this was exactly what i was looking for! thank you!

Posts made by zecchi

-

RE: DWC-style messageposted in Duet Web Control wishlist

-

RE: Hotend always on after updating RRF3posted in Duet Hardware and wiring

@deckingman unfortunately T-0 (or any negative value ) doesn't work. At this point I'll leave "T0", as others say there is no difference for me. thank you all!

-

RE: Hotend always on after updating RRF3posted in Duet Hardware and wiring

@Veti yeah, I've noticed. Thank you for the info

-

RE: Hotend always on after updating RRF3posted in Duet Hardware and wiring

@Rushmere3D yeah, it's true, it was only to see "off"

thank you -

RE: Hotend always on after updating RRF3posted in Duet Hardware and wiring

Removing T0 at the end of config.g the hotend is no more active but in standby. Is there any way to shut it down?

-

Hotend always on after updating RRF3posted in Duet Hardware and wiring

Hi,

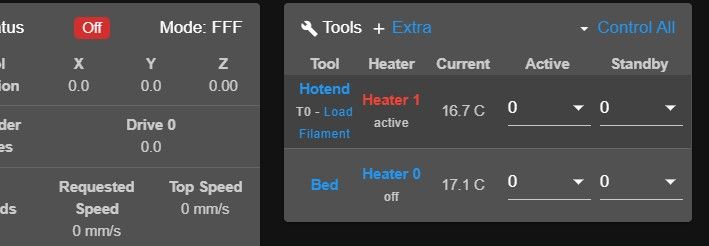

I've just updated to RRF3 and I've noticed that the hotend (hetear 1) is already active when I turn on the printer (even if the power supply is off). Look at the picture

This is my config file:

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X1 Y0 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E408.50 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z1500.00 E3600.00 ; set maximum speeds (mm/min)

M201 X2500.00 Y2500.00 Z50.00 E1500.00 ; set accelerations (mm/s^2)

M906 X1200 Y1200 Z1200 E1200 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X310 Y315 Z265 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop

M574 Z1 S2 ; configure Z-probe endstop for low end on Z; Stall Detection

;M915 X Y S7 F0 H200 R2 ; X and Y motor stall detection; Z-Probe

M558 P1 C"zprobe.in" H5 F250 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z1.20 ; set Z probe trigger value, offset and trigger height

M557 X50:260 Y20:230 S105 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 S1.2 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S100 ; set temperature limit for heater 0 to 100C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C; Fans

M950 F0 C"fan0" Q1000 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q1000 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on

M950 F2 C"fan2" Q1000 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off; Tools

M563 P0 S"Hotend" D0 H1 F0:2 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S22.5 R23.5 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0I've already checked the onboard leds: 3.3V is on, 5V is on, e0 Heat as well as Bed Heat are off.

I've also tried to add "M104 S0" in confing.g but it doesn't work.Any advice is welcome. Thanks.

-

DWC-style messageposted in Duet Web Control wishlist

Hi,

Is there any way to display DWC-style messages instead "M291 messages"? I think they look much better than standard messages.

If so, how can I use them?Thanks

-

RE: Experimenting with the emergency buttonposted in General Discussion

@dc42 your solution seems work.

I was wondering if M112 has an "automatic reboot", infact when I press the emergency button and wait few seconds DWC seems already rebooted.

-

RE: Experimenting with the emergency buttonposted in General Discussion

@Nathan actually I've had small issues with fans, but now is all ok, so I will try in the next days.

In my opinion there should be a sort of interaction between the two macros for this reason:

Let's suppose the emergency button has been pushed, then the printer is switched off before the emergency button has been released. When the printer is restarted (switched on) there may be some problems due to the emergency button state.I'm a PLC programmer, and usually, to solve this kind of problems, we use rising edge (or falling edge). But for me g-code is completely new and I don't know how to use properly commands ( like M581). For now it's ok, I will try with dc42's solution.

-

RE: Experimenting with the emergency buttonposted in General Discussion

@dc42 thank you, I'll try with this solution tomorrow.

-

Experimenting with the emergency buttonposted in General Discussion

Hi to everyone,

I'm trying to set my red mushroom emergency button to do what i want.

