Hi all, I have many Duet printers, some are wifi2 and some are mini5 (72 in total) and I have a problem with wifi transfer speed. When all the printers are running, it can take 5 minutes or more to transfer a 40Mb print file and that's if the connection doesn't fail first. I seen I can wire an inexpensive off-the-shelf Wiznet 5100 controller to the duet2 wifi, but can the same be done for the mini 5? To stay on topic, Ill mention I have a few printers still running Octoprint via Raspberry Pi connected with ethernet or 5G wifi on the same network, and they never have any issues, its just the 2.4G network.

Thanks guys.

Posts made by Topher

-

Converting Mini 5 wifi to ethernet?posted in Duet Hardware and wiring

-

RE: Convert PT100 Daughter Board to PT1000?posted in Duet Hardware and wiring

@dc42 Thank you, this is what i needed to know to add additional sensors to my printers.

-

RE: Convert PT100 Daughter Board to PT1000?posted in Duet Hardware and wiring

@zapta said in Convert PT100 Daughter Board to PT1000?:

What duet board are you using? Generally speaking, PT1000 doesn't require a daughter board and can connect directly to the duet. You do need to tell the duet though that this is a PT100.

im using Duet 3 mini. I need 2 additional sensors for my build. One for the cooling fan air intake and one on the LDO motor feeder.

-

RE: Convert PT100 Daughter Board to PT1000?posted in Duet Hardware and wiring

@achrn I have a 1mm pitch 300mm long FFC driving my hotend. The wiring path for the sensor has to travel through this.

-

Convert PT100 Daughter Board to PT1000?posted in Duet Hardware and wiring

I was looking at the documentation for the MAX31865 used in the PT100 daughter board. I have long leads on my sensors so i think 100ohm sensors might be problematic for my application and also, I have lots of 1k sensors. Could I change out R1 and R3, and R2 and R4 with the appropriate resistors to compensate for the 1k sensor? I think I could leave the filter caps larger and it should be fine as I dont need super fast readings.

-

RE: Battery Backup Causing Motor Drivers to Shortposted in Duet Hardware and wiring

@dc42 thanks for the quick response. The board is using 2209 drivers so I believe the default mode is stealth chop according to Duet documentation as I didnt declare it with M569. I am running 256 steps, what mode would you suggest I run the drivers in to overcome this issue in the future? Spread Cycle, maybe?

-

Battery Backup Causing Motor Drivers to Shortposted in Duet Hardware and wiring

Hi guys. On our printer racks, we have Model S batteries in parallel with the output of the power supplies for every 2 racks (24 printers) powering all Duet3 minis. The batteries are "ideal" diode isolated for min working voltage drop while preventing surge charging. We just encountered our first major power outage where we lost power for about 2 hours during full operation. The good news - the majority of the printers survived the event. Bad news is 2 printers heater faulted which is to be expected as the battery voltage became too low to heat the hotend to temperature but more interestingly, 3 other printers had a motor driver short fault once the battery hit around 20 volts. The fault was persistent even when the power was restored bringing the rail voltage back up to the normal 25 volts. Hitting the reset button on the printers did not help but power cycling did. None of the drivers were actually damaged. I suspect this simple inexpensive approach for battery backup of this scale may need a pricy investment in a custom power supply on the battery to give me a stable CV output. Cost aside, I would like to not go that route as adding any additional switching would cut battery runtime even with high efficiencies of 90% or so. Curious of your thoughts on this @dc42

image url)

image url) -

RE: Mini 5 mini SD inop after months of useposted in General Discussion

@phaedrux

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.2.2 running on Duet 3 Mini5plus WiFi (standalone mode)

Board ID: 1H88H-V196U-D65J0-40KMU-0Z03Z-RQD4F

Used output buffers: 1 of 40 (1 max)

=== RTOS ===

Static ram: 98732

Dynamic ram: 106368 of which 552 recycled

Never used RAM 39564, free system stack 136 words

Tasks: NETWORK(ready,518) HEAT(blocked,362) CanReceiv(blocked,947) CanSender(blocked,372) CanClock(blocked,363) TMC(blocked,123) MAIN(running,634) IDLE(ready,20) AIN(blocked,269)

