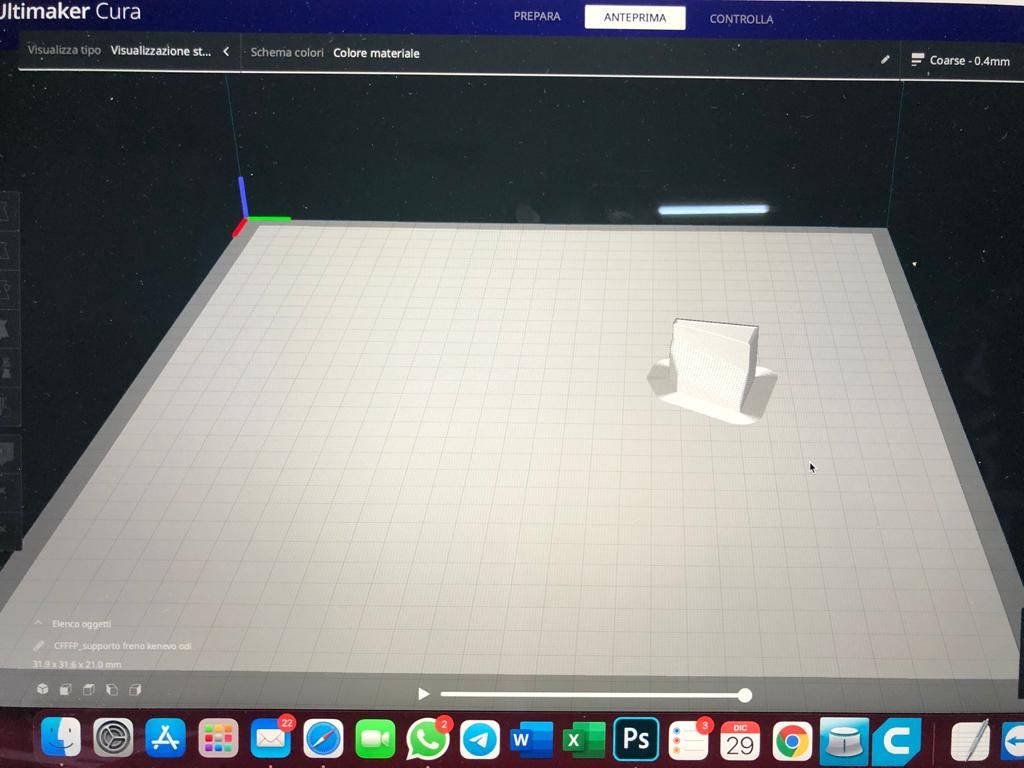

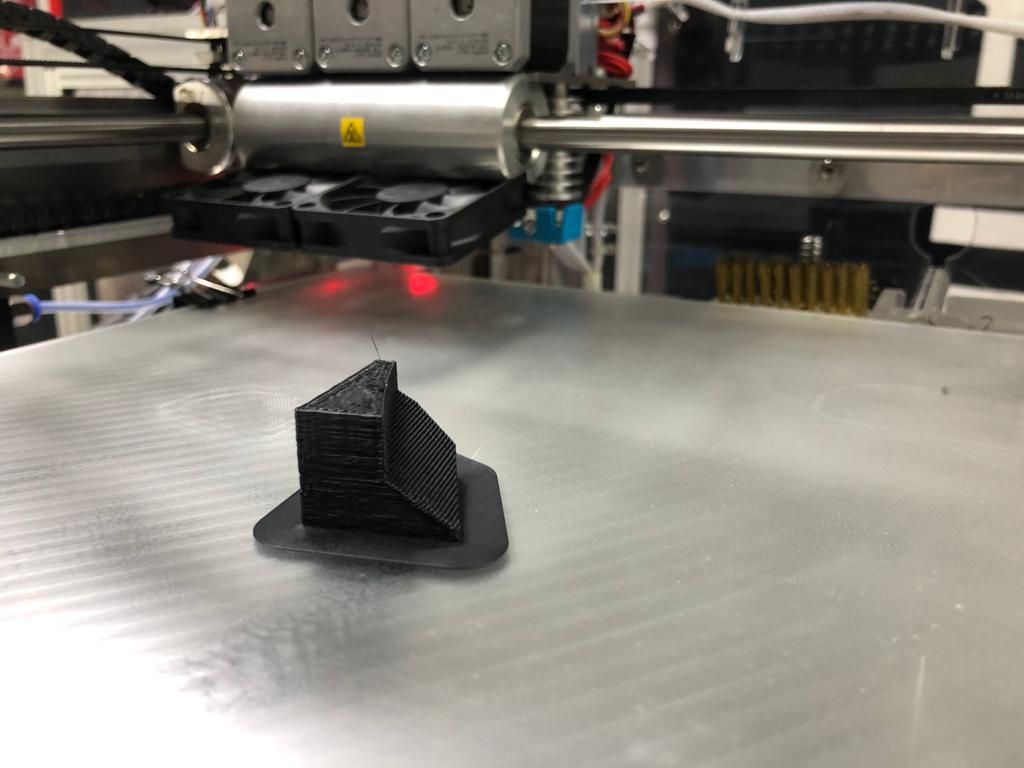

thank you very much, thanks to you I was able to understand where the error was and correct it.In practice I had an inverted axis and the origins were inverted

Best posts made by konte1978

-

RE: pieces made turn out to the contraryposted in General Discussion

Latest posts made by konte1978

-

RE: The chamber heater does not fitposted in My Duet controlled machine

problem solved, in RRF3 if the heater is different from H1 this order must be respected.

M950

M141

M143; Riscaldatore della cameraM950 H4 C"duex.e3heat" T4 ; configura l'uscita per il riscaldamento della camera sull pin e della scheda duex

M141 H4 ; il riscaldatore 4 è il riscaldatore della camera

M308 S4 P"duex.e3temp" Y"thermistor" T100000 B5500 C7.06Ee-8 ; configure sensor 4 as thermistor on pin duex.e2temp

M143 H4 S70 ; set temperature limit for heater 0 to 120C

M301 H4 B1 ; utilizzare il controllo bang-bang per il riscaldatore della camera -

