@hurzhurz I want to thank you for the fantastic work you have done.

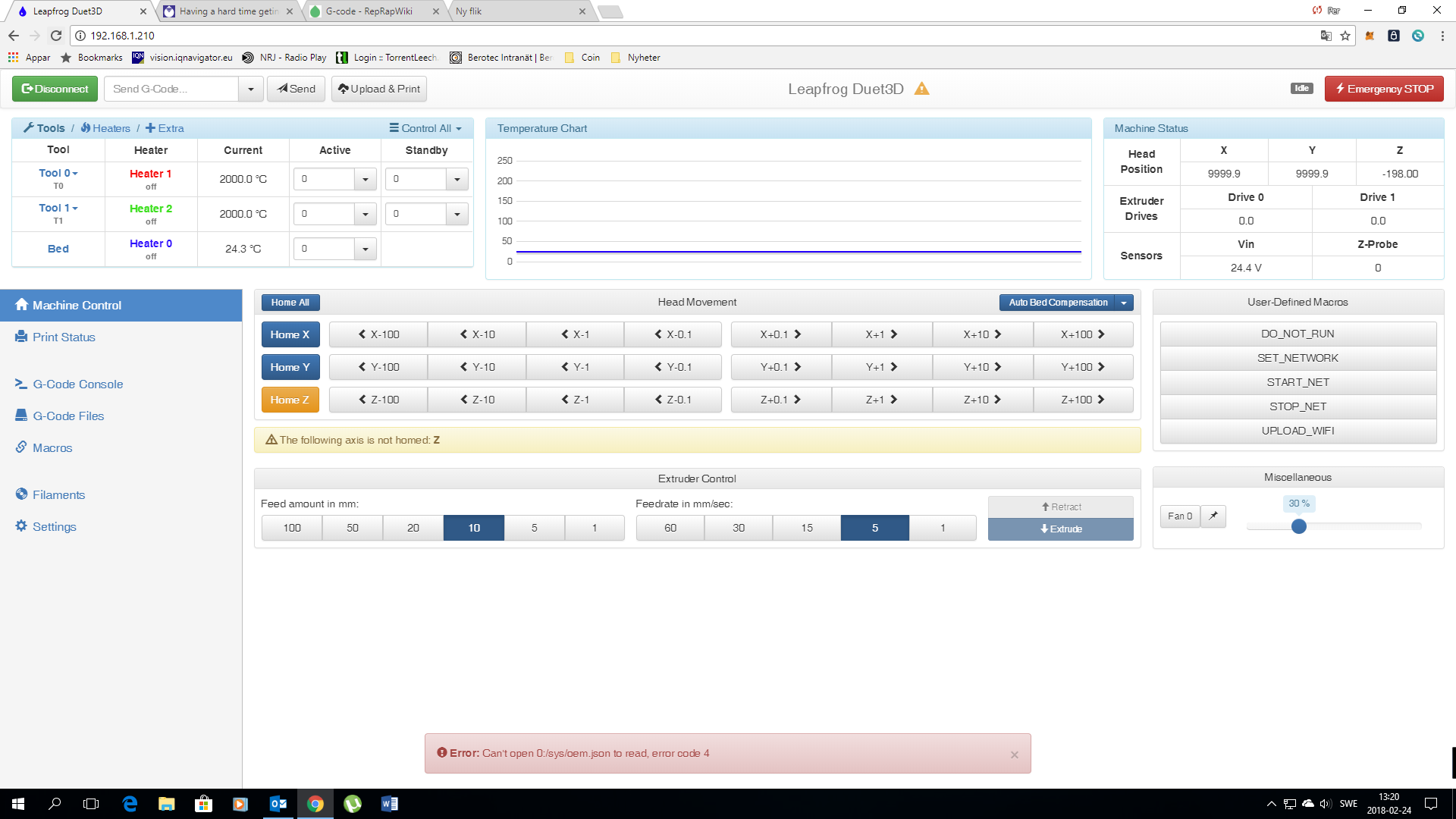

I started looking for a pendant solution for my CNC roughly a week ago and today I finished the build. Almost plug and play with the instructions you provided. Amazing to have a wireless pendant. Still surprises me that it works.

Only thing I had to figure out was where to put the macro folder. It should be in the systems directory and not the macros.

Total cost was 200€ for the six channel pendant and some spare raspberry picos, Panel USB and such. It worked first try and no smoke was produced during the build.

I’m truly grateful  ️

️

Perhaps have rolling side supports instead of fixed ones.

Perhaps have rolling side supports instead of fixed ones.