First of all this the code:in config.g file:

M581 T2 E1 S1 ; run macros "trigger2" for emergency stopin trigger2.g macro:

M106 P0 S1 ;fan 0 on

M106 P2 S1 ;fan 2 on

M81 ;24V power supply off

M112 ;shut down motors and heatersI've two power supplies, one 24v for the heat bed and motors, one 12v/5v for fans and cpu. So, even if i shut down the 24v power supply (via SSR) , fans and cpu can work (in order to cool the hotend).

There'sonly one problem: after m112 command I'd like restart the machine rotating the emergency button, but i'm not able to do so becouse the only thing i can do is press "reset machine" in DWC.

Any help is appreciate

-

RE: Mini differential ir gives me problemposted in IR Height Sensor

solved!!!

the problem was the height beteween nozzle and probe

-

Mini differential ir gives me problemposted in IR Height Sensor

Hi,

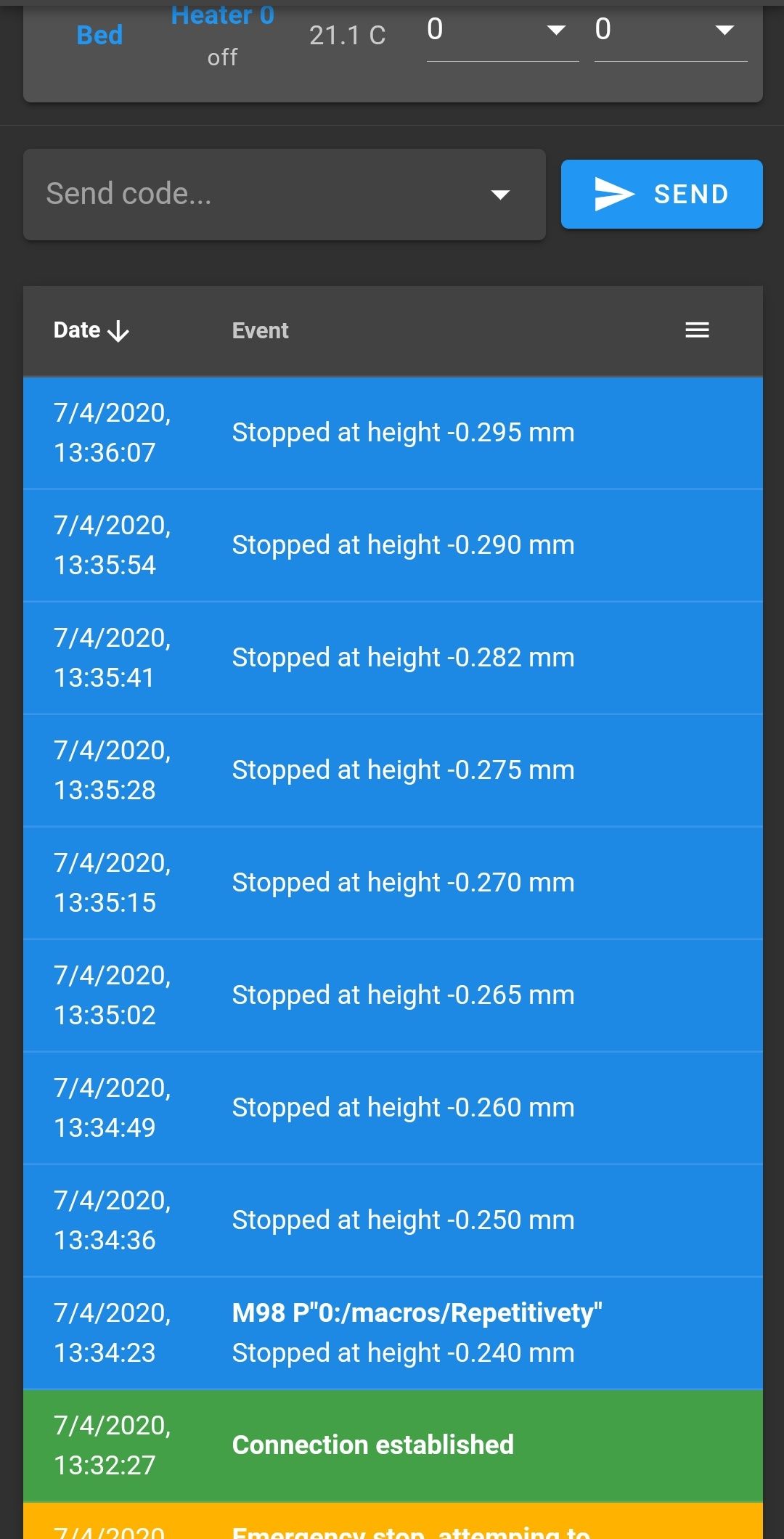

I've bought mini ir sensor. However this is the repetitivity test:

