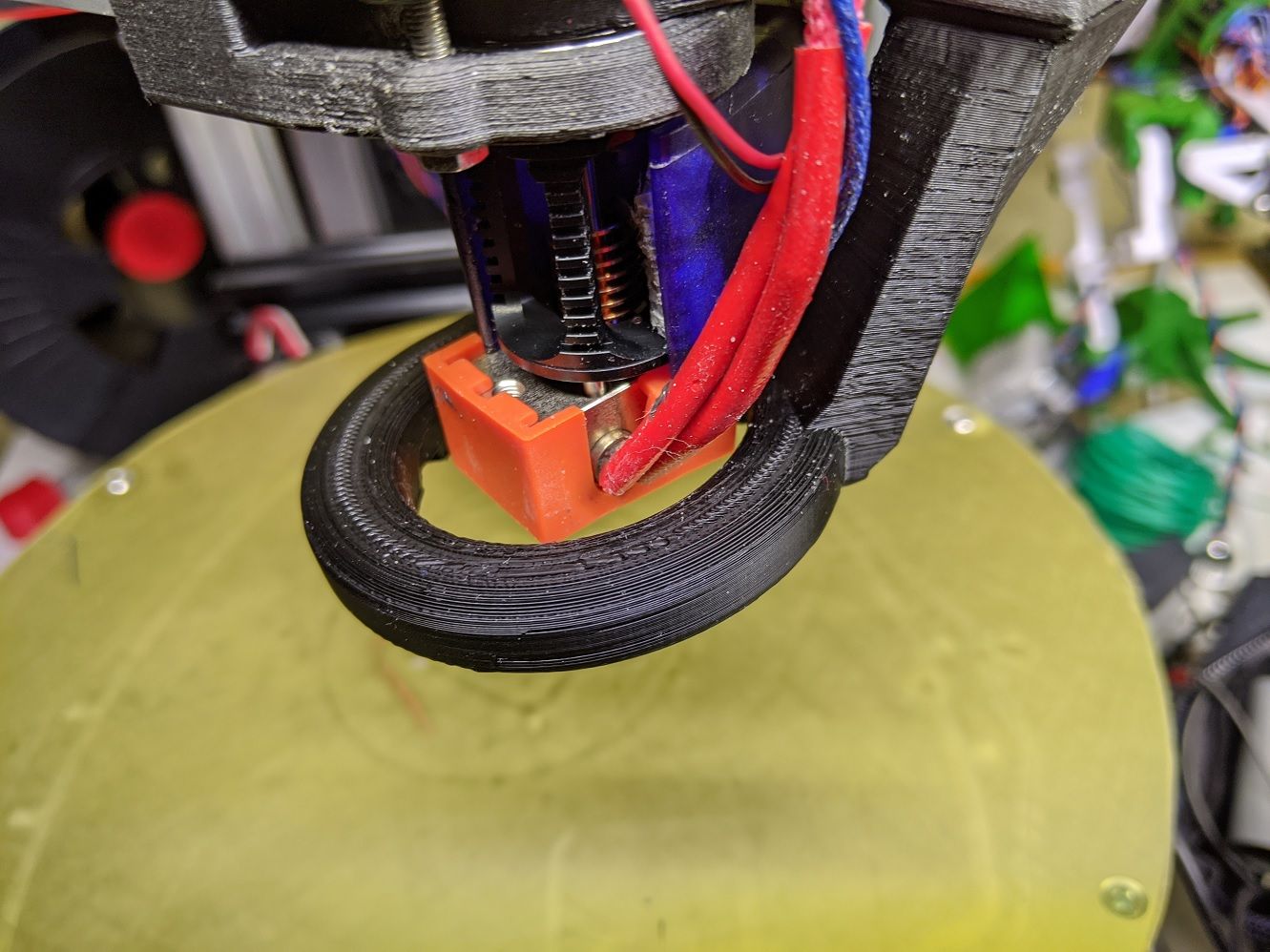

I have build a five bar, it actually works very well. The double arms makes it very strong in the XY-plane, exactly what we need when FDM printing.

