

M561 ; clear any bed transform

G28 ; home all axis bb

M671 X-30.0:364.0 Y175.0:175.0 S5.0 ;bed compensation

G30 P1 X5 Y150 Z-99999

G30 P0 X300 Y150 Z-99999 S2

G90 ; absolute positioning bb

M557 X20:270 Y20:270 S240 ; Define mesh grid

G29 S0 ; Probe the bed and save height map to file

M374 ; Save calibration data. Default is sys/heightmap.csv

M291 P"Probing mesh grid process finished !" R"Probing.." S1 T2

; Probe the bed at 4 points

;G30 P0 X10 Y10 H0 Z-99999 -

This post is deleted! -

This post is deleted! -

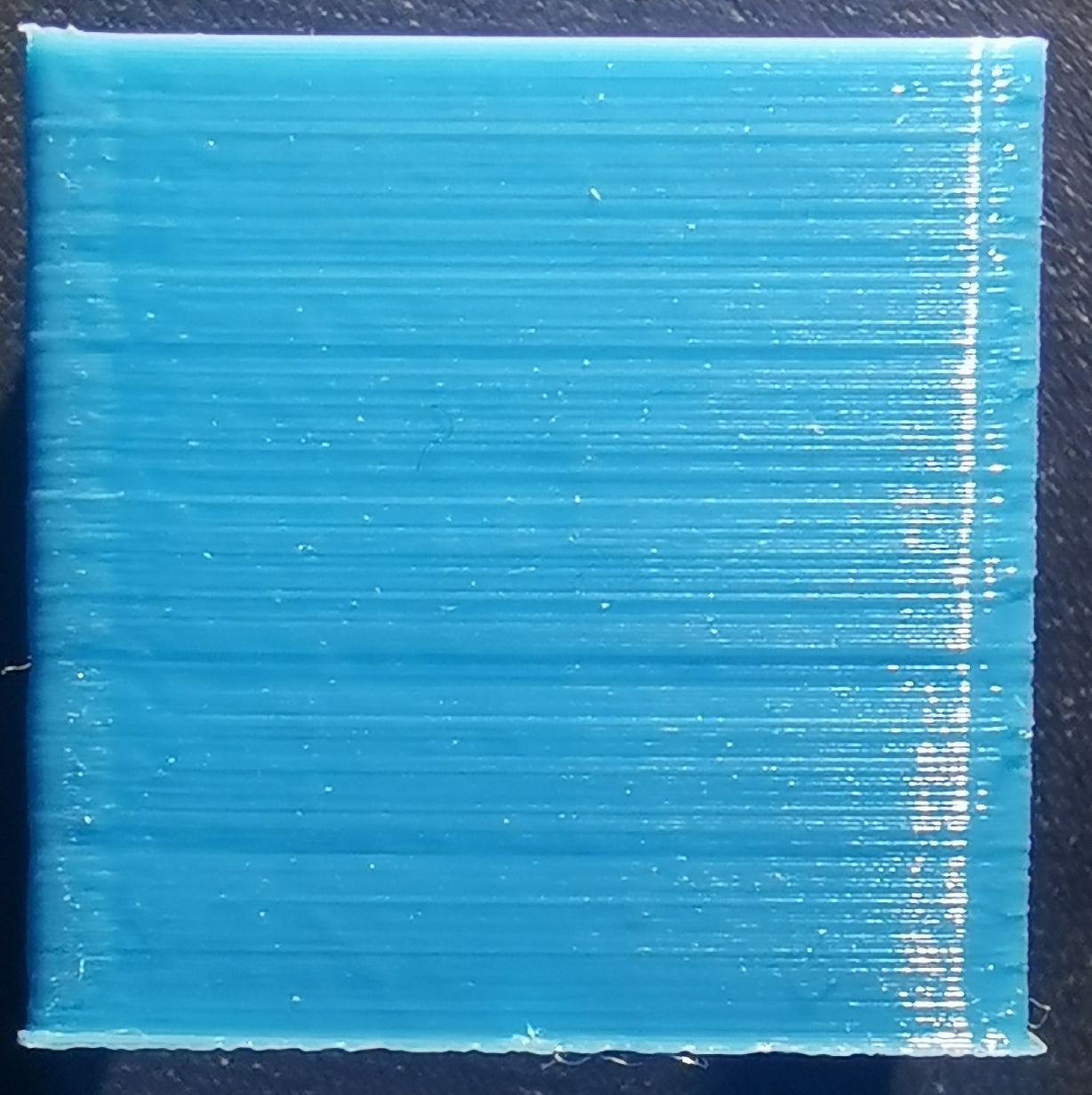

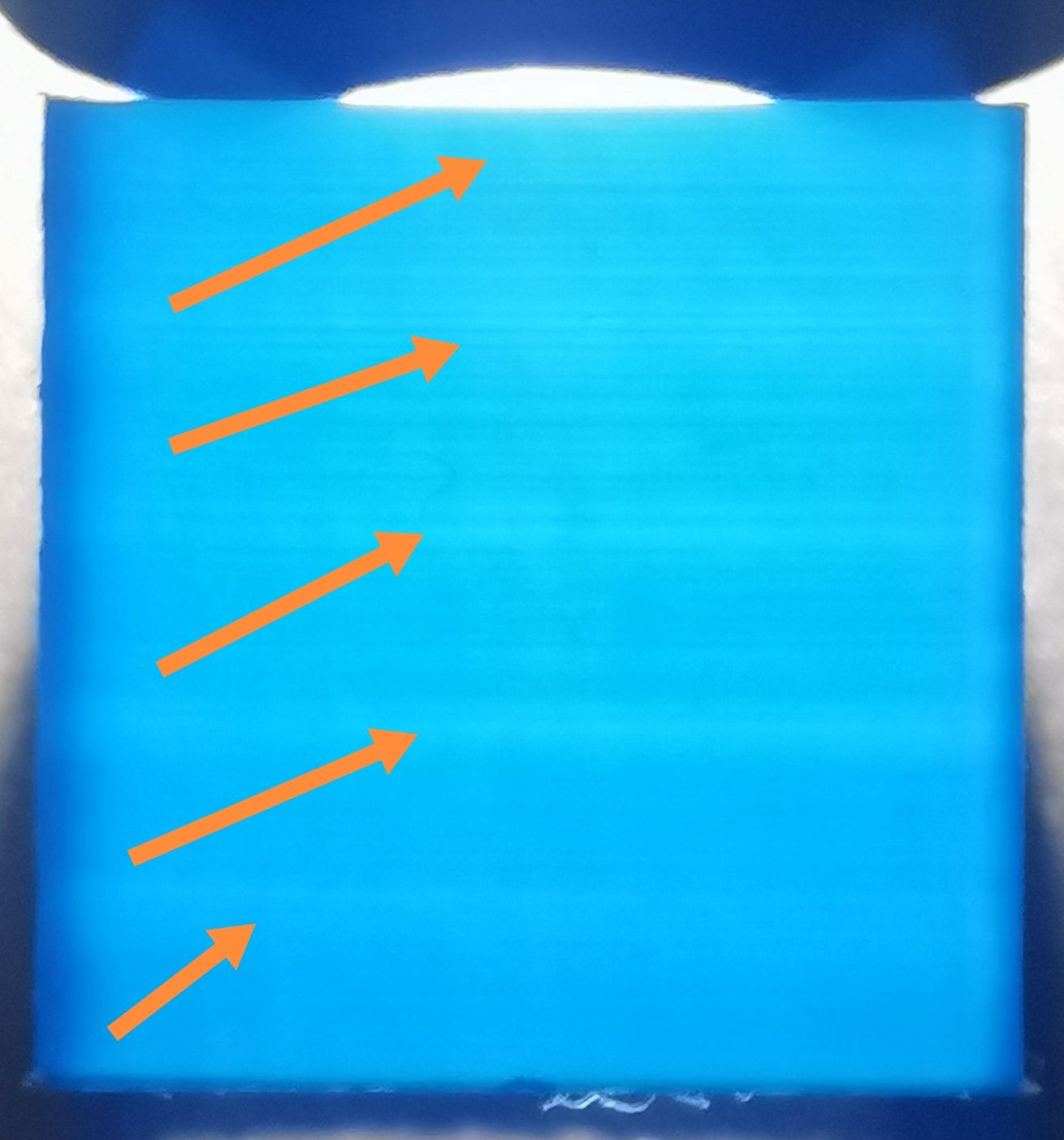

@sgk Hey friends after changing the thermistor probe for a Semitec 104GT-2 the lines are now straight horizontally but the vertical lines are shifted and lack of filament as we see in the photos? Any ideas folks?

-

@sgk to me, that looks like either z banding or a bed that doesn't have great PID control (so the bed temperatures fluctuate through the print).

