Unfortunately the buttons aren't accessible without removing the screen. Not the end of the world, but just wanted to see if there was something I was doing wrong.

Posts made by that guy E

-

RE: Flashing Panel Due firmware over DWCposted in PanelDue

-

Flashing Panel Due firmware over DWCposted in PanelDue

Looking to flash a panel due display current on 3.4.0 and I'm receiving "Error: Failed to communicate with PanelDue bootloader (no START signal received). Please try again or press the Erase and Reset switches on PanelDue." Has anyone found a solution?

Everything I've found says I should be able to flash over DWC without physical erase and reset buttons.

-

Over-powered Warningposted in Tuning and tweaking

In my config I'm loading the config-overide file at the end to make re-tuning easier. This result in heater over-powered warning on every powerup. Is there a way to not display this message?

-

RE: Pause Messageposted in Duet Web Control

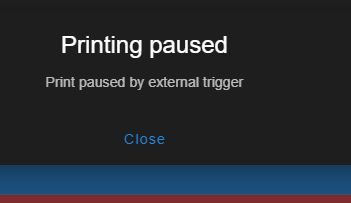

To confirm should 3.4.3 address this or will it be addressed in upcoming 3.5?

3.4.3 does not seem to address the issue and I'm actually having trouble reconnecting to the printer mid print. I'm running into a continually loading white page.

-

RE: Pause Messageposted in Duet Web Control

Been a while, but I finally got about to trying 3.4.2 and the pause message still continues to show every time you reconnect.

-

RE: Panel Duet Chamber Tempposted in PanelDue

I had to change P1 to P0. Looks like its working now.

If I left the P parameter out, the panel due creates two chamber heaters, 0 and 1. Not exactly sure why.

-

RE: Panel Duet Chamber Tempposted in PanelDue

@phaedrux With 3.4.2 not helping, any other thoughts?

Is there a preferred heater number to assign to the chamber from a panel due standpoint?

-

RE: Panel Duet Chamber Tempposted in PanelDue

You are correct, panel due firmware is 3.4.1. Sorry about that.

Updated controller firmware to 3.4.2 and still no luck.

Any chance the panel due is looking for a specific heater number to be referenced for the chamber heater?

-

RE: Panel Duet Chamber Tempposted in PanelDue

@phaedrux

M122:9/22/2022, 7:58:17 AM m122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.0 (2022-03-15 18:57:24) running on Duet 3 MB6HC v1.01 or later (standalone mode) Board ID: 08DJM-956BA-NA3TN-6J9F6-3SD6N-TBBUT Used output buffers: 1 of 40 (21 max) === RTOS === Static ram: 151000 Dynamic ram: 96888 of which 140 recycled Never used RAM 102644, free system stack 200 words Tasks: NETWORK(ready,3452.9%,209) ETHERNET(notifyWait,23.3%,168) HEAT(notifyWait,12.7%,321) Move(notifyWait,1.0%,352) CanReceiv(notifyWait,0.0%,944) CanSender(notifyWait,0.0%,374) CanClock(delaying,4.7%,333) TMC(notifyWait,4276.5%,92) MAIN(running,2747.7%,925) IDLE(ready,0.1%,30), total 10518.9% Owned mutexes: === Platform === Last reset 15:56:16 ago, cause: reset button Last software reset at 2022-09-21 15:38, reason: User, GCodes spinning, available RAM 102644, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 136 MCU temperature: min 37.9, current 38.8, max 46.3 Supply voltage: min 23.7, current 24.2, max 24.4, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.0, current 12.0, max 12.1, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Events: 0 queued, 0 completed Driver 0: standstill, SG min 0, mspos 4, reads 13782, writes 19 timeouts 0 Driver 1: standstill, SG min 0, mspos 4, reads 13782, writes 19 timeouts 0 Driver 2: standstill, SG min 0, mspos 4, reads 13785, writes 16 timeouts 0 Driver 3: standstill, SG min 0, mspos 4, reads 13785, writes 16 timeouts 0 Driver 4: standstill, SG min 0, mspos 4, reads 13785, writes 16 timeouts 0 Driver 5: standstill, SG min 0, mspos 4, reads 13787, writes 15 timeouts 0 Date/time: 2022-09-22 07:58:13 Slowest loop: 4.89ms; fastest: 0.05ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 2.1ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 2 -1 -1, ordering errs 0 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.2 Heater 2 is on, I-accum = -0.0 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === Filament sensors === Extruder 0 sensor: ok === CAN === Messages queued 516376, received 0, lost 0, boc 0 Longest wait 0ms for reply type 0, peak Tx sync delay 0, free buffers 50 (min 50), ts 286881/0/0 Tx timeouts 0,0,286880,0,0,229494 last cancelled message type 30 dest 127 === Network === Slowest loop: 11.61ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 1 of 8 - Ethernet - State: active Error counts: 0 0 1 0 0 Socket states: 5 2 2 2 2 0 0 0Config:

