Post heading:

Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet

Firmware Electronics: Duet Ethernet 1.02 or later

Firmware Version: 2.04RC1 (2019-07-14b1)

Web Interface Version: 1.22.6

CoreXY_UV, ZZ (Nema 23,23_34,17, 34,34)

E3D Supervulcano 2.85- 1.4 nozzle

E3D Supervulcano 1.75- 1.0 nozzle

2x Bondtech QR

XYU closed loop

XYZU ;EXTERNAL drivers on expansion breakout board v1.1

Printer is working fine, so we would like to add the laser filament monitor to do the measuring

of the intended extrusion;

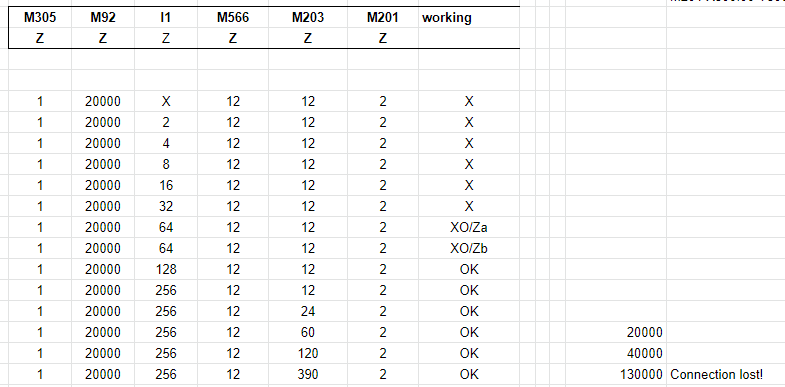

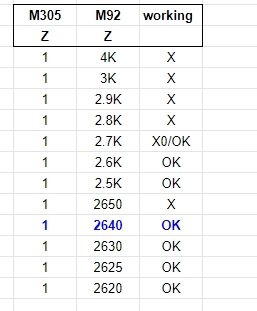

We would like to create data with a simple program for the M592 D0 A? B?

and M592 D1 A? B? command.

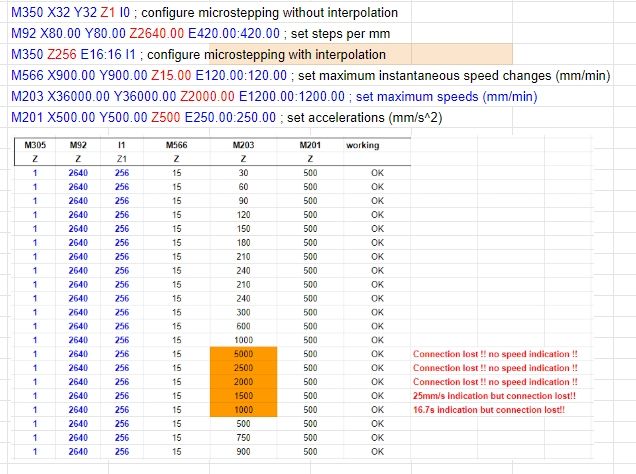

So we found the following code on the forum and added the M591 comment.

M117 Start Extrusion Measurement.

G1 X0 Y430 F6000

M83

G1 X100 E25 F60

M400

M591 D0; show measurement??

M291 S3 R"Measure extrusion 25mm" P"Measure filament taken at 1mm/sec extrusion then press OK"

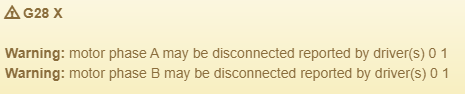

But no success.

Change R% and E values in the M591..

The final answer is no data received.

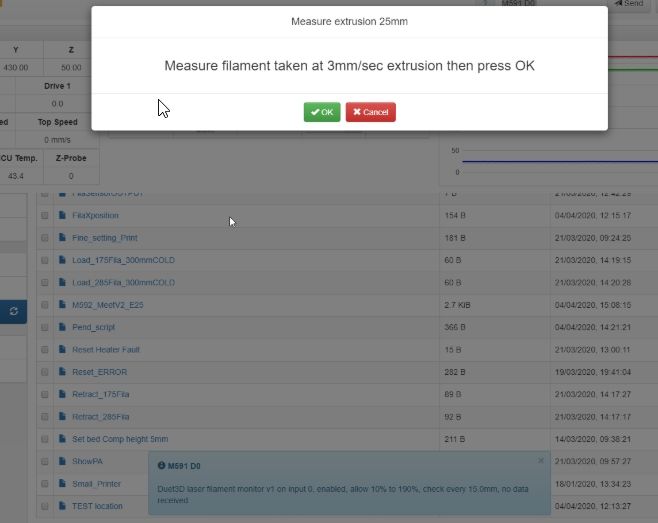

My original setup in the config file;

M591 D0 P5 C"e0_stop" R40:120 E3.0 S1 A1

; Duet3D laser sensor for extruder drive 0, connected to endstop input (E0), tolerance 40 to 120%, 3mm comparison ;length, enabled, check all Ext. motion

M591 D1 P5 C"e1_stop" R40:120 E3.0 S1 A1

; Duet3D laser sensor for extruder drive 0, connected to endstop input (E0), tolerance 40 to 120%, 3mm comparison ;length, enabled, check all Ext. motion

So D0 is used for extruder0 =2.85mm

And D1 for extruder1 =1.75mm

Switching them on;

With a working simplify3d printing code, results with a few seconds to a pause and "too little movement"