Bed Heater Unexpected Behaviour

-

Hello,

Using a Duet Wifi Board to control a core XY printer. The bed heater is configured to work in bang-bang mode. The bed heater is defined as below in config.g:; Heaters M308 S0 P"bedtemp" Y"thermistor" B4138 T100000 ; Set or report sensor parameters M950 H0 C"bedheat" T0 ; Create heater pin M143 H0 S125 ; Maximum heater temperature M307 H0 B1 S1.00 ; Set or report heating process parameters M570 H0 S0 P300 T15 ; Configure heater fault detection M140 H0 ; Set Bed Temperature (Fast) or Configure Bed HeaterThe bed heater was auto-tuned using

M303 H0 S65Which resulted in

M307 H0 R0.740 K0.402:0.000 D3.89 E1.35 S1.00 B0I had to change B0 to B1 to ensure bang-bang mode. This was saved to config-override.g using M500. config.g has M501 at the end.

The bed heater operates normally while setting a target temperature through DWC — it heats to the desired temperature and holds steady. However, once a print job begins, the bed temperature slowly decreases, as though the heater is no longer active. The DWC shows that bed heater is infact in an active state but temperature just keeps dropping. Prior to starting the print, the bed consistently maintains the set temperature. Interestingly, if I pause the print, the bed temperature climbs back up to the set point and stays stable. But when printing resumes, the temperature once again gradually drops.

Seems to be occurring after M303 autotune cycle and was working fine before this.

Any suggestions on what is causing this?

-

-

@fcwilt I believe it’s the default config in Reprap firmware where bed heaters use bang bang and extruders use PID.

-

@RockB said in Bed Heater Unexpected Behaviour:

@fcwilt I believe it’s the default config in Reprap firmware where bed heaters use bang bang and extruders use PID.

Perhaps but it is not a requirement - I use PID for both.

Frederick

-

@RockB what firmware version? Please send M122 and post response.

When a job is running and the bed temp is falling, send M140 to check what temperature it is set to. Also please post your pause.g.

Ian

-

@RockB What type of bed heater are you using? What wattage? Is it a DC heater directly powered by the Duet Wifi?

Does the temperature eventually drop back to ambient, or does the Duet eventually throw a heater fault, indicating it believes something is wrong?

-

@droftarts Firmware version is 3.4.5

Here is the M122 response

=== Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.5 (2022-11-30 19:36:12) running on Duet WiFi 1.02 or later Board ID: 0JD2M-9F8TA-GJ4TD-6J9FG-3S86N-1RPG6 Used output buffers: 8 of 26 (26 max) === RTOS === Static ram: 23836 Dynamic ram: 76316 of which 388 recycled Never used RAM 8180, free system stack 110 words Tasks: NETWORK(notifyWait,35.8%,242) HEAT(notifyWait,3.2%,165) Move(notifyWait,0.6%,268) MAIN(running,59.2%,421) IDLE(ready,1.1%,30), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 70:58:01 ago, cause: software Last software reset at 2025-04-25 12:15, reason: User, GCodes spinning, available RAM 9228, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00417000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x0c Aux0 errors 0,0,0 Step timer max interval 0 MCU temperature: min 28.3, current 30.4, max 35.9 Supply voltage: min 23.6, current 24.0, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/8, heap memory allocated/used/recyclable 2048/124/58, gc cycles 1 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0 Driver 1: standstill, SG min 0 Driver 2: standstill, SG min 0 Driver 3: standstill, SG min 0 Driver 4: standstill, SG min n/a Driver 5: Driver 6: Driver 7: Driver 8: Driver 9: Driver 10: Driver 11: Date/time: 2025-04-28 11:13:20 Cache data hit count 4294967295 Slowest loop: 205.61ms; fastest: 0.12ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 3.9ms, write time 19.6ms, max retries 0 === Move === DMs created 83, segments created 21, maxWait 235090516ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 224, completed 224, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 2], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.5 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Network === Slowest loop: 51.88ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 = WiFi = Network state is active WiFi module is providing access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.27 WiFi MAC address 46:17:93:34:19:50 WiFi Vcc 3.35, reset reason Power up WiFi flash size 2097152, free heap 23432 WiFi IP address 192.168.1.114 Connected clients 1 Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0When I send M140 when job is running, I get

Bed heater 0 (slot 0) is currently at 62.4°CAt this point the temp has already dropped from 65C - which is the setpoint for the bed.