The chamber heater does not fitposted in My Duet controlled machine

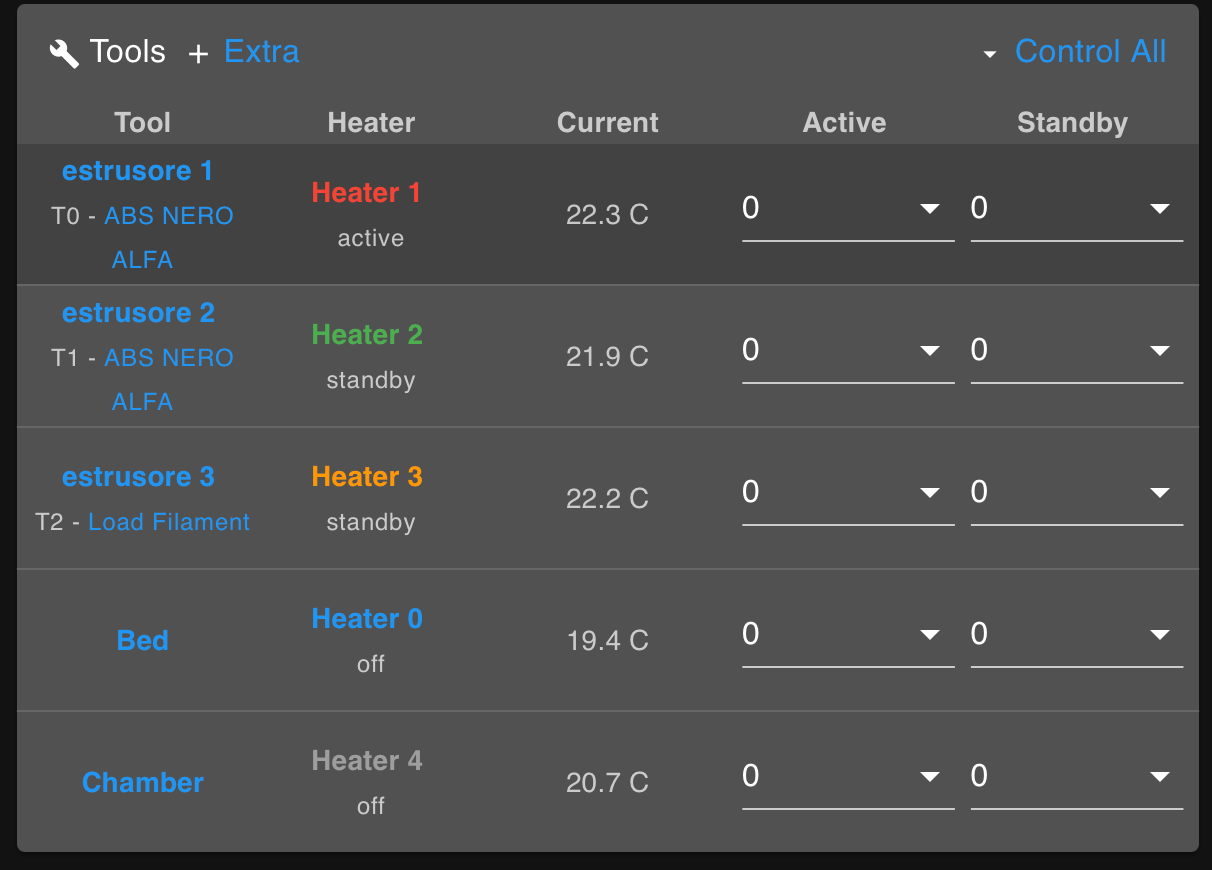

Hi guys, I can't start the chamber heater.

the ssr is connected to output 3 of the duex 5. I am attaching configuration files; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Fri Jul 17 2020 20:24:58 GMT+0200 (CEST); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P" CUBE PRO TRIO" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards HO MODIFICATO S1 CON S0

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M569 P9 S1 ; physical drive 9 goes forwards

M584 X0 Y1 Z2 E3:4:9 ; set drive mapping

M350 X16 Y16 Z16 E16:16:16 I1 ; configure microstepping with interpolation

M92 X87.35 Y87.43 Z1076.77 E80.59:78.85:79.87 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00:120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X15000.00 Y15000.00 Z1200.00 E600.00:600.00:600.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z250.00 E250.00:250.00:250.00 ; set accelerations (mm/s^2)

M906 X1500 Y1500 Z800 E1200:1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent (ho modficato la corrente dei motori dell'estrusore da 800 a 1200)

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Imposta valore minimo deli assi HO SOSTITUITO IL VALORE S0 CON S1

M208 X290 Y295 Z205 S0 ; imposta il valore massimo degli assi HO MODIFICATO IL VALORE S1 CON S0 Y DA 295.3 A 295; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop HO MODIFICATO IL VALORE Y1 A Y2

M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M950 S0 C"duex.pwm5" ; creare il servo pin 0 per BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 A10 R0.75 S0.02 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X-11 Y49.50 Z2.85 ; impostare il valore del trigger della sonda Z, l'offset e l'altezza del trigger 2.50 lasco 2.85 serrato

M557 X11:276.9 Y0:263 S20 ; define mesh grid misure minime e massime di dove andrà a sondare il bltouch; Heaters

;Piatto riscaldato

;M570 H0 P90 T20 ; sto cercando di far aspettare fino che il piatto si riscaldi prima che mi dia errore

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp ho modificato il valore dalla B4138 CON 3950

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S110 ; set temperature limit for heater 0 to 120C

;Estrusore numero 1

M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S290; set temperature limit for heater 0 to 120C

