@fcwilt what i was hoping for was that i could put the locations of my belts in have it touch of near the belts do some calculations and be square, thats it. But now that i know that this is not possible i will try something else, but i still think that a function like this could be very usefull.

Posts made by Killernoy

-

RE: Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

-

RE: Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

@fcwilt i will put them on the print head but this post was not about discussing where i want to put my endstops but to discuss options for compensative homing like the g30 for multiple leadscrews.

-

RE: Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

@fcwilt they are at the bottom of the corner pieces and are activated with a foot on the carriage and the entiere homing system is about 25mm high -

RE: Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

@dc42 i currently have dual enstop mounts but want to have the mounts on the pint head in order to shorten the xy-motion systen by about 20mm in the z direction. -

RE: Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

@phaedrux That is not the point, the unalignment is unknown which is why i want to do the resquaring every time i home the machine and the easiest way to do that is to measuare the points and after that to adjust for the difference which is what the g30 comand does.

-

RE: Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

@phaedrux exactly. i would love to have the points predefined so that the board can calculate the corection needed. Is that possible or would i have to do some remapping trikery to make the printer think the x axis is a z axis with two leadscrews and then do the same for y?

-

RE: Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

@jay_s_uk said in Dual x and y homing similar to g30 for multiple z screws:

@killernoy you could, in which case you just map them together in M584 and you're done.

Would there not be any issue of both motors getting out of sync?

yes, as i am building it unaligned the tention on the rods connecting the carriages with the print head will pull it back into misalignment.

-

RE: Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

@jay_s_uk what im thinking about is one end stop for both motors like a z probe for multiple z axis

-

Dual x and y homing similar to g30 for multiple z screwsposted in General Discussion

I would like to have my machine home the x and y axis similar to my z axis which is homed like described here https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors