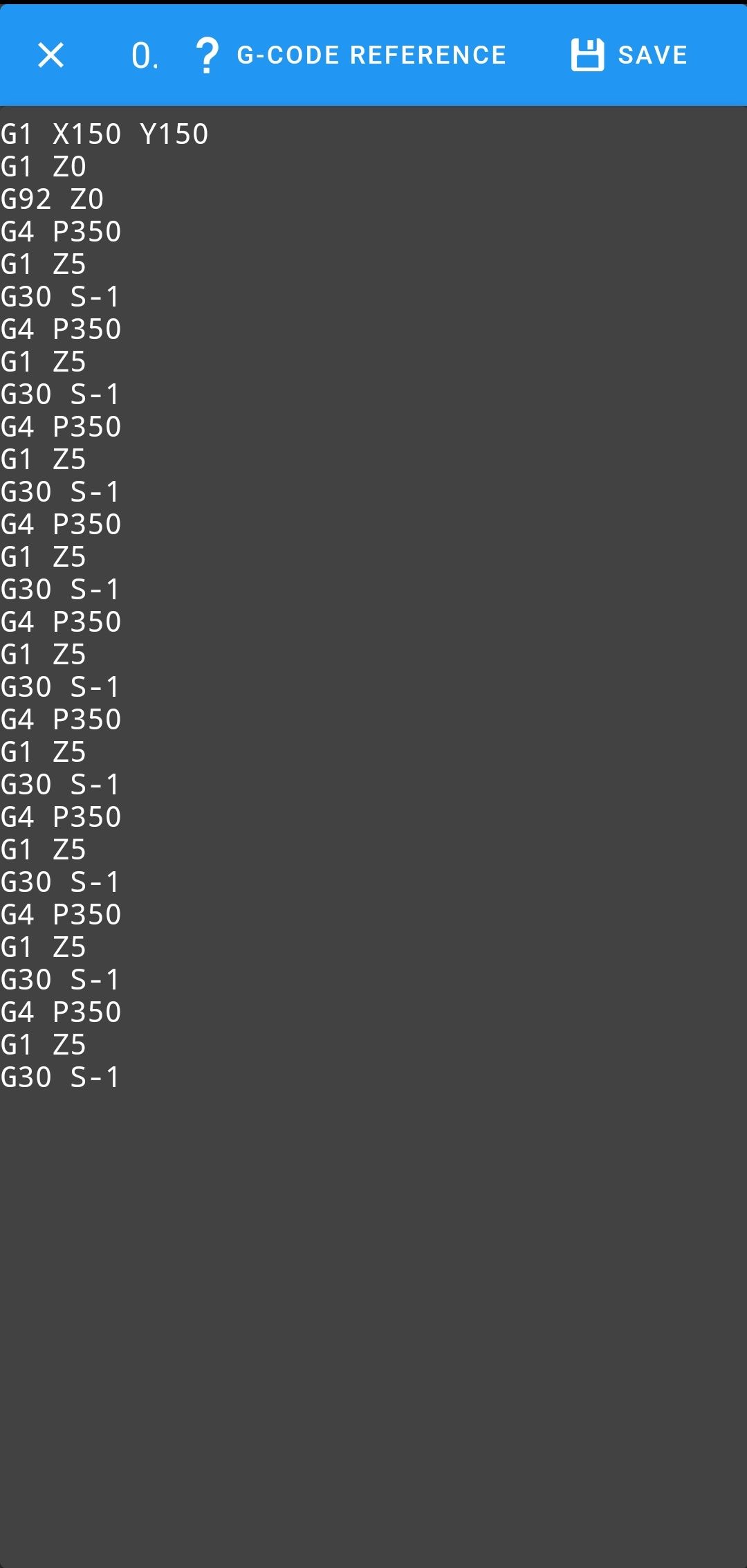

This is the macros that I've used :

I think the problem is the trigger height ( now the sensor is 3mm from the nozzle, too much

)... So for now, I want to change the support in order to decrease the height between nozzle and sensor.

