@infiniteloop

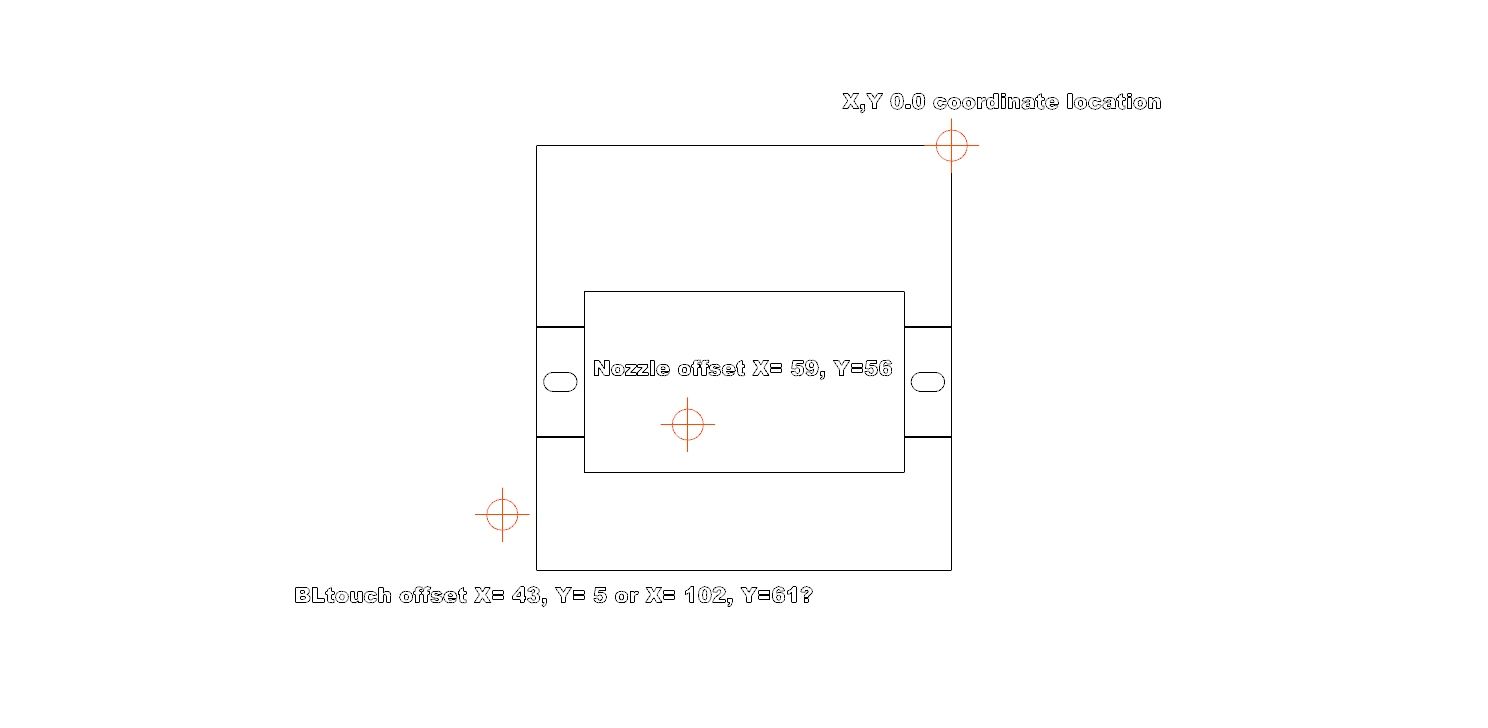

Yeah the intention is for the end stops to be positioned in the right rear corner of the printer (replicator 2 conversion) if looking at it from the front as in the image below.

config.g

; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin

; Axis Limits

M208 X200 Y90 Z150 S0 ; set axis maxima and high homing switch positions

M208 X-59.83 Y-56.05 Z0 S1 ; set axis minima and low homing switch positions

; Enable Panel Due Connector

M575 P1 S1 B57600 ; Enables connector and sets baud rate

; Endstops- Switches

M574 X1 S1 P"!xstop" ; X min active high endstop switch

M574 Y1 S1 P"!ystop" ; Y min active high endstop switch

M574 Z1 S1 P"!zstop" ; Z min active high endstop switch - Config for hard Z Endstop

