I leave the results for those who suffer from the same symptoms as me.

This issue was resolved in RRF 3.3

Posts made by psyblue

-

RE: I can't print a small object with Duet3 +1LCposted in Using Duet Controllers

-

RE: CAN Failure after bootloader updateposted in Using Duet Controllers

@dc42, I am also glad that the problem disappeared with the bootloader 2.3, but I am curious if the above symptoms match the potential problem with Bootloader 2.2

-

RE: CAN Failure after bootloader updateposted in Using Duet Controllers

All of the above symptoms are considered a problem with Bootloader 2.2.

After updating to Bootloader 2.3 via ATMEL-ICE, everything works fine.

Thank you for the bootloader 2.3.

-

RE: I can't print a small object with Duet3 +1LCposted in Using Duet Controllers

Thank you very much for your kind comment. I'm reading the thread you gave me.

-

I can't print a small object with Duet3 +1LCposted in Using Duet Controllers

Attached file is a small-spacer-part. (8 x 20mm cylinder)

I have several printers.

One of them is Duet2 Ethernet + Duex5 + RRF3.2.2

The other is Duet3 6HC + 1LC + RRF3.2.2Duet2 board can print it perfect.

Duet3 + 1LC does not print properly.

It seems that the 1LC Extruder ignores the movement of the short filament as '0' through several experiments.It is not a motor torque problem. When I disassemble the extruder and observe the extruder motor, it hardly rotates unlike duet2.

Even printers with Duet3 + 1LC seem to print normally when printing large obects. But, looking it closely, thin-walled-infills were not printed properly.

Please comment on what I need.

If you have 1LC-Extruder-printer, please print the attached STL. (It's very small, - 20x8mm cylinder) And I hope you would share the result.

Thanks.

-

RE: CAN Failure after bootloader updateposted in Using Duet Controllers

I am Korean in Korea, bought at filastruder.com

Isn't it a known problem?

It could be an important source of potential bugs in the future.

I can send you one, if you want. Of course, I want to get it back with the improved one.However, I have anxiety that seems to work normally in your hand as always

Or, I ordered ATMEL ICE. I will reprogram it and report the result.

It will take about 2 weeks.And short question,

Is there any changed or added pull-up/ pull-down resistor on 3HC board? -

RE: CAN Failure after bootloader updateposted in Using Duet Controllers

Dear dc42,

First of all, thank you very much for the always quick and kind reply.

I've tried following your advice, One of three boards could be made with firmware v3.1.1 + Bootloader v1.3.

I repeated the test with this.

I thought it was OK with firmware v3.1.1 + Bootloader v1.3, but there was a problem.

When 3HC is disconnected from every cable (include CAN) and only power is connected, does not the DIAG red LED flash at all, just off state.

Repeated plugging in and unplugging the CAN cable, the red LED starts blinking.The other 2 3HC are still ICE"ICE-state" (I don't know what to call it in English. I call it'ICE'. power-on, no response, no blinking, do nothing state)

Disconnected the 3HC board from CAN and set the address to zero (all switches off), does not the DIAG red LED flash at all, just off state.

The 3HC is not connected to CAN in any way.In my experience, I suspect the bootloader 2.2. the bootloader procedure seems to be stuck in the CAN init loop.

Even when it worked normally in the past, sometimes (30% probability) there was a situation where it was suspected that booting was delayed.

Because I found a case where the contents of config.g were not passed to 3HC.

So, I put "G4 S2" (delay 2 seconds) at the beginning of config.g.I hope you try to reproduce the same situation as me.

And 1LC looks fine.

-

RE: CAN Failure after bootloader updateposted in Using Duet Controllers

As a result, The worst has happened. All three HC3 boards have been ICE-state(red diagnostic LED off, No response).

No response for M122 B1. No response to the reset buttonI tested several things using the HC3 board I had.

RRF3.1 + Bootloader1.3 (estimated, No ID on diagnostics) -> good

RRF3.2.2 + Bootloader1.3 -> good

RRF3.2.2 + Bootloader2.2 -> Abnormal

RRF3.2.2 + Bootloader1.3 Down grade -> HC3 ICE-stateNo problem on 1LC board.

I need the ATMEL ICE tool.

-

CAN Failure after bootloader updateposted in Using Duet Controllers

After testing several times, I suspect bootloader v2.2.

Any advice would be appreciated.

Environment :

- Board configuration: MB6HC----------3HC----------1LC

- Frimware: v3.2

- Bootloader: v2.2

- CAN Bus termination: open on 3HC, 120 Ohm termination on 1LC, cables are good condition.

