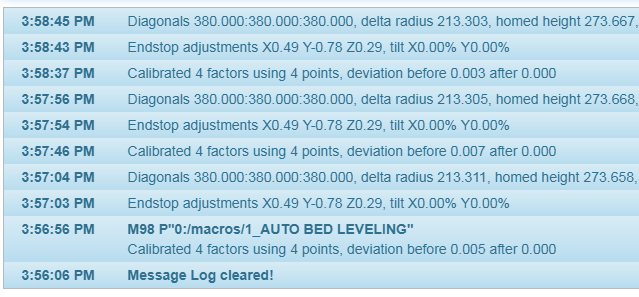

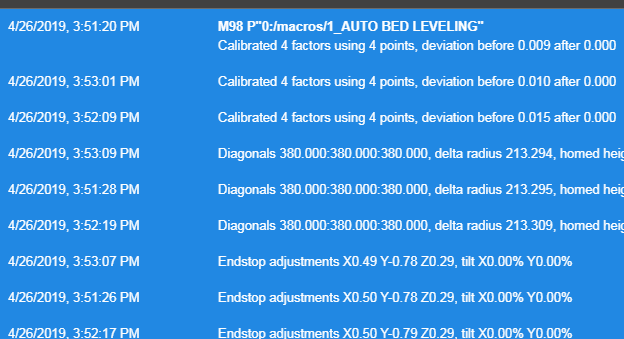

The console displays shown help us determine multiple (3X) G32 convergence when called from a macro. Console display are from M665 and M666 calls within the macro.

Under DWC 1.21 the posted results are rationally presented chronologically whereas in 2.0.0-RC6 the M665 and M666 results are separately grouped. Chronological display (1.21) is sensible making associating adjustments with convergence error easy,

Or did you make the change for a reason that is not obvious to me?

Best posts made by Ethelred

-

Irrational G-Code Console Orderingposted in Duet Web Control

-

RE: Hobby servo behaviorposted in Duet Hardware and wiring

I had purchased from Amazon (addicted, I fear) and was unaware of the Pololu info at that time. Amazon almost never has any reliable tech info and sometimes publishes downright lies.

So thanks - I've ordered 180 degree replacements (metal gear MG90S).

I had tested microsecond values but had just not included them in this post. I'll fill in the blanks when the new ones arrive. -

RE: M558 ignores quantity of probe hitsposted in General Discussion

Replacement probe arrived and installed. Works perfectly and converged at 0.003mm - good enough for government work. I must have somehow bumped or otherwise disturbed the optical alignment.

AND the good news is the latest I-R probes now have surface mount emitter/detector optics which are impossible to move out of alignment. Thanks DC42 or Tony or whoever. -

RE: Max file count errorposted in General Discussion

@Ethelred

Flashed an updated PanelDue binary and all is well - gadzooks, the previous version was pre-historic.

Thanks to all for the help. -

RE: Delta: Increase/Override bed radius?posted in Tuning and tweaking

@bearer Sorry, I think you are wrong. At least in latest firmware 2.05.1 the "P" parameter is functional ( Invoking via the S parameter does nothing ). My previous post's screenshot is directly from the console and I tested the command functionally and M564 P1 does indeed allow out of limit effector travel. Perhaps you are running an older firmware version.

Latest posts made by Ethelred

-

RE: Duet dementiaposted in General Discussion

Not so - M665H is the homing height distance from the bed in the case of a Delta printer.

Does no one think it just might be the Duet electronics? Are you monitoring this Mr. Crocker? -

RE: Duet dementiaposted in General Discussion

Same as original post.. To recap

The printer homes normally. Don't know if thehoming offset leaves the nozzle in the correct location (no way to measure that). If, for example I command a simple G1 X100 the nozzle scoots away in an approximately 45 deg angle for perhaps 80-100mm and the Z ht looks to drop perhaps 20mm. If I reverse with a G1 X-100 it appears to return to the original position. Crazy. -

RE: Duet dementiaposted in General Discussion

@Phaedrux New, fast, big SD same behavior. No tpre0.g tpost0.g files.

I'm thinking a controller board glitch. Initial fail followed a perfect print with NO changes whatsoever. My problem (one of many) is that I'm electronically and software challenged. I'm tempted to buy a new board or take up golf.

-

RE: Duet dementiaposted in General Discussion

@Phaedrux

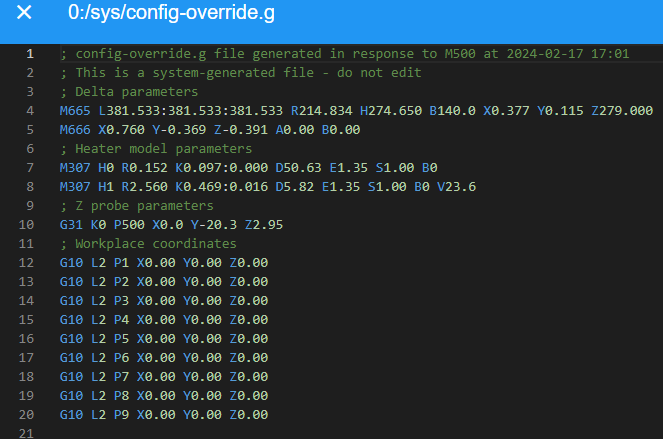

Config-overide. Sorry to be so unresponsive but what with cleaning out and moving house priorities get confused. Hopefully new SD tomorrow.

