@Phaedrux

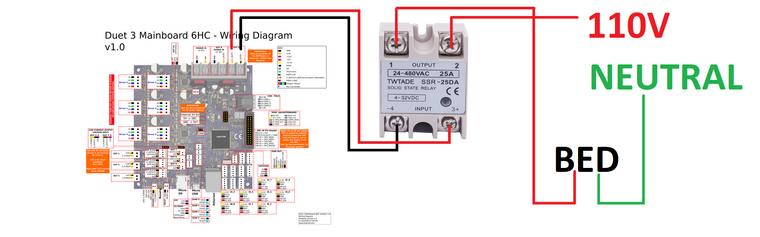

It is wired exactly like this

https://th.bing.com/th/id/R.18b40bc0cfbe9ea27c4958b16836aeab?rik=2r0ohUBcqSE%2F6w&pid=ImgRaw&r=0

https://th.bing.com/th/id/R.18b40bc0cfbe9ea27c4958b16836aeab?rik=2r0ohUBcqSE%2F6w&pid=ImgRaw&r=0

@phaedrux do I need to supply the input from the psu the SSR already has 110 going into it I am just using the duet to trigger it to turn on (if I understood this correctly) the board itself isn’t supplying the voltage.

I can’t seem to get the bed heater working if I trigger the bed heater the temperature never rises and the SSR light doesn’t come on. I have the SSR wired Input as positive goes to the V_out0 on duet 3 and the negative goes to the out0- port on the duet3. The load positive goes to the psu and the other side goes to the bed heater which is then grounded. The bed heater worked on my old duet WiFi board with same SSR. I used a multimeter on the v_out0 and out0- ports on the duet3 and the voltage doesn’t seem to change when the bed heater is switched on. Attached is my config… is my pin name wrong on my 950 command maybe? Also bed heater never gets warm to the touch.

; Configuration file for Duet 3 (firmware version 3)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

M552 S1 P0.0.0.0

; Drives

M569 P0.5 S1 ; physical drive 0.5 goes forwards

M569 P0.4 S0 ; physical drive 0.4 goes forwards

M569 P1.0 S1 ; physical drive 1.0 goes forwards

M569 P1.1 S1 ; physical drive 1.1 goes forwards

M569 P1.2 S1 ; physical drive 1.2 goes forwards

M569 P0.2 S1 ; physical drive 0.2 goes backwards

M569 P0.1 S1 ; physical drive 0.1 goes backwards

M569 P0.0 S1 ; physical drive 0.0 goes backwards

M569 P0.3 S0 ; physical drive 0.3 goes backwards

M584 X0.4 Y0.5 Z1.1:1.0:1.2 E0.2:0.1:0.0 C0.3 ; set drive mapping

M350 1 I0

M350 C8 I0 ; configure microstepping without interpolation

M350 X16 Y16 Z16:16:16 E16:16:16 I1 ; configure microstepping with interpolation

M92 X100 Y100 Z3205:3205:3205 E405:405:405 C100 ; set steps per mm

M566 X1000 Y1000 Z100:100:100 E1500:1500:1500 C2 ; set maximum instantaneous speed changes (mm/min)

M203 X24000 Y24000 Z900:900:900 E3600:3600:3600 C5000 ; set maximum speeds (mm/min)

M201 X3000 Y3000 Z100:100:100 E1500:1500:1500 C400 ; set accelerations (mm/s^2)

M906 X1400 Y1400 Z900:900:900 E1000:1000:1000 C400 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

;Stall Detection - Used for homing

M915 C S5 F0 H200 ; Coupler

M915 X Y S5 F0 H400 ; X / Y Axes

;Leadscrew locations

M671 X-43.9:-48.23:304 Y5:262:140 S25 ;Front left, Rear Left, Right S7.5 is the max correction

