Hi all,

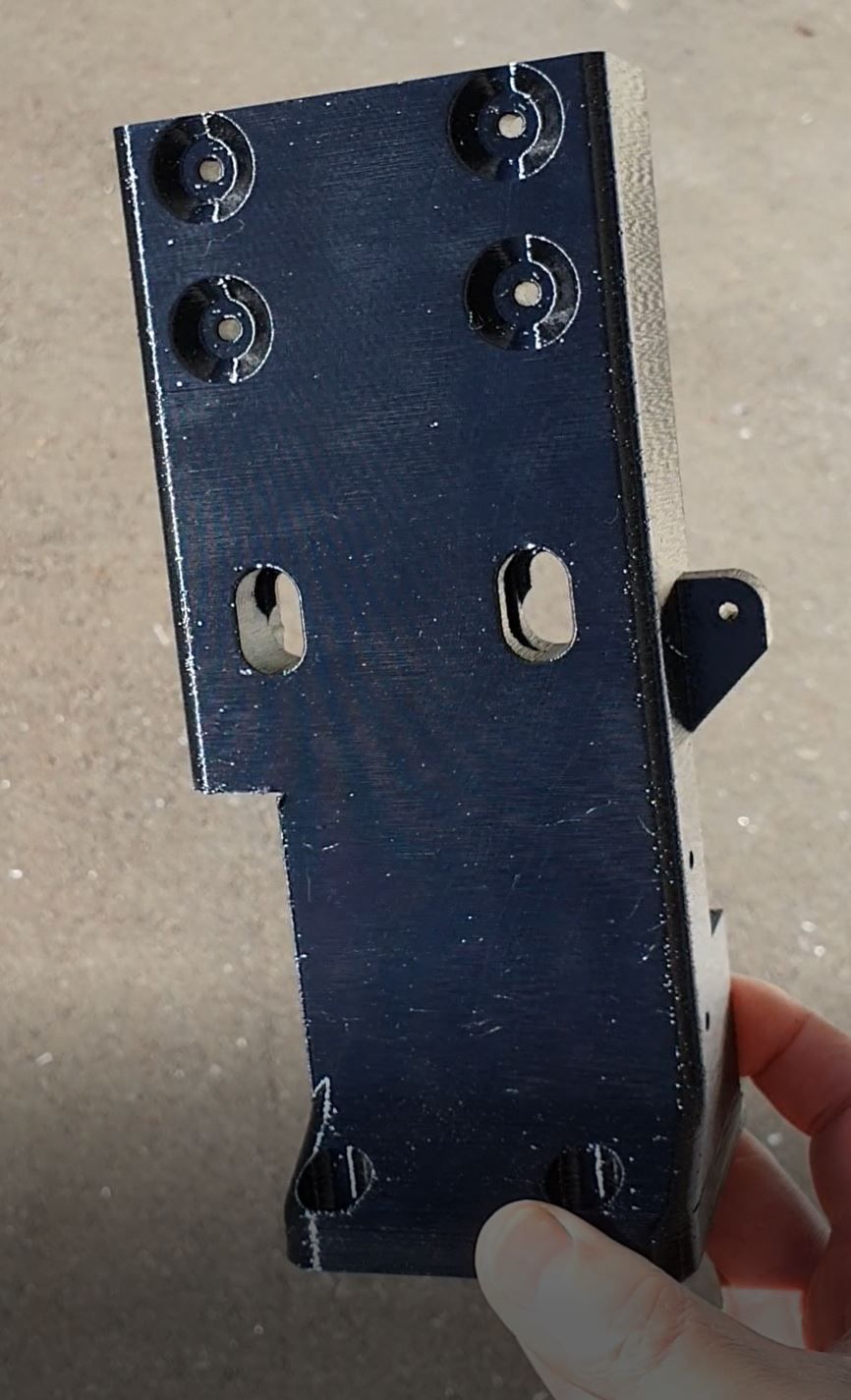

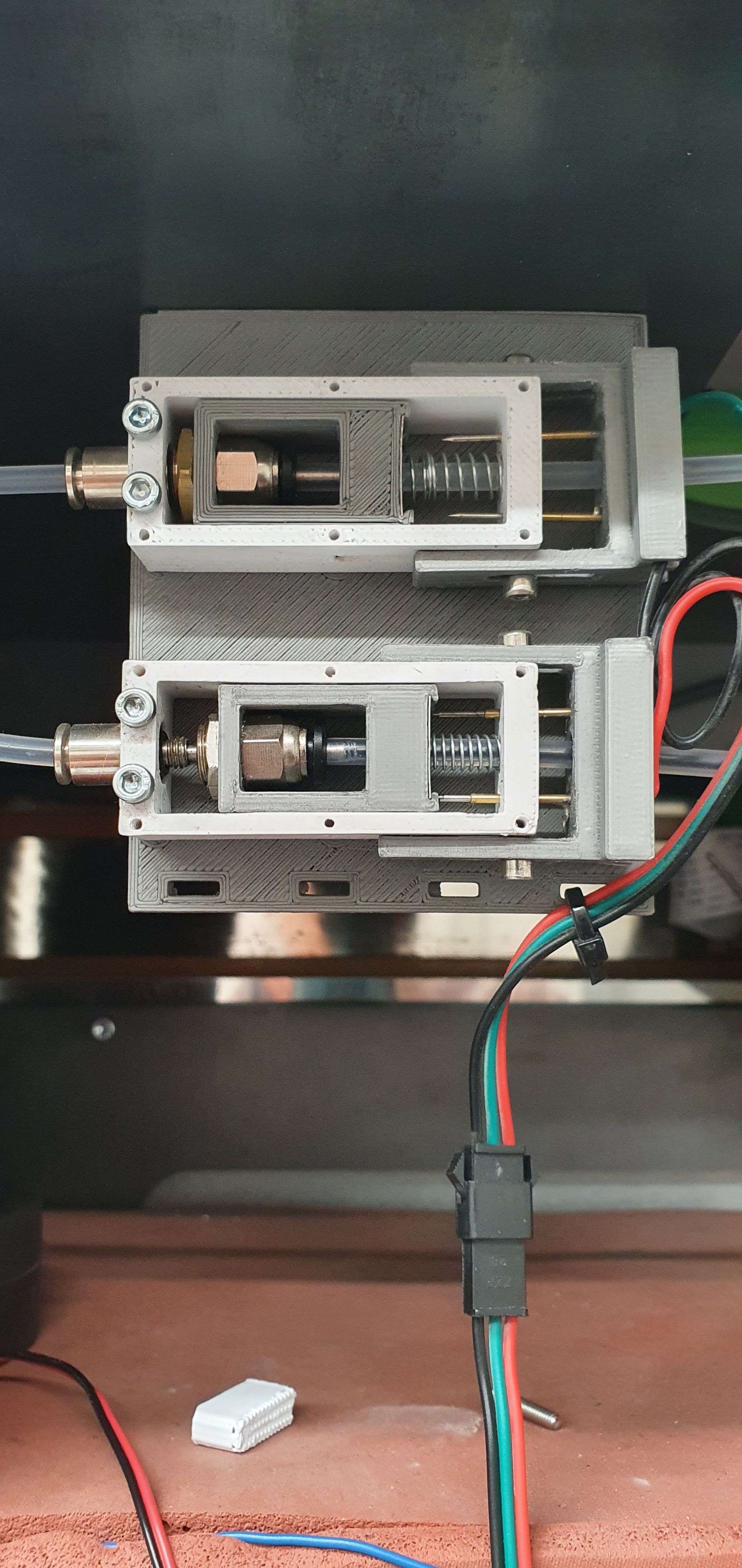

I designed a filament pressure sensor some time back for our large printers and it seems to be reliable.

I thought it might be useful and can share more information if people are interested.

I have found that this sensor has replaced the need for a filament rotating monitor (this is good because I have had lots of issues with these) and even the need for a filament out switch (for a basic setup) if you use it with a feeder motor.

(we use orbiters as our feeder) We need a filament feeder because our machine is big, although it would be great on a smaller machine also to take the load off the extruder.

It works like this:

We have orbiter feeders in our reel chamber, when you put filament in the feeder it is driven through this sensor up to the print head. Once it hits the print head the shuttle moves back and makes a connection that stops the feeder motor. if the print head starts extruding and taking filament the shuttle drops back and the feeder motor starts again, so it starts and stops over and over supplying the extruder with a slight positive pressure. when the feeder motor is driven we send a division of the stepper pulses to the duet, emulating a rotating filament sensor input (#7 pulse generation sensor). if the nozzle gets gammed then there won't be enough pluses from the feeder dive then the print will pause, if the filament runs out or a PTFE tube breaks then there will be too many pluses and the print will pause also.

I have designed it so you can put more filament in truck-and-trailer style, so the new roll of filament is pushing the old up to the head and it won't get jammed through this sensor setup.