There are a few tricky parts building a five bar.

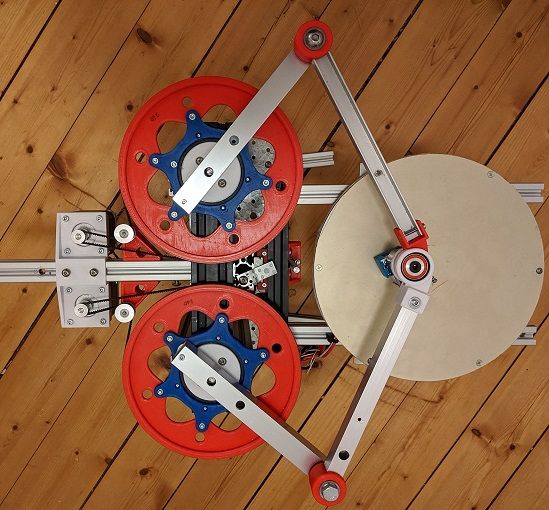

You need to gear down your motors a lot to get enough steps/mm. And you need a gearbox with almost no backlash at all. The normal gearboxes you often find with steppers have way too much backlash. Ideally you would want a harmonic drive or possibly a cycloidal gearbox. I used gigantic pulleys (260t) and belts on my machine.

You have to be very precise on the length of the arms, and the angle of your homing sensors. A small error will result in warped parts. This is the similar to a delta printer, except that the firmware have amazing calibration algorithms to compensate for errors. The Five Bar firmware has no such features.

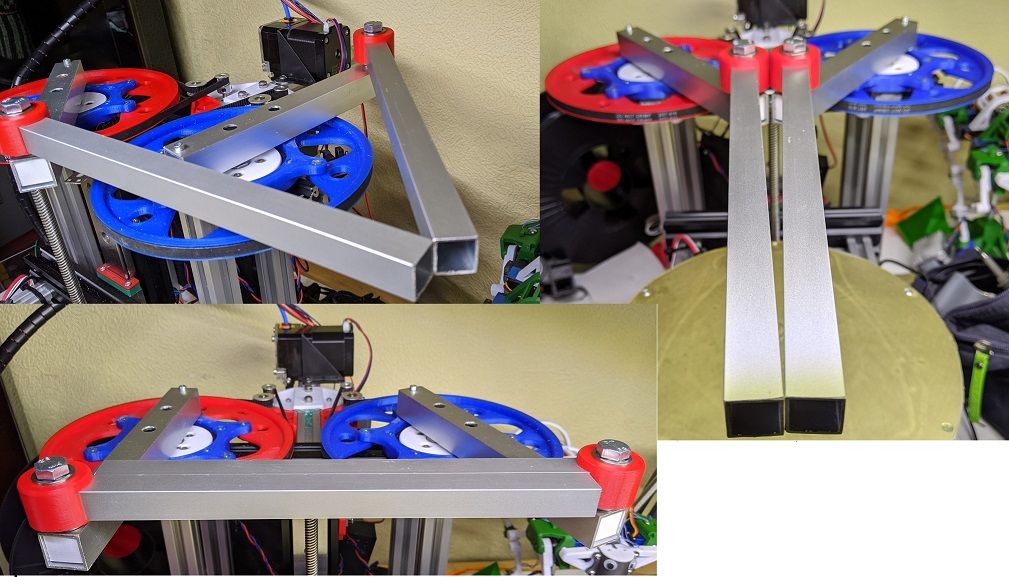

It can also be tricky to make the arm move in a perfectly flat plane. It's important to make sure all bearing rotate in the same plane. It is actually an over constrained system and if not built perfect there will be tensions in the arms.

A bed probe can compensate for small errors ofc.