Thanks @droftarts so i will use manuel Bed Levelling Assistant.

Posts made by gringo

-

RE: CoreXZ X-Gantry levelingposted in General Discussion

-

CoreXZ X-Gantry levelingposted in General Discussion

Hello everyone,

Is it possible to automatically level the X gantry on a CoreXZ (Voron Switchwire)?

Like with a CoreXY with 3 Z motors, for example. -

RE: OrcaSlicer 1.9.0 adds codes that breaks printer.posted in Third-party software

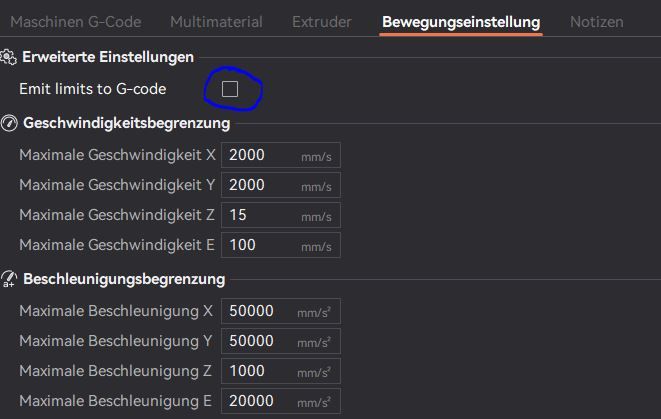

There is a switch at the printer preferences page.

Search the side where you can set the speed and acc limits.

You can choose if orca slicer put them to the G_Code or not.

I had the same Problem and it took a while to check what happened.

-

RE: No access to the Printerposted in General Discussion

Checked it today.

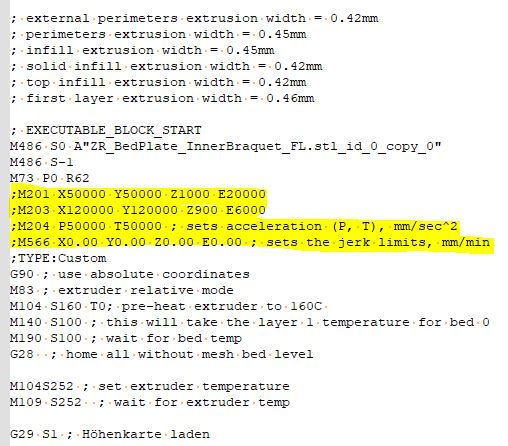

OrcaSlicer 1.9.0 edited some Rows in the G-Code, after I commented it out it works.

-

RE: No access to the Printerposted in General Discussion

Using OrcaSlicer 1.9.0 and testet PrusaSlicer 2.7.1.

There is no difference between both.

I’m thinking if PA or IS reduces the print speed, but i don't changed anything.. -

RE: No access to the Printerposted in General Discussion

Erased the Firmware and flashed it with BOSSA again.

Printer runs.But the other Problem is still there.

The Printer prints too slow. Fast moves are ok.It looks to me as if the acceleration is no longer correct when printing.

The rapid traverse is accelerated correctly and also driven quickly. -

No access to the Printerposted in General Discussion

Hello everyone,

After 3 weeks I have started up my printer again and I have noticed that it no longer prints correctly.

If I don't print and move the axes, the movements are carried out with the set accelerations and speeds.

When printing, the printer does not reach the set accelerations and speeds.

First layer should be 70mm/s and it prints at 4mm/s. It looks as if the acceleration values suddenly no longer fit, because you can see how it accelerates and requires a greater distance to do so.I have not adjusted anything on the printer or the slicer. I have only updated OrcaSlicer to 1.9.0.

I then wanted to update the firmware from 3.5.0RC1 to 3.5.0RC2 and now have no access to the printer at all. No IP or temperature is displayed on the PanelDue and I can't see the interface in the browser.

The data is available on the SD card.

However, access is not possible.I’m using Duet 3 6HC

I am extremely annoyed.

How can I access the printer again?

Thanks for your help

-

RE: Duet3 6HC with Goliath Hotend PT1000 temperature too hotposted in General Discussion

Thanks for the correction, I had mistyped.

