How to configure Delta with 4 arms?

-

Hello Mates - I have a delta with 3 arms - I would like to know what is required to control a delta with 4 arms - What changes are needed in the configuration and kinematics and where would I begin to start figuring this out? Why you ask - Stupidly I am contemplating what's required to go massively big like CAD Zilla - https://www.youtube.com/watch?v=KKT8AXAvRgc&t=302s can print 30 meters a minute at 1.5 mm layer height - Is anyone interested in collaborating on a project like this?

-

@kcmarine that video doesn't show the printer clearly. Is the 4th tower there to support a moving extruder, or does it provide a redundant pair of arms to the effector?

-

It is a delta with four pairs of arms.

-

@oliof you are correct - yes a delta with four vertical arms that connect to the end effector

-

With delta kinematic, the position of each of the three sliders can be determined independently from the position of the effector, right?

If so, it's possible that the kinematic can be generalized for an arbitrary number N of towers without much additional complexity. Unless if I am missing something.

The over constraining with N>3 is another issue.

-

@kcmarine said in How to configure Delta with 4 arms?:

@oliof you are correct - yes a delta with four vertical arms that connect to the end effector

Why 4 as opposed to 3?

Thanks.

Frederick

-

@kcmarine yes, it's over-constrained. Unless the build is extremely accurate or any inaccuracies are very accurately calibrated out, the arms will fight each other.

-

@dc42 Thanks for the reply guys,

Reasons, why to use four arms, is due to:

- the large size - print volume 3 meters square

- at this large size, rigidity, stiffness, and speed is key – 30 meters per minute @ 1.5 mm layer height

- Smaller footprint for build plate in a square than a triangle

- With a smaller footprint its easier in insulate and less heating is required

- Four motors provide error checking, one motor is out of position the other motors stop the movement.

The working design built by CAD ZILLA has four vertical arms - In the video, (https://www.youtube.com/watch?v=KKT8AXAvRgc)

-

@zapta Thanks for the reply - I was pleased to know that you consider it's not a lot of additional complexity. I am prepared to investigate further and put in the work - and would like to know where to start - CAD Zilla has done this so it's achievable - I would like to see if it's possible on a smaller scale and then I can scale up 10 X to the size of these machines - any help you can give would be appreciated

-

@kcmarine said in How to configure Delta with 4 arms?:

I was pleased to know that you consider it's not a lot of additional complexity.

@kcmarine, with RRF it doesn't matter what I say, it matters what @dc42 says.

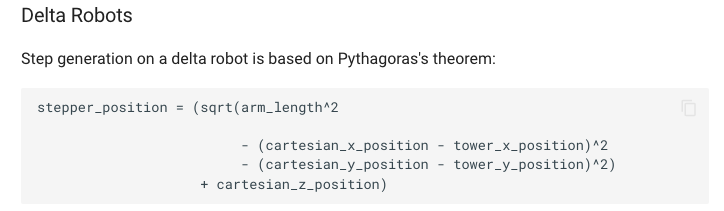

Reading through Klipper's documentation it seems that indeed the position of each vertical slider is determined independently based on the x/y constant position of the tower relative to the bed. This suggests that theoretically, generalizing the delta kinematic to N towers should be relatively straightforward.

-

The guy in the video already said, that three arms would not allow the fourth arm to move in a wrong way. We have seen closed loop steppers, but they only control their own moves AFAIK. Reading in the encoder signals of four motors is sheer overload for the common RRF controller.

You would need servo motors instead of steppers. I'm wondering how good RRF is at controlling them?

And an overall closed loop printer would be a complete new story for RRF(5.0?)Why not build a cartesian printer that big? Much easier to implement closed loop IMHO...

-

@kcmarine if you can overcome the build precision and calibration issues, then RRF already supports that kinematics. The delta support was expanded to support up to 6 towers a long time ago.

-

@dc42 Thanks for all your input, do you know of any delta projects like this with more than 3 arms, I have searched the web and cannot find any examples in RRF. @o_lampe mentioned reading the encoder signals from four motors is sheer overload for a common RRF controller. If this is correct then am I understanding it is beyond the capabilities of the Duet 6HC - would that be correct statement? If so what direction should I redirect my focus - @zapta thanks for the links - I will dig deeper and get my head around how to implement this into the config - Cheers for your help guys

-

@kcmarine if you want to use motors with encoders for closed loop control then you will need to use either Duet 3 EXP1HCL boards to drive them (in which case a Duet 3 Mini main board should suffice), or external closed loop drivers and a Duet 3 MB6XD main board. Standard controller boards do not support encoders on stepper motors.

-

@o_lampe said in How to configure Delta with 4 arms?:

The guy in the video already said, that three arms would not allow the fourth arm to move in a wrong way.

What does this mean, that in case of misalignment, one or motor will skip steps? How does that work with close loop servo?

I would think that in case of a misalignment, something needs to give, e.g. slip, deform, or break.

-

@dc42 said in How to configure Delta with 4 arms?:

The delta support was expanded to support up to 6 towers a long time ago.

With a sufficient number of towers (5?), is it ok to have just one rod per tower instead of two?

-

@zapta said in How to configure Delta with 4 arms?:

@dc42 said in How to configure Delta with 4 arms?:

The delta support was expanded to support up to 6 towers a long time ago.

With a sufficient number of towers (5?), is it ok to have just one rod per tower instead of two?

With 6 towers you could have one rod per tower.

-

@zapta I am assuming that this is what he refers to in the video as error checking, by having four arms, - if an issue like this would occur then the machine stops and throws an error to the operator - could be something like sensorless homing I am just guessing now ??

-

@dc42 I have read all the docs on https://www.klipper3d.org/Kinematics.html referring to the kinamatics and I am failing to see where to make the changes in config files - can you point me in the right direction, please - I have 2 FLSun SR and going to give this a crack

-

Does this help?

"RRF 2.03 and later allow you to configure more than 3 towers (maximum 6 in total) on a delta machine. Typically, additional towers are used to carry extruders, allowing the Bowden tube to be shortened."

https://docs.duet3d.com/User_manual/Machine_configuration/Configuration_linear_delta