@droftarts I am more than happy to write up my findings and help with the documentation. I think last night I discoevered that the M350 command doesnt have an effect, and instead off scaling values for microstepping etc need to be incorporated into M92. I am now looking into why the joints aren't moving the correct amount, It may be because of my closed loop stepper drivers so once i've done some learning I will feed back the information

Best posts made by NortonAntivirus

-

RE: CNC Parallel SCARA Plasma Cutter - GCODE Issuesposted in CNC

Latest posts made by NortonAntivirus

-

RE: Closed Loop Control - Parallel SCARAposted in CNC

@JoergS5 @o_lampe

Thank you greatly for your advice! I have since replaced what I thought was a faulty harmonic gearbox, the backlash in that joint is now greatly reduced. For a university dissertation I had measured the stall torque and repeatability of the harmonic gearboxes, i found stall torque to be around 4.2Nm and precision to be around 0.28 arcmin. A MATLAB simulation model of my parallel SCARA revealed I only needed around 1.1Nm of torque to operate with the speeds and accelerations needed for thin steal.I am still having some strange behaviours occurring with the machine, circles are still not fully circular, and occasionally joint positions are not achieved in a smooth manner. I am wondering if it's a calibration issue, however I shall now investigate the behaviour of bearings incase they're causing issues. I had previously tried using some sprung lanyards to apply tension on bearings and joints to ensure backlash and engagement is consistent. I will try and post some more pictures of the machines behaviours this evening.

Many thanks!

-

Closed Loop Control - Parallel SCARAposted in CNC

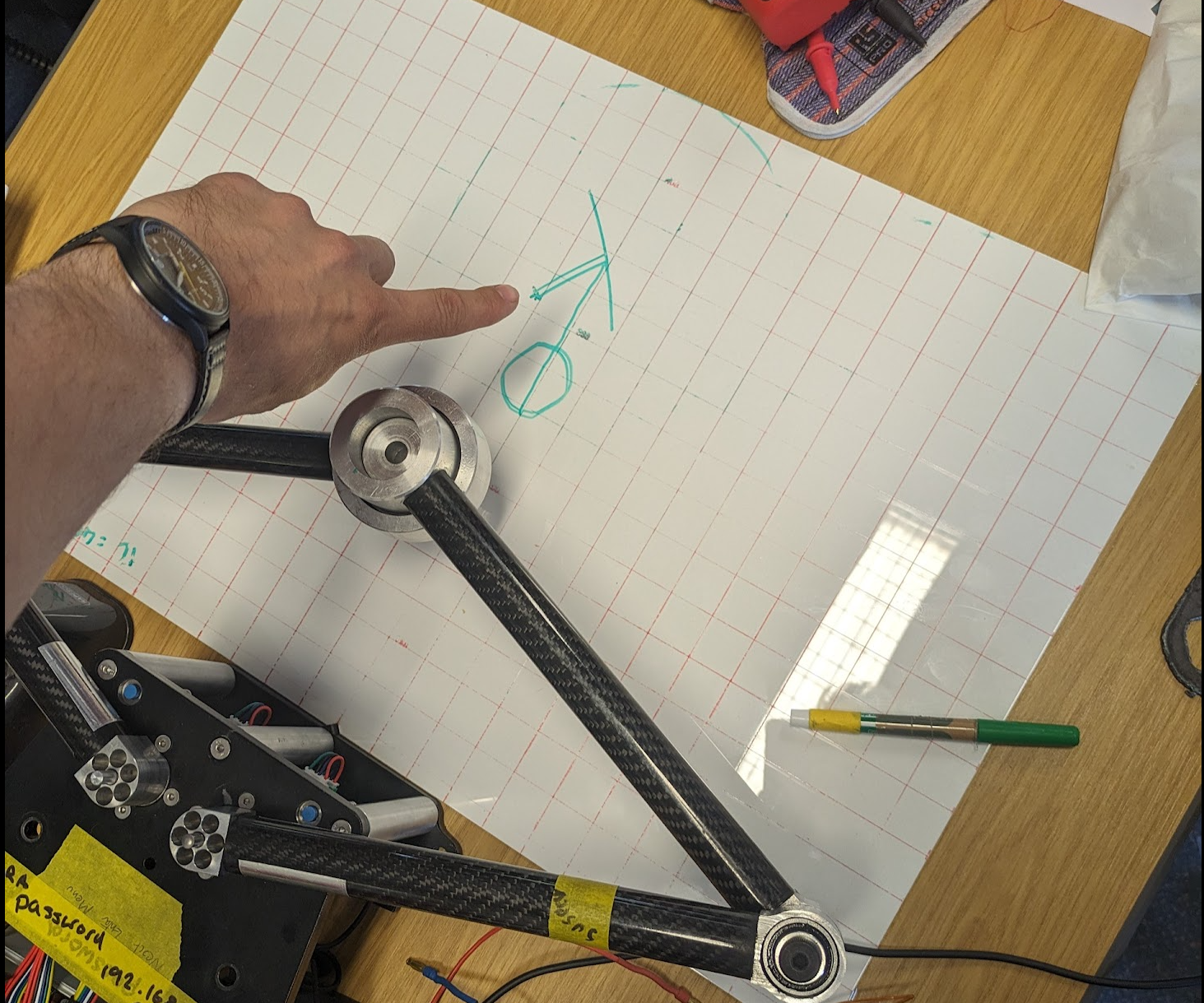

Hello, I have recently been building a CNC Parallel SCARA machine. It is functional, however I have backlash in one of the harmonic gearboxes. This can be seen in the photo with my hand pointing to two parallel arc lines, these are caused by the right joint, and they should overlap but due to backlash they don't.

