New Input Shaping plugin v3.4.1-b1

-

@SputnikOC3d download this Steve.

-

@jay_s_uk

m122

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.4.0 (2022-03-15 18:59:15) running on Duet 3 Mini5plus WiFi (SBC mode)

Board ID: G1R6K-M396U-D65J0-40KM4-3G03Z-HZ0QD

Used output buffers: 1 of 40 (16 max)

=== RTOS ===

Static ram: 103684

Dynamic ram: 100772 of which 20 recycled

Never used RAM 37236, free system stack 206 words

Tasks: ACCEL(notifyWait,0.0%,346) SBC(ready,3.6%,473) HEAT(notifyWait,0.0%,358) Move(notifyWait,0.0%,363) CanReceiv(notifyWait,0.0%,942) CanSender(notifyWait,0.0%,372) CanClock(delaying,0.0%,339) TMC(notifyWait,1.2%,115) MAIN(running,94.4%,384) IDLE(ready,0.0%,29) AIN(delaying,0.8%,264), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:02:51 ago, cause: software

Last software reset at 2022-04-13 22:15, reason: HeatTaskStuck, GCodes spinning, available RAM 33300, slot 2

Software reset code 0x4143 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0000080f BFAR 0xe000ed38 SP 0x20031c0c Task ACCE Freestk 334 ok

Stack: 00000001 00053fcc 210c0000 00000000 404b5800 369dc3a0 3edb7e85 3331bb4c 40000000 b5ddc58d 388ab355 bb360b61 3e2aaaab 3f800000 42fa0000 3ca3d70a 40000000 43800000 3d600000 00000000 00053e1f 20031588 20031588 00000006 0008649f 00000000 20031588

Error status: 0x00

Aux0 errors 0,0,0

MCU revision 3, ADC conversions started 171323, completed 171323, timed out 0, errs 0

Step timer max interval 1472

MCU temperature: min 31.1, current 31.1, max 32.8

Supply voltage: min 24.0, current 24.0, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 2, read errors 0, write errors 0, ifcnt 135, reads 9165, writes 0, timeouts 0, DMA errors 0, CC errors 0

Driver 1: standstill, SG min 0, read errors 0, write errors 0, ifcnt 135, reads 9165, writes 0, timeouts 0, DMA errors 0, CC errors 0

Driver 2: standstill, SG min 2, read errors 0, write errors 0, ifcnt 135, reads 9166, writes 0, timeouts 0, DMA errors 0, CC errors 0

Driver 3: standstill, SG min 58, read errors 0, write errors 0, ifcnt 137, reads 9166, writes 0, timeouts 0, DMA errors 0, CC errors 0

Driver 4: standstill, SG min 78, read errors 0, write errors 0, ifcnt 137, reads 9165, writes 0, timeouts 0, DMA errors 0, CC errors 0

Driver 5: standstill, SG min 170, read errors 0, write errors 0, ifcnt 119, reads 9165, writes 0, timeouts 0, DMA errors 0, CC errors 0

Driver 6: standstill, SG min 0, read errors 0, write errors 0, ifcnt 69, reads 9166, writes 0, timeouts 0, DMA errors 0, CC errors 0

Date/time: 2022-04-13 22:18:32

Cache data hit count 376716422

Slowest loop: 7.60ms; fastest: 0.09ms

=== Storage ===

Free file entries: 10

SD card 0 not detected, interface speed: 0.0MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters 2 -1 -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== CAN ===

Messages queued 907, received 0, lost 0, boc 0

Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 18 (min 18), ts 504/0/0

Tx timeouts 0,0,504,0,0,403 last cancelled message type 30 dest 127

=== SBC interface ===

Transfer state: 4, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 12442/6677

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0, IAP RAM available 0x0f1ec

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server v3.4.0

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 0

Full transfers per second: 38.79, max time between full transfers: 43.2ms, max pin wait times: 27.7ms/0.2ms

Codes per second: 0.01

Maximum length of RX/TX data transfers: 4204/1532 -

@ratrig0331 thanks for your M122 report. I've seen this issue once before. I am fairly sure it is caused by problems with the accelerometer wiring that result in communication issues between the accelerometer and the Duet.

-

I noticed just today, that this plugin existed. Must have been two days before release or so that I wrote a macro myself for doing this. (see below)

Turns out I basically hit bullseye by accident with my shaper settings after running my macro and now comparing the results with the plugin, just because I did not know that MZV would dampen two frequency amplitudes and the second one did luckily coincide perfectly with the amplitude of my x-axis

But the user Interface of the plugin is very good especially the merged frequency analyses of multiple axis and the damping curves preview for the shapers.