;Estrusore numero 2

M308 S2 P"spi.cs2" Y"rtd-max31865" ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S270

;Estrusore numero 3

M308 S3 P"spi.cs3" Y"rtd-max31865" ; M308 S3 P"duex.e2temp" Y"thermistor" T100000 B4725 ; configure sensor 3 as thermistor on pin duex.e2temp

M950 H3 C"duex.e2heat" T3 ; create nozzle heater output on duex.e2heat and map it to sensor 3

M143 H3 S270 ; set temperature limit for heater 0 to 120C

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

; Riscaldatore della camera

M141 H4 ; il riscaldatore 4 è il riscaldatore della camera

M308 S4 P"duex.e3temp" Y"thermistor" T100000 B5500 C7.06Ee-8 ; configure sensor 4 as thermistor on pin duex.e2temp

M950 H4 C"duex.e3heat" T4 ; configura l'uscita per il riscaldamento della camera sull pin e della scheda duex MODIFICATO 3 CON 4

M143 H4 S70 ; set temperature limit for heater 0 to 120C

M301 H4 B1 ; utilizzare il controllo bang-bang per il riscaldatore della camera OK

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"ESTRUSORI" S0 H3:2:1 T120 ; set fan 0 name and value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"NOZZLE" S0 H1:2:3 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"LUCI LED" S0 H-1 ; set fan 2 name and value. Thermostatic control is turned off

M950 F3 C"duex.fan6" Q500 ; create fan 3 on pin duex.fan6 and set its frequency

M106 P3 C"VENTOLA 6" S0 H-1 ; set fan 3 name and value. Thermostatic control is turned off

M950 F4 C"duex.fan7" Q500 ; create fan 4 on pin duex.fan7 and set its frequency

M106 P4 C"VENTOLA 7" S0 H-1 ; set fan 4 name and value. Thermostatic control is turned off; Tools motori estrusore

M563 P0 S"estrusore 1" D0 H1 F0:1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"estrusore 2" D1 H2 F0:1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"estrusore 3" D2 H3 F0:1 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C; Sensori di folamento degli estrusori se imposto l'ultima S0 disabilita il confronto tra filamento aspetatto e quello realmente estruso,S1 abilita il controllo

M591 D0 P5 C"e0stop" R5:190 E3.0 S0 ; ho configurato il filamento del primo estrusore sull'uscita e0stop valori sensibilità filamneto originale R40:120

M591 D1 P5 C"connlcd.encb" R5:190 E3.0 S0 ; ho configurato il filamento del secondo estrusore sull'uscita stop10(ECN_B) valori sensibilità filamneto originale R40:120

M591 D2 P5 C"e1stop" R5:190 E3.0 S1 ; ho configurato il filamento del terzo estrusore sull'uscita e1stop valori sensibilità filamneto originale R40:120; Custom settings are not defined

M575 P1 S1 B57600 ;per abilitare lcd paneldue

M501 ;Legge i parametri dalla eprom -

RE: pieces made turn out to the contraryposted in General Discussion

thank you very much, thanks to you I was able to understand where the error was and correct it.In practice I had an inverted axis and the origins were inverted

-

pieces made turn out to the contraryposted in General Discussion

hi guys the pieces made with the printer as if they were mirrored, what should I change on the firmware?

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Fri Jul 17 2020 20:24:58 GMT+0200 (CEST); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P" CUBE PRO TRIO" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M569 P9 S1 ; physical drive 9 goes forwards

M584 X0 Y1 Z2 E3:4:9 ; set drive mapping

M350 X16 Y16 Z16 E16:16:16 I1 ; configure microstepping with interpolation

M92 X87.35 Y87.43 Z1076.77 E82.09:82.09:82.09 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00:120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X15000.00 Y15000.00 Z1200.00 E600.00:600.00:600.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z250.00 E250.00:250.00:250.00 ; set accelerations (mm/s^2)

M906 X1500 Y1500 Z800 E1200:1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent (ho modficato la corrente dei motori dell'estrusore da 800 a 1200)