Owned mutexes: USB(MAIN)

=== Platform ===

Last reset 00:03:21 ago, cause: power up

Last software reset at 2021-09-01 21:06, reason: User, GCodes spinning, available RAM 33744, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Aux1 errors 0,0,0

Supply voltage: min 0.0, current 0.9, max 0.9, under voltage events: 0, over voltage events: 0, power good: no

Driver 0: position 0, ok, SG min/max not available, read errors 0, write errors 0, ifcnt 0, reads 0, writes 0, timeouts 0, DMA errors 0

Driver 1: position 0, ok, SG min/max not available, read errors 0, write errors 0, ifcnt 0, reads 0, writes 0, timeouts 0, DMA errors 0

Driver 2: position 0, ok, SG min/max not available, read errors 0, write errors 0, ifcnt 0, reads 0, writes 0, timeouts 0, DMA errors 0

Driver 3: position 0, ok, SG min/max not available, read errors 0, write errors 0, ifcnt 0, reads 0, writes 0, timeouts 0, DMA errors 0

Driver 4: position 0, ok, SG min/max not available, read errors 0, write errors 0, ifcnt 0, reads 0, writes 0, timeouts 0, DMA errors 0

Driver 5: position 0, ok, SG min/max not available, read errors 0, write errors 0, ifcnt 0, reads 0, writes 0, timeouts 0, DMA errors 0

Driver 6: position 0, ok, SG min/max not available, read errors 0, write errors 0, ifcnt 0, reads 0, writes 0, timeouts 0, DMA errors 0

Date/time: 1970-01-01 00:00:00

Cache data hit count 475358797

Slowest loop: 0.19ms; fastest: 0.12ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 0.2MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters = -1 -1, chamberHeaters = -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is ready with "M122" in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 0.19ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 0 of 8- WiFi -

Network state is disabled

WiFi module is disabled

Failed messages: pending 2779096485, notready 2779096485, noresp 2779096485

Socket states: 0 0 0 0 0 0 0 0

=== CAN ===

Messages queued 1009, send timeouts 1008, received 0, lost 0, longest wait 0ms for reply type 0, free buffers 16

ok

M22

SD card 0 may now be removed

ok

M21Error: M21: Cannot initialise SD card 0: Card is unusable

ok - WiFi -

-

RE: Cloud Print Filesposted in Using Duet Controllers

@phaedrux we are running mostly Duet 3 mini and do have a stockpile of rbp3b+ from our octoprint days. I don't know how confident I am however in code setting something like this up, or do you think I could connect with google drive with linux?

-

Cloud Print Filesposted in Using Duet Controllers

Hi guys, we now have 60 printers and it's becoming quite cumbersome to load files to them all. Almost daily, we have new files to print but also we may print many repeats from years ago. What I would just love is to have all my files stored in one location or a way to push my database to all the printers at once so I can add, delete, or edit the files from one place. Then for my print queue for each printer, I would configure a google sheet to input the file names and output a text file which will call the files in order to print and prompt to start the next file once a print is complete. Anyway, something like this would save us loads of time! Any ideas or is this a fiction fantasy?

-

RE: Mini 5 mini SD inop after months of useposted in General Discussion

@phaedrux Ill give it a go this weekend! I believe tried to mount the card but cant recall for sure. Ill let you know!

-

Mini 5 mini SD inop after months of useposted in General Discussion

Ive had a Mini 5 in commission for about 6 months and its been working just fine. 2 months ago, out of the blue, it would not load the files from the SD card. I was slammed for time to diag it so I put a new board in that printer to keep the farm turning out max capacity. I tried a new SD, used Bossa to flash new FW, and I can connect and send/receive with YAT terminal. Purchased through Spool3D, they advised the forum before they can issue warranty.

Thanks!

-

Adding additional Temp Sensors to Duet3 miniposted in Using Duet Controllers

Hi guys, Ive used up my dedicated temp0,1,2 inputs on my Duet3 mini. Just wondering if anyone has wired their own resistor network to use other inputs such as io0.in - io6.in. I looked at this schematic here: https://github.com/Duet3D/Hardware/blob/master/Duet3/Duet3_MB6HC_schematic_v1.0.pdf - and found there is already a resistor network implemented, probably to protect the chip from overvoltage situations, so Im thinking adding another network on top of this will have some skewed readings. Any input would be appreciated!

