@engikeneer

The testing continues. Thank you again for your suggestions.

I did a test to see if temps made any difference. Printed a cylinder and went from 200c to 220 in 5c increments every 10mm. Zero no difference in how the seam was printed. Bit surprises it made no difference but a worthwhile test.

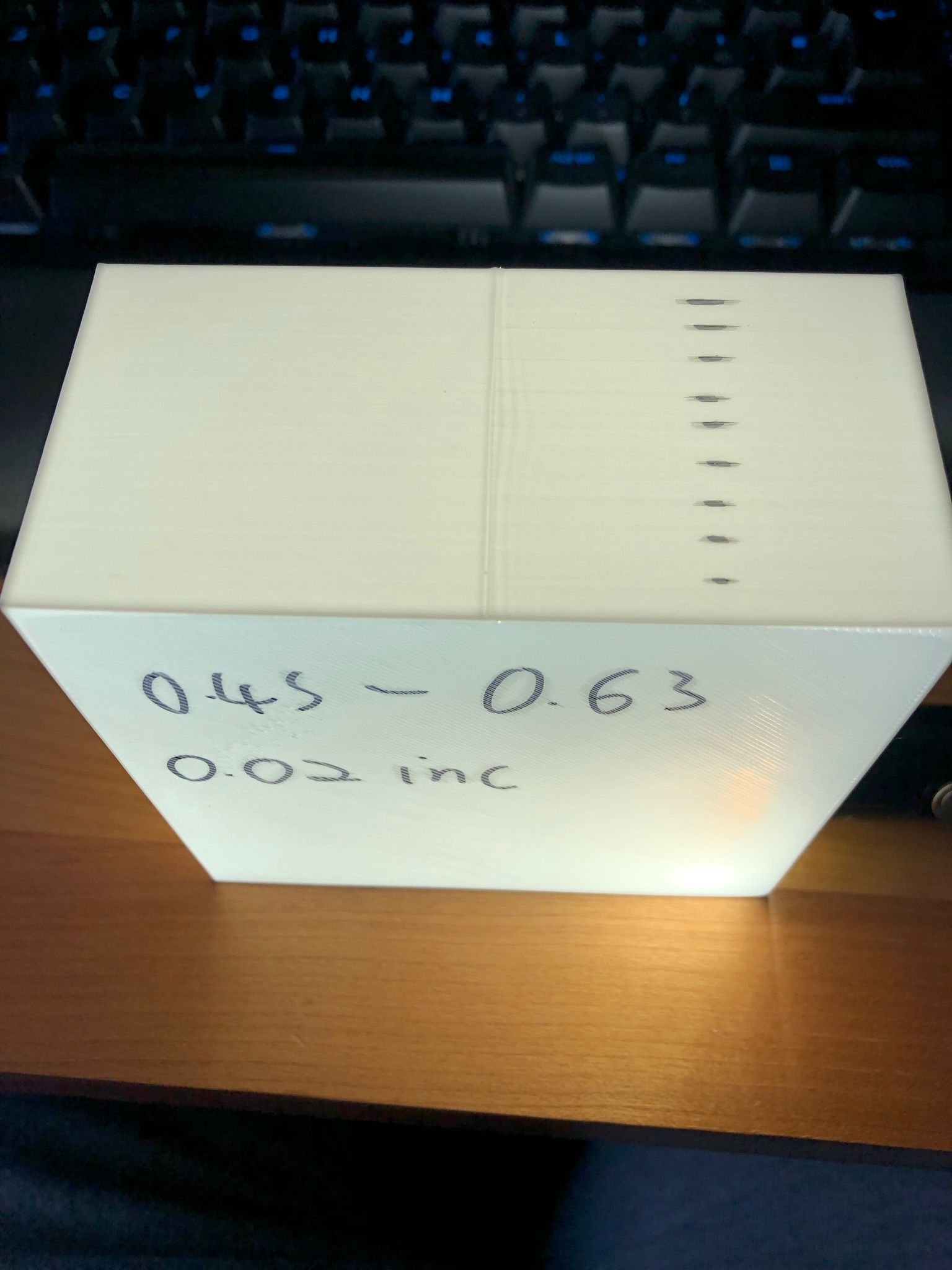

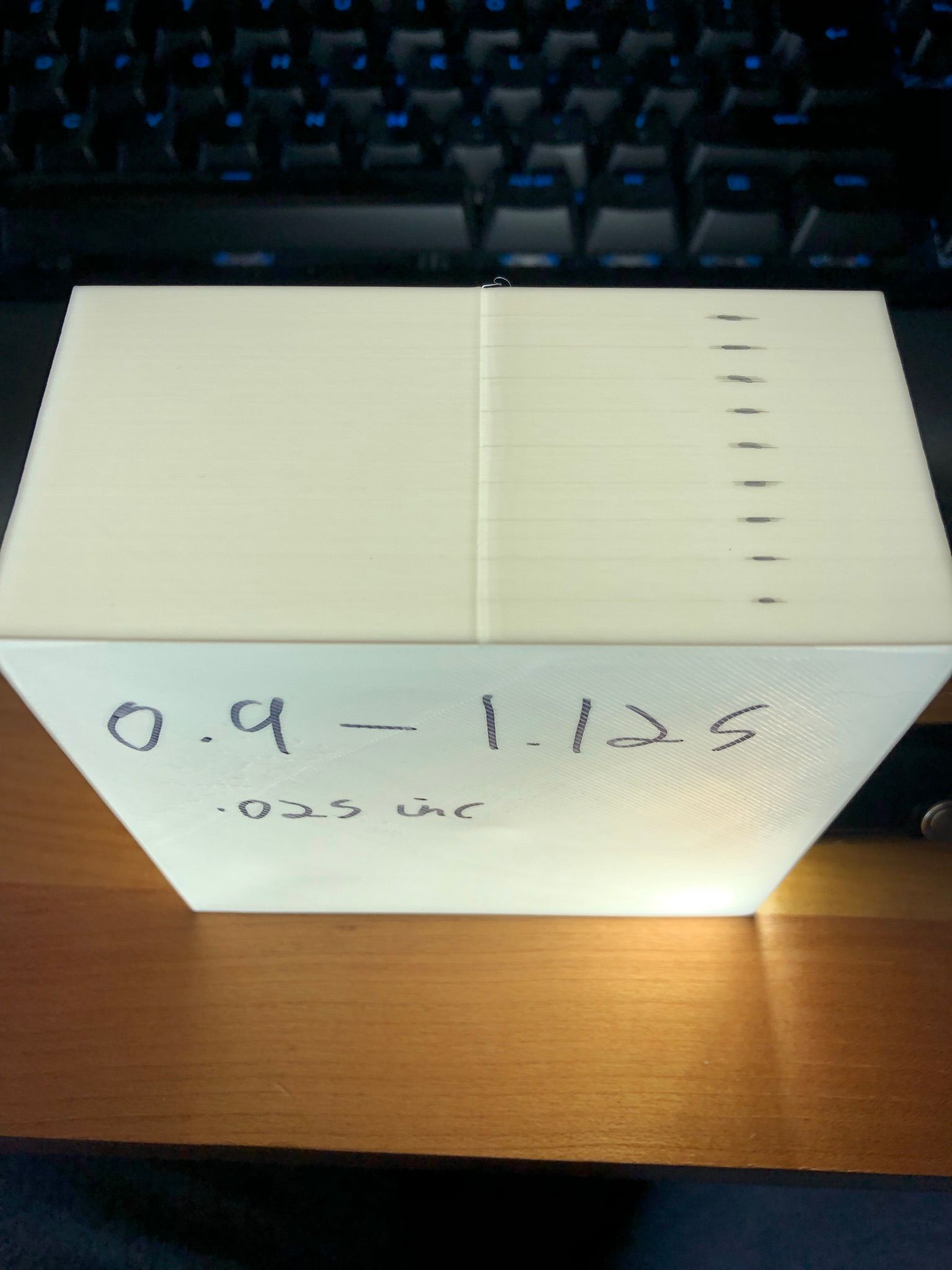

I have continued with some box tests. I thought I was making progress but still cannot find a PA setting to get the sword test print I have to not weld itself together and I really don't want to have to use the slicer wipe function as that only works on a retraction. Anyway here are some pics of the box tests

Looked like there was a sweet spot between 0.9 and 1.1 but my print to try and find it didn't really have a huge range of differences.

