Unable to set up a servo pin for BLTouch

When attempting to set up a BLtouch (genuine) for the first time I followed the BlTouch guided install PDF. The directions are clear and foolproof. However my system does not like the M950 command and returns the error message "Error in macro line 45 while starting up: exactly one of EFHJPSR must be given". Line 45 corresponds to M950 S0 C"exp.heater3"

I've tried variations of the M950 command by mapping other available heater pin names on the expansion header and the result is always the same error.

And here I'm stuck. Any suggestions?

Steve Graber

Config.g

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Cerberus400_1" ; set printer name

M665 R220.7 L454.9876 B180 H334 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 goes backwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E4 ; set drive mapping

M350 X32 Y32 Z32 I0 ; configure microstepping without interpolation

M350 E16 I0 ; configure microstepping with no interpolation

M92 X160.00 Y160.00 Z160.00 E2725.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E40.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E3000.00 ; set maximum speeds (mm/min)

M201 X1700.00 Y1700.00 Z1700.00 E120.00 ; set accelerations (mm/s^2)

M906 X1100 Y1100 Z1100 E550 I40 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 Z0 S1 ; set minimum Z

; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop

; BLTouch

M558 P9 C"^zprobe.in" H5 F100 T2000

M950 S0 C”exp.heater3”

G31 X0 Y-37 Z3.3 P25

M557 R150 S25

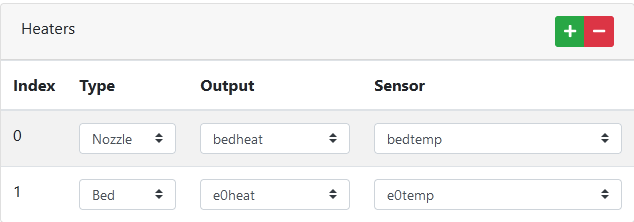

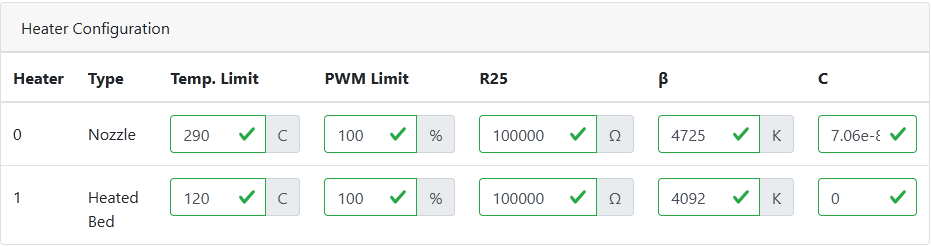

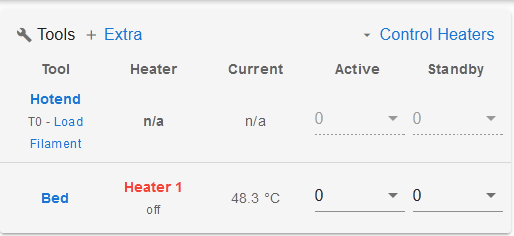

; Heaters

M308 S0 P"e0temp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin e0temp

M950 H0 C"e0heat" T0 ; create bed heater output on e0heat and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin bedtemp

M950 H1 C"bedheat" T1 ; create nozzle heater output on bedheat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M950 F1 C"fan0" Q25000 ; create fan 0 on pin fan0 and set its frequency

M106 P1 S0 H1 B.3 T45 ; set fan 0 value. Thermostatic control is turned on

M950 F0 C"fan1" Q25000 ; create fan 1 on pin fan1 and set its frequency

M106 P0 S0 H-1 ; set fan 1 value. Thermostatic control is turned off

; Tools

M563 P0 S"Hotend" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S11 R12 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.5.1 (2024-04-19 14:40:46) running on Duet WiFi 1.02 or later

Board ID: 08DGM-917NK-F2MS4-7JTDL-3S46N-TDSND

Used output buffers: 3 of 26 (14 max)

Error in macro line 45 while starting up: exactly one of EFHJPSR must be given

=== RTOS ===

Static ram: 23256

Dynamic ram: 72180 of which 0 recycled

Never used RAM 14852, free system stack 184 words

Tasks: NETWORK(1,ready,15.0%,220) HEAT(3,nWait 5,0.0%,328) Move(4,nWait 5,0.0%,359) MAIN(1,running,84.8%,761) IDLE(0,ready,0.1%,29), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:16:18 ago, cause: software

Last software reset at 2024-05-10 13:39, reason: User, Gcodes spinning, available RAM 14876, slot 1

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

MCU temperature: min 32.7, current 33.2, max 34.2

Supply voltage: min 11.9, current 12.0, max 12.2, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/48/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min n/a

Driver 1: standstill, SG min n/a

Driver 2: standstill, SG min n/a

Driver 3: standstill, SG min n/a

Driver 4: standstill, SG min n/a

Driver 5:

Driver 6:

Driver 7:

Driver 8:

Driver 9:

Driver 10:

Driver 11:

Date/time: 2024-05-10 13:56:08

Cache data hit count 4294967295

Slowest loop: 9.51ms; fastest: 0.18ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 0.8ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 0, maxWait 0ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00

no step interrupt scheduled

Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0

=== DDARing 0 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Movement locks held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Q0 segments left 0

Code queue 0 is empty

=== Network ===

Slowest loop: 9.45ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0)

HTTP sessions: 1 of 8

=== WiFi ===

Interface state: active

Module is connected to access point

Failed messages: pending 0, notrdy 0, noresp 0

Firmware version 2.1.0

MAC address 60:01:94:2e:c7:08

Module reset reason: Turned on by main processor, Vcc 3.39, flash size 4194304, free heap 42784

WiFi IP address 10.1.1.117

Signal strength -71dBm, channel 11, mode 802.11n, reconnections 0

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

No worries. I'm just happy to get it working and to move on to my next issue, which is to figure out exactly how many steps/mm this big stepper puppy needs and what the actual mix ratio is supposed to be. The Cerambot documentation is thin, to put it kindly.

No worries. I'm just happy to get it working and to move on to my next issue, which is to figure out exactly how many steps/mm this big stepper puppy needs and what the actual mix ratio is supposed to be. The Cerambot documentation is thin, to put it kindly.