Pressure Advance Calibration

-

Z seam alignment - User specified

Z seam position - back

Seam corner preference - noneProduces the desired result. That's in 4.4.1. In older versions there was an X and Y position you could specify. The setting is still there in the settings visibility filter, but it's not being shown and I'm not sure what's blocking it. Regardless, setting it to back, front, left, or right works to align it to a face.

-

@Phaedrux

Does not work for me

Cura 4.4.1, settings as you've specified - seam is generated in one of the corners no matter what coordinates i set.

Can you share a gcode of the cube (20x20x20) with a single perimeter with a seam in the center of one of the sides so i can modify it for my printer, please? -

@SnakeSP said in Pressure Advance Calibration:

@Phaedrux

Does not work for me

Cura 4.4.1, settings as you've specified - seam is generated in one of the corners no matter what coordinates i set.

Can you share a gcode of the cube (20x20x20) with a single perimeter with a seam in the center of one of the sides so i can modify it for my printer, please? -

@burtoogle Thanks!

-

@SnakeSP sorry for providing misinformation. I'm surprised that the stock Cura build won't allow it.

-

thanks for this thread!

after playing a bit with pressure advance i was able to boost the quality of at least one print and i feel the shape of the model matters a lot. pressure advance enabled me to print a model with tiny 45 degree overhanging sharp corners.

-

I have tuned PA according to the method in the wiki, not with the script, but by printing a 100mm cube and adjusting on the fly. I have settled on 0.7, with a bowden tube of around 480mm length.

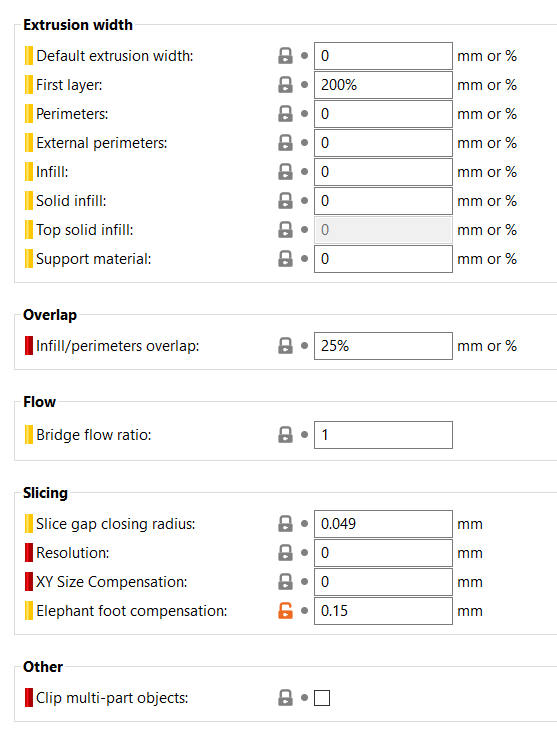

While my corners, overall surface and z-seam look better, I'm now getting gaps in the infill - not in the parameters though. I looked in PrusaSlicer and the only setting I can find that mentions overlap is "Infill/Perimeters overlap". By default, it was set to 25%. Is this the value I need to change?

If yes, what should I change it to? -

@devleon yes the wiki does mention that maps may form. It's like the slicers have been compensating for bulging line ends already. Try an additional 3-5%.

-

I changed the value from 25%, to 30% and to 40% with no difference.

Thinking more about it, I don't think it's Infill/Perimeter Overlap. Shouldn't it be the extrusion width for solid infill? After all the lines are now thinner on the first layer than before. This is what my config looks like in PrusaSlicer:

Printing the same G-Code with PA disabled, and I get a beautiful first and second layer with no gaps. As soon as PA is enabled, I get gaps in the first and second layer between the individual lines of filament.

-

I don't let slic3r pick the extrusion width normally. All widths would either be same as nozzle size or a bit more. 200% for first layer is an old school hack for bed adhesion. Try with first layer at nozzle size and 0.2 layer height.

-

@SnakeSP I feel your pain, as Ideamaker is the same way. It says i can put the seam anywhere, but it always puts it at a corner. I'm going to try this out with a large diameter cylinder instead of a square.

-

I know, but this is a bit silly.

I am using a cloned Titan extruder. A bad clone. -

Just want to share a few changes I made in the python script.

- Prints a box instead of two walls

- Tidied up the skirt generation as id did some strange moves

- has a text block for starting gcode and end gcode

-

May I ask for help interpreting the result? Looks like the higher PA is the better the result? I'm using a direct drive. Thanks.

-

This post is deleted! -

@MartinNYHC Yes it would appear that way buy you should also test with an actual print to check for any unintended behaviours of running with a high pressure advance value.

How long is your bowden tube? Have you tried the cube wall method shown here? https://duet3d.dozuki.com/Wiki/Pressure_advance#Section_Simplest_Method_Possible

-

@Phaedrux There's only a short PTFE tube between extruder and hotend. I think it's about 20mm. Will do some additional tests today.

-

I've updated the *.py file with

- preamble

- postamble

- klipper compatibility

- Marlin compatibility

These are my results:

Delta Fyling extruder PA 0 - 0.5 over 40mm PLA

Delta Fyling extruder PA 0 - 0.5 over 40mm PLA carbon fiber

-

undefined jim546 referenced this topic

undefined jim546 referenced this topic

-

undefined jim546 referenced this topic

undefined jim546 referenced this topic

-

undefined jim546 referenced this topic

undefined jim546 referenced this topic

-

I have tuned PA according to the method in the wiki, not with the script, but by printing a 100mm cube and adjusting on the fly. I have settled on 0.7, with a bowden tube of around 480mm length.

-

@duosvid said in Pressure Advance Calibration:

I have tuned PA according to the method in the wiki, not with the script, but by printing a 100mm cube and adjusting on the fly. I have settled on 0.7, with a bowden tube of around 480mm length.

overall surface and z-seam look better, I'm now getting gaps in the infill - not in the parameters though . .