and just for fun, here is a normal benchy printed on it

(for now I use 0.8mm nozzle, but sucessfully tested a custom made 1.6mm nozzle

Best posts made by Zoltan3D

-

RE: My DIY BigBoy :p 1000x1000x1100mm toyposted in My Duet controlled machine

-

My DIY BigBoy :p 1000x1000x1100mm toyposted in My Duet controlled machine

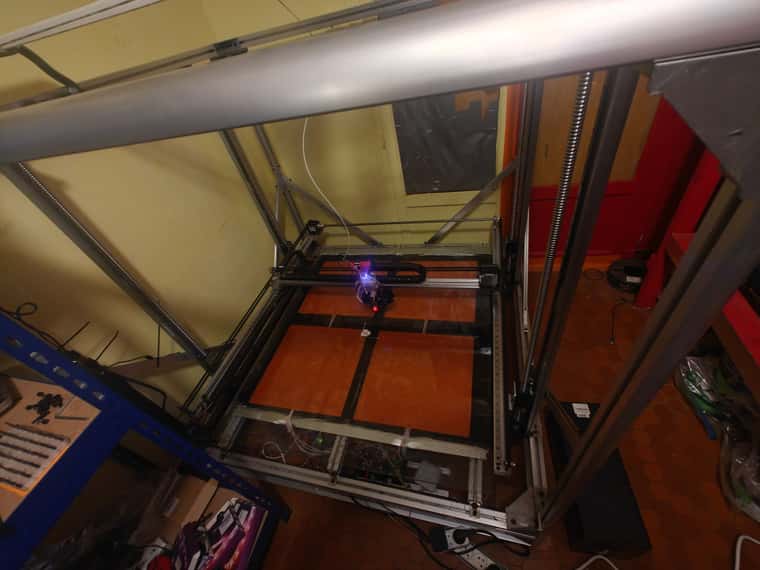

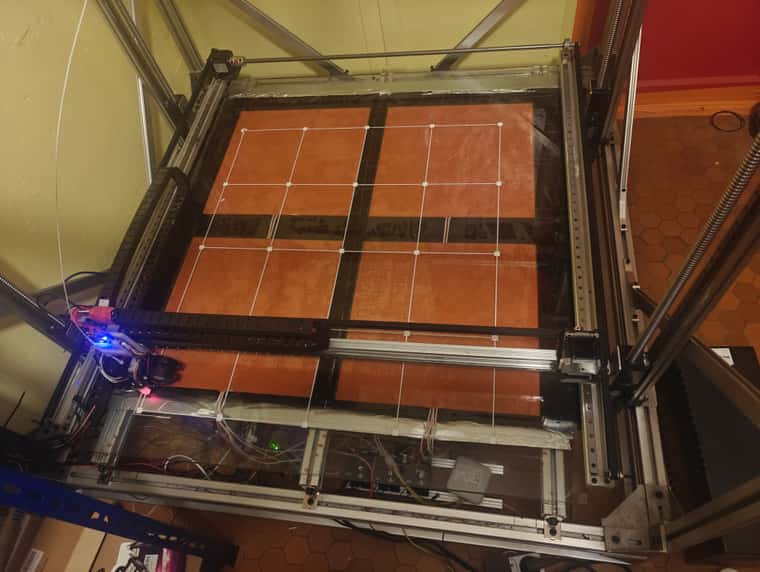

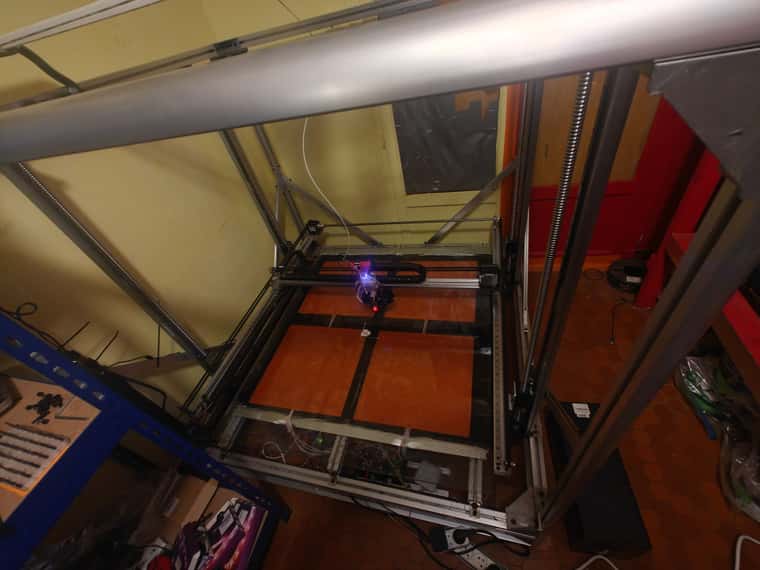

Here is the Beast

it's one of my DIY projects, I had designed it with a biqu board + DM542 drivers for all nema23 motors.

it's one of my DIY projects, I had designed it with a biqu board + DM542 drivers for all nema23 motors.