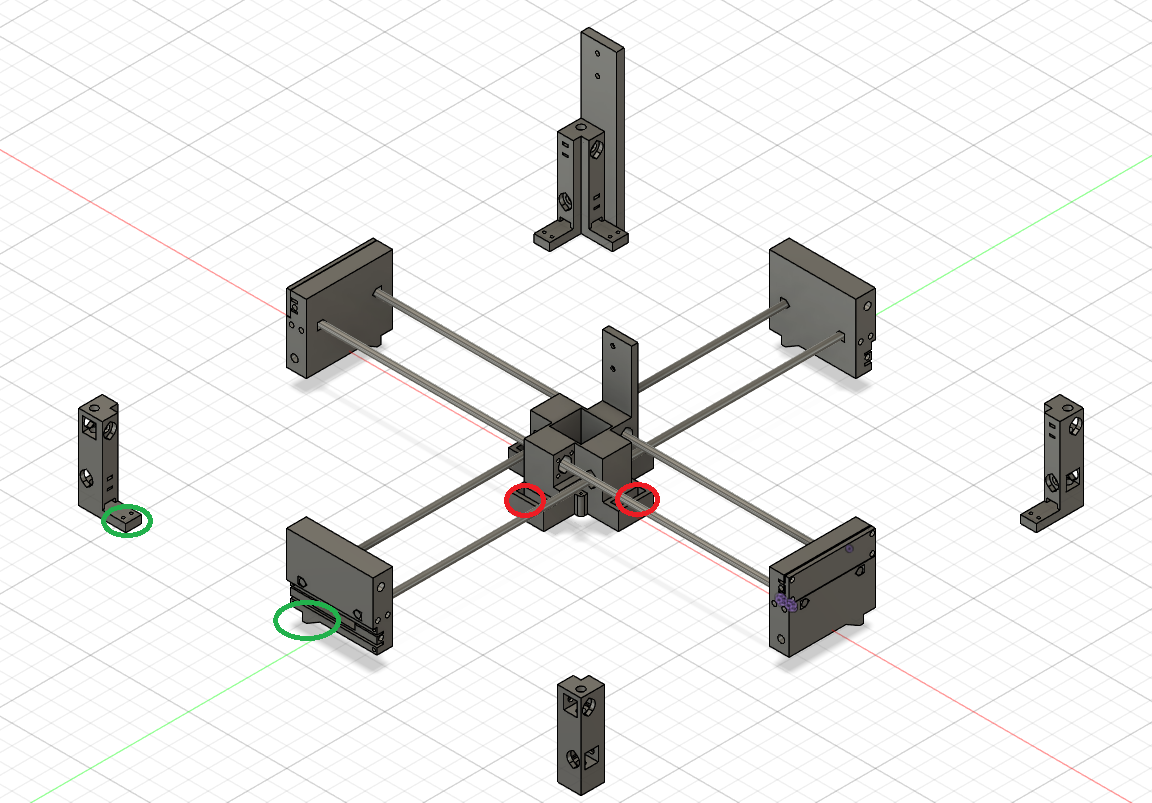

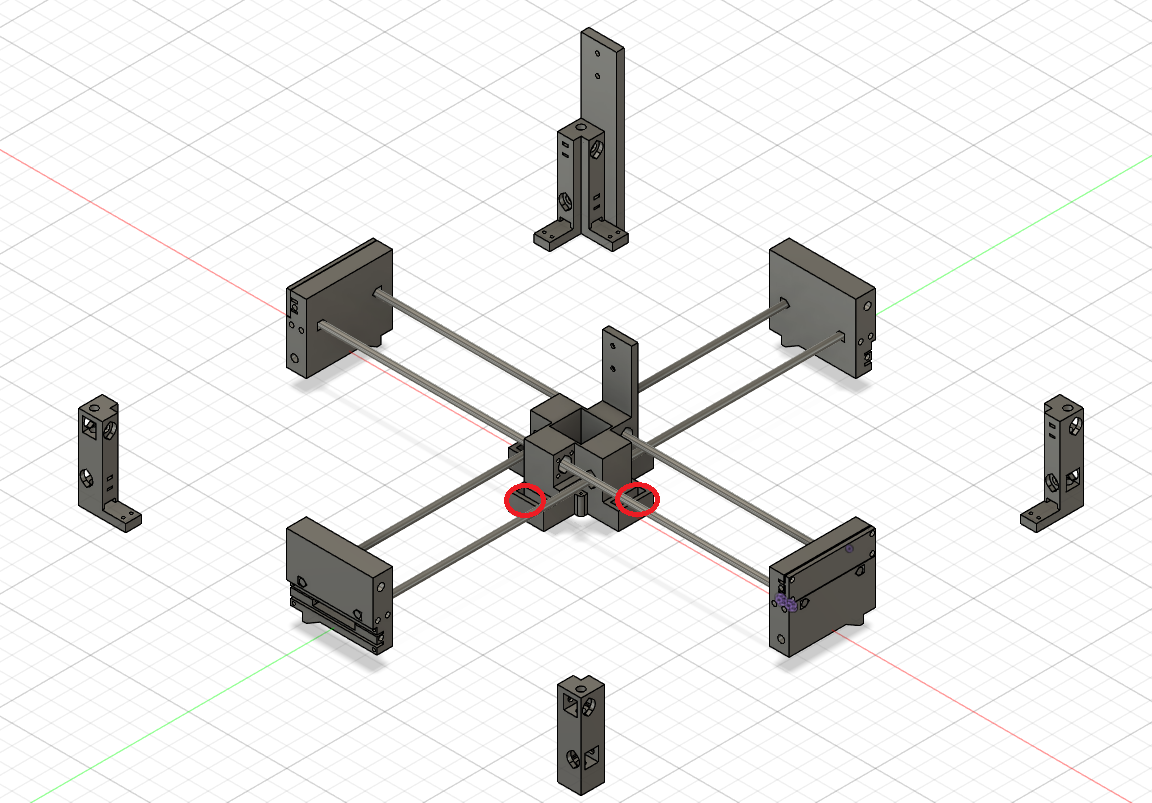

I have a design similar to the ultimaker machines but with independent motors on each side, that makes it possible to put two endstops on the printhead and home against the x and y carriages.