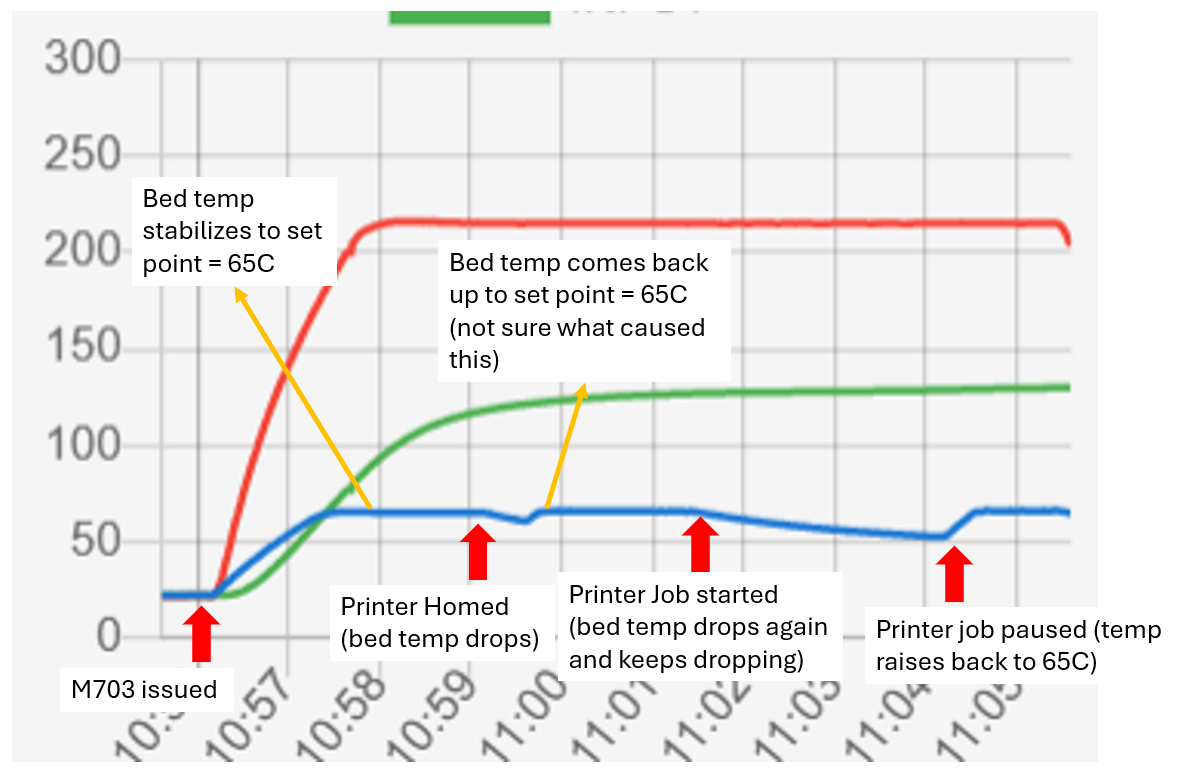

Below temperature graph shows the same - Blue line is the bed temperature

The pause.g is below

; pause.g ; called when a print from the SD card is paused M83 ; Set extruder to relative mode G1 E-5 F6000 ; Move G91 ; Set to Relative Positioning G1 Z1 F360 ; Move G90 ; Set to Absolute Positioning G1 F6000 X{move.axes[0].min} Y{move.axes[1].min} Z{move.axes[2].max} ; Move M107 ; Fan Off set global.dato0 = job.duration echo >"0:/data/temp" ";Recorded Temperature" ; Echo command echo >>"0:/data/temp" "G10 P0 S"^heat.heaters[1].active^":"^heat.heaters[2].active^" R"^heat.heaters[1].standby^":"^heat.heaters[2].standby ; Echo commandThe 0:/data/temp contains

G10 P0 S0.0:0.0 R0.0:0.0And eventually, after a while I get an error message

-

@sebkritikel Its a standard rectangular silicone AC bed heater 150W @ 110V. Using an SSR to control the bed heater. Didn't have an issue in the past and was working fine.

Temperature does drop down and Duet throws a heater fault

-

@RockB does your SSR have an LED to indicate that the control circuit is receiving power? If so, is it illuminated while the bed temperature is dropping, before the heater fault is raised?

Three possibilities occur to me:

-

Your slicer is turning off bed heat after the first layer. Slicers typically support separate temperature settings for the first layer and subsequent layers.

