@phaedrux So I have been tuning for a few days and Im trying to set up pressure advance now. Im following the guide at https://duet3d.dozuki.com/Wiki/Pressure_advance but I don't see any change vertically in the print. However the test print looks great.

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Voron V1.9" ; set printer name

M669 K1 ; select CoreXY mode

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S0 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z400.00 E832.0 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E700 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X-25 Y-25 Z-2 S1 ; set axis minima

M208 X325 Y300 Z450 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

; Z-Probe

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

G31 P500 X-26 Y-2 Z2.5 ; set Z probe trigger value, offset and trigger height

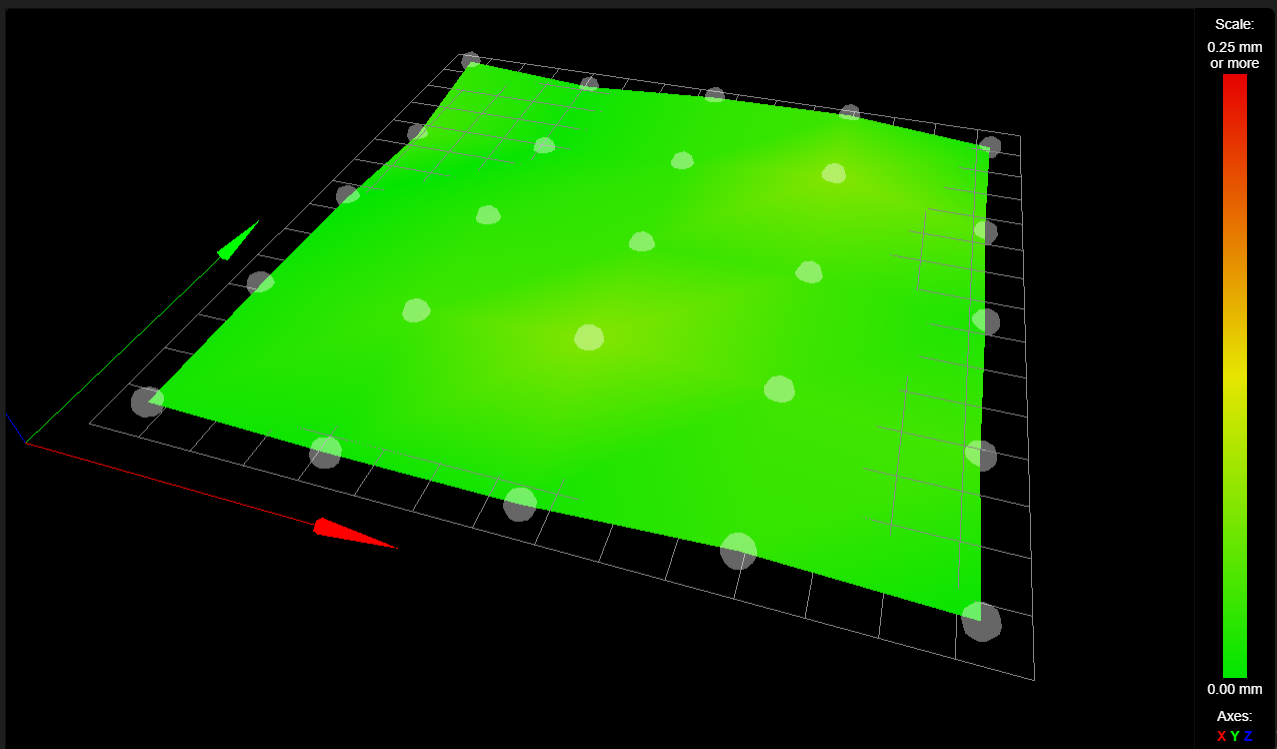

M557 X15:325 Y05:325 S56 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Presure Advance

M572 D0 S0.1

M501

And here is my slicer layer change settings using S3D.

{if layer_num== 1}M572 D0 S0.0

{elsif layer_num== 25}M572 D0 S0.01

{elsif layer_num== 50}M572 D0 S0.015

{elsif layer_num== 75}M572 D0 S0.02

{elsif layer_num== 100}M572 D0 S0.025

{elsif layer_num== 125}M572 D0 S0.03

{elsif layer_num== 150}M572 D0 S0.035

{elsif layer_num== 175}M572 D0 S0.040

{elsif layer_num== 200}M572 D0 S0.045

{elsif layer_num== 225}M572 D0 S0.05

{elsif layer_num== 250}M572 D0 S0.055

{elsif layer_num== 275}M572 D0 S0.06

{elsif layer_num== 300}M572 D0 S0.065

{elsif layer_num== 325}M572 D0 S0.07

{elsif layer_num== 350}M572 D0 S0.075

{elsif layer_num== 375}M572 D0 S0.08

{endif}

Im not sure if was on,,, went through the settings. Or just ran the whole print at S0.1