I tried today (+30°C) same behavior. From the answers I understand that it should have worked with the command M592 D0 A-0.11 B0.04 L2 alone, right?

Posts made by RomeoFox

-

RE: M592 activation issueposted in General Discussion

-

RE: M592 activation issueposted in General Discussion

@phaedrux said in M592 activation issue:

ate, but it can't push unmelted plastic.

At 1.75mm filament, that's 28.2mm³ per second with a Dragon High Flow Hotend and ABS+.

The extruder starts to slip through individual teeth between 900 and 1000 mm/min. Therefore, I assume that the 4% should actually still be possible at 700mm/min.

-

RE: M592 activation issueposted in General Discussion

@phaedrux said in M592 activation issue:

How are you comparing? The effect should be quite subtle regardless.

I measure the filament feed on the feed side of the extruder by marking the filament with a pencil and steel ruler and extruding 100mm. At speeds below 5mm/s, the feed is exactly 100mm. At 11.7mm/s =700mm/min 4% are missing = only 96mm are fed.

I would have expected 4%/4mm to be easily compensated.

-

M592 activation issueposted in General Discussion

Right now I am trying to calibrate the dynamic nonlinear extrusion (M592).

-> https://forum.duet3d.com/topic/6015/guide-for-finding-the-values-for-m592-non-linear-extrusion/5

The result of the table from the thread is the following command: M592 D0 A-0.11 B0.04 L2

=> Should result in an effective correction of 4% at 11.6 mm/s.

Whereby with L2 any limitation should be switched off.For test purposes, I have tried values up to 0.2 for M592 Bxxx and have the impression that nothing is happening at all.

For testing I use the following command: G91 G1 X-100 E100 F700

However, I cannot see any difference between

G91 G1 X-100 E100 F700 (due to movement with correction) and G91 G1 E100 F700Does G592 need to be activated elsewhere?

M115

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.0rc1 ELECTRONICS: Duet 3 MB6HC v1.01 or later FIRMWARE_DATE: 2022-02-09 10:28:13 -

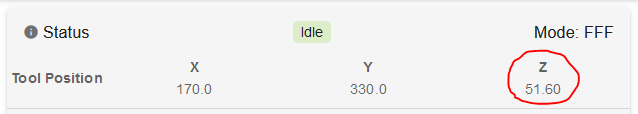

DWC enable second decimal place in the Z coordinateposted in Duet Web Control wishlist

In the DWC, the second decimal place in the Z coordinate is rounded. Is there a possibility to change this, i.e. to display Z 123.45 instead of Z 123.50 ?

-

RE: 3.4.0beta7+7 mesh bed issue?posted in Using Duet Controllers

General conditions:

- Voron 2.4 350x350

- magnetic bed with steel plate and smooth PEI film (polyetherimide)

I think that it does not work properly because:

- see pictures and that at 0.3mm height of the first layer, right side is about 0.1mm too high, especially right front

- with a sheet of paper under the nozzle I could reproduce the pictures, there is a height difference of 0,1mm

- this does not seem to be due to the sensor, which gives correct distance values

- for the 0.1mm height difference both the scanning speed and the dot density seem to be irrelevant 7x7 to 11x11 I tried out

Have you done a first layer test print with it enabled and disabled to see if there is a difference?

- yes, looks better without compensation

Can you send M122 and share the results here to see if mesh is in fact enabled?

=== Move ===

DMs created 125, segments created 47, maxWait 654699ms, bed compensation in use: mesh, comp offset 0.000Can you share your full config and homing files as well? Slicer start gcode?

clickDo you see the Z motors move to compensate?

Seems to be soThank you for your efforts!

Update:

Via M114 I get a correct display of the compensation at the position in relation to the heightmap.csvM114

X:170.000 Y:170.000 Z:25.000 E:9.522 E0:1839.0 Count 54400 0 9974 Machine 170.000 170.000 25.000 Bed comp -0.065Update2:

I manually checked the height correction via babystepping 0.01mm.

A correction is applied:

-> g1 z1 leads to different absolute heights with G92 S2 and G92 S1- the tendency of the compensation seems to be correct, but it is undercompensated by felt factor of 2.

- G30 at the points leads to correct offsets

- manual G30 = babystepping and looking at Z-probe value confirms G30

-

RE: Input Shaper Questionsposted in Tuning and tweaking

Since I do not have an accelerometer here is my learning

- for my Voron 2.4. 350x350 there is a strong resonance at 65mm/s in X-axis direction

- for my understanding the resonance frequency is independent of the acceleration

- the effects were strong waves at the test example for pressure advance: https://duet3d.dozuki.com/Wiki/Pressure_advance

- in the end it was mainly the correct adjustment of the jerk that prevented the waves. There seems to be too much and too little here

Here are my current values:

M566 X400.00 Y400.00 Z100.00 E3000.00 P1 ; set maximum instantaneous speed changes (mm/min) M203 X60000.00 Y60000.00 Z6000.00 E4000.00 ; set maximum speeds (mm/min) M201 X2500 Y2500 Z500.00 E4000.00 ; set accelerations (mm/s^2) M593 p"mzv" F46 ; input shaping M572 D0 S0.03 ; pressure advance -

3.4.0beta7+7 mesh bed issue?posted in Using Duet Controllers

Is there a known bug with the 3.4.0beta7+7 regarding mesh bed (G29)?

