Posting here since it's 5 axis, but this is for a 3D printer project.

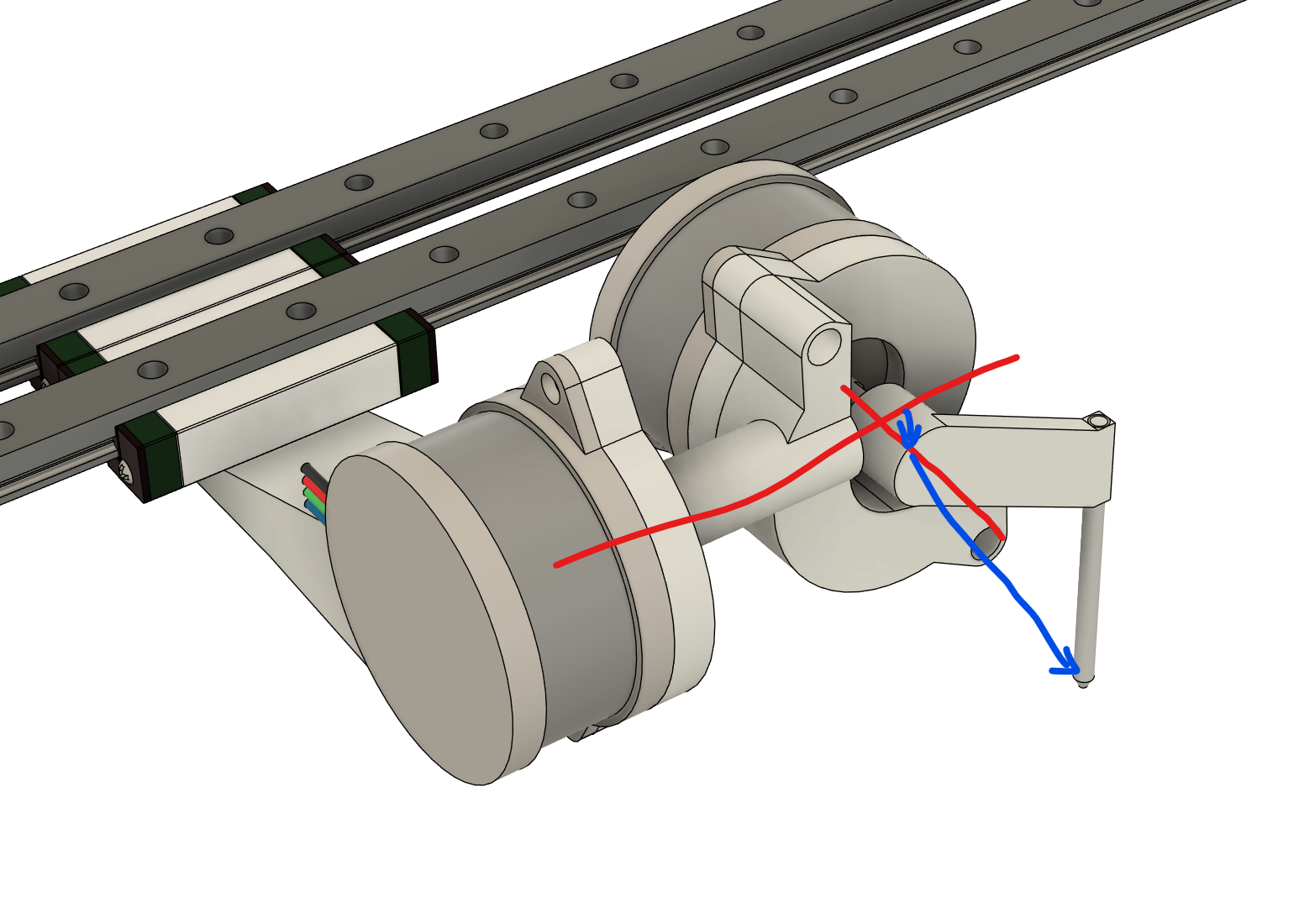

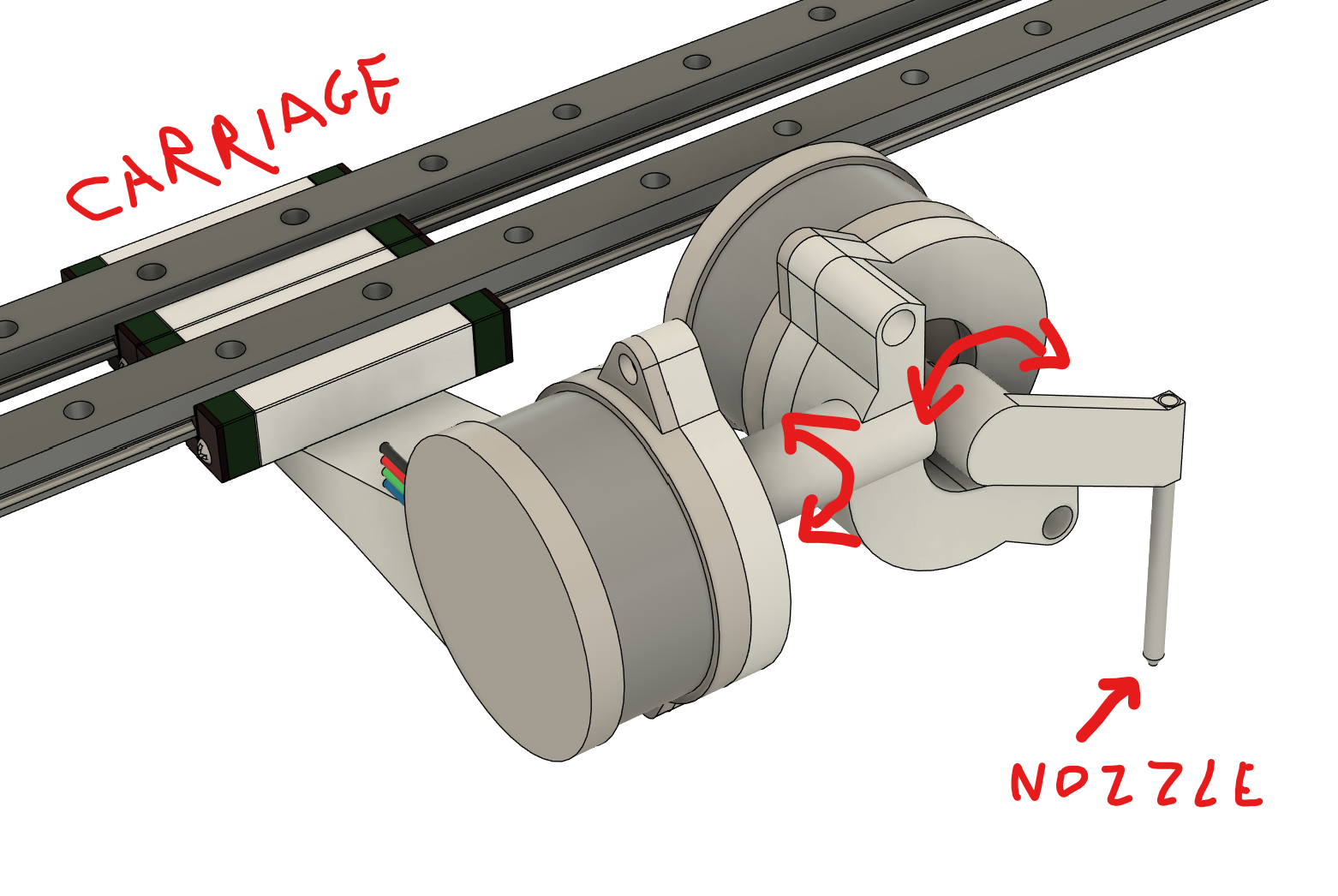

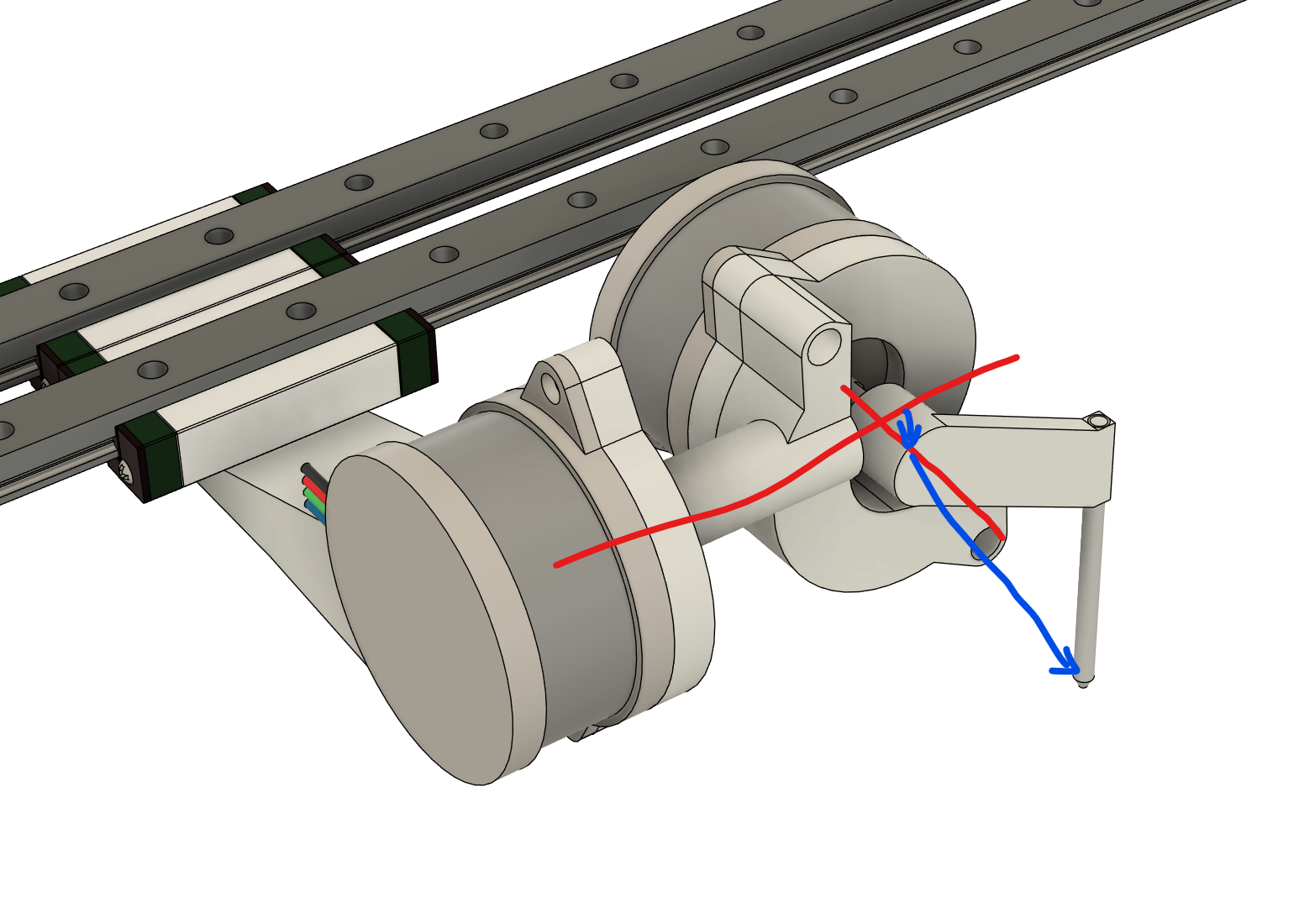

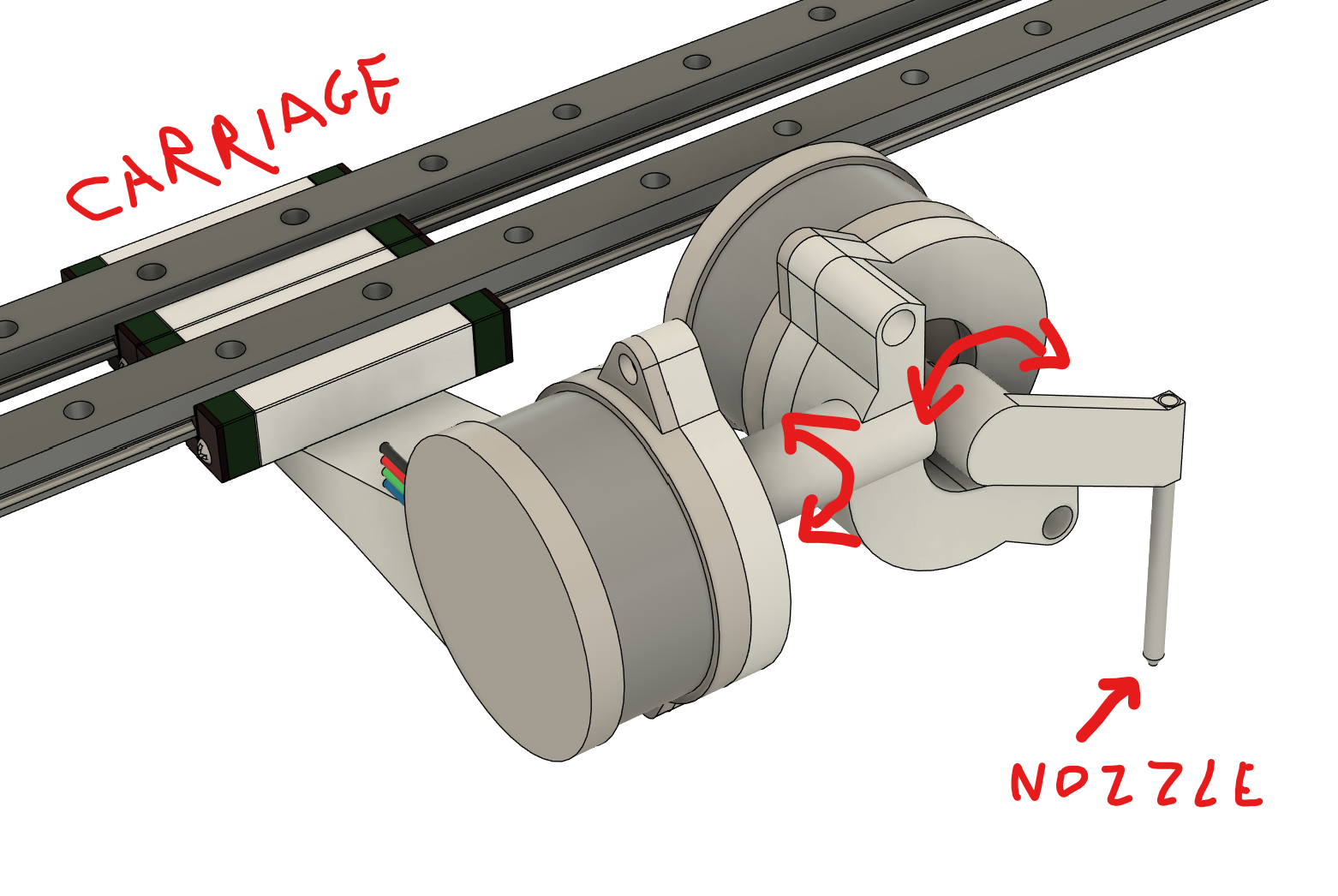

Only focusing on the rotational axes in this topic, I want to build the illustrated design so that the nozzle can rotate.

At rest position the axis closest to the end effector is parallel to the Y axis, and the next one is parallel to the X axis. Both have offsets (one relative to the other and to the end effector).

XY axes are CoreXY, Z connected to the carriage, fixed bed. So reading the documentation this would be a XYZAB or something like that? And there should be some way to configure them using M669, but am not sure the firmware has support for all the parameters. It mostly talks about AC/BC configurations where offsets are supported, but doesn't mention offsets for AB and I couldn't find a good example configuration to get inspiration from.

What I would like to get from the firmware is the IK solving so that when the g-code asks for a motion that involves A and B axes rotation, it will adjust the XYZ position so that the end effector stays in the same place with relation to the bed, but changes angles.

I'm asking here if this is supported by the firmware so that I don't invest time in building a device that cannot be configured.

Edit: here are the two vectors I'm wondering how to configure.