Symptom :

- No CAN-diagnsis-red-LED blicking on 3HC after power-on and communication time-out for'M122 B1' command.

- If CAN cable between 3HC and 1LC is unplugged, CAN-diagnsis-LED(red) on 3HC starts blinking.

- Then operates normally after plugged.

- Before update the bootload, it worked good.

Diagnosis results

- Before update

M122 B121 Diagnostics for board 121: Board TOOL1LC firmware 3.1.0 (2020-05-15b1) Never used RAM 8.7Kb, max stack 352b HEAT 1184 CanAsync 1460 CanRecv 1416 TMC 204 AIN 524 MAIN 2308 Last reset 00:00:51 ago, cause: power up Driver 0: standstill, SG min/max 0/0, read errors 0, write errors 0, ifcount 9, reads 25502, writes 9, timeouts 1, DMA errors 0, failedOp 0x80 Moves scheduled 0, completed 0, hiccups 0 VIN: 24.1V MCU temperature: min 13.6C, current 17.7C, max 17.7C Ticks since heat task active 58, ADC conversions started 50881, completed 50880, timed out 0 Last sensors broadcast 00000000 found 0 61 ticks ago Free CAN buffers: 36 NVM user row b1d088a9 fffff8bb 20002a18 b TSENS 0006f9 GAIN 015ac2 OFFS 00241e CAL 1f2a- After update

M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.2 running on Duet 3 MB6HC v0.6 or 1.0 (standalone mode) Board ID: 08DJM-956BA-NA3TJ-6JKDG-3S86R-TU9UT Used output buffers: 1 of 40 (22 max) === RTOS === Static ram: 149788 Dynamic ram: 92720 of which 76 recycled Never used RAM 116248, free system stack 188 words Tasks: NETWORK(ready,163) ETHERNET(blocked,118) HEAT(blocked,302) CanReceiv(blocked,834) CanSender(blocked,352) CanClock(blocked,356) TMC(blocked,19) MAIN(running,1095) IDLE(ready,19) Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:01:22 ago, cause: power up Last software reset at 2021-03-03 11:41, reason: User, GCodes spinning, available RAM 116152, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Aux1 errors 0,0,0 MCU temperature: min 17.0, current 17.3, max 17.4 Supply voltage: min 23.8, current 23.8, max 23.9, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.0, current 12.0, max 12.1, under voltage events: 0 Driver 0: position 8, standstill, reads 15712, writes 0 timeouts 0, SG min/max not available Driver 1: position 8, standstill, reads 15712, writes 0 timeouts 0, SG min/max not available Driver 2: position 20727, standstill, reads 15712, writes 0 timeouts 0, SG min/max not available Driver 3: position 0, standstill, reads 15713, writes 0 timeouts 0, SG min/max not available Driver 4: position 0, standstill, reads 15712, writes 0 timeouts 0, SG min/max not available Driver 5: position 0, standstill, reads 15712, writes 0 timeouts 0, SG min/max not available Date/time: 2021-03-03 14:59:00 Slowest loop: 22.45ms; fastest: 0.05ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 2.2ms, write time 16.4ms, max retries 0 === Move === DMs created 125, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 1, completed moves 1, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 Heater 1 is on, I-accum = 0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is ready with "M122 " in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 28.11ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 1 of 8 - Ethernet - State: active Error counts: 0 0 1 0 0 Socket states: 5 2 2 2 2 0 0 0 === CAN === Messages queued 11, send timeouts 0, received 36, lost 0, longest wait 0ms for reply type 0, free buffers 48 M122 B1 Diagnostics for board 1: Duet EXP3HC firmware version 3.2 (2021-01-05) Bootloader ID: SAME5x bootloader version 2.2 (2021-01-16b1) Never used RAM 154896, free system stack 200 words HEAT 102 CanAsync 94 CanRecv 87 TMC 64 MAIN 299 AIN 257 Last reset 00:00:07 ago, cause: software Last software reset data not available Driver 0: position 0, 80.0 steps/mm, standstill, reads 35212, writes 11 timeouts 0, SG min/max 0/0 Driver 1: position 0, 80.0 steps/mm, standstill, reads 35214, writes 11 timeouts 0, SG min/max 0/0 Driver 2: position 0, 80.0 steps/mm, standstill, reads 35217, writes 11 timeouts 0, SG min/max 0/0 Moves scheduled 0, completed 0, in progress 0, hiccups 0 No step interrupt scheduled VIN: 24.3V, V12: 12.3V MCU temperature: min 28.1C, current 28.1C, max 28.1C Ticks since heat task active 30, ADC conversions started 7772, completed 7771, timed out 0 Last sensors broadcast 0x00000000 found 0 33 ticks ago, loop time 0 CAN messages queued 18, send timeouts 0, received 108, lost 0, free buffers 36 M122 B121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.2 (2021-01-05) Bootloader ID: SAMC21 bootloader version 2.2 (2021-01-16b1) Never used RAM 4140, free system stack 96 words HEAT 90 CanAsync 89 CanRecv 83 TMC 60 MAIN 218 AIN 70 Last reset 00:00:45 ago, cause: power up Last software reset data not available Driver 0: position 0, 420.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 13, reads 22960, writes 13, timeouts 0, DMA errors 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0 No step interrupt scheduled VIN: 24.1V MCU temperature: min 6.1C, current 10.1C, max 10.1C Ticks since heat task active 227, ADC conversions started 45840, completed 45839, timed out 0 Last sensors broadcast 0x00000002 found 1 230 ticks ago, loop time 0 CAN messages queued 422, send timeouts 0, received 385, lost 0, free buffers 36 -