I would like to add encoders to the output of my gearboxes so that the system can run in a closed loop mode. Is this something anyone has any experience with? I have been unable to find any information regarding encoders other than those mounted directly to stepper motors.

I currently have the following setup:

SKRv1.4 -> MKS Servo 42c Closed Loop Stepper Driver -> Nema 17 -> Harmonic Gearbox. I would like to encode the output of the harmonic gearbox, ideally by using this as I already have two: https://www.mouser.co.uk/ProductDetail/Bourns/EMS22A50-B28-LS6?qs=%2FxQVPCMPNzhvTDKFYgIzpQ%3D%3DI had been considering trying to run the MKS Servo 42C by placing the magnet on the output shaft, however I have been unable to find any people who have done this successfully.

Many thanks!

-

RE: CNC Parallel SCARA Plasma Cutter - GCODE Issuesposted in CNC

Hello everyone,

I have a slight update: I am unable to draw circles... it transpires that one of my gearbox and motor assemblies has a lot more backlash, resulting in around 7mm of inaccuracy at the end effector in working positions. I would like to add encoders to the output shafts of the gearboxes. Is this something that can be achieved in reprap firmware? I cannot seem to find anything about it. Ideally I would use 2 of these as I already have them from a past project. Once again, any help would be greatly appreciated. Many thanks!

https://uk.rs-online.com/web/p/mechanical-rotary-encoders/7899490 -

RE: CNC Parallel SCARA Plasma Cutter - GCODE Issuesposted in CNC

@o_lampe Just a temporary setup, ultimately I will make a proper table and area for it but only once I've got it working somewhat nicely

