Hello to all:

Machine: CoreXY (300x300), with Duet2 2.05 and DWC 2.07

config (1).g homeall.g

The bed is a 1/4in MIC 6 tooling plate with a 3 point (manual) leveling system:once leveled it was fine for over a year, I used no compensation. Z axis was homed using an optical end-stop, still is.

I just changed my printing surface (magnetic) from Geckotek to PEI and decided to add an original BL-Touch to my setup . I plan to create a map once, and load it at print time.

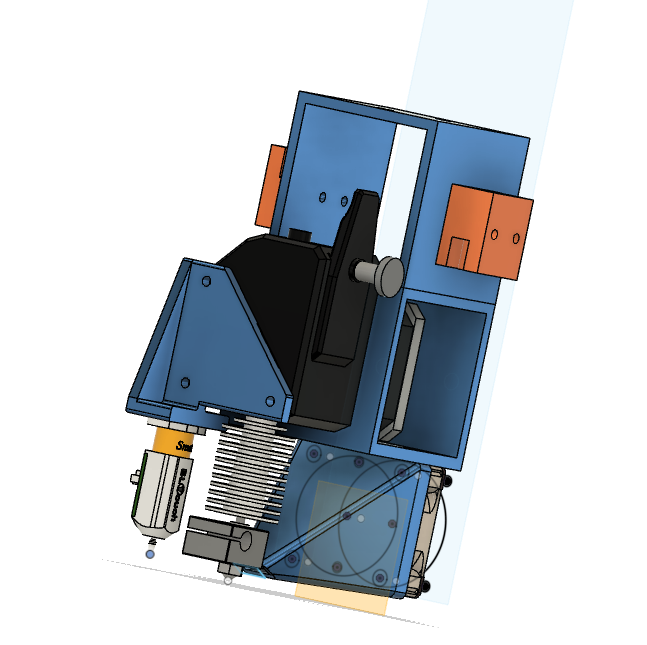

I have proceeded very slowly with this step as I do not want to damage my new print surface... The BL-Touch is precisely placed via a bracket I printed from the Fusion360 CAD model I prepared for my printer.

I have had no issues and I believe all the proper steps are in place for the mesh leveling. I searched this forum for information and actually found a tip for the M558 (thanks ...).