-

RE: Fan PWM to DC voltage converterposted in General Discussion

@alankilian oh wow, long thread. Can't believe I missed it. Thanks!

-

Fan PWM to DC voltage converterposted in General Discussion

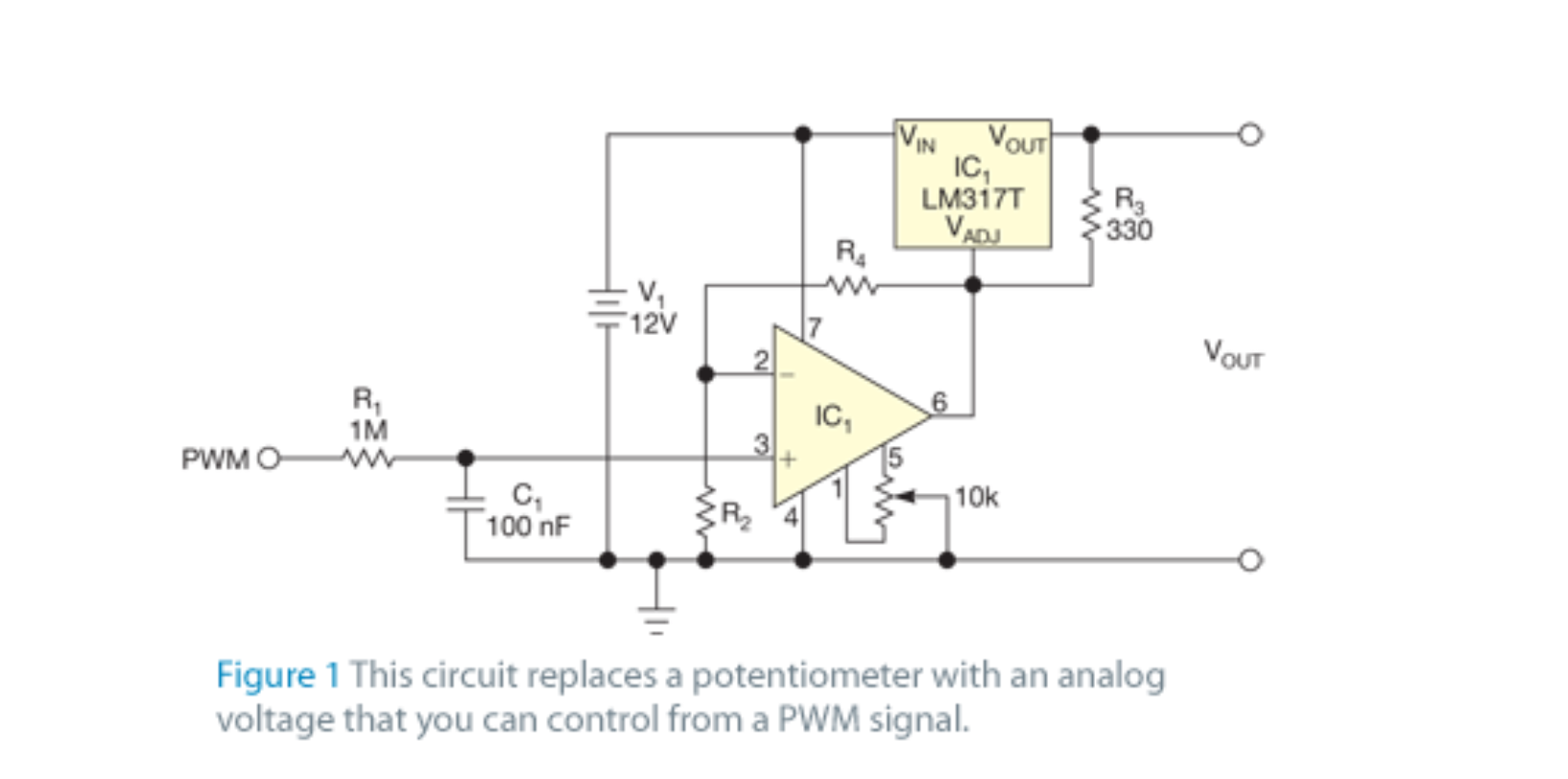

Wondering if anyone had a solution to driving cheapy 2 wire dc fans with PWM. We go through a lot of fans here because the PWM seems to destroy them. I was looking at making a converter to convert my 24v pwm signal to a DC voltage that varies by PWM duty. Ive tried making some inductors with a flyback diode and it works pretty well but because I need roughly 1k turns of wire, the coil just becomes a big resistor at full power not allowing the fan to spin to its full RPM when needed. With duet, the fan PWM is limited to 65khz which is pretty low for the inductor route so I started hunting for an electronic solution. I found this little circuit which is a good starting place.

I need to make 60pcs, one for each of our duet printers so it will be worth putting in the effort to layout something and have JLC PCB run some boards. -

RE: Custom Macro For Tuning a Heaterposted in Using Duet Controllers

@phaedrux haha. wise guy! Its not that I need to leave them unattended while tuning or that it is hard the way it is. We have a warehouse with racks full of printers... Everyday we are repairing 5 or more printers and when there are quite a few on the bench being serviced, it would be nice to have a tone to know when the tune is done so it can go back on the rack and get making us money! Id like to think paying an employee to needlessly stare at a screen waiting 20 minutes for the tune to complete is just not necessary. Also to access the results from the 12864 screen to press ok which sends M500 rather than trying to remember what window that printer was on with the desktop would be helpful. Heaven forbid you start sending commands to the wrong printer and wreck a print!

-

Custom Macro For Tuning a Heaterposted in Using Duet Controllers

I wrote this macro for my menu display, just wondering if after calling

M307should the macro not be interrupted by the tuning itself? The DWC says it's tuning but the macro continues down to the end. Do I need some conditional code to halt the macro while the tune is running?Thanks!