; Axis Limits

M208 X-15 Y-20 Z0.5 S1 ; set axis minima

M208 X310 Y310 Z700 S0 ; set axis maxima

; Endstops

M574 X1 S3 ; configure sensorless endstop for low end on X

M574 Y1 S3 ; configure sensorless endstop for low end on Y

M574 Z1 S1 ; configure Z-probe endstop for high end on Z

; Z-Probe

M558 P8 C"^io3.in" X0 Y0 Z1 H5 F100 T3000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height

M557 X30:260 Y30:260 S45 ; define mesh grid

M307 H1 B0 R3.167 C154.3 D6.11 S0.50

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

;307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M307 H1 B0 R3.167 C154.3 D6.11 S0.50

M143 H1 S300 ; set temperature limit for heater 1 to 300C

M308 S2 P"temp2" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin temp2

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S300 ; set temperature limit for heater 2 to 300C

M308 S3 P"temp3" Y"thermistor" T100000 B4138 ; configure sensor 3 as thermistor on pin temp3

M950 H3 C"out3" T3 ; create nozzle heater output on out3 and map it to sensor 3

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H3 S300 ; set temperature limit for heater 3 to 300C

; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 C"HotEnd0Always" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 C"HotEnd1Always" S1 H-1 ; set fan 1 name and value. Thermostatic control is turned off

M950 F2 C"out6" Q500 ; create fan 2 on pin out6 and set its frequency

M106 P2 C"HotEnd2Always" S1 H-1 ; set fan 2 name and value. Thermostatic control is turned off

M950 F3 C"1.out6" Q500 ; create fan 3 on pin 1.out6 and set its frequency

M106 P3 C"HotEnd0Temp" S0 H1 T45 ; set fan 3 name and value. Thermostatic control is turned on

M950 F4 C"1.out7" Q500 ; create fan 4 on pin 1.out7 and set its frequency

M106 P4 C"HotEnd1Temp" S0 H2 T45 ; set fan 4 name and value. Thermostatic control is turned on

M950 F5 C"1.out8" Q500 ; create fan 5 on pin 1.out8 and set its frequency

M106 P5 C"HotEnd2Temp" S0 H3 T45 ; set fan 5 name and value. Thermostatic control is turned on

; Tools

M563 P0 S"HotEnd0" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z-5.7 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"HotEnd1" D1 H2 F1 ; define tool 1

G10 P1 X0 Y0 Z-6.12 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"HotEnd2" D2 H3 F2 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

@phaedrux they are just standard two pin connectors on the fans i would prefer to have them connected to the board via connector vs directly to the psu i know the fans do work as they used to be connected to duet wifi

@phaedrux

i was trying to get the F0,1,2 as always on and F3,4,5 (there are 3 hot ends) to be turned on based on temperature (if i have them backwards i can move cables easily)as of right now none of them are always on.

I restored the default homing file and went back to the z1 s1 and it looks like it is working now something in the homing file must have been out of whack thanks!

Still need to figure out how to get the hotend fans to stay on any ideas?

@dhusolo

I should have mentioned this is about the 30th modification that i made to try to figure it out on my own that is why i had z2 s2. I tried z1 s1 before , i did it again to make sure still but allas it is still not working.

I am working on using Duet 3 and Duet 3 extension board to my core xy printer (based off railcore II) however i am having a few issues with wiring/configuring

Issue 1: For my z endstop i have a mechanical endstop (2 pin) plugged into pin 2 and 3 of IO_3 port but it won't stop the z axis when homing.

Issue 2: How can i set up fans as always on for hot ends?

