@fcwilt I don't have the tools to make something with sufficient precision unfortunately

Posts made by TinkerBill

-

RE: Making it fitposted in My Duet controlled machine

-

RE: Making it fitposted in My Duet controlled machine

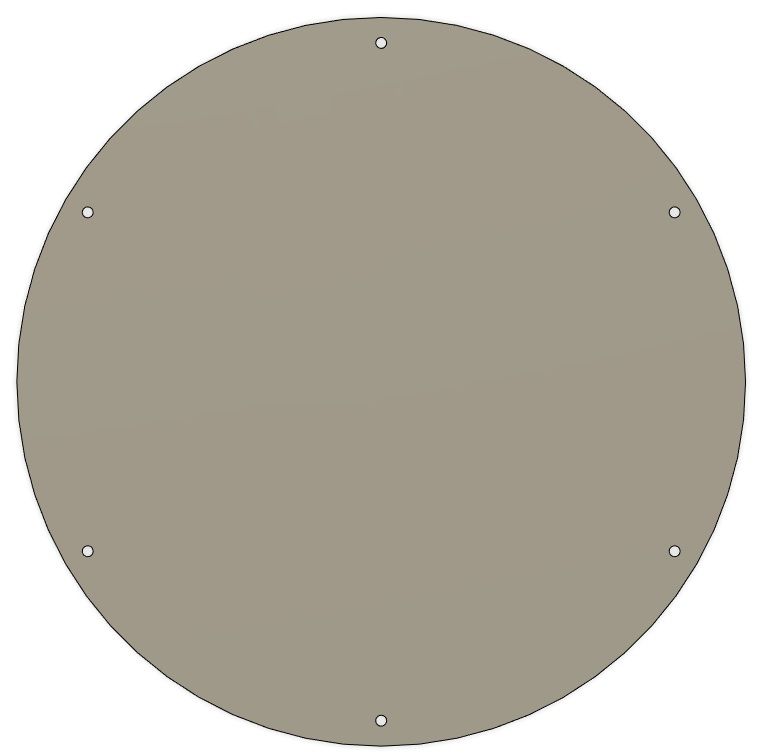

@bearer Current bed is 200mm diameter, 6 3mm holes seemingly evenly spaced around it, 7mm inset from edge to center of the hole. Pic is a brief sketch I threw together on F360.

New extrusions can be pretty much whatever length, though I'd probably max out at 300mm to keep the footprint small.

-

RE: Making it fitposted in My Duet controlled machine

@bearer the current extrusions are 230mm so I can get longer ones relatively easily online (circa £30-40 for the set from oozenest) rewiring to the top would mean making a new loom for a lot of the components which I'd rather avoid (currently don't have most my tools....)

-

RE: Making it fitposted in My Duet controlled machine

@DIY-O-Sphere I started debating to/on one side, rather than internal. Feet is a good call though, might do that. Thanks

-

RE: Making it fitposted in My Duet controlled machine

@fcwilt As it's a delta, with the print bed attached to the top of the base extrusions, extending the base extrusions will change the distance between the center of each extrusion where it currently mounts. Picture an equilateral triangle, with a circle touching the middle of each edge. Then make each edge longer, the circle will need to be larger.

-

RE: Making it fitposted in My Duet controlled machine

Edited from desktop, should have pic visible now

-

Making it fitposted in My Duet controlled machine

So, whilst upgrading to metal corners I have ended up with the duet not being able to fit between my stepper motors (see pic - edit: Veti, was trying from mobile, pic now attached).

I see my options as:

- get longer horizontal extrusions, providing more space, but needing a new heated bed/print surface

- go back to the worn plastic corners and make do

- be slightly mad and remove motor housing with a file to make this fit...

As you can probably guess, I'd rather do 1 and continue upgrading. However I'm struggling to figure out what size bed (and where I'd get it, I'm uk based) for what size horizontals.