So my question is if this is possible or if i would have to home in the middle, split up the x axis, home again on each far end and then combine the axis again. -

How to remove Sensor not ready errorposted in Tuning and tweaking

I want setup a Dummy heater so I Put this in to Config.g:

M308 S5 P"duex.e4temp" Y"thermistor" T100000 B4138 ; configure sensor 5 as thermistor on pin duex.e4temp M950 H5 C"e6heat" T5 ; create Dummy heater and map it to sensor 4I Tested Sensor 5 using M308 S5 and got this

M308 S5 Sensor 5 type Thermistor using pin (e4temp,duex.e4temp,exp.thermistor5,exp.37), reading 40.5, last error: sensor not ready, T:100000.0 B:4138.0 C:0.00e+0 R:4700.0 L:0 H:0Now I want to know how I remove This Error

-

RE: Dual Thermistor setupposted in Duet Hardware and wiring

I have also Tested this

M308 S5

Sensor 5 type Thermistor using pin (e4temp,duex.e4temp,exp.thermistor5,exp.37), reading 40.5, last error: sensor not ready, T:100000.0 B:4138.0 C:0.00e+0 R:4700.0 L:0 H:0 -

RE: Dual Thermistor setupposted in Duet Hardware and wiring

@dc42 I have added this to my config.g but the temperature of the dummy heater is not showing up neither in the web control nor thru M105

M308 S5 P"duex.e4temp" Y"thermistor" T100000 B4138 ; configure sensor 5 as thermistor on pin duex.e4temp

M950 H5 C"e6heat" T5 ; create Dummy heater and map it to sensor 4 -

RE: Mesh bed compensation with E3D Krakenposted in General Discussion

@T3P3Tony I think I've read your article about the Kraken when I first looked into buying one.

So no mesh bed compensation for me then.

Thanks again for the help. -

RE: why did my Printer melt?posted in Tuning and tweaking

I´m now set up with the config from the Tool, but the E6 LED is still lit up is this because i have my BLTouch on PWM5?

-

RE: Mesh bed compensation with E3D Krakenposted in General Discussion

@Phaedrux Ok I will let it generate a detailed Grid map from time to time to check if everything is all right

-

RE: Mesh bed compensation with E3D Krakenposted in General Discussion

The bed should be mostly Flat I´m using a machined Aluminium Plate with 4 Leadscrews (Yes, I know it´s over constraint but i didn´t when I ordered it) and the true Z alignment enabled (https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors)

-

Mesh bed compensation with E3D Krakenposted in General Discussion

Can I Use Mesh bed compensation with my E3D Kraken or would the other 3 Nozels rip my print of while the active one follows the Grid?

-

RE: Dual Thermistor setupposted in Duet Hardware and wiring

@dc42 said in Dual Thermistor setup:

I haven't tried it, but I think you could do it with RRF3. Configure the heater and sensor 1 as normal. Configure a dummy heater using sensor 2. Something like this:

M308 S0 <sensor 0 parameters>

M308 S1 <sensor 1 parameters>

M950 H0 C"bedheat" T0 ; the real bed heater

M950 H1 C"e6heat" T1 ; the dummy bed heater

M140 H0:1

M140 S80:0

M116

M140 S80:70

M116

M140 S70:70

M116This won't work if T2 reaches X before T1 reaches X+10.

Since I had that accident were my Hotend melted(https://forum.duet3d.com/topic/13380/why-did-my-printer-melt), I want to get this right:

Does e6heat = !duex.e6heat

or e6heat = !duex.e5heat

or neither of the above? -

RE: why did my Printer melt?posted in Tuning and tweaking

I´m going through the configuration tool in order to avoid any further Problems

Thanks again to everyone that gave me advise for software.