; Configuration file for Duet 3 (firmware version 3)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Duet 3" ; set printer name

M669 K1 ; select CoreXY mode

M552 S1 P0.0.0.0

; Drives

M569 P0.5 S1 ; physical drive 0.5 goes forwards

M569 P0.4 S0 ; physical drive 0.4 goes forwards

M569 P1.0 S0 ; physical drive 1.0 goes forwards

M569 P1.1 S0 ; physical drive 1.1 goes forwards

M569 P1.2 S0 ; physical drive 1.2 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.3 S0 ; physical drive 0.3 goes backwards

M584 X0.5 Y0.4 Z1.0:1.1:1.2 E0.2:0.1:0.0 C0.3 ; set drive mapping

M350 1 I0 ; configure microstepping without interpolation

M350 X16 Y16 Z16:16:16 E16:16:16 I1 ; configure microstepping with interpolation

M92 X100 Y100 Z3205:3205:3205 E405:405:405 C100 ; set steps per mm

M566 X1000 Y1000 Z100 100 E1500:1500:1500 C2 ; set maximum instantaneous speed changes (mm/min)

100 E1500:1500:1500 C2 ; set maximum instantaneous speed changes (mm/min)

M203 X24000 Y24000 Z900:900:900 E3600:3600:3600 C5000 ; set maximum speeds (mm/min)

M201 X3000 Y3000 Z100 100 E1500:1500:1500 C400 ; set accelerations (mm/s^2)

100 E1500:1500:1500 C400 ; set accelerations (mm/s^2)

M906 X1400 Y1400 Z900:900:900 E1000:1000:1000 C400 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

;Stall Detection - Used for homing

M915 C S5 F0 H200 ; Coupler

M915 X Y S5 F0 H400 ; X / Y Axes

;Leadscrew locations

M671 X-43.9:-48.23:304 Y5:262:140 S25 ;Front left, Rear Left, Right S7.5 is the max correction

; Axis Limits

M208 X-15 Y-20 Z0.5 S1 ; set axis minima

M208 X310 Y310 Z700 S0 ; set axis maxima

; Endstops

M574 X1 S3 ; configure sensorless endstop for low end on X

M574 Y1 S3 ; configure sensorless endstop for low end on Y

M574 Z2 S2 ; configure Z-probe endstop for high end on Z

; Z-Probe

M558 P8 C"^io3.in" X0 Y0 Z1 H5 F100 T3000 ; set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z0 ; set Z probe trigger value, offset and trigger height

M557 X5:275 Y5:290 S15 ; define mesh grid

; Heaters

M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin temp1

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S300 ; set temperature limit for heater 1 to 300C

M308 S2 P"temp2" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin temp2

M950 H2 C"out2" T2 ; create nozzle heater output on out2 and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S300 ; set temperature limit for heater 2 to 300C

M308 S3 P"temp3" Y"thermistor" T100000 B4138 ; configure sensor 3 as thermistor on pin temp3

M950 H3 C"out3" T3 ; create nozzle heater output on out3 and map it to sensor 3

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H3 S300 ; set temperature limit for heater 3 to 300C

; Fans

M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency

M106 P0 C"HotEnd0Always" S1 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency

M106 P1 C"HotEnd1Always" S1 H-1 ; set fan 1 name and value. Thermostatic control is turned off

M950 F2 C"out6" Q500 ; create fan 2 on pin out6 and set its frequency

M106 P2 C"HotEnd2Always" S1 H-1 ; set fan 2 name and value. Thermostatic control is turned off

M950 F3 C"1.out6" Q500 ; create fan 3 on pin 1.out6 and set its frequency

M106 P3 C"HotEnd0Temp" S0 H1 T45 ; set fan 3 name and value. Thermostatic control is turned on

M950 F4 C"1.out7" Q500 ; create fan 4 on pin 1.out7 and set its frequency

M106 P4 C"HotEnd1Temp" S0 H2 T45 ; set fan 4 name and value. Thermostatic control is turned on

M950 F5 C"1.out8" Q500 ; create fan 5 on pin 1.out8 and set its frequency

M106 P5 C"HotEnd2Temp" S0 H3 T45 ; set fan 5 name and value. Thermostatic control is turned on

; Tools

M563 P0 S"HotEnd0" D2 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z-6.3 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"HotEnd1" D3 H2 F1 ; define tool 1

G10 P1 X0 Y0 Z-6.12 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"HotEnd2" D4 H3 F2 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

@phaedrux

Tried to get some better images not sure what all is relevant