ferruled connectors

-

Thanks for the speedy reply!

-

The ferrules are important for the VIN power and heated bed. Less so for the hot end heater connection.

-

what size are these ferrules? I need to replace mine at the heated bad

-

@Dugee Ferrules are sized for the wire, not the terminal.

-

One of the reasons I like the general 3d community is that you can ask the stupid/obvious question without being patronised or belittled. Everyone is always keen to help the beginner.

Many thanks.

-

I have added a note about ferrules to the documentation:

https://duet3d.dozuki.com/Wiki/Connector_and_spare_part_numbers#Section_Ferrules

-

Risky business specifying size according to colour; while there are a few standards to choose from, you can also get almost any size in any colour. While it'll be correct for the ones supplied by Duet3d the end user can easily end up with a different size if ordering new ones based on colour.

-

@bearer exactly why i have the mm^2 in the documentation.

-

@T3P3Tony yes, maybe i should have been clearer; I'd put the size first to emphasize size instead of colour.

-

@bearer fair enough - I have updated it to make it clearer.

-

But how do I correctly fit those ferruled connectors into the terminals ? Do I flatten them first with pliers before putting them into the terminals and tighten the terminals' screws, or do I put the ferruled connectors as they originally are ("cylindrical", not mechanically deformed -- flattened) into the teminals and force-screw the terminals's screws until they mechanically flatten the ferruled connectors ?

-

This post is deleted! -

they are meant to be used with a ferrule crimp tool.

-

@mihaitintea Pliers don't really work very well. Ideally you'd use crimpers meant for ferrules that compress them in all directions to create a tight pinch. Pliers or vice grips can be used, but you risk damaging the wires or creating a poor mechanical crimp.

-

I use a ferrule crimping tool that I bought from Maplin, who sadly went bust. A search on eBay UK turned up this https://www.ebay.co.uk/itm/Ferrule-Crimper-Cable-Tube-Crimping-Plier-Tool-1200X-Wire-Terminal-Connector-Set/392118937290 and several other listings for similar products.

-

There is a wide range of types of crimping tools, while I tend to prefer the sort of D shaped dies the smallest terminals used on the Duet works best with square type of crimpers, and not the type that create extremely serrated sides.

So the type dc42 links to is probably the best bet.

-

Bought a ferrule crimping tool.....problem solved.

-

Hello

Thanks for the answers but I believe I did not make myself very well understood.

The ferrule connectors that I am talking about are already crimped to the wires, from the factory.

I was talking about tightening the ferrule connectors into the Duet3D board terminal blocks.

The out-of-the-box ferrule connector is a hollow tube. One end of this tube is factory-crimped to the wire, and the other end of this tube is free and goes into Duet's terminal blocks.

Do I tighten this free end of the tube in the Duet board's terminal block until the tube gets mechanically deformed ? Or do I do the flattening myself (e.g., using pliers) until the connector gets shaped as a flat rectangle, and put that flattened end of the connector in Duet's terminal blocks and then tighten those screws ?

Which way is best ? In time, which of these variants is the most reliable (i.e., does not need to be pereiodically verified and tightened again)

Thanks and regards

-

@mihaitintea said in ferruled connectors:

Do I tighten this free end of the tube in the Duet board's terminal block until the tube gets mechanically deformed ?

Yes, after crimping the ferrule onto the wire it will have one of several shapes; this goes straight into the terminal block and you tighten down the screw in the terminal according to the torque for the terminal. If that results in the ferrule further deforming then thats ok.

-

@mihaitintea said in ferruled connectors:

The out-of-the-box ferrule connector is a hollow tube. One end of this tube is factory-crimped to the wire, and the other end of this tube is free and goes into Duet's terminal blocks.

Do I tighten this free end of the tube in the Duet board's terminal block until the tube gets mechanically deformed ? Or do I do the flattening myself (e.g., using pliers) until the connector gets shaped as a flat rectangle, and put that flattened end of the connector in Duet's terminal blocks and then tighten those screws ?