)... So for now, I want to change the support in order to decrease the height between nozzle and sensor.

Have you any advices? Thanks -

RE: DWC gives me problemsposted in Duet Web Control

I've deleted all the content of 'sys' folder and I've re-uploaded all the files. It seems to be better.

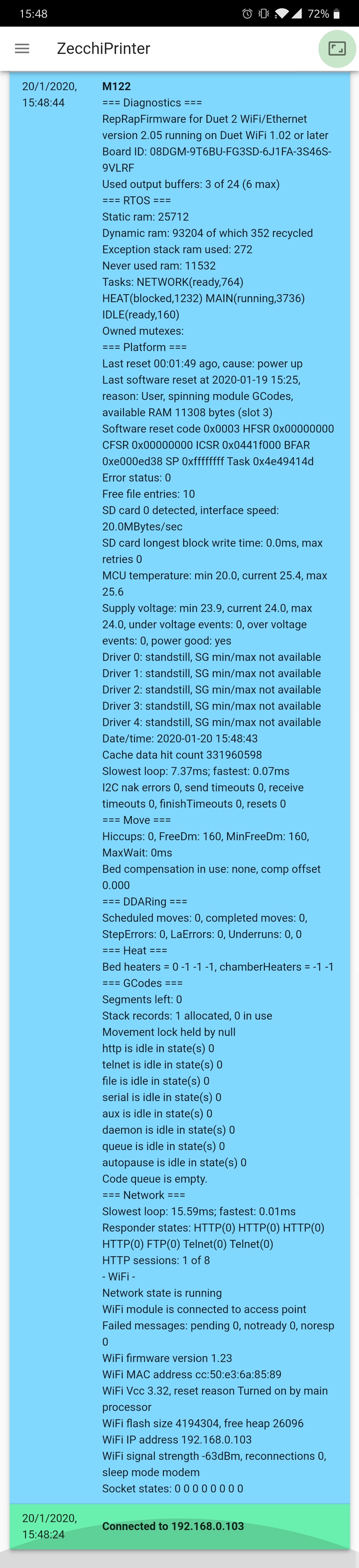

Anyway this is the M122 command response

-

DWC gives me problemsposted in Duet Web Control

Hi,

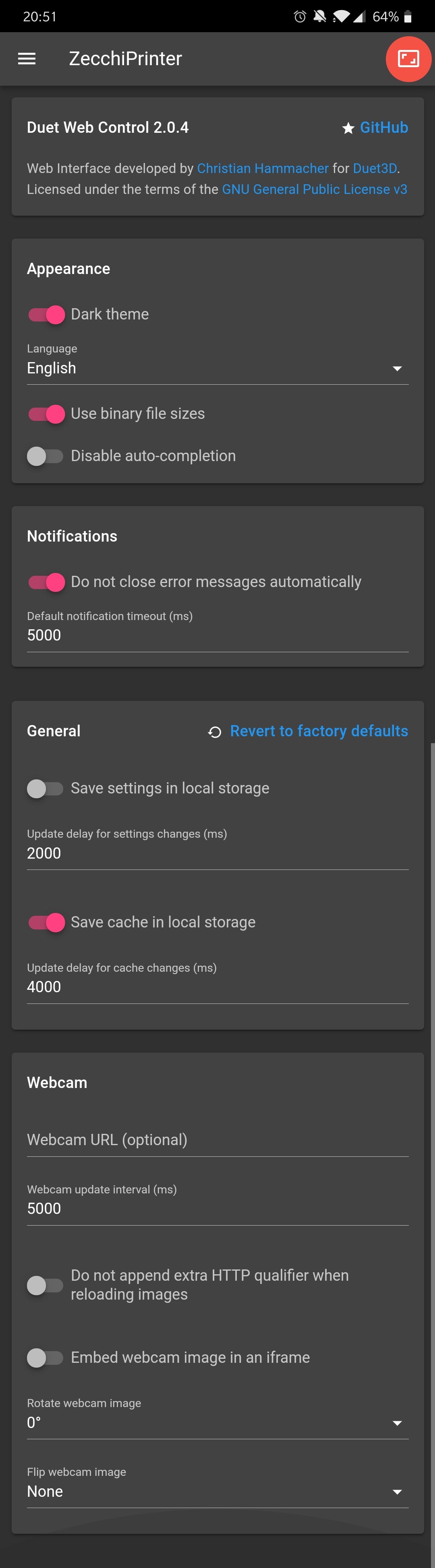

I've upgraded DWC to 2.04 version, following the instructions. But, something must be wrong.Firs of all.

