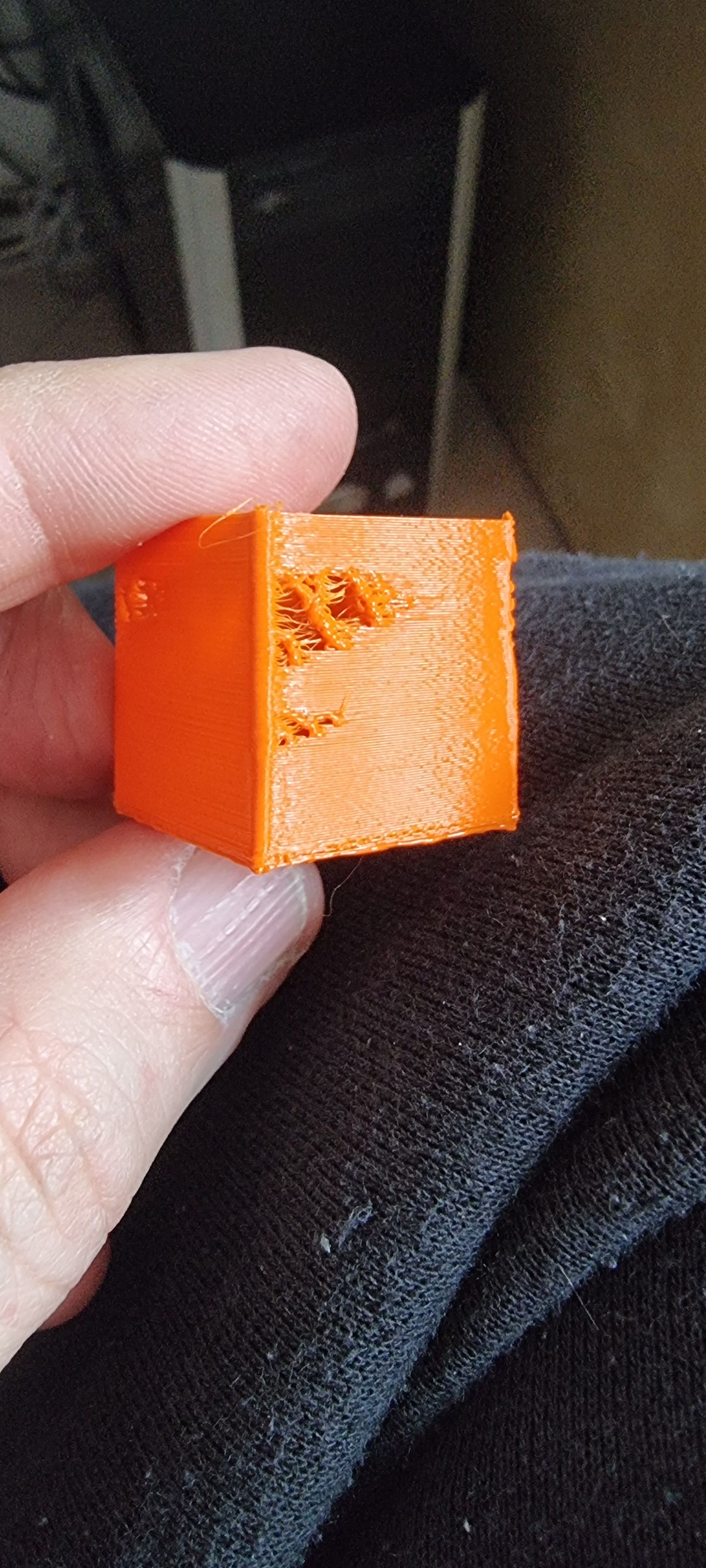

Bondtech X2 tremendous under extrusion error

-

Good moring, I've just finished mith Bontech X2 with an original E3D Chimera + but I can't make it work! I always experience tremendous under extrusion errors:

I've changed the nozzles, the short PTFE tubes, the throats but nothing works. It makes THE SAME error with both the extruders and with every material I print (PLA, PETG).

