@zapta yeah it does actually. I don’t think I will switch back even if I hate SBC

Posts made by minim

-

RE: Anybody using a Duet board with a Klipper SBC?posted in General Discussion

-

RE: Anybody using a Duet board with a Klipper SBC?posted in General Discussion

@gaweyo It was a bit easier from a pc than from my phone

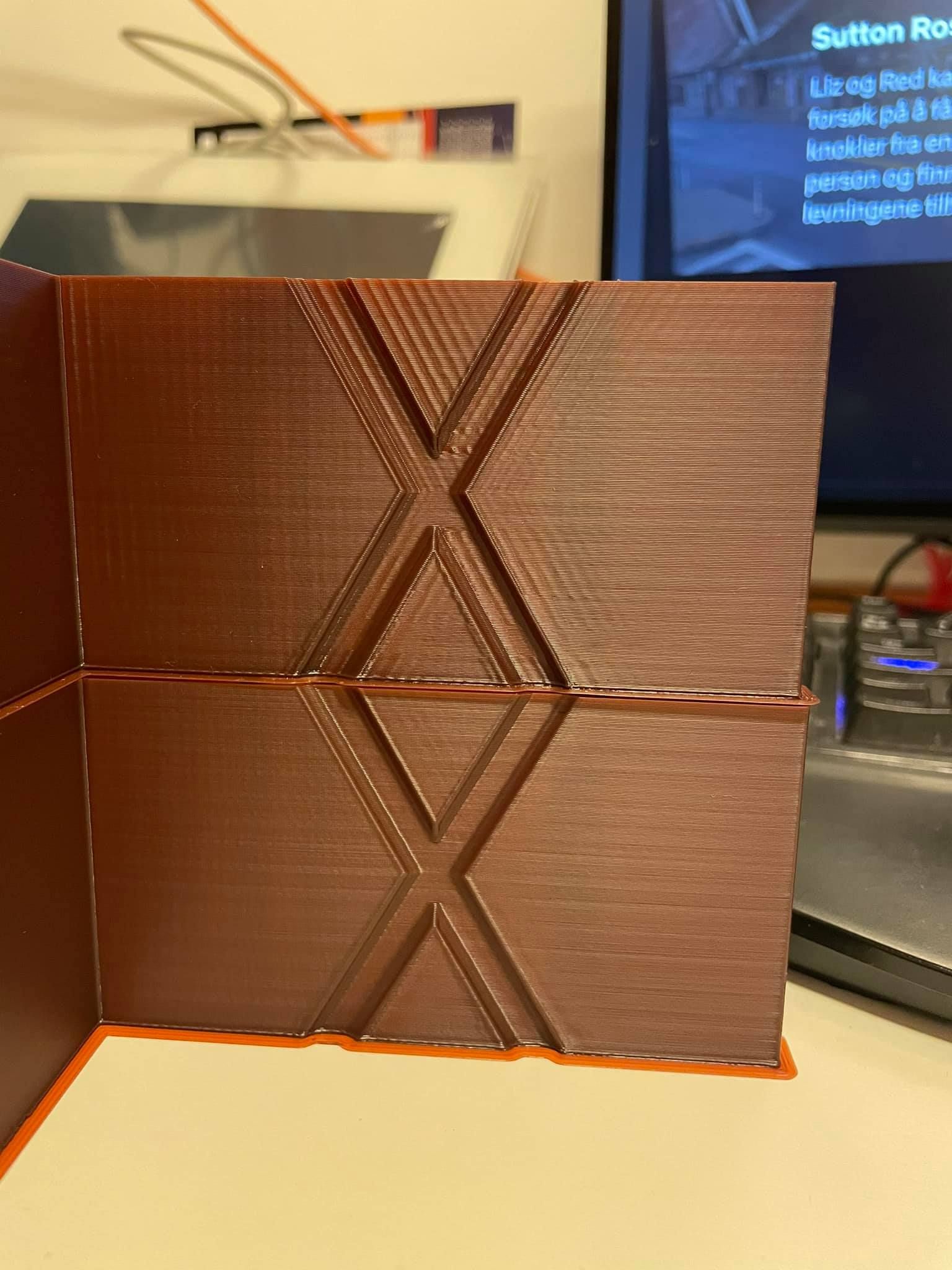

I have some issues in the Z axis after a crash during config but it still shows great improvement of ringing in the lower print with input shaper enabled. Upper print is without input shaper. Both are done with 1500mms accleration increasing each 5mm up to 7000mm/s accleration and the print speed is 100mm/s.