In the post above it should read 30 and not 20 degrees.I have 30 degrees difference with the Extrudr GreenTEC Pro.

50 degrees and more with the CR3D ABS FibCR20.That was misleadingly expressed by me

I tested 2 PT1000. With both the same.

I think I will buy a 2K Ohms and a 1K ohms resistor for testing.

-

RE: Duet3 6HC with Goliath Hotend PT1000 temperature too hotposted in General Discussion

The temperature range for the CR3D ABS FibCR20 is between 240-260 degrees, I now print at 190 degrees.

There is something wrong.Unfortunately I don't have any resistore here with which I can test this

-

RE: Duet3 6HC with Goliath Hotend PT1000 temperature too hotposted in General Discussion

The temperatures are not correct even after calibration. I print a technical filament 30 degrees colder than specified.

M308 S1 P"temp1" Y"pt1000" A"HotEnd" ; configure sensor 1 as PT1000 on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 R5.509 K0.341:0.695 D3.11 E1.35 S0.70 B0 V23.9 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C -

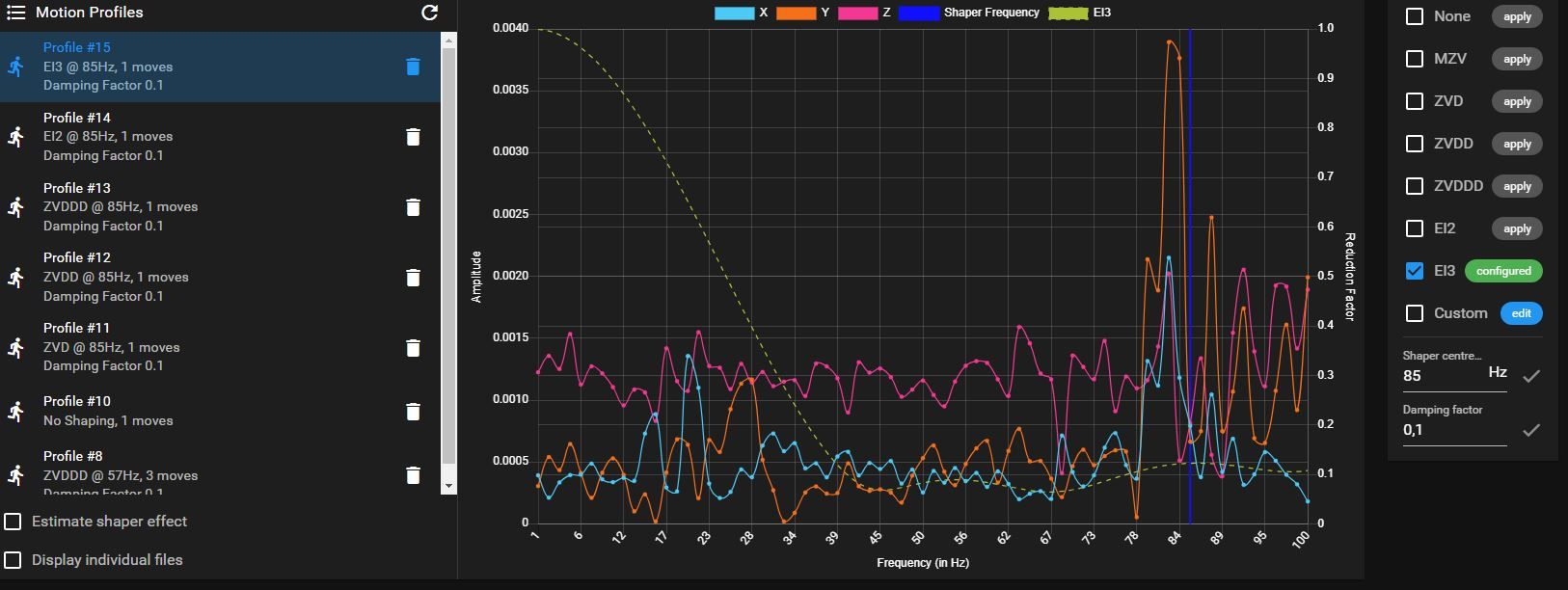

RE: Input Shaping evaluation help neededposted in General Discussion

Thank you for the execution,

I have two other printers with Duet Boards where I print slower and with much less acceleration.