All help appreciated

-

RE: Smart Effector Tiltposted in Tuning and tweaking

@danal I assumed that was the issue, I'll see if some brackets similar to my effector ones since the issue, otherwise I'll be looking for affordable (read budget

) magnet rods

) magnet rods -

RE: Smart Effector Tiltposted in Tuning and tweaking

@bpislife adapter is part of the package. Going to try printing brackets for them to see if it works, otherwise going with https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.co.uk%2Fulk%2Fitm%2F132544828361

-

RE: Smart Effector Tiltposted in Tuning and tweaking

@barracuda72 basically because I hadn't thought that far

all just ebay stuff?

all just ebay stuff?@dc42 is bearing spacing essentially space between the ends of the two rods? So across carriage and across effector? Think the rods move ok, they certainly do effector end.

-

RE: Smart Effector Tiltposted in Tuning and tweaking

@3mm The brackets are 3d printed resin, but have some flaws. The lift is basically just where i had to force the bracket off the build plate.

Secondly, the bubble moves to the nearest edge, the effector tilt is not in only one axis. I'm taking that to mean it's a more general error than just one bracket.

As for the magnetic option mentioned later, removing the brackets and using the provided carriage adapters allow the effector to be used with magnetic arms (as designed i believe)@Danal the brackets are shaped to allow full movement, I'd run into that problem on bracket v1...

@BPisLife because the ones i saw advertised alongside the effector were quite expensive for a job hunting grad

@dc42 I'm wondering if the point made in carriage bearings being the same height is my problem. If the width between the carriage connections and effector connections are different the effector might twist? Thanks for the link, lots of good points for me to test

-

RE: Smart Effector Tiltposted in Tuning and tweaking

Showing the spirit level in different positions relative to a tower. Final pic shows how I've avoided magnetic rods.

If you want something specific, just sayEDIT: ....I can only see the picture notifications... tried to use 'upload file' option... what do?

EDIT2: Drive folder containing photos https://drive.google.com/drive/folders/1XFckeTPgctmidWqsH-gkmm1hjfphliyE?usp=sharing -

Smart Effector Tiltposted in Tuning and tweaking

Probably being an idiot, but having just set up a new smart effector (though not with magnetic arms...) it tilts up towards the closest tower.

I assume that, as the arms are all same length, I'm either seeing the movement due to compatibility issue without the magnetic arms or I've poorly spaced the arms?

TIA

-

Temporary Effector FSR for Bed Levellingposted in Third-party add-ons

I recently got a FSR and was wondering if I could mount it to the hotend like this printer does: (about 25 second in) https://www.youtube.com/watch?v=_1hWOxVixxw

I've got the Duet 0.8.5 with a v1 breakout board on the effector.

Thanks!

Bill -

RE: Heater Fault - Using old style E3D v6 hotendposted in Tuning and tweaking

Ok, I think I'm going to bite the bullet and get some kit from the e3d site. Thanks for the help.

-

RE: Heater Fault - Using old style E3D v6 hotendposted in Tuning and tweaking

So there's no way of changing the expected rate of heat increase? I can't tell the printer I expect it to rise by at least 0.5 deg/s instead of 1.7?

-

RE: Heater Fault - Using old style E3D v6 hotendposted in Tuning and tweaking

I've not got a spare heater cartridge, will try the copper grease. If that doesn't work, what bodge could I do to just stop the software worrying about the time taken to heat up? Rather not order another new heater cartridge…. (again I'm cheap/broke)

-

RE: Heater Fault - Using old style E3D v6 hotendposted in Tuning and tweaking

Should have tried that myself, no worries.

SENDING:M307 H1

Heater 1 model: gain 340.0, time constant 140.0, dead time 5.5, max PWM 1.00, mode: PID

Computed PID parameters for setpoint change: P13.4, I0.095, D51.4

Computed PID parameters for load change: P13.4, I0.949, D51.4Is there anything wrong here? Reaally don't know what I'm looking for

-

RE: Heater Fault - Using old style E3D v6 hotendposted in Tuning and tweaking

I sent a M307, didn't get anything back… Probably the problem then?

-

RE: Heater Fault - Using old style E3D v6 hotendposted in Tuning and tweaking

My config file doesn't have a M307 line, are the values on http://reprap.org/wiki/G-code#M307:_Set_or_report_heating_process_parameters worth using?

Sorry if these are dumb questions - not much software experience…