;---------------------------------------------------------------------------- ;------------------------Tune Bed Heater------------------------------------- ;---------------------------------------------------------------------------- ; when M986 is called do: M400 ; allow buffer to finish for lighting M150 U255 R55 ; Set caution light ;tone for operator M300 S550 P200 G4 P200 M300 S800 P200 G4 P200 M300 S1100 P200 M291 S3 P"Proceed?" R"BED HEATER TUNE" M400 M150 U255 B65 ; set light purple for heating up M303 H0 S75 ; run tune for bed ;tune finished sound tone for operator M300 S550 P200 G4 P200 M300 S800 P200 G4 P200 M300 S1100 P200 M400 ; allow buffer to finish for lighting M150 U255 R55 ; Set caution light M291 S3 P"Save Settings?" R"TUNE COMPLETE" M400 ; allow buffer to finish for lighting M150 R255 ; Set caution light M500 ;tone for operator M300 S550 P200 G4 P200 M300 S800 P200 G4 P200 M300 S1100 P200 -

RE: Creating a pin for trigger#.gposted in Using Duet Controllers

@phaedrux Ha, it works. Cant wait to apply this at work tomorrow. What I am using it for: we have 4k nest cameras on each rack of 12 printers. In the middle of the night if I need to check on them the room is too dark so Ive got a wifi switch that ill connect a 12v supply to and trigger a micro relay at the duet board closing this contact thus turning on the lights of each printer for any given rack. I wish we could just connect the printers together with CAN BUS and send global messages to do things like this or tell all 60 of my current duet printers to preheat, or send a command over the internet to stop any one print. Ive already got our main supplies wired to a smoke detector to immediately disconnect the power and battery backup at the first sign of smoke. With safety out of the way, now I just need some other features for production. Thanks again for the help!

-

RE: Creating a pin for trigger#.gposted in Using Duet Controllers

@phaedrux ok, that makes so much more sense. I didnt read anything that suggested this and Ive been looking to do this project for a few years so I already had it in my mind the pin needed to be released before it could be assigned to a different function! Really appreciate the effort. Im going to try it right now with a spare board I have here at home.