-

RE: Duet dementiaposted in General Discussion

SD on the way - What would one do without Amazon ?

I'm in the dark as to "open file count", it's impact , and what to and how to mitigate it.

-

RE: Duet dementiaposted in General Discussion

Changes made to config file as suggested and 3.5.1 update installed.

Strange behavior persists. !!! -

RE: Duet dementiaposted in General Discussion

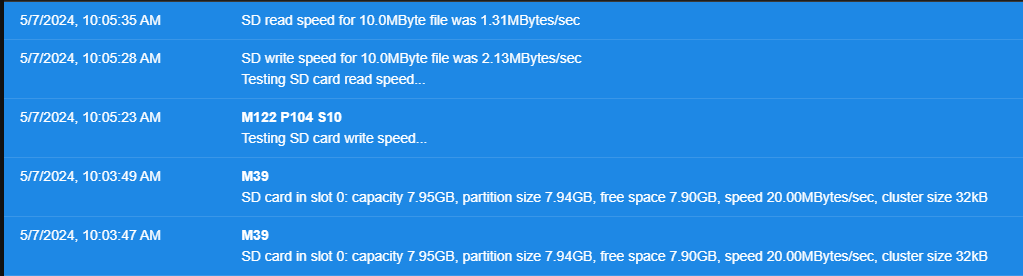

Reformatted old SD. Ethernet board. M122 and M39 appear ok to these old eyes.

console.txt

-

RE: Duet dementiaposted in General Discussion

No joy - SDformatter. Copied full system back and exact same behavior.

-

RE: Duet dementiaposted in General Discussion

Now as well, I'm unable to log onto the printer via the web interface. So I removed and read the SD card on the computer. Did a line-by-line visual compare of SD-config.g (below) with a same date backup copy on the computer. Exact match !

////////////////////////////////////////////////////////////////////////////////////////////////

; Configuration file for Duet WiFi (firmware version 3.4)

; executed by the firmware on start-up

;

; EDITED RAB 02/22/2024 // Chg ExtFeed to P4 was P3 // Deleted PurgeMotor //; General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

; M550 P ; set printer name

M665 R212.69 L380 B135 H278.937 ; Set R=delta radius, L=diagonal rod length, B-printable radius and H-homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

M550 P# FOLLY ; Set machine name

; M551 P ; Set password

M540 PBE:EF:DE:AD:FE:ED ; Set MAC address

M552 S1

; M552 P"0.10.0.0.173" ; Enable network and acquire dynamic address via DHCP

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P4 S0 ; physical drive 4 goes backwards

M584 X0 Y1 Z2 E4 ; set drive mapping (WAS E3)

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z160.00 E509.93 ; set steps per mm

M566 X750.00 Y750.00 Z750.00 E2000 ; set max instant speed chg (mm/min) chg 09/09 was 600XYZ

M203 X30000.00 Y30000.00 Z30000.00 E9000.00 ; set maximum speeds (mm/min)

M201 X2836.33 Y2836.33 Z2836.33 E3000.00 ; set accelerations (mm/s^2)

;

; Input Shaping

; M955 P0 C"spi.cs4+spi.cs3" ; Accelerometer

M593 P"ZVD" F36 ; Input shaping / Frequency

;

M572 D0 S0.055 ; SET PRESSURE ADVANCE

M906 X1200 Y1200 Z1200 E1000 I50 ; set motor currents (mA) and motor idle factor in per cent

M84 S2 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; set minimum Z; Endstops

M574 X2 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop

M666 X0.29 Y-0.46 Z0.17 ; Endstop offset; Z-Probe

M558 P1 C"zprobe.in" H3.5 A5 S0.01 R1 F120 T4500 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y-20.3 Z2.92 ; set Z probe trigger value, offset and trigger height

M557 R130 S50 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 A"BED H0" ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat

M307 H0 R0.146 K0.089:0.000 D29.12 E1.35 S1.00 B0 ; Set PID for 100C HPB Heater

M140 H0 ; map heated bed to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130CM308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 A"E0 heater" ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.497 K0.440:0.000 D7.74 E1.35 S1.00 B0 V23.9 ; H1 Extruder PID parameters // 230 (NOTE - FUSED @ 165C)

M143 H1 S286 ; Set MAXIMUM OVERSHOOT TEMP limit for H-1 WORKING TEMP = 280C w; Fans

M950 F0 C"fan0" Q250 ; PARTFAN on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off; Tools

M563 P0 S"EXTRUDER" D0 H1 ; define tool 0 Extruder heater

M563 P1 S"EXTRUDER" D0 H1 ; define tool 1 Extruder heater (Added 06-23 for dual filament extrusion)

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active >>>> was P99; Miscellaneous

M501 ; load saved parameters from non-volatile memory

T0 ; select first tool -

Duet dementiaposted in General Discussion

Upon starting a print on my Duet 2 delta the nozzle crashed into the bed - violently. It had been printing perfectly and no adjustments of any kind were made. Trouble shooting homed correctly. Using the PanelDue move screen Zup/down was perfect. However, commanding a +X100mm move caused a large move to (estimate) X85 Y30 Z30. Other moves similarly goofy. Steppers and pulleys rock solid - belts tight etc etc. Any ideas?