Hi there!!! the setup is complete!! hopefully everything goes fine with this configuration, i just moved the 4th axis putting the conector in the extruder´s driver and works fine so far. i put the pictures here to see the mechanical configuration, and if you have any questions for the development of the firmware just let me know.!

Best posts made by ander

-

RE: Flying extruder with 4th axisposted in Firmware developers

-

RE: Auto delta calibration issueposted in General Discussion

Hi, i just checked it and it was this, thanks for the help,you guys are giving a really nice support

-

RE: Flying extruder with 4th axisposted in Firmware developers

Hi there!!!

a bit late but here goes my setup:

https://www.youtube.com/watch?v=ToBLN7YHWt4 -

Automatic Three-Coordinate Measuring Instrumentposted in General Discussion

Hi there everyone!

I´ve been using duet boards for some years now(i already have 3 of them on 3 custom printers).

and i was wondering that technically this machines can be used as a measuring tool.

One of my printers is retired now but, if anyone could give me a hand with the development of the firmware, i could modify it to use it a n automatic three coordinate measuring tool.

What are your thoughts about the idea? -

RE: Automatic Three-Coordinate Measuring Instrumentposted in General Discussion

@o_lampe

I was referrig to a pretty expensive machine that exist already, they use it to measure acurately. it has a sensor where the extruder would go, and touches the part, for measuring.

Latest posts made by ander

-

RE: Automatic Three-Coordinate Measuring Instrumentposted in General Discussion

@o_lampe

I was referrig to a pretty expensive machine that exist already, they use it to measure acurately. it has a sensor where the extruder would go, and touches the part, for measuring. -

Automatic Three-Coordinate Measuring Instrumentposted in General Discussion

Hi there everyone!

I´ve been using duet boards for some years now(i already have 3 of them on 3 custom printers).

and i was wondering that technically this machines can be used as a measuring tool.

One of my printers is retired now but, if anyone could give me a hand with the development of the firmware, i could modify it to use it a n automatic three coordinate measuring tool.

What are your thoughts about the idea? -

RE: bad model parametersposted in General Discussion

@droftarts

Can anyone help me? it is still giving me the same error.

i run m303 several times, then m500 and still same error when powering on the printer.

Thanks -

RE: bad model parametersposted in General Discussion

@droftarts

You are rigth, all the problems started when i upgraded the firmware.

It was giving me errors when heating up the bed. i runned m303 several times, try to do some changes and didn´t work and i changed the heating element for a more powerfull 220v silicon one. the bed itself is 460 in diameter, and yes, it takes a while to heat up.

i run m303 back again to show the results, and see if we can get someting out of it.

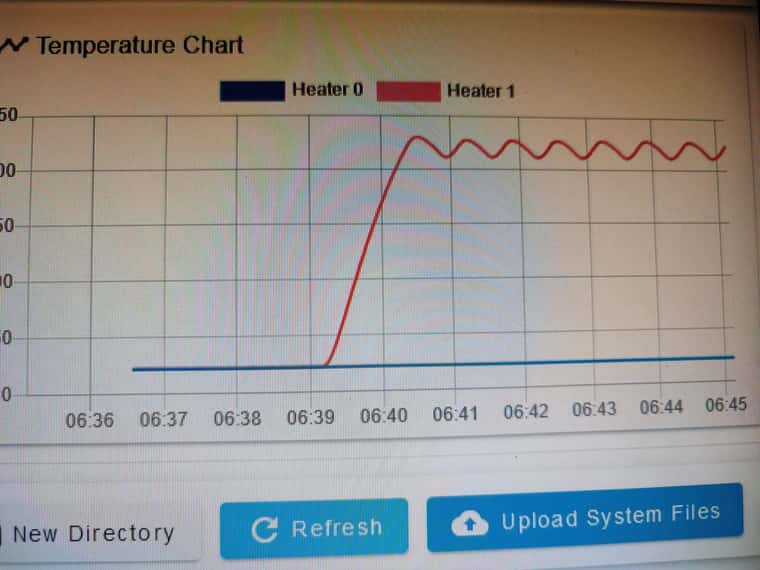

m303 h1 s220

Auto tuning heater 1 using target temperature 220.0°C and PWM 0.50 - do not leave printer unattendedAuto tuning heater 1 completed after 3 idle and 5 tuning cycles in 386 seconds. This heater needs the following M307 command:

