Well no one could tell me how to just drive a specific stepper output...

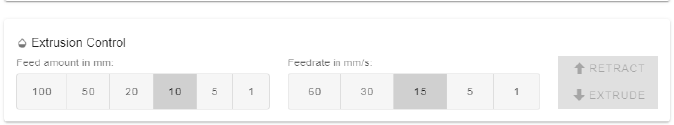

So, I decided to simply de-allocate three of the Z motors at a time in the M584 line of the config.g and do a Z move of the remaining one after an M564 H0 to allow un-homed movements. SMALL moves!

Doing that I could see which of the 4 Z motors was actually moving as compared to which one I thought should be moving.

Turned out instead of:

; --- drive map ---

; _______

; | 3 | 4 |

; | ----- |

; | 2 | 5 |

; -------

; FRONT

I actually had:

; --- drive map ---

; _______

; | 5 | 4 |

; | ----- |

; | 2 | 3 |

; -------

; FRONT

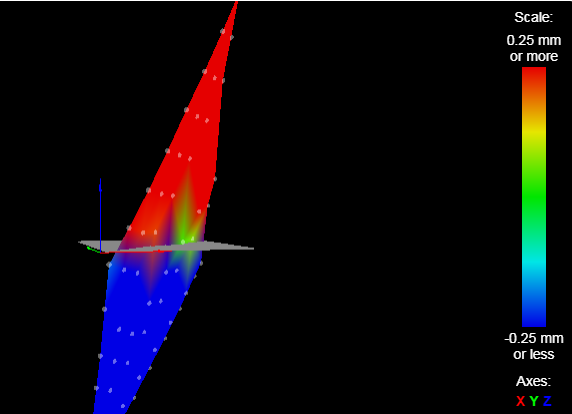

Which utterly screwed up everything causing the incrementing LR corner error and decrementing RF corner error with each G32 command. The errors even accelerated as with each subsequent G32 the error was greater demanding greater yet miscorrections

I'd traced all the cables manually but accidentally swapped those two even writing which Z motor they were(n't) on the cables.

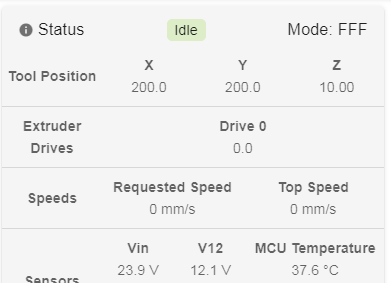

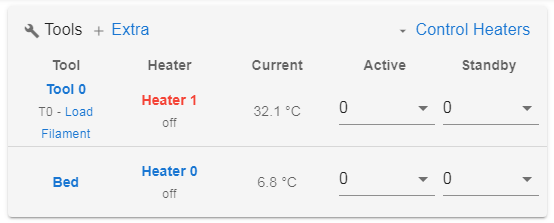

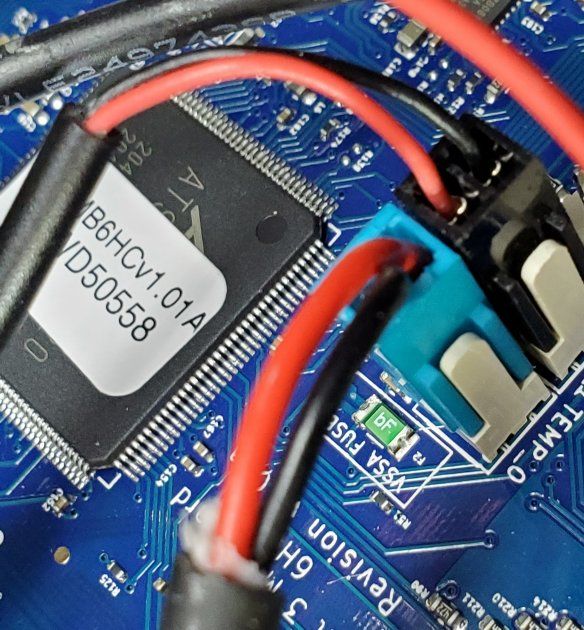

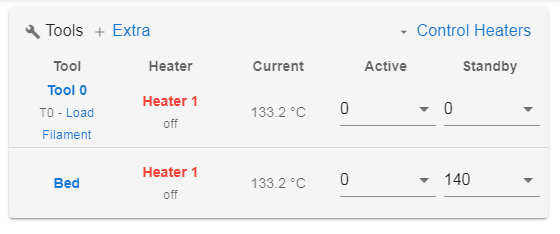

I swapped those two on the 6HC and then ran HOME ALL and then consecutive G32s.

12/28/2021, 3:06:34 AM G32

Leadscrew adjustments made: -0.757 -0.154 1.087 -1.036, points used 4, (mean, deviation) before (0.024, 0.619) after (-0.000, 0.000)

12/28/2021, 3:07:28 AM G32

Leadscrew adjustments made: 0.099 0.146 0.462 0.296, points used 4, (mean, deviation) before (0.286, 0.104) after (-0.000, 0.000)

12/28/2021, 3:08:30 AM G32

Leadscrew adjustments made: 0.015 0.026 0.055 0.039, points used 4, (mean, deviation) before (0.038, 0.011) after (-0.000, 0.000)

12/28/2021, 3:21:13 AM G32

Leadscrew adjustments made: 0.007 0.005 0.006 0.006, points used 4, (mean, deviation) before (0.006, 0.001) after (0.000, 0.000)

Dang, what a struggle that was.

I do like the results! I appreciate only 0.0003" errors!!

So the lesson with 4 Z motors is this:

If, with repeated G32 (bed.g) runs any one corner increases its error positively while any other corner simultaneously has an increasingly negative error electrically swap those two corner's Z motors.

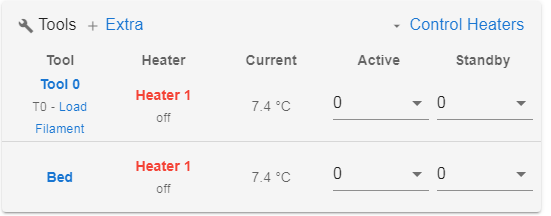

image url)

image url) image url)

image url) image url)

image url) image url)

image url) image url)

image url)