It was noisy and not great .. So I decided to put a Duet 6HC + 1LC in SBC and hopp no more need for any driver, the 6HC manages all the motors by itself (1X + 1Y + 4Z)

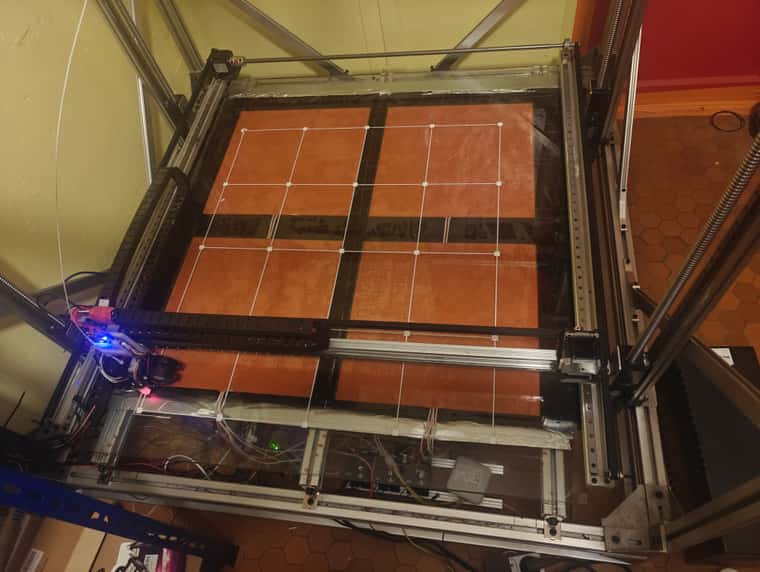

In addition I had fun adding instead of the single heating mantle of 2000W controlled by a useless external thermometer, 4 silicone plates of 500x500mm and 800W each, and thanks to the 6HC I can control them one by one, like that no need to heat everything and eat 2000W for nothing.

All 4 heating element work in 220V, controlled by one 24DC 220AC SSR eachWhat do you think

Latest posts made by Zoltan3D

-

RE: Display Memory free spaceposted in Duet Web Control

@dc42 Oh thanks you a lot,

I will try this when my 5 day 7kg TPU print will finish

and will come back to report it.