-

RE: CNC Parallel SCARA Plasma Cutter - GCODE Issuesposted in CNC

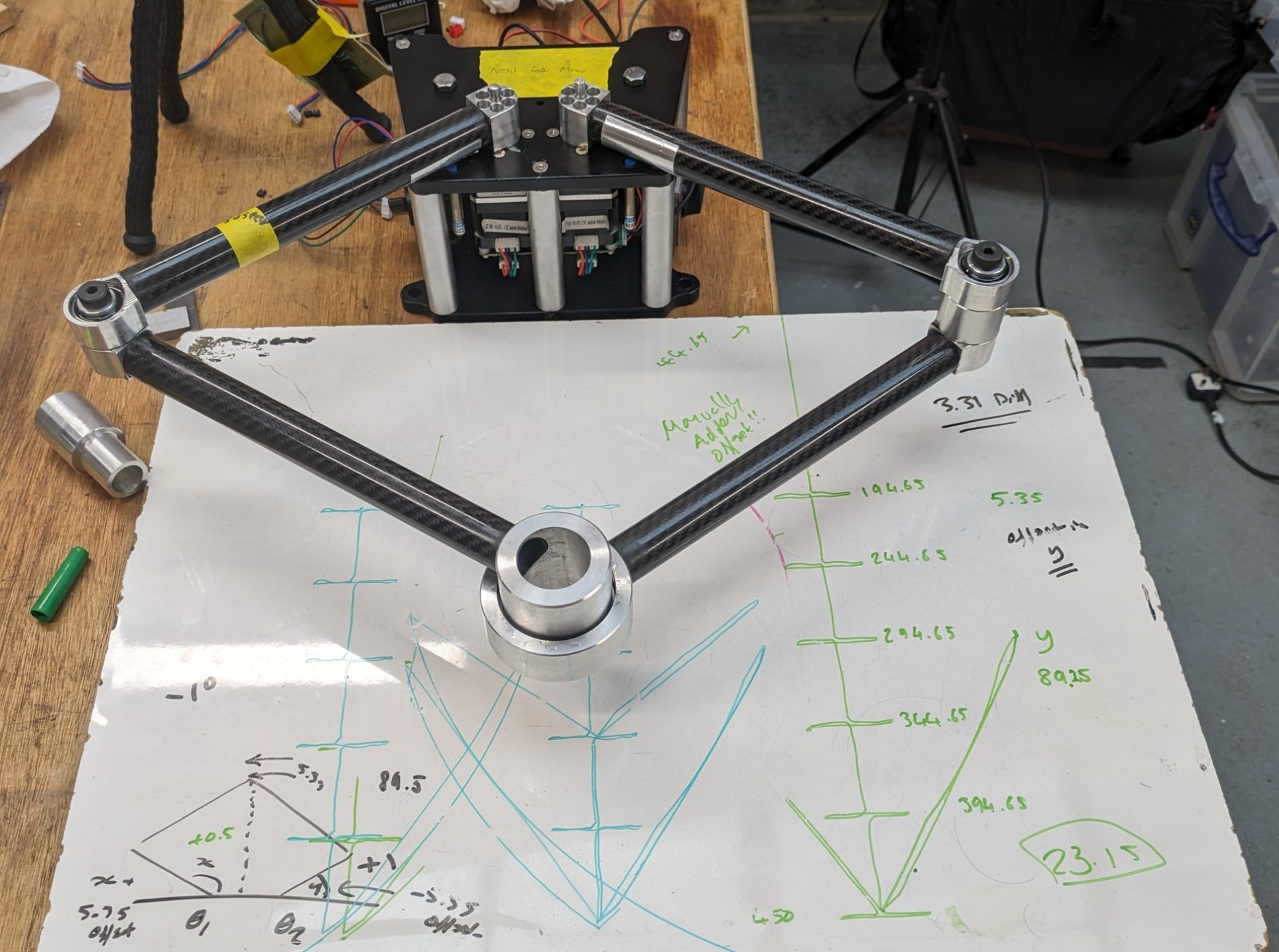

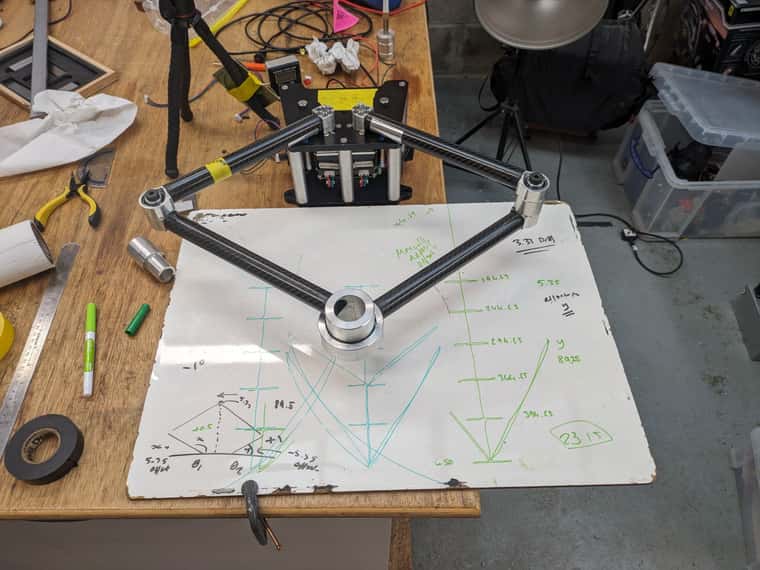

So a little update, I have spent a long time trying to calibrate things. I am currently using servo42c drivers, because my testing shows they increase torque from the little nema motors massively. I think my right gearbox and servo42c arrangement may be damaged, as it doesn't seem as repeatable as the left motor assembly. I think I may laser cut a grid to use as a positioning template so I can see difference between intended end effector position and achieved position. I have been using a whiteboard and a pen for this so far but it's not ideal. Both my motors are able to be manually driven from 90 degrees to horizontal and align nicely. I think maybe my arm lengths are wrong, as the aluminium piecesal are glued into the carbon tubes their lengths aren't very precise. I've tried to account for this but I don't think it's very good yet.

-

RE: CNC Parallel SCARA Plasma Cutter - GCODE Issuesposted in CNC

@droftarts I am more than happy to write up my findings and help with the documentation. I think last night I discoevered that the M350 command doesnt have an effect, and instead off scaling values for microstepping etc need to be incorporated into M92. I am now looking into why the joints aren't moving the correct amount, It may be because of my closed loop stepper drivers so once i've done some learning I will feed back the information

-

RE: CNC Parallel SCARA Plasma Cutter - GCODE Issuesposted in CNC

@o_lampe Thanks for your help! I have managed to get the machine working with Fusion 360. Does anyone happen to have a calibraiton procedure? I have tried measuing arm lengths, homing positions and end effector positions to calculate homing offsets etc, however I am struggling to get the machine to draw circular circles and to make shapes that are the correct size. If anyone has a good methodology for calibration please let me know ! Thanks

-

RE: CNC Parallel SCARA Plasma Cutter - GCODE Issuesposted in CNC

@dc42 Okay, will this still work with a desired feedrate in cartesian space? Presumably for plasma cutting I dont want the end effector to be adjusting velocities. Additionally, are you aware of any post processors or methods for GCODE generation that would work well with my machine? I am wondering about changing it from CNC mode to FFF mode, it seems more parallel scara printers exist so wondering fi thats a more proven path.

-

RE: CNC Parallel SCARA Plasma Cutter - GCODE Issuesposted in CNC

@dc42 @o_lampe I am currently using a BTT SKR V1.4 board, the latest firmware I can run on this board is 3.3.0. This means I think im unable to set G94 or G93 commands. Any ideas? If its the case I need to buy a new board do you happene to have any recommendations?