; Configuration file for Duet3 (firmware version 4.0 or newer) ; executed by the firmware on start-up ; General preferences M111 S0 ; Debugging off M575 P1 B115200 S1 ; set baud rate for panel due G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves G4 S1 M118 P2 S"{""controlCommand"":""reset""}" ;reset display ;M669 K1 ; Select CoreXY mode M669 K1 X1:1:0:0:0:0 Y-1:+1:0:0:0:0 Z0:0:1:1:1:0 U0:0:0:0:0:1 ;Select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed ; Network M552 S0 ; Ethernet ON G4 S1 ; WAIT 1 SECOND M552 S1 ; ENABLE NETWORK AS CLIENT ; --- Z Drive map --- ; _______ ; | 2 | ; | ----- | ; | 1 | 3 | ; |_______| ; front ; ; (looking at the printer from the top) ; Drive directions M569 P0 S0 D3 H5 V25 ; A M915 P0 T5 R0 H336 M569 P1 S0 D3 H5 V25 ; B M915 P1 T5 R0 H336 M569 P2 S1 D3 ; Z1 M569 P3 S1 D3 ; Z2 M569 P4 S1 D3 ; Z3 M569 P5 S0; Extruder ; Motor mapping and steps per mm M584 X0 Y1 Z2:3:4 E5 M350 X16 Y16 Z16 E16 I1 ; Use 1/16 microstepping with interpolation everywhere M92 X80 Y80 Z1280 ; Set XYZ steps per mm (1.8deg motors) M92 E400 ;steps per mm LGX M350 X32 Y32 Z32 E32 ;Increase Z & E microstepping ; Drive currents M906 X1600 Y1600 Z1600 E700 ; XYZ and E current LGX M906 I15 ; Idle current percentage M84 S120 ; Idle timeout ;Acceleration and speeds M566 X250 Y250 Z100 E300 ; (jerk) Set maximum instantaneous speed changes (mm/min) was M203 X12500 Y12500 Z2000 E7000 ; Set maximum speeds (mm/min) M201 X7000 Y7000 Z1500 E2000 ; Set max accelerations (mm/s^2)' ; Endstops M574 X2 P"^!io3.in" S1 ; DEFINE X ENDSTOP M574 Y2 P"^!io4.in" S1 ; DEFINE Y ENDSTOP M574 Z0 P"nil" ; No Z endstop ; Axis travel limits M208 X0 Y0 Z0 S1 ; Set axis minima M208 X510 Y331 Z635 S0 ; Set axis maxima ; Bed leveling M671 X13:244:454 Y13.5:326.5:13.5 S20 ; Define Z belts locations (Front_Left, Back_Middle, Front_Right) M557 X35:450 Y20:270 P5:5 ; Define bed mesh grid (inductive probe, positions include the probe offset!) M376 H10 ; Fade mesh out compensation over 20mm Z ; Bed heater M308 S0 P"TEMP0" Y"thermistor" T100000 B3950 A"Bed Temp" ; configure sensor 0 as thermistor on pin bedtemp (heater sensor) M950 H0 C"OUT0" T0 Q10 ; create bed heater output on out0 and map it to sensor 0. Set PWM frequency to 10Hz M140 P0 H0 ; Mark heater H0 as bed heater (for DWC) M143 H0 S120 ;Set bed max M307 H0 B1 S1.0 ; Enable Bang Bang mode and set PWM to 100% ; Hotend heater M308 S1 P"TEMP3" Y"thermistor" T100000 B4267; define E0 temperature sensor M950 H1 C"OUT1" T1 ; heater 1 uses the e0_heat pin and sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S305 ; Set temperature limit for heater 1 ;Chamber Heater ;M308 S2 P"TEMP2" Y"thermistor" T10000 B3892 A"Chamber Temp" ; define chamber temp sensor M308 S2 P"TEMP2" Y"thermistor" A"Chamber Temp" T100000 B4725 C7.06e-8 ;R5000 M950 H2 C"OUT2" T2 ; create heater output on out2 and map it to sensor 2 (mic6 sensor). Set PWM frequency to 10Hz M141 P1 H2 ; Mark heater H2 as Chamber temp (for DWC) M143 H2 S75 ;Set chamber max M307 H2 B1 S1.0 D120 ; Enable Bang Bang mode and set PWM to 100% ; MCU sensors M308 S3 Y"mcu-temp" A"MCU" M308 S4 Y"drivers" A"Duet Drivers" ; Fans M950 F0 C"out5" Q250 ; Create fan 0 (hotend) M106 P0 C"Hotend_Fan" S0 H1 T40 ; Configure fan 0: Thermostatic control is turned on, based on sensor #1 M950 F1 C"out4" Q250 ; Create fan 1 (part cooling) M106 P1 C"Part_Fan" S0 H-1 ; Configure fan 1: Thermostatic control is turned off M950 F2 C"OUT7" Q250 ;CREATE FAN2 (ENCLOSURE FAN) M106 P2 C"Enclosure_Fan" H3:4 T40:70 ;CONFIGURE FAN THERMOSTATIC CONTROL IS ON BASED ON SENSOR 3 &4 M950 F3 C"OUT8" ;CREATE FAN2 (CHAMBER FAN) M106 P3 C"Chamber_Fan" B.25 X0.5 H2 T20 ;CONFIGURE FAN ; Z probes M558 K0 P8 C"!io5.in" T60000 F300 H5 S0.01 R0.2 G31 K0 P500 X-18 Y-34.5 Z0 ; Tools M563 P0 D0 H1 F1 ; Define tool 0 using fan 1 for M106 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C ;Filament Detect ;M950 J1 C"IO6.IN" ;Create pin1 M591 P1 D0 C"IO6.IN" S0 ;SET FILAMENT MONITOR EXTRUDER 0 ENDSTOP ;Pause M950 J2 C"!IO1.IN" ;Create pin2 M581 P2 T1 C0 S1 ;SD CARD M950 D1 C"spi.cs0" ;DEF1NE SD CARD READER M501 ; load config-override.g T0 ; select tool 0 -