and will come back to report it. -

Display Memory free spaceposted in Duet Web Control

Hello all,

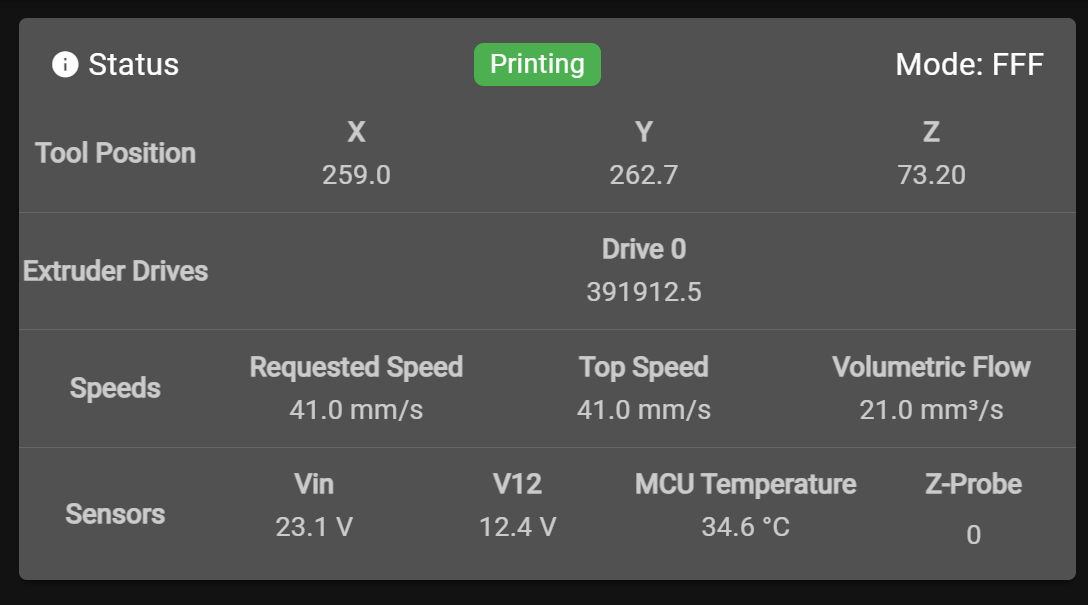

I made a 1000x1000x1000mm printer since 2 years, and last year I upgraded to Duet 6HC + 1LC in SBC with a Pi 4+, and it work like a charm

In january, I added a Creality Nebula webcam and setup it with DuetLaps to make cool timelaps of multiple day prints.

I also upgraded the SD card from 8 to 32Go (and extended de system partition )

All works perfectly ...

But it took me 2 days to figure out a simple thing ... how the f****** I can see free disk space .... A thing you can directly see in a Klipper interface because it's and important information ...

Okay so after a long search; I found M39 give me this information ...

But there was no way to show this information in DWC permenantly ? Or how to make a macro to display this ? an M39 Macro will only show this information in the Console,

Is there a way to display it with an M117 or even better an M291 ?

Or the top : can it be displayed in Status windows ? there was many useless information and space in this status like the Vin informations ....

Thanks a lot

-

RE: A macro to Enable/Disable Filament sensor during print ?posted in Tuning and tweaking

@moth4017 thanks guys for your help,

So in fact, macros are just normal config commands, but are temporary

-

A macro to Enable/Disable Filament sensor during print ?posted in Tuning and tweaking

Hello,

I recently added a Biqu filament sensor that I have in stock since they sent it to me to beta test

It's a pulsing sensor, so can detect filament runout and clog or tangle

It work with M591 D0 P7 C"121.io1.in" L7 R80:120 E15 S1It works perfectly, but sometimes it give fake error with soft TPU, because the TPU extend

I know I can change the R value to bigger spacing value.

But I really want to find a way to make one Enable and one Disable Macro for enable or disable sensor while printing

And if possible with some visual tip in the menu like a green dot or something to show if it's enabled or disabled .Someone more familiar with macros can help me with this please ?

PS : also, is it possible to make a different Pause routine for filament runout than a normal Pause ?