If it is z banding, I.e. some issue with the z axis motion, things to look for would be:

- is there room for the ball screw to float a bit in case there is any misalignment?

- are the ball screws straight?

- do they wobble at all as the z axis moves?

- are the z guides giving the bed enough support (I.e. can the bed move in x and y at all)

For the PID issue, watch your bed temp during a print - it should be pretty stable. Also double check you are using it in PID mode, not bang bang

-

@engikeneer

hello thank you very much for your help. This has to say that I am an average novice there are things that I do not understand, excuse me

but how do I know and how can I verify all this?I put a new thermistor for the hotend I must also do for the bed?the z rods are mounted on sfu1204 I imagine they are straight.

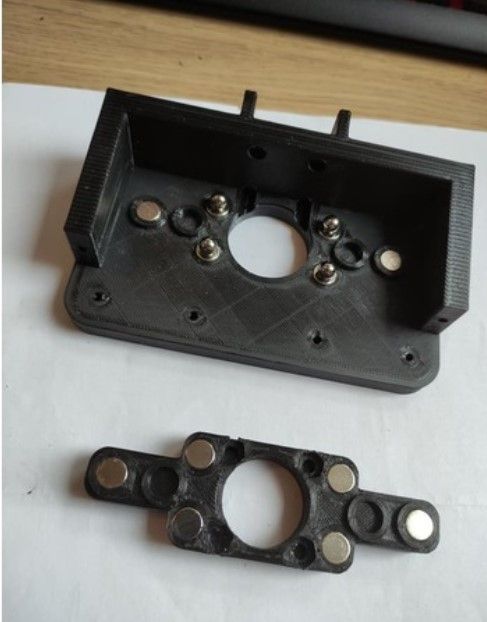

i have this the z

-

@sgk i have this for z

-

@sgk well that mount looks good for the bed end - looks like it's got some room for flex in x and y which is good.

Maybe down at the motor end, might be worth checking that. Is the coupler to the z motor perfectly concentric? I had a cheap one once that wasn't and made the bottom of the z screw wobble a lot. Maybe loosen the screws for the black support piece so it is slightly free and see if it wants to wobble? -

@sgk I run a BLV with SF1024 ball screws as well. With this set up you need the top blocks - the approach with lead screws does not translate well when you change to ball screws. Your variations in the horizontal layers going vertically is from micro shifts that are occurring, and it’s exacerbated with a two screw setup over a three a axis layout.

You also may want to rerun a PID. What version of the firmware are you running?