-

Your bed heater has a resettable thermal cutout, which just happens to be cutting out when you start the print, and resetting some time later.

-

There is a firmware bug that affects bang-bang control. This seems unlikely, however it is very unusual to be using bang-bang control because it tends to create vertical striations on the print. With SSR-controlled heaters it is usual to use PID but to set the PWM frequency low, e.g. 10Hz. You can set this frequency in the M950 command that you use to define the port that the SSR is connected to.

-

-

@dc42 I updated the heater control mode from Bang-bang to PID in the config.g file using the results from a previous auto-tuning cycle (M303 H0 S65).

The parameters I applied were:M307 H0 R0.740 K0.402:0.000 D3.89 E1.35 S1.00 B1Unfortunately, I am still observing the same issue — the bed temperature drops.

Interestingly, after switching the bed heater to PID control in config.g and removing the redundant bed heater settings from config-override.g, the bed maintained the setpoint temperature (65°C) correctly after running M703.

However, the bed temperature immediately began to drop once I homed all axes — even before starting a print job.

If no additional actions are taken after running M703, the bed heater maintains temperature without any issues. This behavior seems increasingly bizarre.I also double-checked the first few lines of the G-code. There is nothing that would turn off or modify the bed heater during the first layer or afterward.

This seems to rule out issues #1 and #3 from your troubleshooting list. I will next check on #2 (the LED status on the SSR) and report back.For some context, the printer workflow (not configured by me) is such that users first run a filament load macro (M703), which calls the filament-specific config.g file. This file contains:

; Set the thermostatic fan M106 P0 S1 H1 T45 ; Set the extruder flow rate M92 E325 ; Set the head temperatures G10 P0 S215 R150 ; Set the bed temperature M140 S65The slicer profile (Simplify3D) provided by the manufacturer is set to ignore temperature commands (i.e. temperature controllers are turned off in Simplify3D), so all temperature settings are managed either via filament macros or manually at the printer.

The slicer profile (simplify3D) for this particular printer is configured by manufacturer (again not by me) to ignore temperature controls and all temperature controls are embedded into filament config.g or directly controlled at printer.

Any suggestions on what might be causing this?

-

@RockB as I understand it, you are saying that if you simply home the printer from the console, the heater turns off.

Please post your homing files and config.g.

How are you homing the Z axis? If you are homing it using a BLTouch or similar, you may have it set to turn off all heaters during probing. They should automatically be turned on again after probing; but I am wondering whether there is some error occurring that causes them to be left off. Does Z homing complete without incident or are there any warning or error messages?

Firmware 3.4.5 is quite old. Upgrading to 3.5.4 is recommended.

When you changed to PID control, did you also change the PWM frequency in the M950 command to 10Hz?

-

@dc42 That is correct, heater seems to turn off when homing and when print job is started. The Z-axis is homed using a simple end stop/micro-switch (the platform presses against the switch to register Z0)