M307 H1 R5.033 K0.424:0.000 D7.16 E1.35 S0.50 B0 V23.8

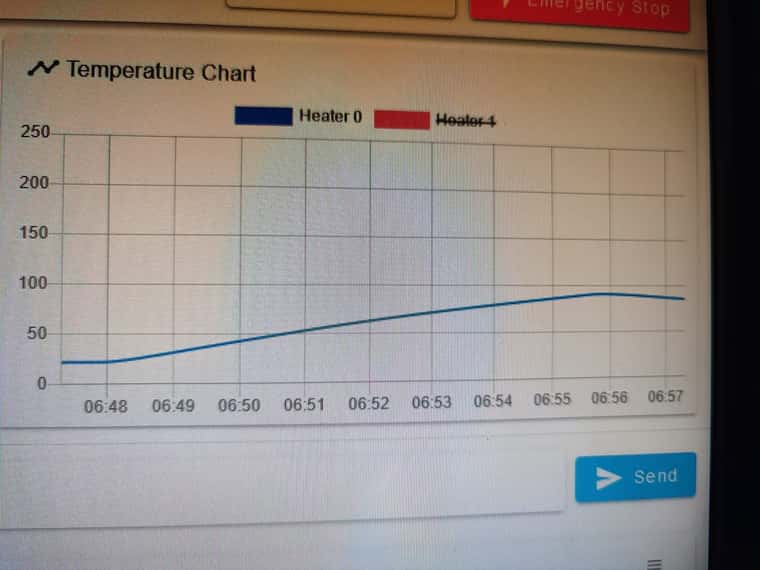

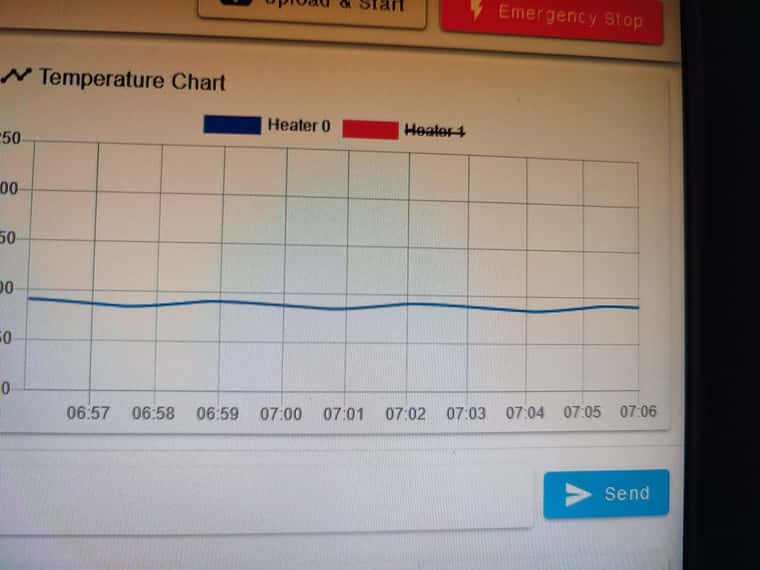

m303 h0 s90

Auto tuning heater 0 using target temperature 90.0°C and PWM 1.00 - do not leave printer unattendedM307 H0 R0.175 K0.111:0.000 D15.43 E1.35 S1.00 B0

Send M500 to save this command in config-override.g

-

bad model parametersposted in General Discussion

Hi there!

Every time i power on my delta printer puts "bad model parameters" on the screen.

And a warning that says heater 1 predicted maximun temperature at full power is 660C.