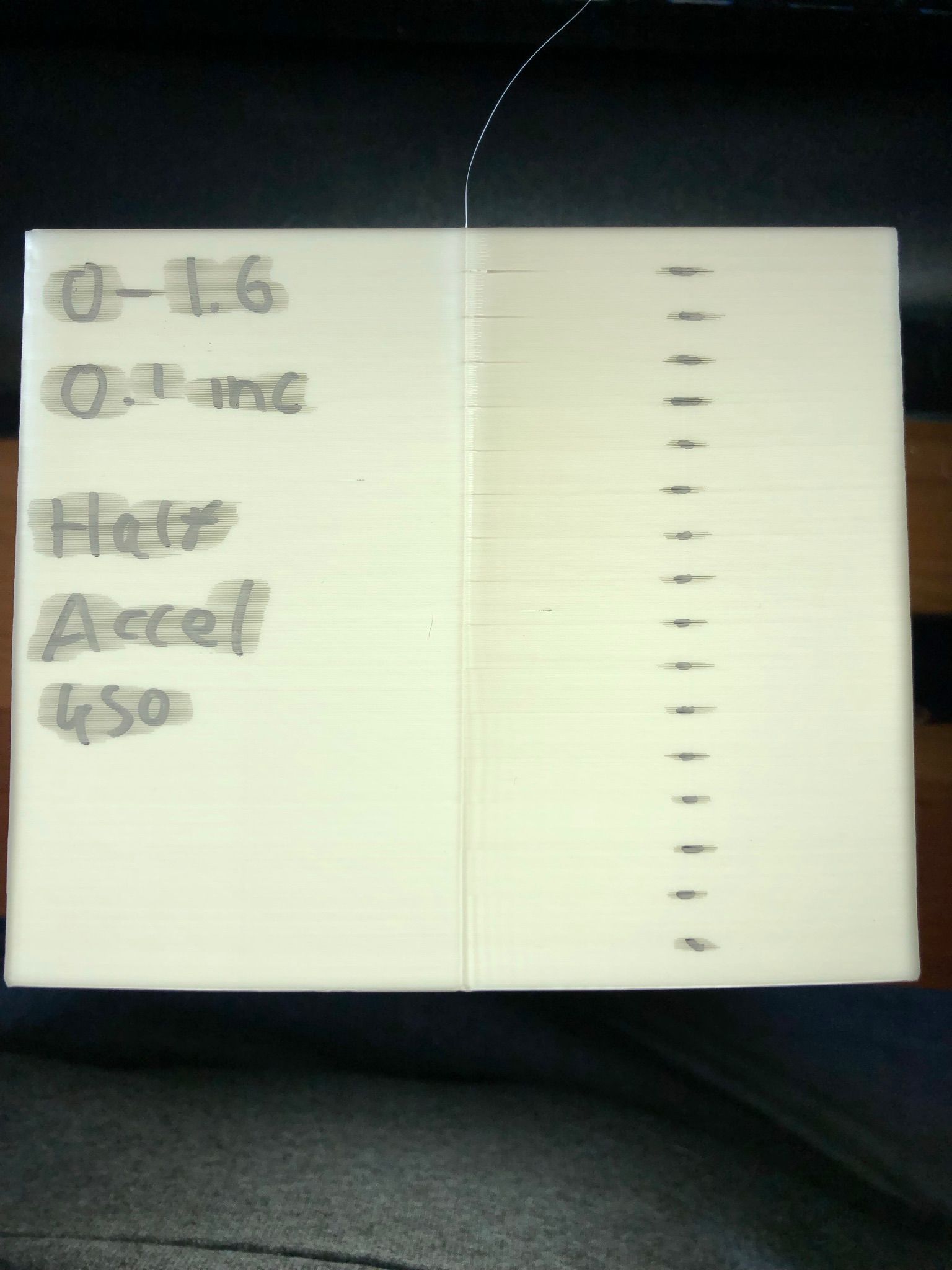

I found a forum thread here that talks about LOWERING the jerk on the travel axis.

Worth a shot, so i have halved my XYZ (delta) jerk speed from 900 to 450 and did another box test

This looks quite encouraging somewhere between 0.3 - 0.6

On all of the pictures, the black mark shows when the PA value was changed.

I am currently running the same test but with a 30mm cylinder to see if they compare to how the box prints or if it is different.

My bowden tubes are tight in the clips. I haven't yet checked about the backlash but I think in the tests I have done that could have been canceled out. Will check anyway once i stop the next print.

M201 X5000 Y5000 Z5000 E10000 ; Set accelerations (mm/s^2) Used to be 1500

M203 X18000 Y18000 Z18000 E20000 ; Set maximum speeds (mm/min)

M566 X900 Y900 Z900 E1000 P1 ; Set maximum instantaneous speed changes (mm/min)

M207 S3.0 F5000 T3600 Z0

My current settings. The last picture is using 450 for XYZ jerk values.