Here is the config.g

; General Preferences G90 ; Set to Absolute Positioning M83 ; Set extruder to relative mode M669 K1 ; Set kinematics type and kinematics parameters M550 P"My Printer" ; Set Name ; Network M98 P"0:/data/network" ; Enable/disable network interface ;M552 S1 ; Enable/disable network interface M586 P0 S1 ; Configure network protocols: Enable HTTP M586 P1 S0 ; Configure network protocols: Disable FTP M586 P2 S0 ; Configure network protocols: Disable Telnet ; Drivers M569 P0 S0 ; Set motor driver direction M569 P1 S0 ; Set motor driver direction M569 P2 S1 ; Set motor driver direction M569 P3 S0 ; Set motor driver direction M584 X0 Y1 Z2 E3 ; Set drive mapping M350 Z32 I0 ; Set microstepping mode M350 I1 X16 Y16 E16 ; Set microstepping mode M92 X100 Y100 Z800 E250 ; Set axis steps per unit M566 X300 Y300 Z12 E500 ; Set allowable instantaneous speed change M203 X3000 Y3000 Z3000 E6000 ; Set maximum feedrate (mm/min) M201 X500 Y500 Z24 E800 ; Set max acceleration (mm/s^2) M906 I30 X320 Y320 Z320 E1500 ; Set motor currents (mA) M84 S60 ; Set Idle Time-out ; Axis limits M208 S1 X0 Y0 Z-0.7 ; Set axis min travel M208 S0 X140 Y135 Z150 ; Set axis max travel ; End stops M574 X1 S1 P"xstop" ; Set endstop configuration M574 Y2 S1 P"ystop" ; Set endstop configuration M574 Z1 S1 P"zstop" ; Set endstop configuration M950 J1 C"!e0stop" ; Create GPIO/servo pin M581 P1 T2 R1 ; Configure external trigger#.g ; Z Probe M558 P0 H1.7 F120 T6000 ; Set Z probe type M557 P3:3 X{15,move.axes[0].max-15} Y{15,move.axes[1].max-15} ; Set Z probe point or define probing grid G31 K0 P500 X0 Y0 Z0 ; Set or Report Current Probe status ; Heaters M308 S0 P"bedtemp" Y"thermistor" B4138 T100000 ; Set or report sensor parameters M950 H0 C"bedheat" Q10 T0 ; Create heater pin, 10Hz PWM M143 H0 S125 ; Maximum heater temperature M570 H0 S0 P300 T15 ; Configure heater fault detection M140 H0 ; Set Bed Temperature (Fast) or Configure Bed Heater M307 H0 R0.740 K0.402:0.000 D3.89 E1.35 S1.00 B0; Autotune on 04/25 - PID mode ;M307 H0 R2.430 K0.560:0.000 D5.50 E1.35 S1.00 B1; - original in config-override.g M308 S1 P"e0temp" Y"thermistor" R4700 T100000 B3950 A"Heater1" ; Set or report sensor parameters M950 H1 C"e0heat" T1 ; Create heater pin M143 H1 S300 ; Maximum heater temperature M307 H1 B0 S1.00 ; Set or report heating process parameters M308 S2 P"e1temp" Y"thermistor" R4700 T100000 B3950 A"Heater2" ; Set or report sensor parameters M950 H2 C"e1heat" T2 ; Create heater pin M143 H2 S200 ; Maximum heater temperature M307 H2 B0 S1.00 ; Set or report heating process parameters M302 P0 S185 R150 ; Allow cold extrudes M308 S10 Y"mcu-temp" A"MCU" ; Set or report sensor parameters M308 S11 Y"drivers" A"Drivers" ; Set or report sensor parameters M308 S12 Y"dhthumidity" A"Humedad" ; Set or report sensor parameters ; Fans M950 F0 C"fan0" Q500 T1 ; Create fan pin M106 P0 S1 T45 H1 C"Fan Tool" ; Set fan configuration M950 F1 C"fan1" Q500 ; Create fan pin M106 P1 S0 H-1 C"Layer Fan" ; Set fan configuration M950 F2 C"exp.heater3" Q500 ; Create fan pin M106 P2 C"LED" S255 ; Set fan configuration M950 F8 Q500 T1 C"fan2" ; Set fan configuration M106 P8 S1 T160 C"Filter" H1 ; Set fan configuration ;M950 F8 Q500 ; Set fan configuration ;M106 P8 S1 T160 C"Filter" ; Set fan configuration ; Tools M563 P0 D0 F1 H1 S"Tool1" ; Define tool G10 P0 X0 Y0 Z0 ; Set workplace coordinate offset or tool offset G10 P0 R0 S0 ; Set initial tool temperature ; LCD M575 P1 S1 B57600 ; Set serial comms parameters ; Global Variables (not modifiable) global delete = 0 ; Global variable declaration "runonce.g" global dato0 = 0 ; Global variable declaration global dato1 = 0 ; Global variable declaration global dato2 = 0 ; Global variable declaration global dato3 = 0 ; Global variable declaration global dato4 = 0 ; Global variable declaration global areaX = 145 global areaY = 135 ; Always at the end M911 S23 R23.5 P"M98 P""0:/sys/autosave.g""" ; Configure auto save on loss of power M501 ; Read stored parameters T0 P0 ; Tool selection by default M98 P"0:/data/height_map" ; Load the height map from file and activate mesh bed compensation M98 P"0:/sys/autopower.g" ; Read the file in case of power outageHere is homeall.g

; homeall.g ; call home all the axes M106 P2 S1 ; Set fan G91 ; Set to Relative Positioning G1 H2 Z1 F3000 ; Move G1 H1 F6000 X{-move.axes[0].max -- move.axes[0].min} Y{move.axes[1].max} ; Move G1 H1 F6000 X{-move.axes[0].max} ; Move G1 H1 F6000 Y{move.axes[1].max} ; Move G1 X5 Y-5 F6000 ; Move G1 H1 F360 X{-move.axes[0].max/2} ; Move G1 H1 F360 Y{move.axes[1].max/2} ; Move G1 H1 Z{-move.axes[2].max} F3000 ; Move G1 H2 Z5 F3000 ; Move G1 H1 Z{-move.axes[2].max} F360 ; Move G90 ; Set to Absolute Positioning G92 Z0 ; Set Position M400 ; Wait for current moves to finishWhen I had initially changed to PID control, I had just changed B1 to B0 in M307 command (from auto-tune) for bed heater. I have now updated the M950 to include Q10 parameter.

