@oliof Thanks!

@everyone Almost all of my questions have now been answered. Let this post die! (see my new post)

@oliof Thanks!

@everyone Almost all of my questions have now been answered. Let this post die! (see my new post)

Ok here are some questions I have. Sorry if this info is readily available somewhere.

Duet 2 Ethernet - firmware 2.03 to 2.05

I am using 2 Z motors on headers ZA and ZB. Do I double the value for amps of the motor when I input the rated z amperage?

I have my BLtouch as a z-probe wired like this:

BLTouch-------to------Duet

out (white) --- Zprobe header, input

GND (black) --- Zprobe header, GND

+5V (red) --- Expansion, +5v (pin1.)

Control (yellow) --- Expansion, Heater3 (pin 8.)

GND (brown) --- Expansion, GND (pin 2.)

Is this a typical configuration, and if so, do I set the servo control to E3 Channel?

For my fans, I have 2 extruders, each with their own heatsink fan. I also have a parts-cooling fan. I set the extruder fans for no thermostatic control, so they would be on all the time, wired to the non-pwm fan headers. I set the parts-cooling fan to no thermostatic control so my slicer can control it, wired to pwm control. Will those configurations operate my fans as intended?

How do I add a 3rd always-on fan for the duet board cooling? Possibly wire the two extruder, always-on fans in parallel?

I am not sure how to configure my tool. I currently have a single Tool 0, set with extruders E0 and E1, heaters E0 and E1, and fans 1 and 2. Is this a typical configuration?

Is there a spot to input the x-offset for the space between my two extruder nozzles?

Thanks for your time and advice, Dad

@oliof Thanks!

@everyone Almost all of my questions have now been answered. Let this post die! (see my new post)

config-override.g

homeall.g

bed.g

Cura start code - I accidently uninstalled Cura and I have not reconfigured the start code from the default "custom printer" gcode since reinstalling it. On my previous setup, I had added lines to probe around the heat bed before each print to check for level and to compensate accordingly. I can't remember where I got that info though. Im sure it's completely wrong but here it is:

G28 ;Home

G1 Z15.0 F6000 ;Move the platform down 15mm

;Prime the extruder

G92 E0

G1 F200 E3

G92 E0

My X and Y motors are stock. Should both be the Creality 42-34.

Both of the Z motors are new. Here is the Amazon listing.

Both of the extruder motors are also new. (note they are Nema14) Here is the Digi-Key listing. Each motor uses a 200mm belt with a 20-tooth pulley to drive an 80-tooth pulley.

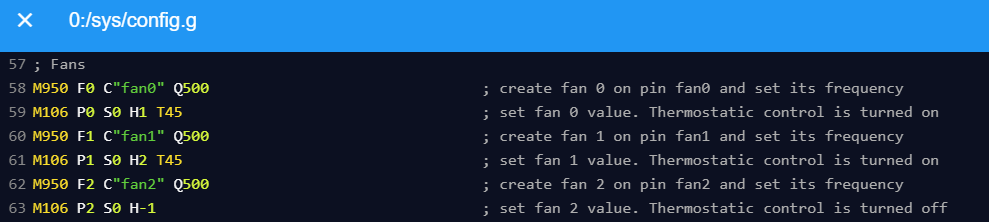

As far as the fan configuration goes, here is what I see when I check my config file:

Im not sure what your screenshot is from, maybe im missing something..

BTW I attached my config-override as requested.

See pictures and files.

I didn't realize this forum had an instant messaging feature.

@paulhew I am not sure where I heard someone use this term, but I just mean a dual extruder assembly - 2 hot ends.

What works -

What has not been configured/need help with -

Need video/messaging support.

This is a legitimate post. I am 100% trustworthy.

I built a machine too complicated for me to gcode. I need someone's help to compile/configure the machine with my help. To make decisions for me, asking me to measure X or Y or what is the value of X or Y etc.

It is a modified Ender 3 v2 with new Duet 2 ethernet board running RRF 3, new second Z axis motor, new dualstruder with z probe. I don't know why I made so many changes at once but I did. I have spent hours here and there over the past several months trying to get this configured with no luck. I can access web control etc. Im pretty sure I know all of the dimensions and offsets, aside from the probe offset.

I will pay for someone to Skype/Discord etc with me to get this thing printing. Somewhere around $75 an hour with a minimum of $100, probably rounded up in your favor. I can send the money via PayPal or Zelle or similar service. I can provide pictures, diagrams, specs, etc. We can discuss a date and time to connect that works for both of us.

I feel dumb.

Dad

email me:

davidcwasd@gmail.com

Hey guys, im trying to setup my printer after taking a few months off of....trying to setup my printer.

I need to find and set the zprobe offset, but I cant command the printer to lower the nozzles because it isnt homed, but I cant home it until I know the zprobe offset. Using G92 Z, I can raise the tools and lower them back to the position it was at but I cant go lower. Is there a command to unlock the printer so I can lower it without it needing to be homed? Or is there a good way to find the zprobe offset knowing I cant home my z axis? Thanks

Dad

@phaedrux said in Duet2 Ethernet RRF3 Motor issue:

If you send M906 in the console by itself it will report back with whatever default currents it's using. See what that is. Then change your config.g to add a M906 line to set the currents correctly and see how it behaves.

^ After finally getting a chance to input the correct current values for the motors, the binding seems to have stopped!!! Thanks guys.

@phaedrux ok so

M906 X1200 Y1200 Z800:800 E800:800?

Im not sure about the Z motors in series if I list it twice like I do for the 2 extruders.

m906

Motor current (mA) - X:0, Y:0, Z:0, E:0:0, idle factor 30%

hm.... currently looking up my motors' rated currents again to reenter info.

Dad

EDIT:

Alrighty so I have these motors at the rating listed:

X,Y - 1.5amps each

Z,Z in series - 1amp each

E,E - 1amp each

Is this the proper format for m906 assuming 85% ratings in milliamps?

M906 X1275 Y1275 Z850:850 E850:850

@phaedrux

interesting, i input all the motors' current in the config wizard but something must have happened...

the motor is smooth when powered off.