I have not tested Klipper yet, but I am planning to build the next printer and run it with Klipper to have a comparison.

I printed the VZ Cupe at 100mm/s with 5K ACC of the outer perimeter.

Reducing the acceleration of the outer perimeter to 2K at 100mm/s has brought significant improvement.In my opinion, I should also be able to select the speed and acceleration in the selection window for Input Shaper as the frequencies change at different speeds and accelerations.

-

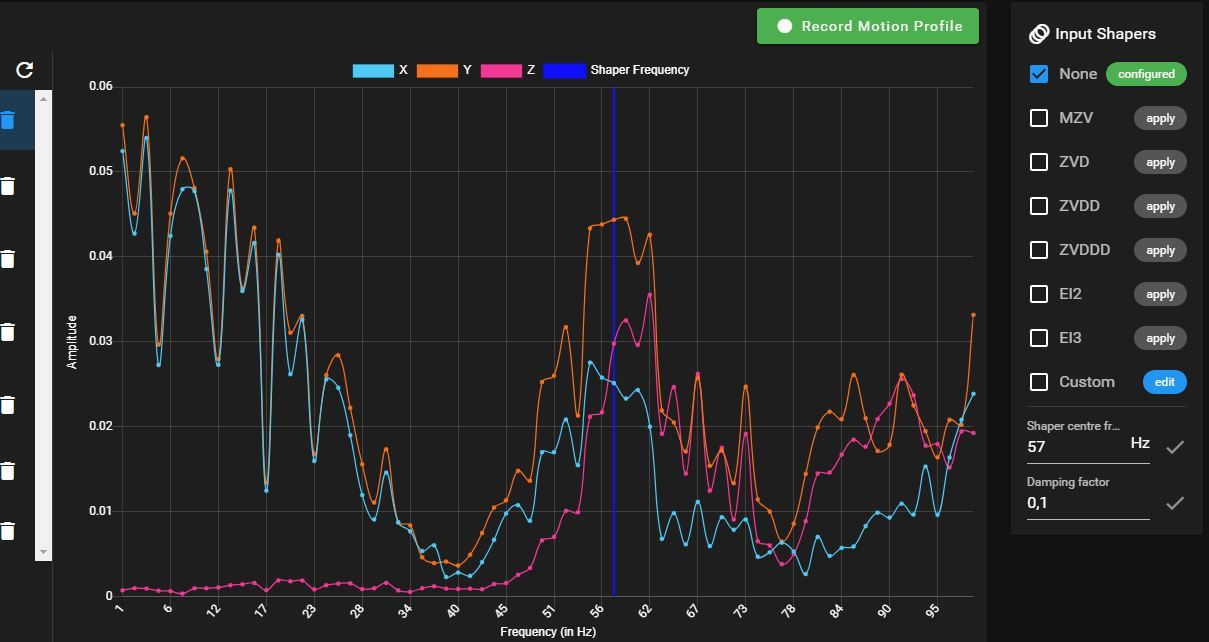

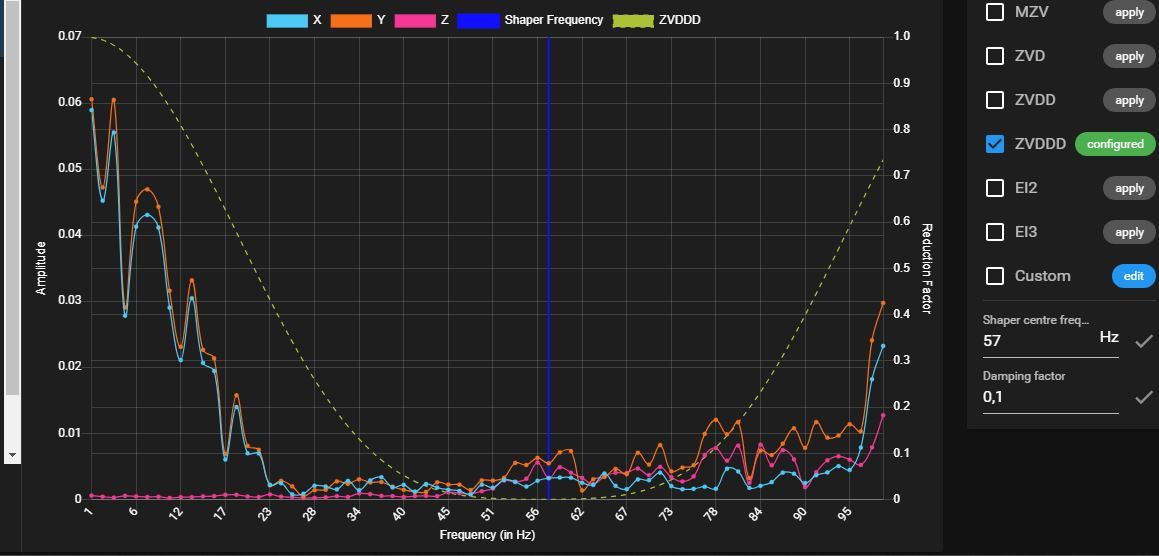

RE: Input Shaping evaluation help neededposted in General Discussion

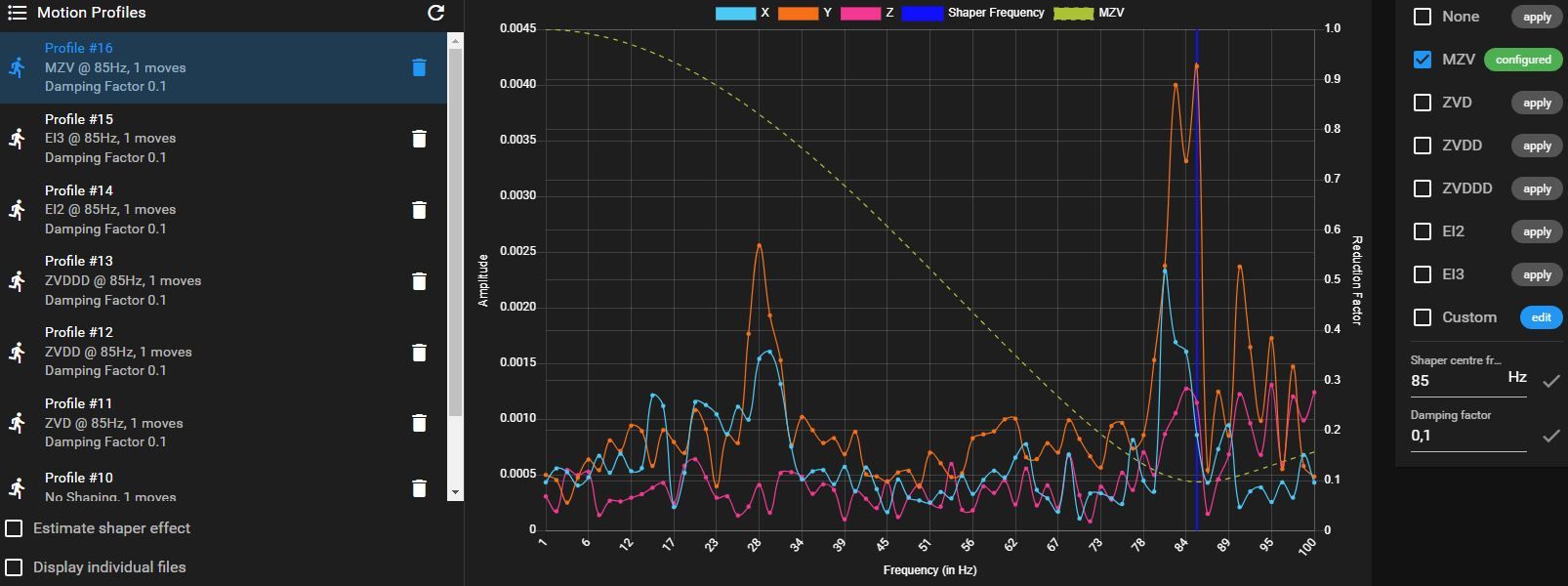

Here is a photo from a actual print.

Tested different Shaper, started with ei2@56Hz --> zvddd@57Hz --> zvddd@80Hz.I can´t see any difference.