To me it looks like the result is not applied.config.g

; Z-Probe M558 P5 C"^io3.in" H4 F300 T45000 G31 P500 X0 Y25 Z0.99 M557 X20:320 Y26:320 P10:10bed.g (not shown here: drive learning is performed 3 times in a row)

G1 F40000 X40 Y15 Z7 G30 P0 X40 Y40 Z-99999 ; probe near a leadscrew G1 F40000 X40 Y310 Z7 G30 P1 X40 Y335 Z-99999 ; probe near a leadscrew G1 F40000 X320 Y310 Z7 G30 P2 X320 Y335 Z-99999 G1 F40000 X320 Y15 Z7 G30 P3 X320 Y40 Z-99999 S4 ; probe near a leadscrew and calibrate 4 motors G1 X170 Y145 Z7 F40000 G30 P3 X170 Y170 Z-9999 -

RE: Dynamic settings / dampen vibrationsposted in General Discussion

Thank you for the tips.

I was finally able to locate the problem after days. It seems to be related to the "Cutting corners" function of the "SuperSlicer". I deactivated it and now the oscillations are back where they should be: approx. 46 Hz.

But now all screws are really, really tight

Now the

M593 p "zvd" F46 ; input shapingis sufficient again.

I also lowered the instantaneous speed change and acceleration values a bit. Here is still missing some fine tuning.

-

Dynamic settings / dampen vibrationsposted in General Discussion

I'm trying to motivate my new Voron 2.4 350x350 to produce consistent print results. Unfortunately, I am struggling with massive oscillations exactly between 35 and 90 mm/sec. The trigger seems to be the excitation of the toothed belt (GT2) on the X-axis.

Here my setup for the dynamic part:M566 X1500 Y1500 Z100 E2000 P1 ; set maximum instantaneous speed changes (mm/min) M203 X60000 Y60000 Z6000 E4000 ; set maximum speeds (mm/min) M201 X5000 Y5000 Z1500 E4000 ; set accelerations (mm/s^2) M593 p "zvd" F15 ; input shaping M572 D0 S0.03 ; pressure advanceAre there any other controls in the software that I have overlooked?

-

RE: Make more gcode file memory availableposted in Using Duet Controllers

That was exactly the problem. Thank you!

How to create a new SD card can be found here: https://duet3d.dozuki.com/Wiki/SD_Card

I also replaced the original Sandisk ultra with the faster extreme, which resulted in a significant jump in upload speed. It was worth it for that alone.

-

Make more gcode file memory availableposted in Using Duet Controllers

on my Duet3D 6HC I need more free capacity for gcode files. I feel here are about 150 MB available on the original 16GB SD card via the web interface. How can I increase the space?

-

RE: Unofficial RRF 3.4.0beta7+4 filesposted in Beta Firmware

Have installed the firmware due to file upload issues. Now I get the following errors on every move which make it impossible to work:

Error: Driver 0.2 error: ok

Error: Driver 0.3 error: ok

Error: Driver 0.0 error: ok

Error: Driver 0.1 error: ok

Error: Driver 0.5 error: okFurthermore an event notification window appears.

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.0beta7+6 ELECTRONICS: Duet 3 MB6HC v1.01 or later FIRMWARE_DATE: 2022-01-13 18:24:07

-

RE: Stable uploads of large filesposted in General Discussion

That worked, but now I get a lot of event errors:

Error: Driver 0.2 error: ok

Error: Driver 0.3 error: ok

Error: Driver 0.0 error: ok

Error: Driver 0.1 error: ok

Error: Driver 0.5 error: okAs we speak, development seems to be going on live:

M115

FIRMWARE_NAME: RepRapFirmware for Duet 3 MB6HC FIRMWARE_VERSION: 3.4.0beta7+6 ELECTRONICS: Duet 3 MB6HC v1.01 or later FIRMWARE_DATE: 2022-01-13 18:24:07I will now follow up in the linked thread to the firmware. Thanks for the help.

-

RE: Stable uploads of large filesposted in General Discussion

Unfortunately no. Just updated the boards to the release 3.4.0 beta 7. Still errors during upload:

Error: Uploaded file CRC is different (949aee68 vs. expected 884c939a)

-

Stable uploads of large filesposted in General Discussion

I'm trying to upload gcode files of about 65MB to my Duet3D 6HC (Firmware 3.3) via the Duet web interface. Here I get every time an error code at the end that the checksums do not fit.

An upload via Prusaslicer "unfortunately" worked, but was also buggy and destroyed my 12h print just before the end. So now I simulate the files before I print them. It turned out that the only way seems to be to copy the file directly to the SD card of the Duet3D.

Although the computer and the Duet3D are connected to the same router via LAN, I can't get an error-free file transfer via the web interface for large files >50MB.

Using the SD card every time is not an option for me.Is there a trick to make the transfer more robust?