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Imposta valore minimo deli assi

M208 X290 Y295.3 Z205 ; imposta il valore massimo degli assi ho tolto il valore S0 ALLA FINE DELLA RIGA; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M950 S0 C"duex.pwm5" ; creare il servo pin 0 per BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 A10 R0.75 S0.02 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X-11.70 Y-51.2 Z2.85 ; impostare il valore del trigger della sonda Z,QUANDO SI SPOSTA L'ESTRUSORE REGOLARE IL VALORE Z 2.75 LASCO 2.85 SERRATO

M557 X12.3:290 Y24.80:295 S20 ; define mesh grid; Heaters

;Piatto riscaldato

;M570 H0 P90 T20 ; sto cercando di far aspettare fino che il piatto si riscaldi prima che mi dia errore

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp ho modificato il valore dalla B4138 CON 3950

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S110 ; set temperature limit for heater 0 to 120C

;Estrusore numero 1

M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S290; set temperature limit for heater 0 to 120C

;Estrusore numero 2

M308 S2 P"spi.cs2" Y"rtd-max31865" ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S270

;Estrusore numero 3

M308 S3 P"spi.cs3" Y"rtd-max31865" ; M308 S3 P"duex.e2temp" Y"thermistor" T100000 B4725 ; configure sensor 3 as thermistor on pin duex.e2temp

M950 H3 C"duex.e2heat" T3 ; create nozzle heater output on duex.e2heat and map it to sensor 3

M143 H3 S270 ; set temperature limit for heater 0 to 120C

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

; Riscaldatore della camera

M141 H4 ; il riscaldatore 4 è il riscaldatore della camera

M950 H4 C"duex.e3heat" T4 ; configura l'uscita per il riscaldamento della camera sull pin e della scheda duex

M308 S4 P"duex.e3temp" Y"thermistor" T100000 B5500 C7.06Ee-8 ; configure sensor 4 as thermistor on pin duex.e2temp

M143 H4 S70 ; set temperature limit for heater 0 to 120C

M301 H4 B1 ; utilizzare il controllo bang-bang per il riscaldatore della camera

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"ESTRUSORI" S0 H3:2:1 T120 ; set fan 0 name and value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"NOZZLE" S0 H1:2:3 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"LUCI LED" S0 H-1 ; set fan 2 name and value. Thermostatic control is turned off

M950 F3 C"duex.fan6" Q500 ; create fan 3 on pin duex.fan6 and set its frequency

M106 P3 C"VENTOLA 6" S0 H-1 ; set fan 3 name and value. Thermostatic control is turned off

M950 F4 C"duex.fan7" Q500 ; create fan 4 on pin duex.fan7 and set its frequency

M106 P4 C"VENTOLA 7" S0 H-1 ; set fan 4 name and value. Thermostatic control is turned off; Tools motori estrusore

M563 P0 S"estrusore 1" D0 H1 F0:1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"estrusore 2" D1 H2 F0:1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"estrusore 3" D2 H3 F0:1 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C; Sensori di folamento degli estrusori se imposto l'ultima S0 disabilita il confronto tra filamento aspetatto e quello realmente estruso,S1 abilita il controllo

M591 D0 P5 C"e0stop" R5:190 E3.0 S0 ; ho configurato il filamento del primo estrusore sull'uscita e0stop valori sensibilità filamneto originale R40:120

M591 D1 P5 C"connlcd.encb" R5:190 E3.0 S0 ; ho configurato il filamento del secondo estrusore sull'uscita stop10(ECN_B) valori sensibilità filamneto originale R40:120

M591 D2 P5 C"e1stop" R5:190 E3.0 S1 ; ho configurato il filamento del terzo estrusore sull'uscita e1stop valori sensibilità filamneto originale R40:120; Custom settings are not defined

