Pattern Pressure Advance Calibration

-

Here is the gcode file:

I am using 118% for both line widths, and a 0.25mm first layer height in that photo.

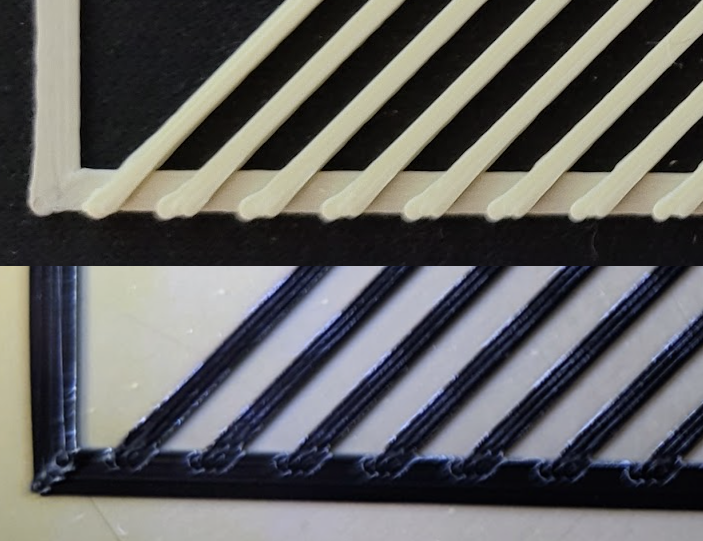

My pattern ends at PA0 look less blobby than your IMO, but my tab is more over-extruded:

I think it's an issue. Even a 0.1mm Z hop can't clear it, and you can see the nozzle has smeared right through a lot of plastic. Overpressuring the nozzle and smearing through extra plastic isn't the best way to start a precision calibration. There are like 43 settings in the script. If adding 1 more can prevent such bad over-extrusion, that seems well worth it to me.

-

I've been running some tests using this pattern on my printer with a 1mm nozzle. I set all line widths to 1mm and everything sticks fine (230C PETG at 30 mm/sec on 70C PEI).

I'm not entirely sure what I should be looking for in the resulting print- the corners should be sharp and not blobby or gapped, but should I also be looking at the ends of the test lines that print on the anchoring border, or is that more of a retraction tuning issue? I am using the default 0.5 mm retraction...

My initial test with the PA at the default range had all the test corners looking identical. I tried again going from 0.1 to 0.5 and finally started to see some gaps in the corners.

-

@CCS86

Yes, but you are comparing 30mm/s first layer to my 150mm/s top layers

My bottom layers are not as blobby, though you can't see it in that photo -

@mrehorstdmd Did you see the guide link up top, next to the 3d preview? Has an example in there showing what to look for

-

@CCS86 Also just to be clear, I don't mean to hand wave your issues here, just comparing with others

- I think the overlap is too much in places as you said, that spot included, so I may reduce that.

- Maybe it should also just print the first layer at your current PA, and not set PA until second layer+? Might also help

- I am wondering if the overextrusion would be less with 120% first layer width, maybe the default of 140% is just a bit aggressive.

- I have pushed a fix for the doubling-up infill line, at least I think so, can you please see if it's still occurring for you?

- I think I see a flow issue with the first layer of the pattern itself (not the perims/anchor/tab), working on that bit. Thanks for spotting that. Not 100% sure yet, though, so I'll update here soon

- I think the overlap is too much in places as you said, that spot included, so I may reduce that.

-

@mrehorstdmd I am curious to see some photos with 1mm nozzle, largest nozzle I have seen used so far is 0.8mm

-

@Ellis I'll print some new tests tonight and shoot some photos and post them. The 1 mm nozzle has been a b**** to print with for everything except single wall vases for a long time. I suspect there's not a lot of pressure in the hot end, and the viscosity of the molten filament probably has less effect on extrusion.

-

@mrehorstdmd Found some small errors in the flow math, hold off for now

-

@mrehorstdmd Ok just pushed a bunch of fixes, all clear

@CCS86 I fixed the flow and overlap issues. The tab seems to print a lot better now. Give it a whirl. -

@Ellis Thanks. I didn't get to it last night anyway, so I'll try it tonight.

-

@Ellis said in Pattern Pressure Advance Calibration:

@mrehorstdmd Ok just pushed a bunch of fixes, all clear

@CCS86 I fixed the flow and overlap issues. The tab seems to print a lot better now. Give it a whirl.Looks soooo much better in the gcode viewer! I'll try it tonight.

Thanks!

-

I took the liberty to submit a feature request (firmware retract) and a small bug report (missing unretract length setting).

-

@oliof I don't quite follow the logic behind having a different unretract length. Is that a common thing? Always seemed... bodgy to me. I don't print with large nozzles very often, though, so maybe that's part of it. PA is supposed to help with what you mentioned (needing extra pressure to start), or is that not typically enough?

I think at a certain point it becomes too many settings & too much clutter - it actually had firmware retract and I removed it (and a few other things) to make it leaner. Software retract works for everyone.

Once it starts becoming a wall of settings, it starts to become really overwhelming for new folks.

It's meant to be a quick test with only the features necessary to get it printed, not a full web based slicer with all the same features as your desktop one, y'know?

Hell, I've even thought about getting rid of the Z hop settings and just baking in the 0.1mm z-hop.

-

@Ellis I usually use Z hop equal to layer thickness when I use it at all, so with the 1 mm nozzle, it's typically 0.5 or 0.6 mm...

-

@mrehorstdmd Hmm, possibly. Might just leave it alone.

Another thing that occured to me, the default print height is 1mm, which could be small for such large nozzles. It has a setting, but it's buried in expert mode then pattern settings. Any thoughts? Maybe do it by layer count instead?

-

I think the print it so small that it doesn't really have much opportunity to curl and cause problematic nozzle strikes

No overhangs either -

a) firmware retract is the only way you get proper retract on mixing hotends (2-in-1 like the relatively new tai chi, 3/5-in-1 like the venerable diamond, or 6-in-1 like @deckingmans). Maybe that's not relevant for your PA test.

b) I tend to stick with firmware retract because it's simple to adjust during a print if necessary.different unretract length is not often needed, but it helped me with weird filaments and with large diameter nozzles.

I'd agree that both are ... rare use cases that don't necessarily need to be reflected. But I personally could use them.

-

@oliof I'll consider putting them under expert mode

For some background, I went into the 3d printing discord and showed it to some new folks, and they were really confused and overwhelmed, basically. Got a lot of screenshots with "what should I change"?, haha.

That's part of what lead to me trimming the fat like this

-

@Ellis I absolutely understand and commend the goal of making this accessible to newcomers. I also do not expect any issue I file to be followed up with (-:

-

@oliof

I am curious if the lack of an unretract distance setting causes issue with the test in your case.If so, that seems a valid reason to add it - so let me know how it goes