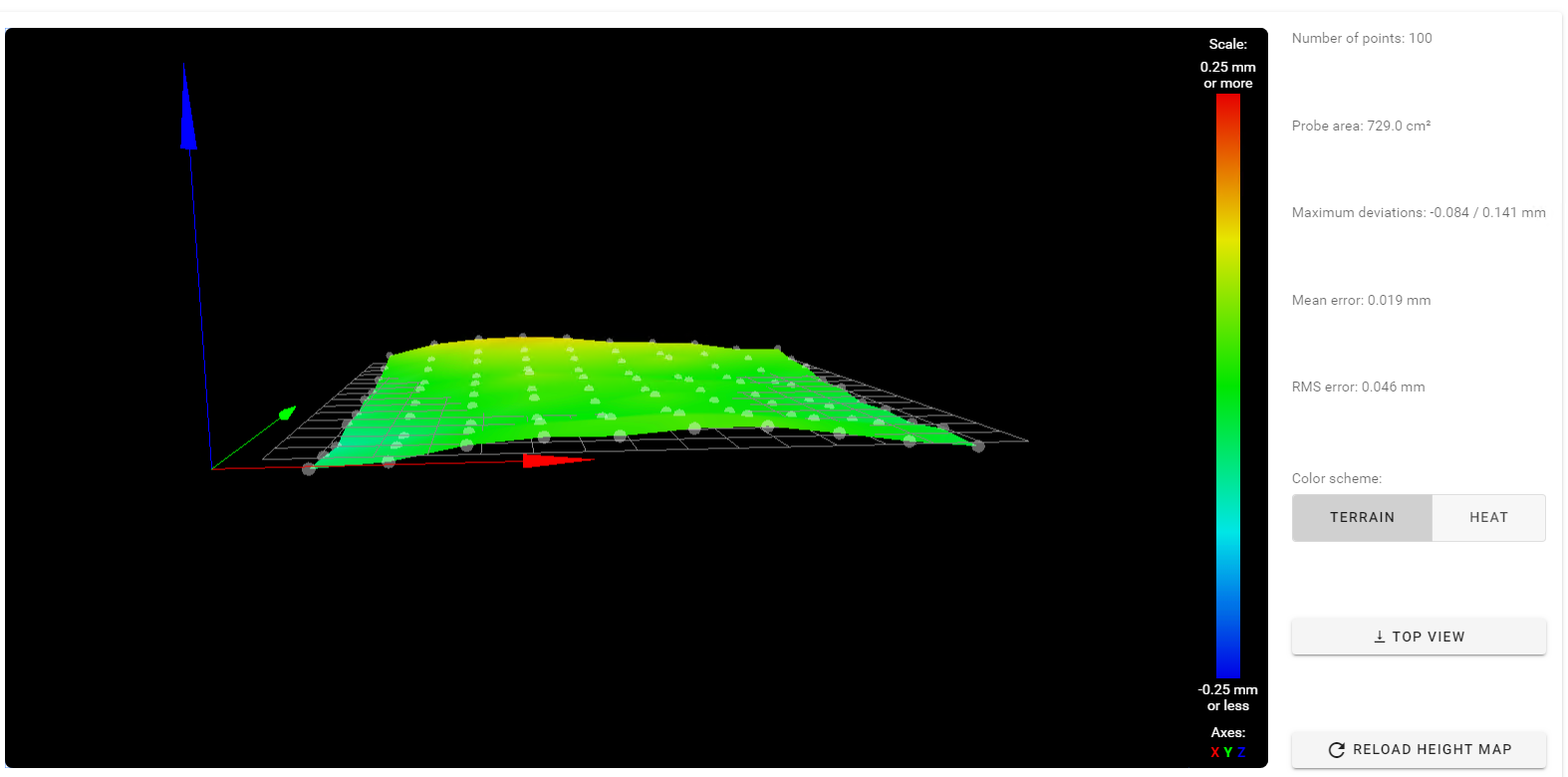

As you can see from the leveling map, no major problems with generating the map (multiple repeats to make sure all is ok). The slight warp towards the back is verified with manual measurements, so the map itself seems ok.

I have done a few tests <air printing> a few mm above the bed a test pattern that runs near the edge of the build plate (actually a 280x280 square) which is right at the edge of the probing area. A M122 while printing confirms that the map is loaded.

I would expect the Z axis position shown in the DWC to change a bit at the head moves around the bed, but the number does not change, and I see (and feel) no movement on the Z-axis.

Enclosed are my config.g and homeall.g files.

From the Homeall file (last commands sent):

;###########################################################################################

; Use Mesh leveling

G90 ; absolute mode

G1 Z10 F600 ;move down bed

G1 X170 Y164 F6000 ;move <probe> to the center of bed (150,150) (not the nozzle)

G30 ;probe bed to establish Z position (set to Trigger height defined in config.g)

G29 S1 ;load mesh map from SD card

;M376 H5 ;compensate within 5mm Z height taper

;###########################################################################################

From the config file:

; ############## Z-Probe ##############

M307 H3 A-1 C-1 D-1

M558 P9 H5 F100 T6000 A10 R0.75 S0.003 B1 ; P9 for BLTouch, dive height 5mm, probe at 100mm/min, travel 6000mm/s, up to 10 probes, pause 0.5s, heaters off

G31 X-20.0 Y-14.0 Z1.85 P25

; ############## Define mesh grid ##############

M557 X5:285 Y5:285 S30 ; Define mesh grid

So, should the Z axis be moving to adjust the first layer height with this map in place ?

What have I missed ?

Any input will be greatly appreciated.

François