M575 P1 S1 B57600 ;per abilitare lcd paneldue

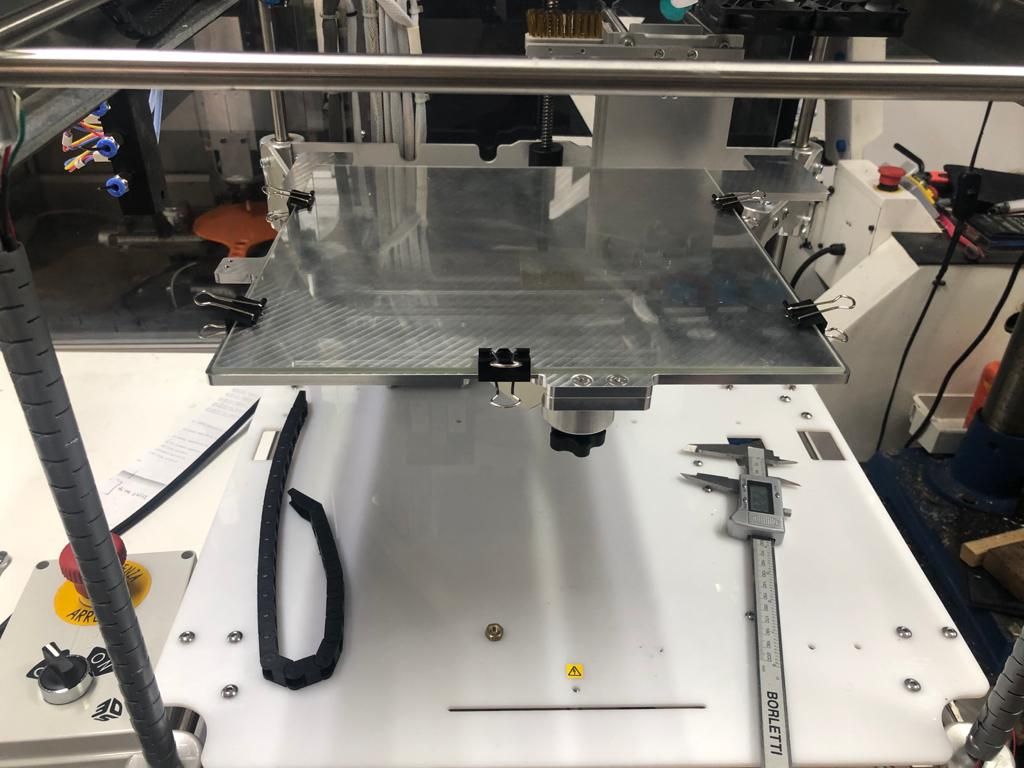

M501 ;Legge i parametri dalla eprom f74543cf-b634-4048-88e9-59d60f3f892c.jpg

f74543cf-b634-4048-88e9-59d60f3f892c.jpg

d669df0c-7fcc-467f-a026-a36f55b12913.jpg

d669df0c-7fcc-467f-a026-a36f55b12913.jpg -

RE: how to purge the filament from the second extruderposted in My Duet controlled machine

First of all, thank you very much, with your help I solved the problem For the extruders I use three fans connected to the same outlet that automatically turns on at 120 degrees. If you see errors in my code or things to improve please tell me. I still have to correct several anomalies but I will ask in another dedicated topic.

-

RE: how to purge the filament from the second extruderposted in My Duet controlled machine

@Phaedrux ; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Fri Jul 17 2020 20:24:58 GMT+0200 (CEST); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P" CUBE PRO TRIO" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M569 P9 S1 ; physical drive 9 goes forwards

M584 X0 Y1 Z2 E3:4:9 ; set drive mapping

M350 X16 Y16 Z16 E16:16:16 I1 ; configure microstepping with interpolation

M92 X87.35 Y87.43 Z1076.77 E82.09:82.09:82.09 ; set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00:120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X15000.00 Y15000.00 Z1200.00 E600.00:600.00:600.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z250.00 E250.00:250.00:250.00 ; set accelerations (mm/s^2)

