@oliof Thanks!

@everyone Almost all of my questions have now been answered. Let this post die! (see my new post)

@oliof Thanks!

@everyone Almost all of my questions have now been answered. Let this post die! (see my new post)

config-override.g

homeall.g

bed.g

Cura start code - I accidently uninstalled Cura and I have not reconfigured the start code from the default "custom printer" gcode since reinstalling it. On my previous setup, I had added lines to probe around the heat bed before each print to check for level and to compensate accordingly. I can't remember where I got that info though. Im sure it's completely wrong but here it is:

G28 ;Home

G1 Z15.0 F6000 ;Move the platform down 15mm

;Prime the extruder

G92 E0

G1 F200 E3

G92 E0

My X and Y motors are stock. Should both be the Creality 42-34.

Both of the Z motors are new. Here is the Amazon listing.

Both of the extruder motors are also new. (note they are Nema14) Here is the Digi-Key listing. Each motor uses a 200mm belt with a 20-tooth pulley to drive an 80-tooth pulley.

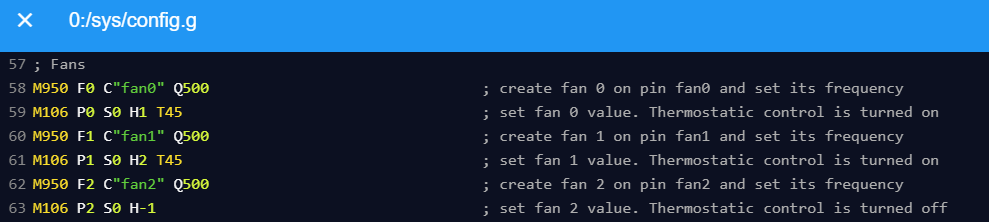

As far as the fan configuration goes, here is what I see when I check my config file:

Im not sure what your screenshot is from, maybe im missing something..

BTW I attached my config-override as requested.

See pictures and files.

I didn't realize this forum had an instant messaging feature.

@paulhew I am not sure where I heard someone use this term, but I just mean a dual extruder assembly - 2 hot ends.

What works -

What has not been configured/need help with -

Need video/messaging support.

This is a legitimate post. I am 100% trustworthy.

I built a machine too complicated for me to gcode. I need someone's help to compile/configure the machine with my help. To make decisions for me, asking me to measure X or Y or what is the value of X or Y etc.

It is a modified Ender 3 v2 with new Duet 2 ethernet board running RRF 3, new second Z axis motor, new dualstruder with z probe. I don't know why I made so many changes at once but I did. I have spent hours here and there over the past several months trying to get this configured with no luck. I can access web control etc. Im pretty sure I know all of the dimensions and offsets, aside from the probe offset.

I will pay for someone to Skype/Discord etc with me to get this thing printing. Somewhere around $75 an hour with a minimum of $100, probably rounded up in your favor. I can send the money via PayPal or Zelle or similar service. I can provide pictures, diagrams, specs, etc. We can discuss a date and time to connect that works for both of us.

I feel dumb.

Dad

email me:

davidcwasd@gmail.com

Hey guys, im trying to setup my printer after taking a few months off of....trying to setup my printer.

I need to find and set the zprobe offset, but I cant command the printer to lower the nozzles because it isnt homed, but I cant home it until I know the zprobe offset. Using G92 Z, I can raise the tools and lower them back to the position it was at but I cant go lower. Is there a command to unlock the printer so I can lower it without it needing to be homed? Or is there a good way to find the zprobe offset knowing I cant home my z axis? Thanks

Dad

@phaedrux said in Duet2 Ethernet RRF3 Motor issue:

If you send M906 in the console by itself it will report back with whatever default currents it's using. See what that is. Then change your config.g to add a M906 line to set the currents correctly and see how it behaves.

^ After finally getting a chance to input the correct current values for the motors, the binding seems to have stopped!!! Thanks guys.

@phaedrux ok so

M906 X1200 Y1200 Z800:800 E800:800?

Im not sure about the Z motors in series if I list it twice like I do for the 2 extruders.

m906

Motor current (mA) - X:0, Y:0, Z:0, E:0:0, idle factor 30%

hm.... currently looking up my motors' rated currents again to reenter info.

Dad

EDIT:

Alrighty so I have these motors at the rating listed:

X,Y - 1.5amps each

Z,Z in series - 1amp each

E,E - 1amp each

Is this the proper format for m906 assuming 85% ratings in milliamps?

M906 X1275 Y1275 Z850:850 E850:850

@phaedrux

interesting, i input all the motors' current in the config wizard but something must have happened...

the motor is smooth when powered off.