Because it can be useful tu Up the Z height automaticly when in runoutThanks a lot

-

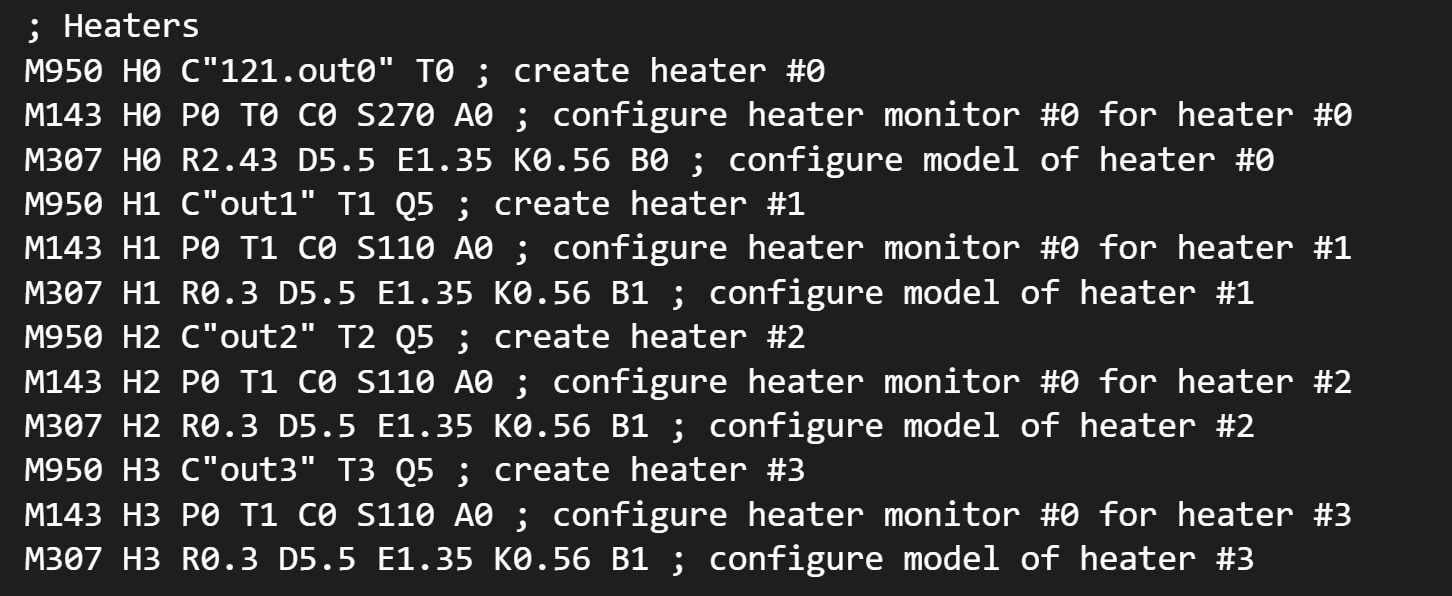

Config Tool 3.5.4, Heated bed SSR Q valueposted in Config Tool

Hello,

I recently modified the heated bed of my 1000x1000x1100 printer.

Indeed, I went from a single 2000W heater, whose temperature is managed by a basic external thermostat, to 4 silicone plates of 500x500 each with its individual control.

(Finally the two at the back are coupled together)They are each controlled by an individual SSR by the Out1 Out2 Out3 ports.

I managed to configure them perfectly, but I found no way to add the Q parameter to the M950 in the configurator.

I have to remember to add them manually after each upload of the config.

Indeed, I have to use Q5 to avoid overloading the SSRs

Is it possible to add a frequency box on the Config Tool?

Many thanks

-

RE: Sharing my confing for Creality K1posted in My Duet controlled machine

@qlqlo I really dont understand why you want to spend lot money on duet to put in a klipper printer ??

-

RE: My DIY BigBoy :p 1000x1000x1100mm toyposted in My Duet controlled machine

and just for fun, here is a normal benchy printed on it

(for now I use 0.8mm nozzle, but sucessfully tested a custom made 1.6mm nozzle

-

My DIY BigBoy :p 1000x1000x1100mm toyposted in My Duet controlled machine

Here is the Beast

it's one of my DIY projects, I had designed it with a biqu board + DM542 drivers for all nema23 motors.

it's one of my DIY projects, I had designed it with a biqu board + DM542 drivers for all nema23 motors.