RE: A heater fault occurs on the LC1 board.posted in Using Duet Controllers

The cause was old auto tuning value.

I commented the M307 line and using the default value, the fault situation disappeared.Thanks Veti !!

-

RE: A heater fault occurs on the LC1 board.posted in Using Duet Controllers

@Veti

Great thanks!!!I'll update the boot-loader & tuning values.

-

RE: A heater fault occurs on the LC1 board.posted in Using Duet Controllers

Thank you for your interest in my writing.

I have a few questions in your relpy.

How to update the bootloader? Is it different from the firmware update?

How did you know it was old PID tunning just by looking at the result? Fortunately, I don't use a fan.

Thanks again. -

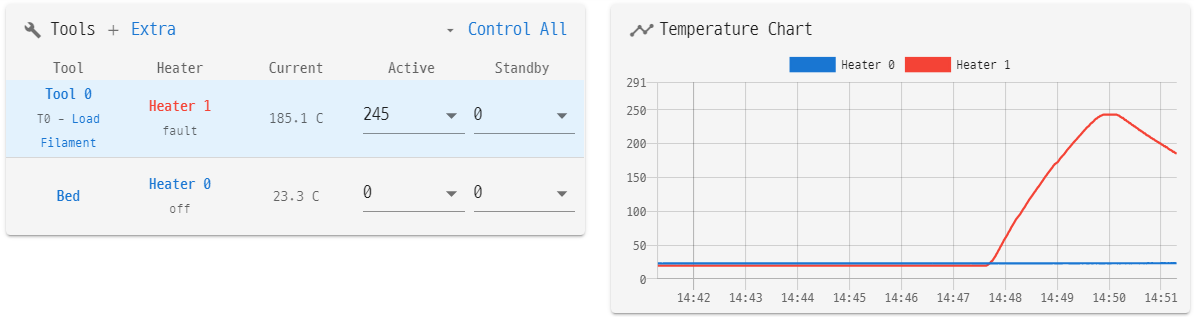

A heater fault occurs on the LC1 board.posted in Using Duet Controllers

A heater fault occurs on the LC1 board at a frequency of about 70%.

Environment

- firmware version: 3.2

- temperature sensor: PT1000

- heating block: Volcano

Symptom

When the temperature is set, the set temperature is normally reached.

After 10~20 seconds, the heater turns off due to a fault.

There is no error message in the console.

M122 B121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.2 (2021-01-05) Bootloader ID: not available Never used RAM 4100, free system stack 50 words HEAT 86 CanAsync 85 CanRecv 83 TMC 54 MAIN 216 AIN 64 Last reset 00:45:37 ago, cause: software Last software reset data not available Driver 0: position 540589, 420.0 steps/mm, standstill, SG min/max 0/270, read errors 0, write errors 0, ifcnt 31, reads 4878, writes 10, timeouts 0, DMA errors 0 Moves scheduled 2213, completed 2213, in progress 0, hiccups 2553 No step interrupt scheduled VIN: 24.0V MCU temperature: min 36.5C, current 43.1C, max 48.2C Ticks since heat task active 71, ADC conversions started 2732191, completed 2732190, timed out 0 Last sensors broadcast 0x00000002 found 1 75 ticks ago, loop time 0 CAN messages queued 27429, send timeouts 0, received 22560, lost 0, free buffers 36Here is my full config.sys file