;Touch Probe

M950 S0 C"exp.heater3" ; define probe servo pin

M558 P9 C"^zprobe.in" H5 F100 T2000 ; BLTouch Probe

G31 P50 X43.07 Y4.68 Z1.355 ; Set Z probe trigger value, offset and trigger height - Increase Z value to move bed closer to nozzle

M557 X0:200 Y0:90 S10 ; Define mesh grid

; Drives

M569 P0 S0 ; Drive 0 goes backwards

M569 P1 S0 ; Drive 1 goes backwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S1 ; Drive 3 goes forwards

M569 P4 S1 ; Drive 4 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X88.573186 Y177.78 Z400 E409 ; Set steps per mm

M566 X900 Y900 Z300 E1200 ; Set maximum instantaneous speed changes (mm/min)

M203 X1080000 Y1080000 Z600 E96000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z100 E2000 ; Set accelerations (mm/s^2)

M906 X900 Y1000 Z400 E1200 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3974 C0 R4700 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M307 H0 R0.261 K0.401:0.000 D3.11 E1.35 S1.00 B0 ; Set PID values for Heatedbed - derived from autotune

M307 H1 R1.219 K0.254:0.000 D6.15 E1.35 S1.00 B0 V19.9 ; Set PID values for Extruder 1 - derived from autotune

; Network

M550 P"Duet_Rep2X" ; Set machine name

;M551 P"XXXXX" ; Set password

M552 S1 ; Enable network

;M552 P192.168.0.98 ;Fixed IP Address

;M554 P192.168.0.1 ;Gateway

;M553 P255.255.255.0 ;Netmask

; Access point is configured manually via M587 by the user

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S0 ; Disable Telnet

; Fans

M950 F0 C"fan0" Q500 ; Set fan 0 value, PWM signal inversion and frequency.

M106 P0 T45 H1 ; Set fan 0. Thermostatic control is turned on at 45 celcius.

M106 P0 S0 ; Switch cooling fan off

; Accelerometer

M955 P0 C"spi.cs3+spi.cs4"

; Tools

M563 P0 D0 H1 F0 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M207 S1.2 F1200 ; set 1.2mm retract distance for G10 command

; Select Tool

T0

; Custom settings are not configured

homex.g

; Lift Z relative to current position

G91

G1 Z5 F150000 H2

G90

; Move quickly to X axis endstop and stop there (first pass)

G1 X-290 F1800 H1

; Go back a few mm

G91

G1 X5 F150000

G90

; Move slowly to X axis endstop once more (second pass)

G1 X-290 F360 H1

; Lower Z again

G91

G1 Z-5 F150000 H2

G90

homey.g

; Lift Z relative to current position

G91

G1 Z5 F150000 H2

G90

; Move quickly to Y axis endstop and stop there (first pass)

G1 Y-155 F1800 H1

; Go back a few mm

G91

G1 Y5 F150000

G90

; Move slowly to X axis endstop once more (second pass)

G1 Y-155 F360 H1

; Lower Z again

G91

G1 Z-5 F150000 H2

G90

homeall.g

; Relative positioning

G91

; Lift Z

G1 Z5 F600 H2

; Course home X and Y

G1 X-290 F1800 H1

G1 Y-155 F1800 H1

; Move away from the endstops

G1 X5 Y5 F150000

; Fine home X and Y

G1 X-290 Y-155 F360 H1

; Code for Hard Endstop home Z

; Move Extruder out of the way

;G90

;G1 X-12 Y-10 F150000

; Home Z against hard enstop

;G91

;G1 Z-200 F400 H1 ; rough home Z axis;G1 Z2 F400 ; move down by 2mm

;G1 Z-155 F40 H1 ; fine home z axis

; Adjust Z distance from Z endstop

;G92 Z0.00 ; positive - Move bed closer to extruder, negative - Move bed away from extruder

; Absolute positioning

G90

; Code for Sensor Based Z Homing

; Go to first bed probe point and home Z

G1 X63 Y16 F150000

G30

; Uncomment the following line to lift the nozzle after probing

G1 Z5 F300 H2

-resized.jpg)

-resized.jpg)