@droftarts

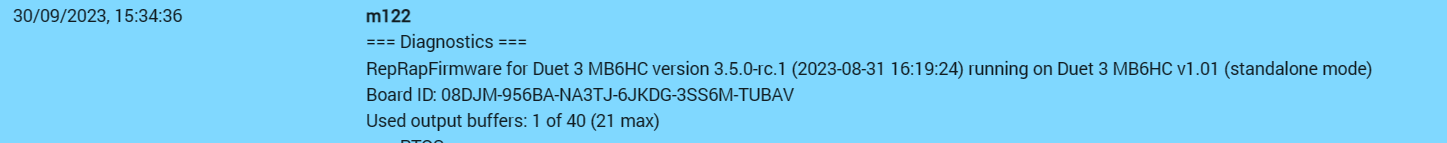

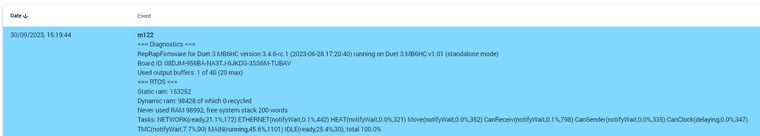

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.5.0-rc.1 (2023-08-31 16:19:24) running on Duet 3 MB6HC v1.01 (standalone mode)

Board ID: 08DJM-956BA-NA3TJ-6JKDG-3SS6M-TUBAV

Used output buffers: 3 of 40 (22 max)

=== RTOS ===

Static ram: 154852

Dynamic ram: 122464 of which 0 recycled

Never used RAM 65676, free system stack 148 words

Tasks: NETWORK(1,ready,38.4%,155) ETHERNET(5,nWait,0.1%,319) HEAT(3,nWait,0.0%,325) Move(4,nWait,0.0%,216) CanReceiv(6,nWait,0.2%,794) CanSender(5,nWait,0.0%,330) CanClock(7,delaying,0.0%,349) TMC(4,nWait,8.3%,59) MAIN(1,running,52.9%,444) IDLE(0,ready,0.0%,30), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:10:41 ago, cause: power up

Last software reset at 2023-12-04 17:11, reason: User, Gcodes spinning, available RAM 65652, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

MCU temperature: min 18.5, current 29.4, max 29.4

Supply voltage: min 24.1, current 24.1, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.0, current 12.0, max 12.1, under voltage events: 0

Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/4/4, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min n/a, mspos 8, reads 13165, writes 11 timeouts 0

Driver 1: standstill, SG min n/a, mspos 8, reads 13166, writes 11 timeouts 0

Driver 2: standstill, SG min n/a, mspos 8, reads 13166, writes 11 timeouts 0

Driver 3: standstill, SG min n/a, mspos 8, reads 13166, writes 11 timeouts 0

Driver 4: standstill, SG min n/a, mspos 8, reads 13166, writes 11 timeouts 0

Driver 5: standstill, SG min n/a, mspos 8, reads 13166, writes 11 timeouts 0

Date/time: 2023-12-04 17:30:53

Slowest loop: 13.67ms; fastest: 0.08ms

=== Storage ===

Free file entries: 20

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 2.9ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, segments created 6, maxWait 545988ms, bed compensation in use: none, height map offset 0.000, ebfmin 0.00, ebfmax 0.00

no step interrupt scheduled

Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0

=== DDARing 0 ===

Scheduled moves 17, completed 17, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 1], CDDA state -1

=== DDARing 1 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Movement locks held by null, null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

Q0 segments left 0, axes/extruders owned 0x0000001

Code queue 0 is empty

Q1 segments left 0, axes/extruders owned 0x0000000

Code queue 1 is empty

=== CAN ===

Messages queued 5953, received 107668, lost 0, boc 0

Longest wait 13ms for reply type 6018, peak Tx sync delay 101, free buffers 50 (min 48), ts 3209/3208/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 13.02ms; fastest: 0.03ms

Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 1 of 8

= Ethernet =

Interface state: active

Error counts: 0 0 0 1 0 0

Socket states: 5 2 2 2 2 0 0 0

=== Multicast handler ===

Responder is inactive, messages received 0, responses 0