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;; Sys-config for Duet3 + 1LC ;;; ;;;; 1LC CAN Address = 121 ;;; ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ; /sys/config.g ;;;;; Ethernet networking ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M550 P"Voron300" ; Machine name and Netbios name (can be anything you like) ;M551 P"tmddms" ; Machine password (used for FTP) ;M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address M552 P192.168.0.230 S1 ; IP address ;M553 P255.255.255.0 ; Netmask ;M554 P192.168.0.254 ; Gateway M586 P0 S1 ; HTTP S0:Disable, S1:Enable M586 P1 S0 ; FTP S0:Disable, S1:Enable M586 P2 S0 ; Telnet S0:Disable, S1:Enable ;;;;; Kinematics ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M669 K1 X-1:-1:0 Y1:-1:0 Z0:0:1 ;Core XY ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves ;;;; Z Axis motor Location ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ; ; Z1 Z2 ; ; ; Z0 Z3 ;;;;; Drives & Axis ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;; Para. : P for driver No. S for Direction (0 = backward, 1 = forward) M569 P0.0 S1 ; A of XY M569 P0.1 S1 ; B of XY M569 P0.2 S0 ; Z0 M569 P0.3 S1 ; Z1 M569 P0.4 S0 ; Z2 M569 P0.5 S1 ; Z3 M569 P121.0 S1 ; Extruder ;;;;; Z Gear Ratio = 5.181818... M584 X0.0 Y0.1 Z2:3:4:5 E121.0 ; set drive mapping M92 X80 Y80 Z414.545454 E420 ; steps/mm @ 16-micro-stepping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M566 X1200 Y1200 Z2400 E2200 ; set maximum instantaneous speed changes (mm/min) M203 X24000 Y24000 Z4800 E2200 ; set maximum speeds (mm/min) M201 X5000 Y5000 Z2000 E3000 ; set Max accelerations (mm/s^2) M906 X1600 Y1600 Z1200 E600 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ;;;;; Axis Limits = Working Area ;;;;;;;;;;;;;; M208 X-140 Y-150 Z0 S1 ; set axis minima M208 X140 Y150 Z250 S0 ; set axis maxima ;;;; 4-Motor-Z-Axis define M671 X-200:-200:200:200 Y-200:170:170:-200 S10.0; S>Maximum correction to apply to each leadscrew in mm ;;;;; Endstops ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M574 X1 S1 P"!^io0.in" ; configure active-low endstop for low end on X via M574 Y2 S1 P"!^io1.in" ; configure active-low endstop for low end on Y via M574 Z1 S2 ; configure Z-probe endstop for low end on Z ;;;;; Z-Probe ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M558 P8 C"121.io0.in" H5 F120 T12000 ; Liquid Head G31 P500 X0 Y0 Z-0.3 ; Liquid Head M950 S0 C"121.io0.out" ; create servo/gpio 0 (for BL Touch) M280 P0 S160 ; BL Touch Reset (servo-0) M280 P0 S10 ; BL Touch Pin Down (servo-0) ;;;;; Mesh Grid M557 X-130:130 Y-130:130 P5:5 ; define mesh grid, NOT nozzle co-orditnate, PROBE point!!! ;G29 S1 ; load height map G29 S2 ; Clear height map ;;;;; Extruder ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M302 S140 R110 ; Allow extrusion starting from 140°C and retractions already from 110°C ;;;;; Bed Heaters ;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M308 S0 P"temp0" Y"thermistor" ; T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"out0" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M570 S60 ; Heater timeout 60 seconds ;;;;; Hot-End Heaters ;;;;;;;;;;;;;;;;;;;;;;;;; M308 S1 P"121.temp0" Y"pt1000" ; Sensor no.1 on temp0, PT-1000 M950 H1 C"121.out0" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S291 ; set temperature limit for heater 1 to 280C M307 H1 A1077.7 C574.8 D5.6 S1.00 V23.9 B0 ; Auto tune result - Super volcano ;;;; Super Volcano auto tune ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;; M303 H1 S250 ;;;; Auto tuning heater 1 using target temperature 250.0°C and PWM 1.00 - do not leave printer unattended ;;;; ;;;; M307 H1 ;;;; Heater 1 model: gain 1077.7, time constant 574.8, dead time 5.6, max PWM 1.00, calibration voltage 23.9, mode PID ;;;; Computed PID parameters for setpoint change: P17.0, I0.299, D66.6 ;;;; Computed PID parameters for load change: P17.0, I0.835, D66.6 ;;;;; Fans ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M950 F0 C"121.out2" Q100 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;;;;; Tools ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;;;;; Custom settings are not defined ;;;;;;;;; ;M555 P2 ; Set output to look like Marlin ;;;;; Miscellaneous ;;;;;;;;;;;;;;;;;;;;;;;;;;; T0 ; select first tool ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;;; Advanced Option ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;; ;;;;; Firmware Retraction M207 S1.0 R0.05 F9999 Z0.1 ; Retraction Setting: 1.0mm +0.1mm, Feedrate=9999mm/min, Z-hopping=0.2mm ;;;;; Pressure advance M572 D0 S0.1 ; Extruder0 0.1sec advance ;;;;; Dynamic Acceleration Adjustment ;;;;;;;;;;;;;;;;;;;;;; M593 F39.7 ; cancel ringing at 40.5Hz