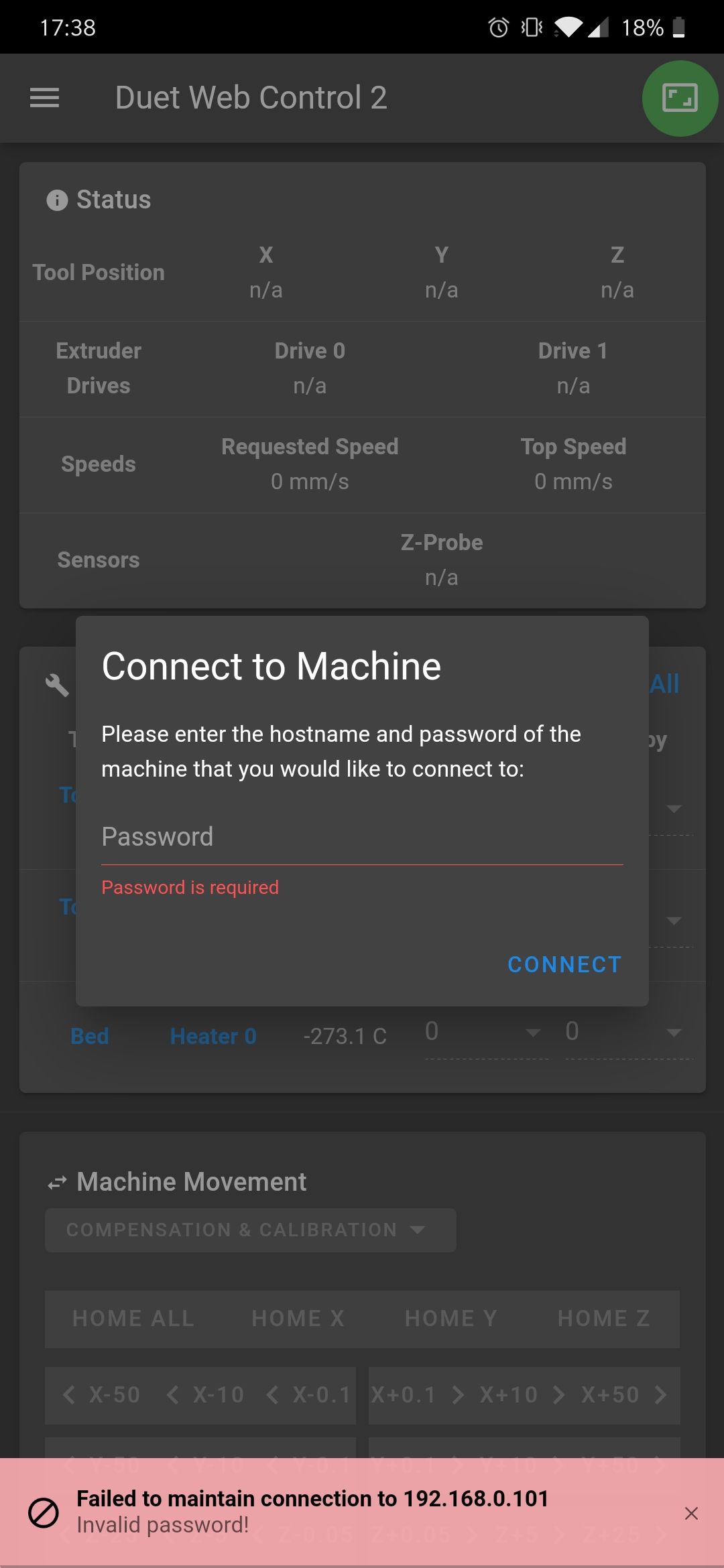

When I try to login it shows me the password request (in blank). I put the password and I can log into the Dwc.But, if I reload the page or if I do a modification to system's file, it shows a black password's box , like this :