Panel Duet Chamber Tempposted in PanelDue

Trying to set chamber temps via panel due, and they keep reverting to the existing setpoint when I hit set. I'm able to set the temp via DWC and gcode commands fine.

Anyone run into this?

Running panel due firmware 3.4.3

-

RE: Pause Messageposted in Duet Web Control

I'll try the newest release when I get a minute tomorrow.

Message

Pause.g

M83 ; relative extruder moves G1 Z{move.axes[2].machinePosition+10} E-4 F60000 G1 X10 Y10 E-4 F60000 -

Pause Messageposted in Duet Web Control

After a pause trigger has occurred, I will continue to receive a pause message that I need to acknowledge every time I connect to DWC until the controller has been reset. Is this an big in DWC or is there an additional acknowledgment I need send in resume command.

RRF 3.4.1 rc1

-

RE: Filament Monitor Flagging When Not Printingposted in Filament Monitor

I will try moving it to start.g

I have a print_start.g which is called out after setting bed and nozzle temps. I was hoping to automate some retract sequences in the filament runout, but I can't include them without first having the nozzle hot.

I might just define it as an external trigger, so I can set it so it to only trigger during a print. Assuming triggers still behave the same

-

RE: Filament Monitor Flagging When Not Printingposted in Filament Monitor

I enabled the filament check during my print start macro and the issue I run into is that on a resume it re-runs the entire macro.

-

Filament Monitor Flagging When Not Printingposted in Filament Monitor

using a simple filament switch style monitor configured like this:

M591 P1 D0 C"IO6.IN" S1On power up I'm seeing filament out warnings before I start a print. I thought the S1 is supposed to set it to only be monitored when printing?