It was noisy and not great .. So I decided to put a Duet 6HC + 1LC in SBC and hopp no more need for any driver, the 6HC manages all the motors by itself (1X + 1Y + 4Z)

In addition I had fun adding instead of the single heating mantle of 2000W controlled by a useless external thermometer, 4 silicone plates of 500x500mm and 800W each, and thanks to the 6HC I can control them one by one, like that no need to heat everything and eat 2000W for nothing.

All 4 heating element work in 220V, controlled by one 24DC 220AC SSR eachWhat do you think

-

If I cancel a print and home X or Y manually, head crash in bedposted in General Discussion

Hello all,

I sucessfully setup my Duet 6HC with 1LC with my giant cartesian printer (900x900x900mm)

For homing and bed mesh I use a BLTouch,

everything work like a charm after some optimisation and printsIf I home X or Y manually with homing button on SBC web control, it's perfect : Z rize some mm, home X or Y or both and go back to the previous Z height

But last day and today i made an error in the print, and Pause and after Cancelled it, After this I removed the print and hit X home button,

Z rize like normally, X go home, and at the moment when the X homing finished, Z go down without never stopping, no stop at 0, no BTtouch deploy, nothing, it crash into the bed and nearly broke my completly new setup ...I made this 2 times, and after I tried on purpose, with a print cancel, and X or Y home, and it reproduce this 100% of time, even after a hard reboot . and with multiple different gcode in case of..

What file can I give to you to find from where this problem comes N because it's really dangerous for the printer

Also I have one other question : If I fail a print on the first layer, and for some reason I hit emergency stop or unplug, when the printer restart, BLTouch directly try to self test, but the probe hit the bed (normal it's too low to self test) the only way I found to go out of this situation is to make a M564 H0 to disable security and after this up Z and restart the printer to remove the BLtouch error signal.

Is there a way with gcode or a config file to make the Z directly go up 5/10mm when you plug in the printer and AFTER this make a BLTouch initialisation ?Thanks a lot

-

Error in ConfigTool when I use 6HC + 1LC + BLTouchposted in Config Tool

Hello,

I setup a new 1000x1000x1000mm printer,

I Use a 6HC + 1LC boards,

ConfigTool Version 3.5.0-rc.2

I setup all perfectly with the Config Tool, but no mater what I try, there was always a BL Touch Z prob notfound error no matter how I try th set the probe ... I even brought a new one ....

No change ....I tried averything and it become to drive me creazy ...

I even tried to create a new config zip wth one other browser in case of .... same...

After this, I tried to open the config.zip and see inside ...After a long search I found the stupid error .... in config.g:

No matter the browser, empty cache of other when I create the zip it give this in Probes :

; Probes M558 K0 P9 C"""121.io0.in""" H5 F120 T6000 ; configure BLTouch probe via slot #0 G31 P500 X0 Y0 Z0.7 ; set Z probe trigger value, offset and trigger height M950 S0 C121.io0.out ; create servo #0 for BLtouchAs you can see C"""121.io0.in""" it's normal than the board does not understand ...

And after M950 S0 C121.io0.out without quotesI cerrected manually the file to give ;

; Probes M558 K0 P9 C"121.io0.in" H5 F120 T6000 ; configure BLTouch probe via slot #0 G31 P500 X0 Y0 Z0.7 ; set Z probe trigger value, offset and trigger height M950 S0 "C121.io0.out" ; create servo #0 for BLtouchAfter three days to have insulted all the names the Bltouch, the duet etc .... it works ...

So now, if I hchange something with the ConfigTool I always need to edit this lines again...

Can you fix this please ?

Thanks a lot