-

RE: [Issue report] Duet 3, Connection lostposted in Duet Hardware and wiring

Thank you for your attention.

I'm inspecting my network router now. It's hard to debugging.

-

Is that the correct gateway address? -> Yes

-

Can you try deleting the entire line and typing again? -> Yes

-

If you send M554 by itself in the console what does it echo back? ->

M552

Ethernet is enabled, configured IP address: 0.0.0.0, actual IP address: 192.168.0.50

M553

Net mask: 255.255.255.0

M554

Gateway: 0.0.0.0 -

If you leave out the netmask and gateway and set the IP address to all 0's to use DHCP what gateway does M554 report? ->

M552

Ethernet is enabled, configured IP address: 0.0.0.0, actual IP address: 192.168.0.50

M553

Net mask: 255.255.255.0

M554

Gateway: 0.0.0.0 -

Can you post your full config.g? -> Above is the full config.g for test.

-

-

[Issue report] Duet 3, Connection lostposted in Duet Hardware and wiring

[Issue report] Connection lost when setting the network gateway manually

- Environment

-Duet3 6HC main board (ver0.6)

-Duet Web Control 3.1.1

-RepRapFirmware 3.1.1 (2020-05-19b2)

I am using Duet2 Ethernet/Maestro and Duet3-6HC.

"Lost connection" occurs often with Duet3.

The result of the test, ...

if the network gateway is set manually and execute M98 P"config.g" in the console. then time out + connection lost.

If you comment on the M554 line, it works good.

The above symptoms are not found in Duet2.

Below is the tested config.g and console prints

;### config.g #################

M550 P"Voron30" ; Machine name and Netbios name (can be anything you like)M552 P192.168.0.230 S1 ; IP address

M553 P255.255.255.0 ; Netmask

M554 P192.168.0.254 ; Gateway

M586 P0 S1 ; HTTP S0:Disable, S1:Enable

M586 P1 S0 ; FTP S0:Disable, S1:Enable

M586 P2 S0 ; Telnet S0:Disable, S1:Enable;### console ##################

-

-

- PM 8:32:53 Connection established

-

-

-

- PM 8:32:30 Connection interrupted, attempting to reconnect...

HTTP request timed out

- PM 8:32:30 Connection interrupted, attempting to reconnect...

-

-

-

- PM 8:32:30 M98 P"config.g"

HTTP request timed out

- PM 8:32:30 M98 P"config.g"

-

- Environment

-

RE: I want to control respectively 4 motors already mapped to Z-axisposted in Tuning and tweaking

Thank you for your reply.

I'm already doing it the same way you do, and I already know the wiki.

My question is some sloppy, so I want to change the question,

what if I want to control respectively the four motors already mapped to Z-axis?

3 Z-axis bed leveling is so simple, but leveling 4 Z-axis has many limitations with rigid not flat bed.

-

I want to control respectively 4 motors already mapped to Z-axisposted in Tuning and tweaking

Four motors are used on the z-axis. The bed is 1000mm by 500mm, 10mm thick aluminum, very rigid.

I'm struggling to automate bed leveling.

The procedure I want to try is :

- Mapping 2 out of 4 motors as if they were one

- Automatic 3 point bed leveling

- Manually adjust gap where the bed is floating.

To do this, we need a method of bundling two motors and treating them as one motor.

-

RE: Heat run away problem at high flow extrusionposted in Tuning and tweaking

@Phaedrux

OK. I'll try that.

I was too blind to auto tuning.