This is my output of m115 :

m115

FIRMWARE_NAME: RepRapFirmware for Duet 2 WiFi/Ethernet FIRMWARE_VERSION: 3.4.6 ELECTRONICS: Duet WiFi 1.02 or later FIRMWARE_DATE: 2023-07-21 14:08:28

And this is my config.g

config(1).g

Can someone please give me a hand? -

RE: Bed heating problemsposted in General Discussion

@droftarts said in Bed heating problems:

M98 P"config.g"

M98 P"config.g" Error: Accelerometer not found on specified port HTTP is enabled on port 80 FTP is disabled TELNET is disabled Endstop configuration: X: high end switch connected to pin xstop Y: high end switch connected to pin ystop Z: high end switch connected to pin zstop U: high end switch connected to pin e0stopError: bad model parameters Warning: Heater 1 predicted maximum temperature at full power is 656°C Warning: Heater 1 predicted maximum temperature at full power is 660°C -

RE: Bed heating problemsposted in General Discussion

@deckingman I just changed the "T" parameter and looks like it is working fine no. thanks so much

-

RE: Bed heating problemsposted in General Discussion

By the way, every time i power the duet it says "bad model parameters".

-

RE: Bed heating problemsposted in General Discussion

@droftarts there you have it :

config.override.g

config.g; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v2.1.8 on Thu Feb 27 2020 08:16:33 GMT+0100 (hora estándar de Europa central) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Muxar 3.1" ; set printer name M584 X0 Y1 Z2 U4 E3 F5 ; set drive mapping M665 R228.6 L407.8:407.8:407.8:340 B200 H440 ; Set delta radius, diagonal rod length, printable radius and homed height M669 X0 Y0 ;esto especifica el ofset de la salida del extrusor referente al centro de la mesa M666 X0 Y0 Z0 F0 ; put your endstop adjustments here, or let auto calibration find them M575 P1 B57600 S1 M955 P0 C"spi.cs2+spi.cs1" M593 P"mzv" F27 ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S0 M569 P4 S0 ; physical drive 3 goes backwards M350 X16 Y16 Z16 U16 E16 I1 ; Configure microstepping with interpolation M92 X80 Y80 Z80 U400 E415 ; Set steps per mm M566 X1200.00 Y1200.00 Z1200.00 U1200 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X12000.00 Y12000.00 Z12000.00 U3000.00 E12000.00 ; set maximum speeds (mm/min) M201 X2000.00 Y2000.00 Z2000.00 U1500.00 E2000.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1200 U1200 E1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 S1 Z-2 ; set minimum Z M208 S0 U1000 ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure Z-probe endstop for low end on Z M574 U2 S1 P"e0stop" M574 F2 S1 P"filamentstop" ; Z-Probe M558 P8 C"E1stop" H5 F1200 T6000 ; set Z probe type to effector and the dive height + speeds G31 P500 X0 Y0 Z-0.26 ; set Z probe trigger value, offset and trigger height/cuanto mas negativo mas separado de la mesa M557 R175 S80 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 R0.083 K1.473:0.000 D5 E1.35 S1.00 B0 ;M307 H0 A215.5 C661.6 D5.8 S1.00 V24.0 B1 ;M307 H0 R0.905 K2.126:0.000 D1.06 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4725 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ;create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S250 ; set temperature limit for heater 1 to 280C M307 H1 R3.841 K0.319:0.000 D7.07 E1.35 S0.50 B0 V23.9;disable bang-bang mode for heater and set PWM limitM307 H1 A346.2 C140 D5.3 B0 S0.8 V23.8 M570 H0 P15 T1 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings M591 D0 P1 C"exp.e2stop" S1 ; filament monitor connected to E2 endstop ; Miscellaneous M501 ; load saved parameters from non-volatile memory; config-override.g file generated in response to M500 at 2020-10-01 11:18 ; This is a system-generated file - do not edit ; Delta parameters M665 L407.800:407.800:407.800:340.000 R228.301 H447.033 B200.0 X-0.618 Y-0.603 Z0.000 M666 X0.660 Y-0.395 Z-0.265 A0.00 B0.00 ; Heater model parameters M307 H0 A72.8 C413.7 D0.2 S0.80 V24.4 B0 M307 H1 A933.6 C181.4 D1.5 S0.5 V24.0 P0.2 B0 ; Workplace coordinates G10 L2 P1 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P2 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P3 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P4 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P5 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P6 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P7 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P8 X0.00 Y0.00 Z0.00 U0.00 G10 L2 P9 X0.00 Y0.00 Z0.00 U0.00