Firmware V3.4.1-RC1 haven't tried other firmware versions yet

-

RE: SD Card Error 1 DUET3 M6HCposted in Duet Hardware and wiring

Connecting ground to the daughter board and the VCC to the io.7 appears to have solved the problem.

I'll continue to monitor and test on another controller.

You've been helpful as always

-

RE: SD Card Error 1 DUET3 M6HCposted in Duet Hardware and wiring

I will give that a shot now.

Using my previous setup I was able to reproduce the issue on another duet3 with 2 different card readers and 2 cable sets. Card readers work as expect them if I connect them to a duet 2.

-

RE: SD Card Error 1 DUET3 M6HCposted in Duet Hardware and wiring

Cable length is 400mm.

No motor cable near by.

SD Card has is 5V VCC with a 3.3 step down on board. We've been running the same board with the 5V SD card pins on a duet2 without issues.

I'll do some more testing with another Duet3 and SD card reader and the same cable. I was at a users facility when I discovered this. I unfortunately did not have an extra reader board with me.

-

RE: SD Card Error 1 DUET3 M6HCposted in Duet Hardware and wiring

For some reason I'm having issue imbedding images or including attachment.

Break out board is wired as such. The 5V and ground are coming off of a 5V power supply which is also power the logic side of the Duet3

Duet3 Temp Daughter Board SD Breakout Card CS0 pin3 -> CS pin1 SCLK pin4 -> SCK pin2 MOSI pin5 -> MOSI pin3 MISO pin6 -> MISO pin4 +5V VCC pin5 GND GND pin6I also installed a jumper between I07.in pin and ground of that connector. I've also tried with out the i07.in jumper and excluded it from the M950. Did not change results.

Config

; General preferences G90 ; Send absolute coordinates... M555 P1 ; Set firmware compatibility to look like RepRapFirmare ;M575 P1 B57600 S1 ; set baud rate for panel due M575 P1 B115200 S1 ; set baud rate for panel due G4 S1 M118 P2 S"{""controlCommand"":""reset""}" ;reset display ;DEVICE NAME M550 P"Carver" ; SET DEVICE NAME ; Network ;WAP M552 S0 G4 S1 ;WAIT 1 SECOND M552 S1 ;ENABLE NETWORK AS CLIENT ;Define Kinematics M669 K0 S100 T0.001 ;set as cartesion M584 Z1:2 ;define Z drives M584 U4 R1 S1 ;define U drives M584 X0 ;define X drives ; Drives M569 P0 S0 ;D3 ; Drive 0 goes backwards M569 P1 S0 ;D3 ; Drive 1 goes Backwards M569 P2 S0 ;D3 ; Drive 2 goes Backward M569 P3 S1 ;D3 ; Drive 3 goes forwards M569 P4 S1 ;D3 ; DRIVE 4 GOES forwards M350 X16 U16 Z16 I1 ; Configure microstepping with interpolation M92 Z800 U177.77777 X320 ; Set steps per mm M566 Z400 U1200 X600 ;DEFINE JERK M203 Z4500 U10800 X7500 ;DEFINE MAX SPEED (MM/MIN) M201 Z4000 U3000 X4000 ; Set max accelerations (mm/s^2)' M906 Z5500 U5500 X5500 I10 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Z-60 U-9999999999 S1 ; Set axis minima M208 Z240 X685 U9999999999 S0 ; Set axis maxima ; Endstops M574 Z2 P"^!io4.in+^!io5.in" S1 M574 X2 P"^!io3.in" S1 ;DEFINE SPINDLE M453 ;SET CNC MODE M950 R0 C"out9+OUT5" L60:10000 ;DEFINE SPINDLEINDEX 0 WITH out9 as pwm OUT5 as on/off M563 P1 S"SPINDLE 1" R0 ;CREATE TOOL 1 WITh SPINDLE 0 AND CALL IT SPINDLE 1 ;VFD Error Check M950 J2 C"IO6.IN" ;create pin3 M581 P2 T2 C0 S1 M582 T2 ;SD CARD M950 D1 C"spi.cs0+io7.in"