@phaedrux

heres a link to a video showing the problem.

I dont believe I have mesh compensation active. I have never turned it on via the web control at least.

@Phaedrux

I have not altered the steps/mm.

The unregistered commands are the movements I tell it to do through the web interface. When I say unregistered I mean they act up, ie only move a small amount, noisy etc.

Each motor has its current set to 80% of its rated value.

Today is the first day I have seen this problem with these motors. They moved fine before.

Both my X and Y motors are showing problems. Can't test Z motors because I cant home Z so I cant ask it to move Z.

Thanks

Dad

Hey dudes. Ive been trying to configure the firmware for my new duet2, and suddenly my motors are acting strangely even though I was only changing settings for m208. I was sending them movement commands testing the end stops etc, and about 30% of the commands dont "register." The motor tries to move, making an unusual noise, and travels about 5mm instead of the requested 50mm. I have lowered the acceleration and movement speeds with no luck.

Any tips appreciated.

Dad

thank you im going to use this too

@phaedrux said in Dual extruder coordinates with illustration:

It may make more sense to have 0,0 be at the center of the bed and then work out from there.

https://duet3d.dozuki.com/Wiki/Centering_the_bed_or_setting_the_bed_origin

I wondered if that was a thing. I wasnt sure if negative coords were appropriate. Ill check out the link, thank you.

@alex-cr

yes very helpful, thank you

@o_lampe

Thanks for the info. I didnt even know IDEX was a thing, good article.

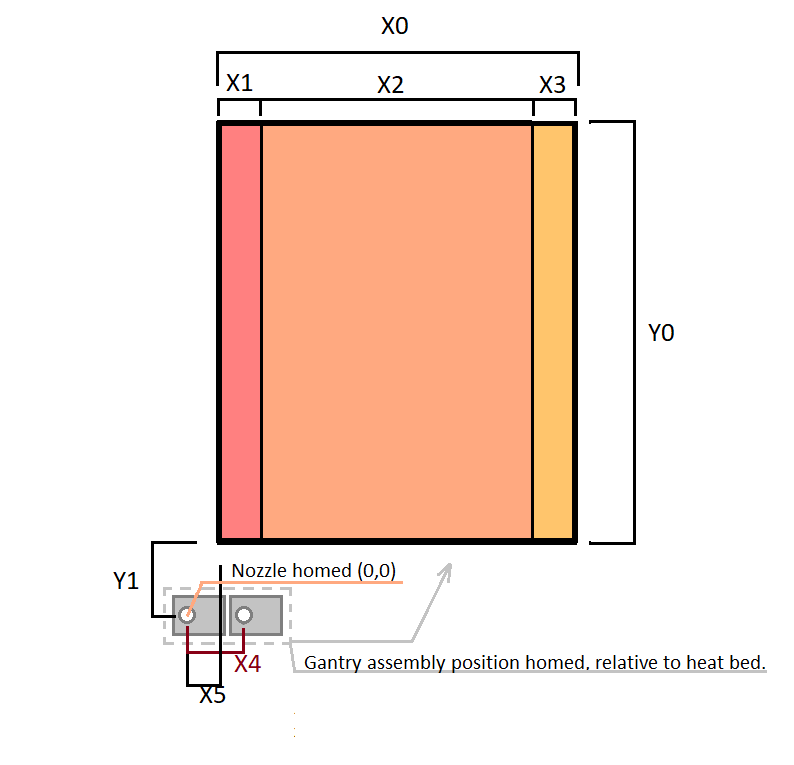

Hello folks, I am in the middle of setting up my duet for the first time with more motors etc, and I have some questions regarding dual extrusion coordinates and gcode using RRF3. First, if these questions are already covered somewhere share the link! I'd be happy to read. Check out my fancy illustration for references. Not to scale - exaggerated to show detail. The two extruders land outside of the heat bed when X and Y end stops are triggered.

I know this is a lot to answer but thanks to anyone who helps!

X0 - 200mm

Y0 - 220mm

X1, X3, X4 - 27mm (I assume all 3 should be the same dimension)

X2 - 146mm

Y1 - 30mm

X5 - 15mm

Thanks, Dad

i see, I assumed the heatsink fans were tool fans considering they are attached to the tools.

I do have 2 tool fans though, fan0 and fan1. I have two extruders each with their own heat sink fans. Fan2 is a parts cooling fan, not a tool fan.

The fan slider is operating my parts cooling fan.

Also, If S0 or S1 is the command for fan start on/off then why is only one fan starting on, when two of them have S1 in the gcode?