I have some issues in the Z axis after a crash during config but it still shows great improvement of ringing in the lower print with input shaper enabled. Upper print is without input shaper. Both are done with 1500mms accleration increasing each 5mm up to 7000mm/s accleration and the print speed is 100mm/s.

-

RE: Anybody using a Duet board with a Klipper SBC?posted in General Discussion

I tested klipper on duet WiFi and deux5 this weekend. I run true bed leveling with it quite fine and the input shaper does magic. The UI is not great compared to duet but I might stay with it because of the magic the input shaper does. Wish I could add a photo here easy and I’ll show the huge difference.

Managed to crash my Z axis during setup so I got some Z banding now but I can’t blame klipper for a user error

-

RE: Where's the Duet Wifi 3?posted in Duet Hardware and wiring

I'm also waiting for the duet wifi 3. No interest what-so-ever in a raspberry pi for this application. KISS is gone out the window it seems. I want to upgrade my printers but until the duet wifi 3 is out there just isn't any point at all.

-

RE: Positioning the printable areaposted in General Discussion

@Danal said in Positioning the printable area:

@minim said in Positioning the printable area:

That's true. I think I will keep M208 at zero then so I can print off if needed and just try to remember where my limits are for the first layers. I guess I'm to set on the cnc way of doing it with machine coordinates on the machine that's always the same and then work coords (G54+++) to cover placement over the workpiece and thought the bed could be solved in a similar maner.

You actually can do this if you want. G10 L2 or L20, and G54 and so forth, all work fine in 3D print mode.

Having said that, I typically M208 -nnn:nnn such that 0,0 is the corner of the bed. Actual coordinates from a CoreXY:

M208 X-16.5:317 Y-10:385 Z-10:315

M208 U0:180And you still get to move to X-16.5 or do you run with M564 S0 to allow movement outside the bed? I don't have the printer here to test but I'll try this later.

-

RE: Positioning the printable areaposted in General Discussion

@dc42 said in Positioning the printable area:

I'll consider applying M208 limits to G30 probing operations in a future firmware release.

that sounds great

Would be great to just have it as a flag on the M208 command so we could choose to use it or not

Would be great to just have it as a flag on the M208 command so we could choose to use it or not  On my delta I'm using the smart effector so I think I would leave that security on for that one also.

On my delta I'm using the smart effector so I think I would leave that security on for that one also. -

RE: Positioning the printable areaposted in General Discussion

That's true. I think I will keep M208 at zero then so I can print off if needed and just try to remember where my limits are for the first layers. I guess I'm to set on the cnc way of doing it with machine coordinates on the machine that's always the same and then work coords (G54+++) to cover placement over the workpiece and thought the bed could be solved in a similar maner.

Maybe I recall wrong about the mesh crash as that's a long time ago now when I was changing the coordinate system last time. Today I crashed again due to a brainfart when I calced the offsets into the coordinates but that was in bed.g file and when doing true bed leveling. Idkn about the deltas but I consider the axis limits to be the safe area the printer can move within and as long as I don't use "M564 S0" it should be safe and not able to crash. If it's desired on delta's wouldn't it be better to allow it for that kinematic? It's not desirable to crash my corexy that I know

-

Positioning the printable areaposted in General Discussion

I home my CoreXY machine with sensor less homing and I have the bump stops mounted so that I'm homed outside the printable area (nozzle can move outside of the bed). I can also move the nozzle outside on all the other edges with my current M208 S1 settings. This is how I want it to be since I can then use scripting for a wipe outside bed or tool changes for later. I also use home at the rear left corner of the printer.