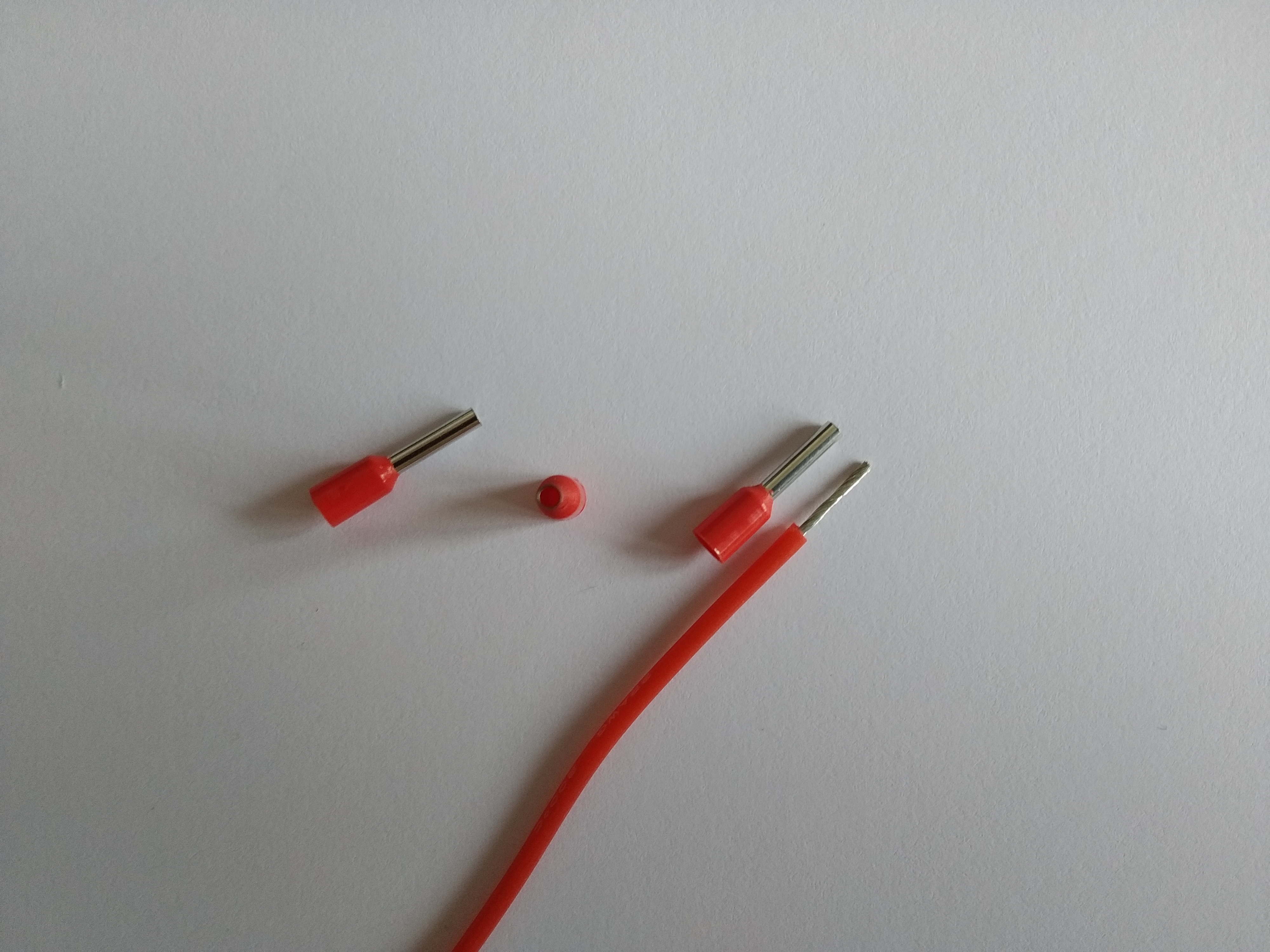

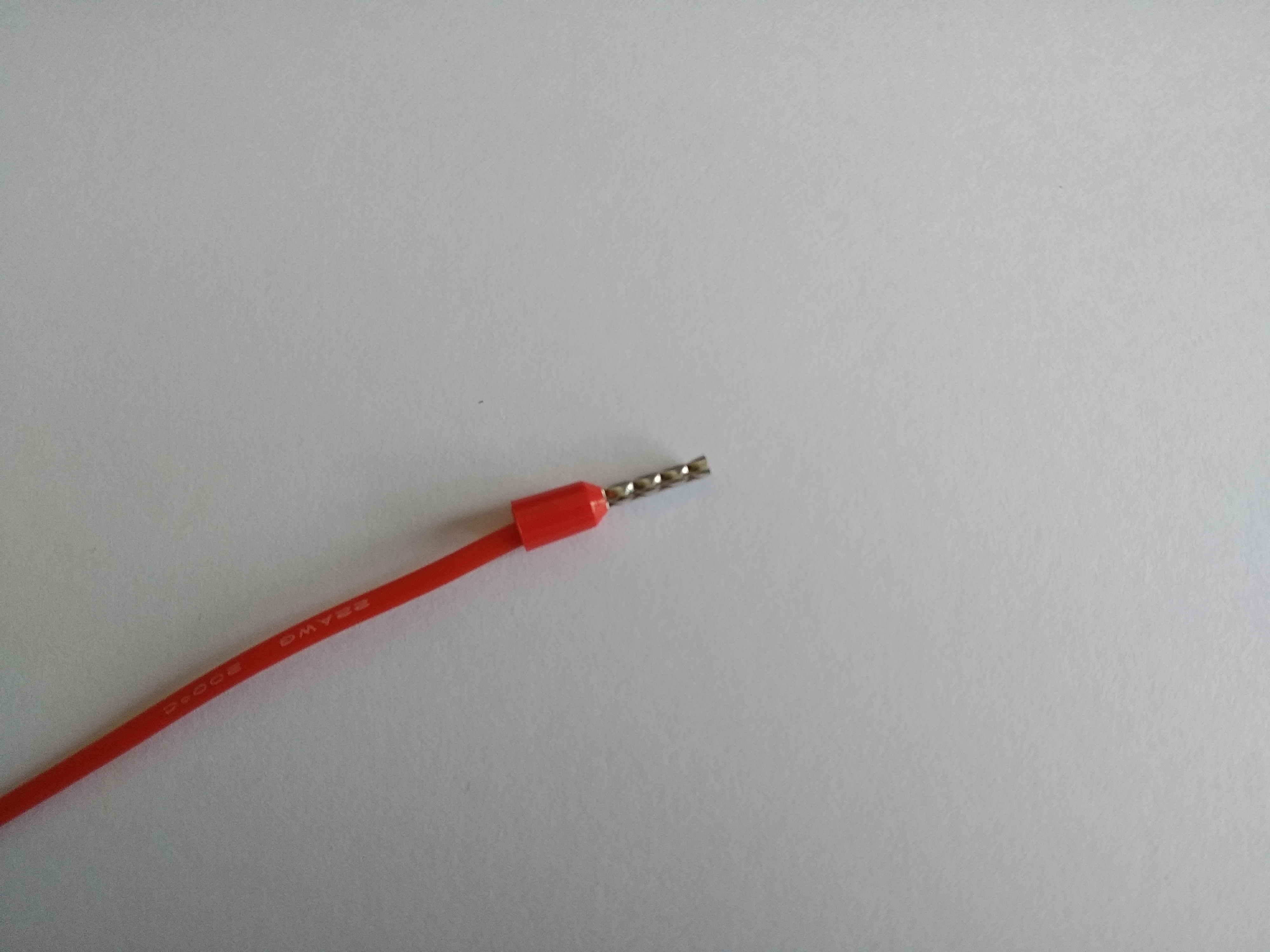

Here's the kind of ferrule that you should be using:

One end is insulated to prevent any chance of a short. The wire is then stripped so that the wire is the same length as the exposed metal part of the ferrule. The wire is inserted into the ferrule and crimped.

If the manufacturer didn't strip the wire long enough, so that metal tube is not filled all the way to the end with wire, simply cut the end of the ferrule off with some side cutters so that you can see the crimped wire at the end of the metal tube.

Then insert the ferrule into the connector and tighten down the retaining screw while supporting the connector against the force of tightening the screw down.