M906 X1500 Y1500 Z800 E1200:1200:1200 I30 ; set motor currents (mA) and motor idle factor in per cent (ho modficato la corrente dei motori dell'estrusore da 800 a 1200)

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Imposta valore minimo deli assi

M208 X290 Y295.3 Z205 ; imposta il valore massimo degli assi ho tolto il valore S0 ALLA FINE DELLA RIGA; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S1 P"zstop" ; configure active-high endstop for low end on Z via pin zstop; Z-Probe

M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed

M950 S0 C"duex.pwm5" ; creare il servo pin 0 per BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 A10 R0.75 S0.02 ; set Z probe type to bltouch and the dive height + speeds

G31 P25 X-11.70 Y-51.2 Z2.75 ; impostare il valore del trigger della sonda Z, l'offset e l'altezza del trigger

M557 X12.3:290 Y24.80:295 S20 ; define mesh grid; Heaters

;Piatto riscaldato

;M570 H0 P90 T20 ; sto cercando di far aspettare fino che il piatto si riscaldi prima che mi dia errore

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp ho modificato il valore dalla B4138 CON 3950

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S110 ; set temperature limit for heater 0 to 120C

;Estrusore numero 1

M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S290; set temperature limit for heater 0 to 120C

;Estrusore numero 2

M308 S2 P"spi.cs2" Y"rtd-max31865" ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S270

;Estrusore numero 3

M308 S3 P"spi.cs3" Y"rtd-max31865" ; M308 S3 P"duex.e2temp" Y"thermistor" T100000 B4725 ; configure sensor 3 as thermistor on pin duex.e2temp

M950 H3 C"duex.e2heat" T3 ; create nozzle heater output on duex.e2heat and map it to sensor 3

M143 H3 S270 ; set temperature limit for heater 0 to 120C

M307 H3 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

; Riscaldatore della camera

M141 H4 ; il riscaldatore 4 è il riscaldatore della camera

M950 H4 C"duex.e3heat" T4 ; configura l'uscita per il riscaldamento della camera sull pin e della scheda duex

M308 S4 P"duex.e3temp" Y"thermistor" T100000 B5500 C7.06Ee-8 ; configure sensor 4 as thermistor on pin duex.e2temp

M143 H4 S70 ; set temperature limit for heater 0 to 120C

M301 H4 B1 ; utilizzare il controllo bang-bang per il riscaldatore della camera; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"ESTRUSORI" S0 H3:2:1 T120 ; set fan 0 name and value. Thermostatic control is turned on

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"NOZZLE" S0 H1:2:3 T45 ; set fan 1 name and value. Thermostatic control is turned on

M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency

M106 P2 C"LUCI LED" S0 H-1 ; set fan 2 name and value. Thermostatic control is turned off

M950 F3 C"duex.fan6" Q500 ; create fan 3 on pin duex.fan6 and set its frequency

M106 P3 C"VENTOLA 6" S0 H-1 ; set fan 3 name and value. Thermostatic control is turned off

M950 F4 C"duex.fan7" Q500 ; create fan 4 on pin duex.fan7 and set its frequency

M106 P4 C"VENTOLA 7" S0 H-1 ; set fan 4 name and value. Thermostatic control is turned off; Tools monitoraggio del filamento

M563 P0 S"estrusore 1" D0 H1 F0:1 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"estrusore 2" D0 H2 F0:1 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

M563 P2 S"estrusore 3" D2 H3 F0:1 ; define tool 2

G10 P2 X0 Y0 Z0 ; set tool 2 axis offsets

G10 P2 R0 S0 ; set initial tool 2 active and standby temperatures to 0C; Sensori di folamento degli estrusori se imposto l'ultima S0 disabilita il confronto tra filamento aspetatto e quello realmente estruso,S1 abilita il controllo

M591 D0 P5 C"e0stop" R5:190 E3.0 S0 ; ho configurato il filamento del primo estrusore sull'uscita e0stop valori sensibilità filamneto originale R40:120