-

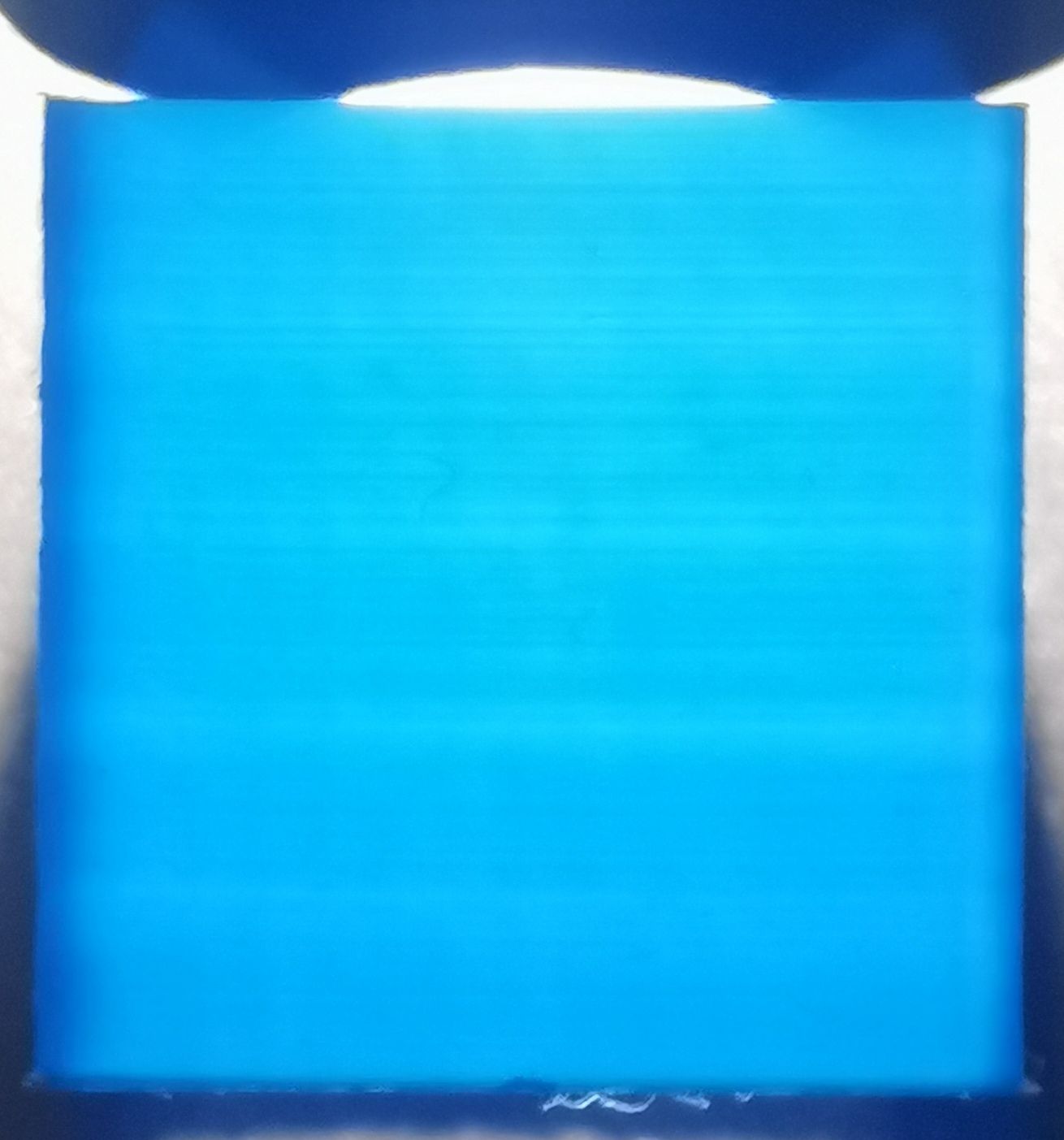

Example of output. Ignore the zits, I was still tuning the pressure advance and coasting after installing ball screws.

.

-

@nuramori hello my print is

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.3 (2021-06-15)

Duet WiFi Server Version: 1.26

i have thsi engine moonsthank you very much friends i will start to control the z.

I have installed a new semitec 104gt-2 104nt-4 and pid 3 x thermistor

It can also come from the hotend fan because at home I can not adjust it? -

are normal when I do the pid my fan does not cut hotend?