Only thing I would like to add though are inputs for the acceleration and speed at which the accelerometer data is collected.

Just a little QOL thing with e.g. a tickbox for "use maximum speeds and accelerations from current config" and if you untick it, you can enter your own values so that they are set before starting the sequence automatically instead of the user having to enter them manually before going to the plugin.

Oh and returning the printhead back to the center position after the last move would not trigger my OCD

Also a little sidenote if a dev reads this:

We now have Height Map in the Control tab

The Accelerometer Viewer in Machine Specific under the Settings tab

and the Input Shaping Plugin under the Plugins tab

One could also debate about the G-Code Viewer (I personally like it under the Job tab) but at least the above three (and maybe even the Object Model browser) are pretty similar and thus should be under the same tab IMO.

Please feel free to discuss my opinion though.the macro if anyone is interested:

var origXAccel = move.axes[0].acceleration var origYAccel = move.axes[1].acceleration var feedrate = move.axes[0].speed if exists(param.F) set var.feedrate = {param.F} echo "speed for accelerometer data collection:", {var.feedrate/60}, "mm/s" else echo "param.F not provided, instead maximum speed (X) is used for accelerometer data collection:", {var.feedrate/60}, "mm/s" G28 G1 X{move.axes[0].max/2} Y{move.axes[1].max/2} F9000 if exists(param.A) echo "setting X and Y acceleration to", {param.A}, "mm/s^2" M201 X{param.A} Y{param.A} M201 else echo "param.A not provided, using current accelerations X:", {var.origXAccel}, "mm/s^2, Y:", {var.origXAccel}, "mm/s^2" echo "collecting acceleration data for X-Axis" G91 ; relative positioning G1 X-50 F9000 G4 S2 M956 P21.0 S1000 A1 F"inputShapingX.csv" G1 X100 F{var.feedrate} G4 S2 echo "collecting acceleration data for Y-Axis" G1 X-50 Y-50 F9000 G4 S2 M956 P21.0 S1000 A1 F"inputShapingY.csv" G1 Y100 F{var.feedrate} G4 S2 G1 Y-50 F9000 G90 ; absolute positioning if exists(param.A) echo "reverting changes in acceleration" M201 X{var.origXAccel} Y{var.origYAccel} M201 -

@schild0r said in New Input Shaping plugin v3.4.0-b1:

We now have Height Map in the Control tab

The Accelerometer Viewer in Machine Specific under the Settings tab

and the Input Shaping Plugin under the Plugins tab

One could also debate about the G-Code Viewer (I personally like it under the Job tab) but at least the above three (and maybe even the Object Model browser) are pretty similar and thus should be under the same tab IMO.this is a good point. The different features are implemented at different levels of "core" from build in from a long time ago to a new and experimental plugin, so the UI location is more based on that than on a logical place for them to be from a user use perspective. We will think about how this could work going forward, especailly as we want to encourage more plugins to the UI.

-

@dc42

It did seem to be my connections I soldered the wires directly to the accelerometer chip with a pig tail plug vs the screw post terminals I had soldered to the chip and everything seems fine now, I still have no clue what to do with the data collected yet but I’m here to learn -

@ratrig0331 I'm glad it's working now.

-

undefined chrishamm referenced this topic

undefined chrishamm referenced this topic

-

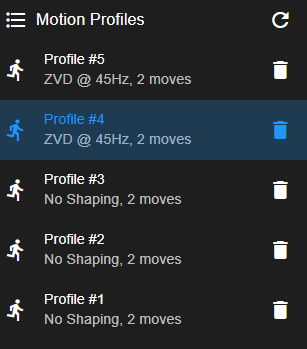

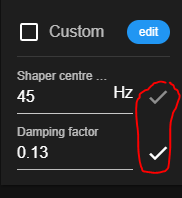

Version 3.4.1 is now available to fix the record dialog for users who have tools with gaps defined (e.g. T1 but no T0).

In addition, the shaper prediction now supports custom shapers - just make sure to be on 3.4.1 before you attempt to use this feature. When you enable it, the shaper parameters are copied from the current input shaper and by using the arrow keys in the edit dialog inputs, you can immediately get an estimate of the resulting damping curve. There is no further documentation about this feature yet and most users should not need it either. I meant to release v3.4.0 with this feature enabled but it still required a fix from v3.4.1.

-

Is there an easy to follow wiring diagram for the LIS3DH and the Duet2Wifi.

I find matching pins tricky and confusing that are listed on

https://docs.duet3d.com/en/User_manual/Tuning/Input_shaping_pluginneed something for my simpler brain lol

-

@chrishamm Installed it this evening on my Predator, it's fairly easy to use and compare the different graphs.