-

RE: Input Shaping evaluation help neededposted in General Discussion

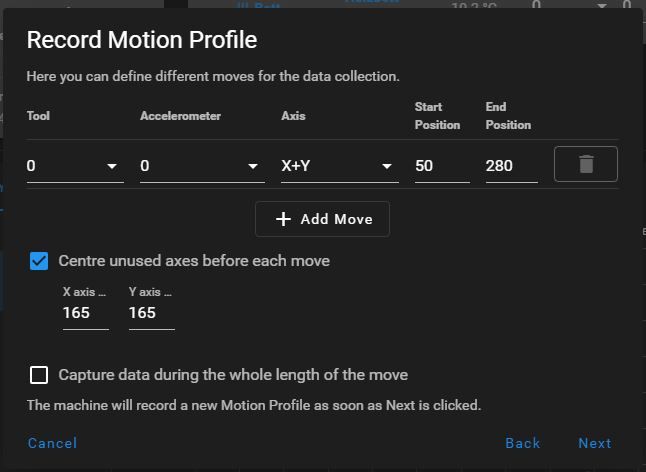

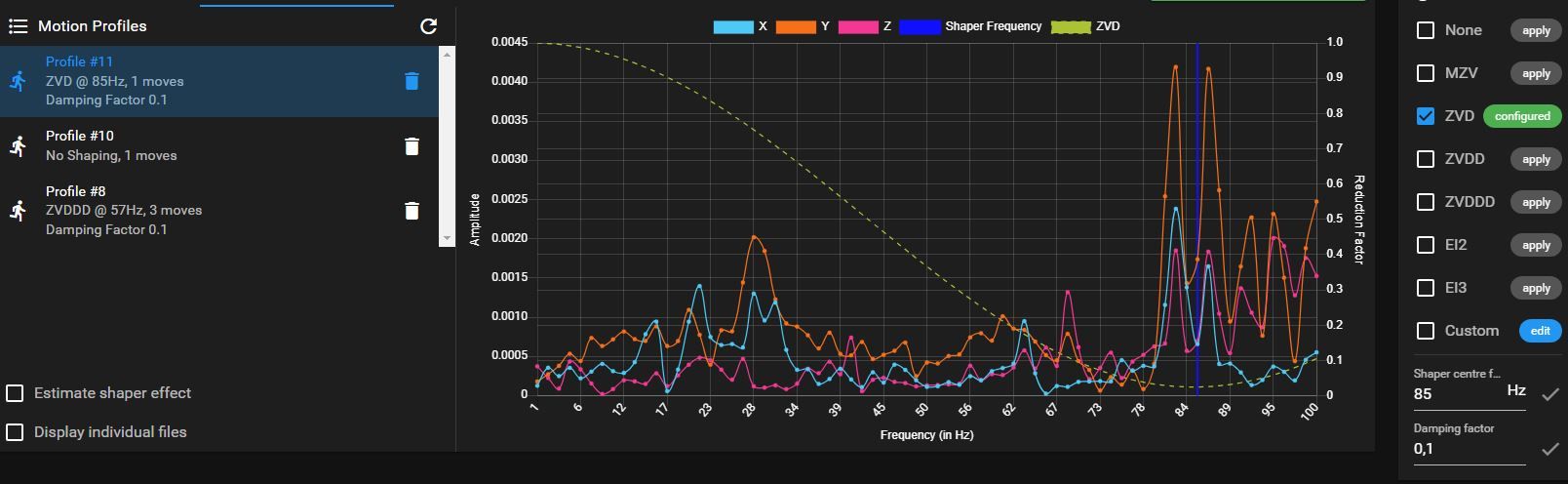

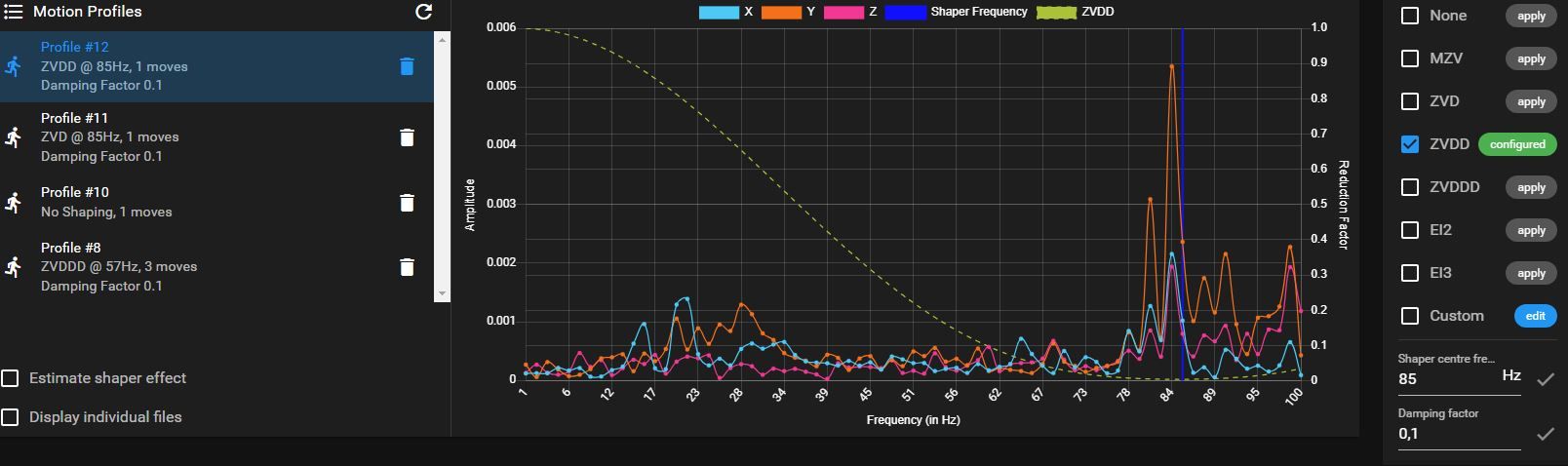

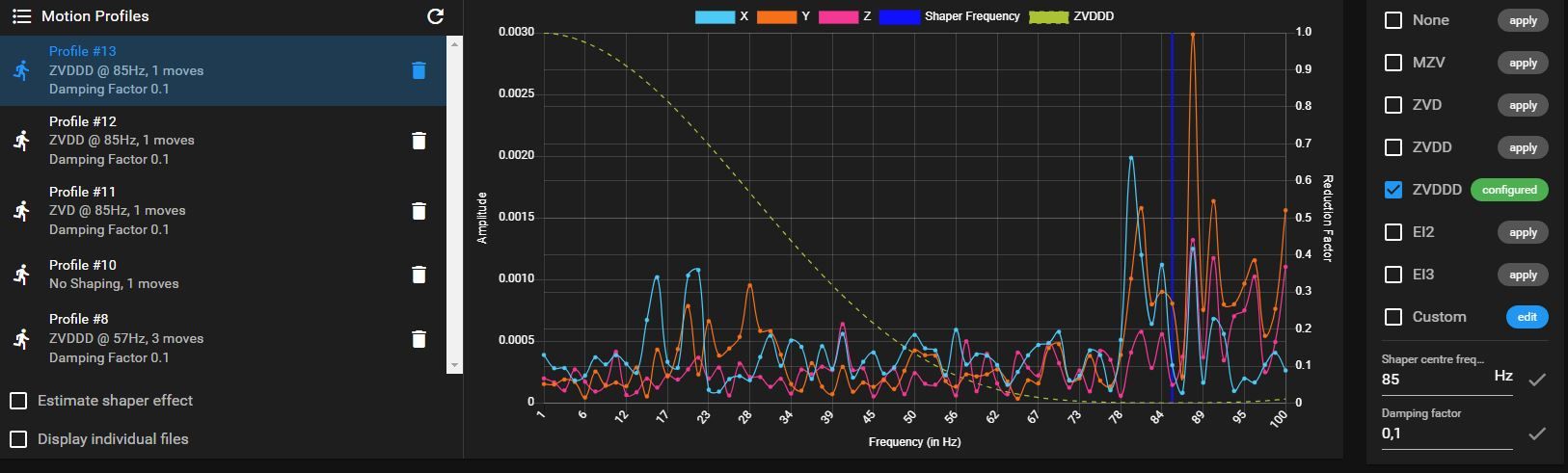

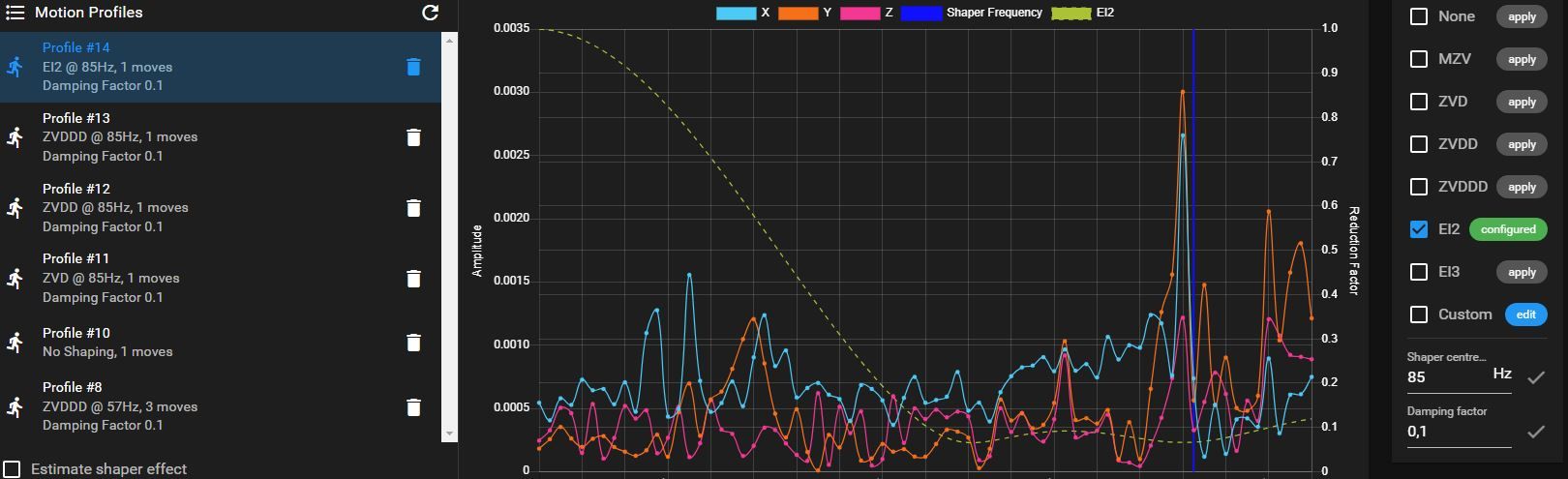

Here are the next measurements

What now? I don't know what to set.

-

RE: Input Shaping evaluation help neededposted in General Discussion

thanks, I will try it and post the results.

But which speeds and accelerations are used for Input Shaping?

-

RE: Input Shaping evaluation help neededposted in General Discussion

I have another question.