Slicer Ideamaker, 0.4mm of extrusion, 60mm/s print speed, no pressure advance, no coasting...step/mm for the extruders are perfectly calibrated. Duet 2WiFI, Volcano hotends

here's the config.g (I've tried different current settings for the steppers increasing and decreasing it but nothing works)

. . . ; Drives M569 P0 S1 ; physical drive 0 goes backwards M569 P1 S1 ; physical drive 1 goes backwards M569 P2 S0 ; physical drive 2 goes backwards M569 P3 S1 ; physical drive 3 goes backwards M569 P4 S0 ; physical drive 4 goes backwards M584 X0 Y1 Z2 E3:4 ; set drive mapping M350 E16 I0 ; configure microstepping without interpolation M350 X16 Y16 Z16 I1 ; configure microstepping with interpolation ;M92 X159.6 Y159.6 Z1188.11 E415:415 ; set steps per mm M92 X79.8 Y79.8 Z1188.11 E415:415 ; set steps per mm M566 X660.00 Y660.00 Z12.00 E1500:1500 ; set maximum instantaneous speed changes (mm/min) #################################### M203 X6000.00 Y6000.00 Z180.00 E10000.00:10000.00 ; set maximum speeds (mm/min) ############################ M201 X500.00 Y500.00 Z20.00 E5000.00:5000.00 ; set accelerations (mm/s^2) ############################### M906 X1200 Y1200 Z900 E700:700 I30 ; set motor currents (mA) and motor idle factor in per cent ###################################e M84 S30 ; Set idle timeout ; Axis Limits M208 X-20 Y-30 Z0 S1 ; set axis minima ################################ M208 X295 Y320 Z350 S0 ; set axis maxima ######################################### ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X10.988 Y-25.702 Z1.245 ; set Z probe trigger value, offset and trigger height ############################################### M557 X0:280 Y-10:285 S20 ; define mesh grid ##################################################### ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 H12 L-5 R4200 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 1 to 280C M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 H13 L-5 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S285 ; set temperature limit for heater 2 to 280C . . .It always looks like the filaments starts to flow out from the nozzle with a "delay" after printing a corner....

Some suggestion?

Thanks -

@thedragonlord you will want to use some small amount of pressure advance to help your corner bulges. Most of the under extrusion starts at them so lack of PA is only exacerbating your issue.

-

@engikeneer Orange material is PETG...I'll try to set a little PA but I don't think it will solve the problem

-

@thedragonlord worth trying a different slicer? does printing at a higher temperature make a difference?

-

@jumpedwithbothfeet said in Bondtech X2 tremendous under extrusion error:

@thedragonlord worth trying a different slicer? does printing at a higher temperature make a difference?

I'm downloading Prusa Slicer to try and no, higher temperature doesn't change the issue.....

-

@jumpedwithbothfeet said in Bondtech X2 tremendous under extrusion error:

@thedragonlord worth trying a different slicer? does printing at a higher temperature make a difference?

Same issue with prusa slicer.....

-

@thedragonlord What retraction setting do you have in your slicer?

"RepRapFirmware does not support individual motor settings where an axis has multiple motors connected to different stepper drivers. The first parameter specified will be used for all motors on the axis. " I don't know if there's an exception for extruders.~~~~ Edit. Yes, there is :-) -

@gixxerfast extruders are treated differently

-

@jay_s_uk Thanks, I sort of guessed it. Would be weird otherwise with all the different multi extruder combos that people have. I'll edit my response above.

-

@thedragonlord just a thought did you work out your extrusion steps cold or hot? I`m thinking along the lines of narrowing down the cause, cold and the fault is most likely hot side etc....

#edit wording

-

@jumpedwithbothfeet said in Bondtech X2 tremendous under extrusion error:

@thedragonlord just a thought did you do work out your extrusion steps cold or hot? I`m thinking along the lines of narrowing down the cause, cold and the fault is most likely hot side etc....

hot

-

@thedragonlord well what goes in must come out, and if the under extrusion is occurring on both nozzles it would be my guess its software/firmware related, maybe try someone's working config file both firmware and slicer for testing/comparison?