I want to illustrate what is happening with bed heater in the graph below:

Very bizarre behaviour and not sure what is causing this. Going back to previous suggestions for troubleshooting,

To answer your previous question: "does your SSR have an LED to indicate that the control circuit is receiving power? If so, is it illuminated while the bed temperature is dropping, before the heater fault is raised?"

Yes, I observed the LED indicators on the SSR during operation. While the temperature is dropping, the control side LED remains ON, indicating that the control circuit is receiving power. However, the load side LED is OFF during this time.After running the M703 command, both the control and load side LEDs cycle rapidly (turning ON and OFF) as expected while heating to the target temperature. Interestingly, once I home the printer or begin a print job, the LED activity slows significantly — and at times, the load side LED remains OFF altogether.

-

@RockB The only thing I've noticed in both your homeall.g and pause.g file are commands for the fans. I notice that your LEDs are defined as a fan, and connected to exp.heater3, in config.g:

M950 F2 C"exp.heater3" Q500 ; Create fan pin M106 P2 C"LED" S255 ; Set fan configurationYour homeall.g turns on the LEDs:

M106 P2 S1 ; Set fanYou have M107 in pause.g, which might turn off the LEDs. Does the bed heater turn off when the LEDs are on? Maybe the LEDs are dragging the voltage down.

Ian

-

@RockB thanks. Please also post your start.g file if you have one, your daemon.g file if you have one, and attach a sample GCode file that demonstrates this issue.

-

@dc42 There is no start.g file. However, I have start and end G-codes in slicer. The start G-code in Slicer is

M98 P"StartPrint.g"The contents of StartPrint.g are as follows:

M106 P2 S1 ; Set fan (LED) G21 ; Set Units to Millimeters M290 R0 S0 G28 ; Home all M703 ; Configure filament G0 Z10 F3600 ; Move M190 ; Wait for bed temperature to reach target temp M116 P0 ; Wait M98 P"0:/data/initData" ; Call Macro/Subprogram M400 ; Wait for current moves to finish M290 R1 S{global.dato0} ; Baby stepping G0 X1 Y0 Z0.2 F3600 ; Move G1 Y40 E35 F180 ; Move G92 E0 ; Set Position M400 ; Wait for current moves to finishThe initData sets variable to 0

set global.dato0 = 0The End G-Code in my slicer is

M98 P"EndPrint.g"The contents of EndPrint.g are as follows;

M400 ; Wait for current moves to finish G91 ; Set to Relative Positioning G0 E-10 F6000 ; Move G92 E0 ; Set Position G0 Z10 F3000 ; Move G90 ; Set to Absolute Positioning T0 ; Select Tool G0 F3000 X{move.axes[0].min} Y{move.axes[1].max} Z{move.axes[2].max} ; Move G10 P0 S0 R0 ; Tool Temperature Setting M140 S0 ; Set Bed Temperature (Fast) or Configure Bed Heater M106 P1 S0 ; Set fan M106 P2 S0 ; Set fan (LED) - turn OFF M84 ; Stop idle hold M400 ; Wait for current moves to finish if global.delete = 1 echo >"0:/sys/autopower.g" ";Powerloss handling" ; Delete a file on the SD card set global.delete = 0 ; Variable assignment M98 P"0:/data/initData" if global.dato0 != move.axes[2].babystep ; microsteps changed echo >"0:/data/initData" "set global.dato0 = "^{move.axes[2].babystep} ; Set or Report Current Probe status M98 P"0:/data/R_end" ; Call Macro/Subprogram M400 ; Wait for current moves to finishI have attached a sample G-code file. Test.gcode

-

@droftarts Looking at the SSR, the it doesn't seem like bed heater turns OFF when LED turns OFF. Is there a good way to test this?

-

@dc42 @droftarts any suggestions?

-

@RockB

M106 P2 S1should turn the LEDs on, andM106 P2 S0should turn them off. Or disconnect them and test.Ian