The Issue I got is how do I set the printable area to be inside the bed? My XY max is X414,Y423 and the printable area is X13-410 and Y18-416. If I use M208 I move my XY0 so I can't move behind the bed without M564 S0 but I don't want to disable that "security" for normal operations. I hope I can solve this in the duet and not the slicer.

Sidenote: is it just me or is the coordinate offset from probe a complete mess when running true bed leveling/ mesh probing with a probe X/Y offset? If you don't mind the offset properly when making the config files for probing it moves OUTSIDE limits set by M208 and crashes the printer. When the axis max is set the printer should under no circumstances (except with M564 S0 enabled) do that IMO.

-

RE: Bigtreetech smart filament sensorposted in General Discussion

Hi. Did u succeed using this sensor? Considering getting one to test..

-

RE: Question about DWC v2xxposted in Duet Web Control

You can also use the old interface when you run dwc2.0RC7. Just add "/reprap" behind the link. I do that since I find the old easier to use.

-

RE: warning z=0 datum was not determinedposted in General Discussion

you also get that message if you home against limit switches (for example on a delta at the top) without homing with the Z probe. My Z switches on my delta is good enough for me not probing with BLtouch each time so I get that each time I don't do a probe run before loading the height map. It's not a error it's just a warning telling you that the height map is based on the Z datum set with the probe and not the limit switches you home against.

-

RE: Duet 3 Mainboard 6HC - initial production run.posted in General Discussion

It will be fun to see the improvement but I don't fancy the idea of a SBC at all. I kinda need it for the stepper drivers on nema 23s.. Time will tell if SBC was the correct decision I guess

-

RE: PT1000 Duet Wifi - Resistor Swapposted in Duet Hardware and wiring

@dc42 so you gain 0.11 in resolution by swapping the resistor from 4K7 to 2K2? Is it even worth doing? I ordered a PT1000 element now for high temp printing and got thrown off by the recomandation of swapping resistor. When I see your estimations I wonder if it's worth the hassle at all. If I gain +/- 0.11 in accurancy by swapping I won't bother with it

-

RE: Firmware 2.03RC5/1.24RC5 releasedposted in Firmware installation

@adrian52 said in Firmware 2.03RC5/1.24RC5 released:

@dc42 sorry - error occurs when starting a print from the homed position. Have got the same behaviour even when trying to print a 40x40x10mm cube. I updated dwc 2 at the same time, but reverting this to rc6 did not change the error. What further information do you need?

I home my delta with G28 before a print and don't have this issue. Maybe upload the start of the file you are printing would reveal something if I compared it to mine.

-

RE: Delta printer max limitsposted in General Discussion

@dc42 on it like sonic!

Edit: now it works fine stopping at the first endstop hit

Thank you dc42!

Thank you dc42! -

RE: Delta printer max limitsposted in General Discussion

Awesome! I'll follow the release on github and test it once a new rls is out. Thanks

-

RE: Delta printer max limitsposted in General Discussion

I'm using 2.03rc2 and an example could be that after G28 I use the Z+25 button in the web interface and it smashes into the home switches. I know I'm to careless when I do such a mistake but I would really prefer not beeing able to crash if it was possible because user error will always occur.

-

Delta printer max limitsposted in General Discussion

I might have missed something but on delta printers M208 isn't used for max according to the manual so I can't limit my Z max like on my corexy. The delta radius is set but it doesn't seem to limit the Z anyways. Shouldn't it be possible to not move the steppers above the tower endstop? After I home I sometimes manage to go Z+ instead of Z- (brain fart..) and crash my carrigies into the homing switches. This ofcourse mess up my offsets and I have to run calibration from scratch again. The software knows how far it is from triggering the ends top on each tower since it know XY and rodlenght so why can't we use a M208 derivative for the towers when on a delta?

Excuse me if this is a setting that I didn't find but I've searched a while for it without finding anything in the documentation or on the forum.

-

RE: New firmware 2.03RC2 availableposted in Firmware installation

Anyone having issues with babystepping not working? On rc2 with dwc 1,23/2.0 and I can't step down but I've never tried on the stable. Will roll back after this print and check.

Edit: just read that M208 is stopping it from going below Z0. What a strange limit to have. Well then it's not a firmware issue atleast since I have M208 set to Z0.