Where can I adjust speeds and acceleration for Input Shaping?

Imthink different speeds and accelerations needs different Input Shaper frequencies. -

Input Shaping evaluation help neededposted in General Discussion

Hey there,

Can someone explain to me which input shaper I should use and how I can get rid of the frequencies below 30Hz.

Or do I have a mechanical problem?

Thanks all

-

RE: Duet3 6HC with Goliath Hotend PT1000 temperature too hotposted in General Discussion

Thanks @dc42

Made a Calibration and will test it now.

Thats the results2.11.2023, 16:08:51 M308 S1 H999

Measured H correction for port "temp1" is 32.11.2023, 16:09:07 M308 S1 L999

Measured L correction for port "temp1" is 1 -

Duet3 6HC with Goliath Hotend PT1000 temperature too hotposted in General Discussion

Hello friends,

I built a VZBOT and use the Goliath hotend. I'm currently doing my first prints and have found that I have to set the temperature of the filament (Extrudr Greentec Pro) 30°C lower than on my other printers. I don't know what the problem is or whether it's just the long melting zone.

Do you have an idea?

When the printer is cold, the bed temperature and hotend are the same.

Bed 19.8°C

Hotend 20.3°C -

RE: No accelerometer found!posted in Duet Hardware and wiring

It works. My fault. Thanks @demonio669