M591 D1 P5 C"connlcd.encb" R5:190 E3.0 S1 ; ho configurato il filamento del secondo estrusore sull'uscita stop10(ECN_B) valori sensibilità filamneto originale R40:120

M591 D2 P5 C"e1stop" R5:190 E3.0 S1 ; ho configurato il filamento del terzo estrusore sull'uscita e1stop valori sensibilità filamneto originale R40:120; Custom settings are not defined

M575 P1 S1 B57600 ;per abilitare lcd paneldue

M501

M500 -

RE: how to purge the filament from the second extruderposted in My Duet controlled machine

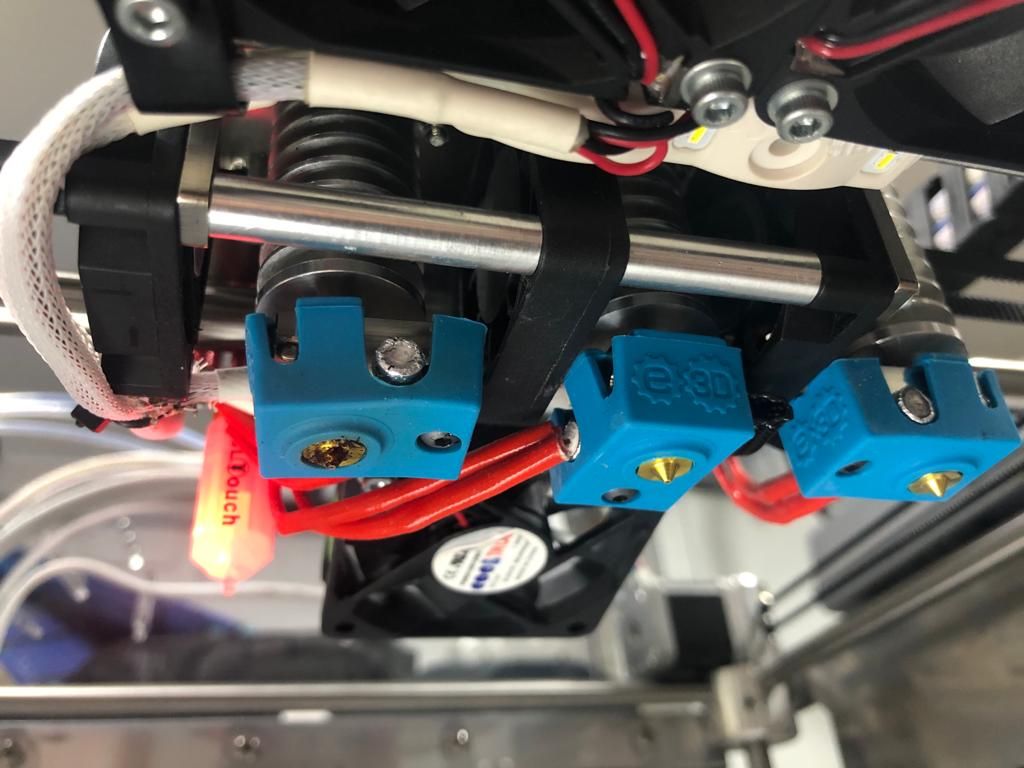

playing I noticed something that I don't think is regular, loading a filament in the first extruder loads it at the same time also on the second one, instead if I load it on the third extruder it loads it well.![alt text])

-

how to purge the filament from the second extruderposted in My Duet controlled machine

Hi guys I don't understand how I can control the second extruder in order to purge the filament before processing. For the first time I use these commands:

G21

G90

G92 E0

G1 E150 F200

M400In Duet Web Control I set the temperature of the second extruder by activating it, but the first extruder always moves.

-

RE: problem attuning bed heaterposted in Config Tool

@Phaedrux Hi I'm using RepRapFirmware for Duet 2 WiFi / Ethernet version 3.2-RC2.

the test goes on even for 30 minutes without giving any error