I would suggest 2 things:

1- Add the damping factor used in the records

I started to "play" with the damping factor to see the impact on the graphs but I lost track of the value used at one point.2- It took me a little bit of time to realize that I needed to click on the check-mark for set the Shaper Center Frequency and Damping factor.

I think I was "deceived" because changing the Shaper Center value immediately moves the blue bar in the graph so I wrongly assumed it would use it when doing a new record.

I must admit that I didn't paid much attention to the summary in the first modal box.This has been mentioned before, I don't know if it has been fixed in this beta but I'm getting this message as well

This printer has a Duet 2 Wifi and a Smart Effector v3 -

Wish there was a video tutorial on the input shaping process with RRF and this plugin. So much content using klipper, yet to find one with duet

-

@adamfilip by and large, the procedure is the same, with the distinction that the tooling around using the accelerometer on Klipper is (naturally) a bit more mature. Not many people do RRF videos though ... but there is not much to it.

- on belt driven axes, multiple peaks on one axis indicate something is loose and is adding additional vibrations. Trying to find those and fixing them is a valuable venture anyways.

- on kinematics combining drives such CoreXY it is desirable that the measured curves match, since it indicates similar tension. Do not confuse this with finding the right tension though. That is dependent on belt lengths and your motion system.

- On Cartesian systems, individual axes may have different curves.

- On RepRapFirmware -- other than klipper -- you can only set one input shaping algorithm, frequency, and damping setting. In practice, the damping factor is enough to cover the usual span of different frequencies on different axes.

- The InputShaping plugin visualizes the measured vibration per axis, but also a recommended frequency, and you can tell it to show the effect on the frequency graph by a given algorithm and damping factor. Ideally, the damping factor is as low as possible to reduce the effect of input shaping on speeds/accelerations that aren't inducing ringing.

- It's likely useful to retune PA after tuning input shaping since there is some interaction between InputShaping and PA.

-

@oliof As I had posted in another thread, I measured my frequencies and applied a shaper and measured again and it looked good. (I haven't posted my results, yet.) But when I printed a test part, the ringing was noticeably worse.

What would this be an indication of? Damping factor too high?

-

@tfjield very hard to say without seeing the curves and the before/after. It might be possible that you saw something on the graph that was just loose and overshadowed the actual measurement.

If all else fails, you can print the klipper ringing tower to validate what you measured.

-

@dc42 said in New Input Shaping plugin v3.4.1-b1:

@ratrig0331 thanks for your M122 report. I've seen this issue once before. I am fairly sure it is caused by problems with the accelerometer wiring that result in communication issues between the accelerometer and the Duet.

I still use the integrated input shaper that is integrated in RRF 3.4.2rc1 (2022-07-06), until I read about the input shaping plugin 3.4.1-b1 today and installed it right away.

After about 30 minutes of use, I had several disconnections with the new plug-in, which I did not have with the previous input shaping plug-in from RRF 3.4.2rc1 (2022-07-06), so I rule out problems with the cable.

I then turned my printer off and on again at the power switch.

After that everything was OK and I haven't had these disconnections anymore.Just for info, maybe it will help !?

Google Translate

----- Original Text -----Ich nutze bis heute den integrierten Input Shaper der in RRF 3.4.2rc1 (2022-07-06) integriert ist, bis ich heute von dem Input Shaping PlugIn 3.4.1-b1 gelesen hatte und es gleich installierte.

Ich hatte mit dem neuen PlugIn nach etwa 30 Minuten Nutzungszeit mehrere Verbindungsabbrüche, die ich mit dem vorherigen Input Shaping PlugIn aus RRF 3.4.2rc1 (2022-07-06) nicht hatte, daher schließe ich Probleme mit dem Kabel aus.

Ich machte dann meinen Drucker einmal Aus und wieder An, am Netzschalter.

Danach war alles OK und diese Verbindungsabbrüche hatte ich bis jetzt nicht mehr.Das nur zur Info, vielleicht hilft es weiter !?

-

@chrishamm @dc42

When will be a release for 3.5:-) -

-

@PCR great can you share the release notes?

-

-

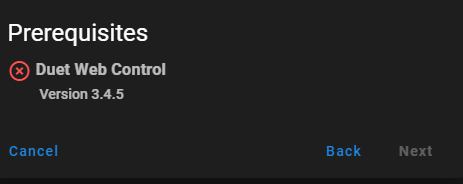

@Adamfilip you can't install 3.5.0-b1 on 3.4.5, only on 3.5b1