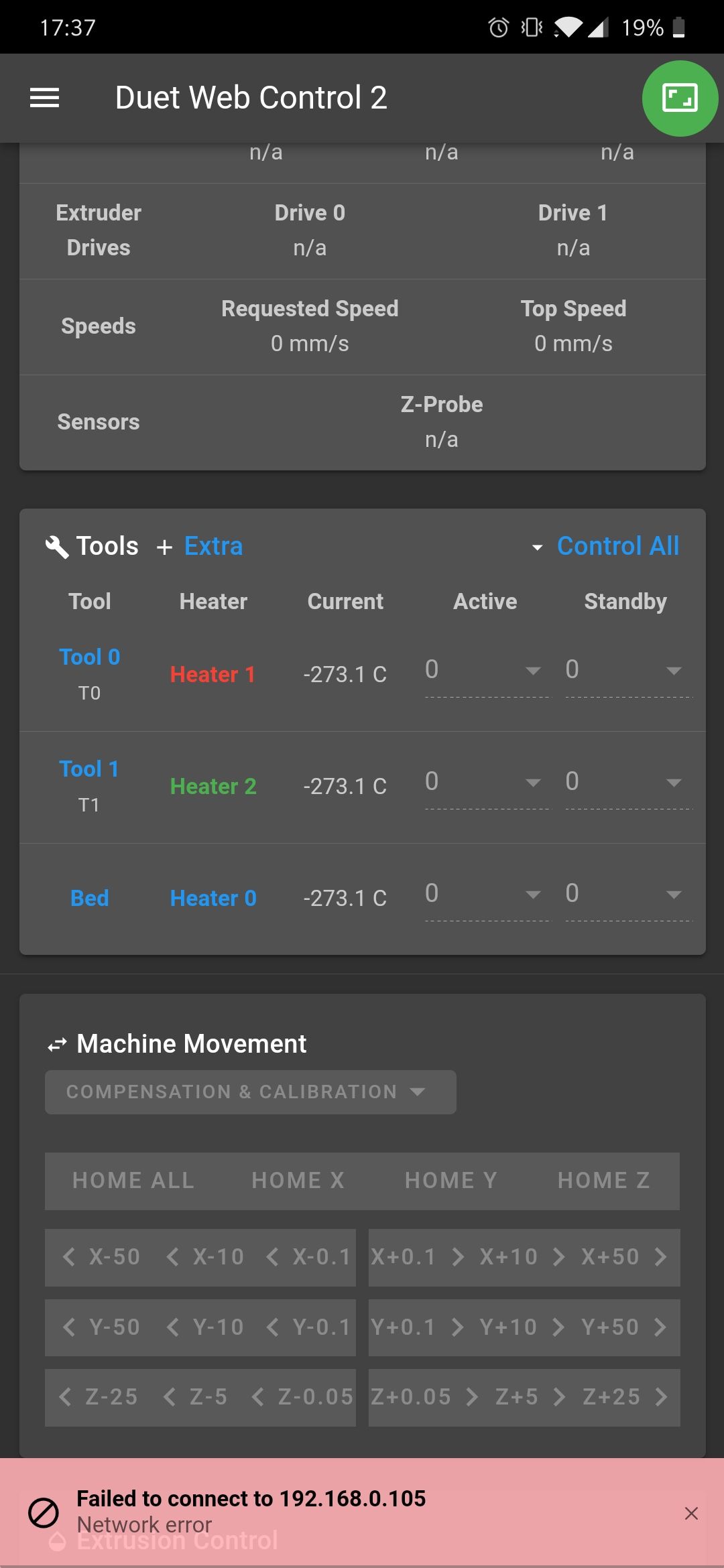

And I can't log into Dwc , neither with the correct password. Sometimes it shows me a "generic Dwc" :

I've also noticed that the IP address is changed.

These are my settings , what can I do?

-

RE: Z axis issue: wrong movement (layers)posted in My Duet controlled machine

All my printer is designed by me.

And yeah , belts are not a good solution for high loads. -

RE: Z axis issue: wrong movement (layers)posted in My Duet controlled machine

@Dkos

I've replaced it in this way:

Actually there are other improvements to do (these lead screws are too short ) but for now it's ok

-

RE: Z axis issue: wrong movement (layers)posted in My Duet controlled machine

And here we go!!

The problem were the two z axis.

Maybe it was due to the elasticity of the belts!!Thanks to all.