Pressure Advance seems to not be working.

-

@Phaedrux - its hardcoded into the code, but i confirm it changes every 25 layers using the command line console. The extruder behaviour changes each time PA changes, i can confirm that. But nothing changes in the print.

Im thinking PA is working but something is masking its effects, hence why i was thinking of changing jerk and possibly acceleration on the extruder.

-

Are you still getting hiccups?

-

@Phaedrux - This is a M122 just ran (around an hour after the print finished, this would still be reporting from the print, right?):

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 2.03 running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DGM-956GU-DJMSN-6J1F4-3SJ6N-1BNBF Used output buffers: 6 of 24 (20 max) === RTOS === Static ram: 25680 Dynamic ram: 94256 of which 308 recycled Exception stack ram used: 492 Never used ram: 10336 Tasks: NETWORK(ready,524) HEAT(blocked,1236) DUEX(suspended,156) MAIN(running,1668) IDLE(ready,160) Owned mutexes: === Platform === Last reset 75:55:33 ago, cause: software Last software reset at 2019-12-31 18:44, reason: User, spinning module GCodes, available RAM 10232 bytes (slot 2) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d Error status: 16 Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest block write time: 378.3ms, max retries 0 MCU temperature: min 40.0, current 54.9, max 59.0 Supply voltage: min 23.9, current 24.4, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max 0/1023 Driver 1: standstill, SG min/max 0/1023 Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max 0/1023 Driver 4: standstill, SG min/max not available Driver 5: standstill, SG min/max 0/270 Driver 6: standstill, SG min/max 0/281 Driver 7: standstill, SG min/max 0/284 Driver 8: standstill, SG min/max 0/291 Driver 9: standstill, SG min/max not available Date/time: 2020-01-03 22:40:42 Cache data hit count 4294967295 Slowest loop: 149.85ms; fastest: 0.08ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Move === Hiccups: 0, FreeDm: 169, MinFreeDm: 145, MaxWait: 156472642ms Bed compensation in use: mesh, comp offset 0.000 === DDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.5 === GCodes === Segments left: 0 Stack records: 4 allocated, 0 in use Movement lock held by null http is idle in state(s) 0 telnet is idle in state(s) 0 file is idle in state(s) 0 serial is idle in state(s) 0 aux is idle in state(s) 0 daemon is idle in state(s) 0 queue is idle in state(s) 0 autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 379.69ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 - WiFi - Network state is running WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 8 WiFi firmware version 1.23 WiFi MAC address 5c:cf:7f:76:71:05 WiFi Vcc 3.32, reset reason Turned on by main processor WiFi flash size 4194304, free heap 24672 WiFi IP address 192.168.0.26 WiFi signal strength -52dBm, reconnections 0, sleep mode modem Socket states: 0 0 0 0 0 0 0 0 -

@Samuel235 said in Pressure Advance seems to not be working.:

this would still be reporting from the print, right?

As long as you haven't run a M122 or power cycled the count should still be from the print.

well I'm all out of ideas. Do experiment with different jerk and acceleration values, but usually the higher values would just mean giving pressure advance room to manage the extruder position rather than limiting it.

-

@DIY-O-Sphere said in Pressure Advance seems to not be working.:

Maybe the jerk value for the extruder is too high.

While setting up PA today, I had the same issue. After decreasing jerk to 1000 mm/min I was able to print the test cube.That's a common case with a geared extruder.....You will find that also documented in other threads

-

Should i try changing the acceleration of XY, just thinking back, on that cube the seam would only cause PA to activate pretty much only on the seam itself, nothing before or after it was instantly on the seam and then stopped as it increased Z to the next layer.

Just putting it out there that maybe my CY acceleration os causing PA to have no time to perform its work?

-

That are the values that I have set for PA

M566 X900.00 Y900.00 Z12.00 E1000.00

M203 X15000.00 Y15000.00 Z300.00 E12000.00

M201 X1600.00 Y1600.00 Z150.00 E3000.00In my opinion all your values are fin exept the jerk.

By increasing the gear ratio you have to decrease jerk.

For a Nimble extruder other users advise to go below 100

I use a BMG which is geared 3:1 -

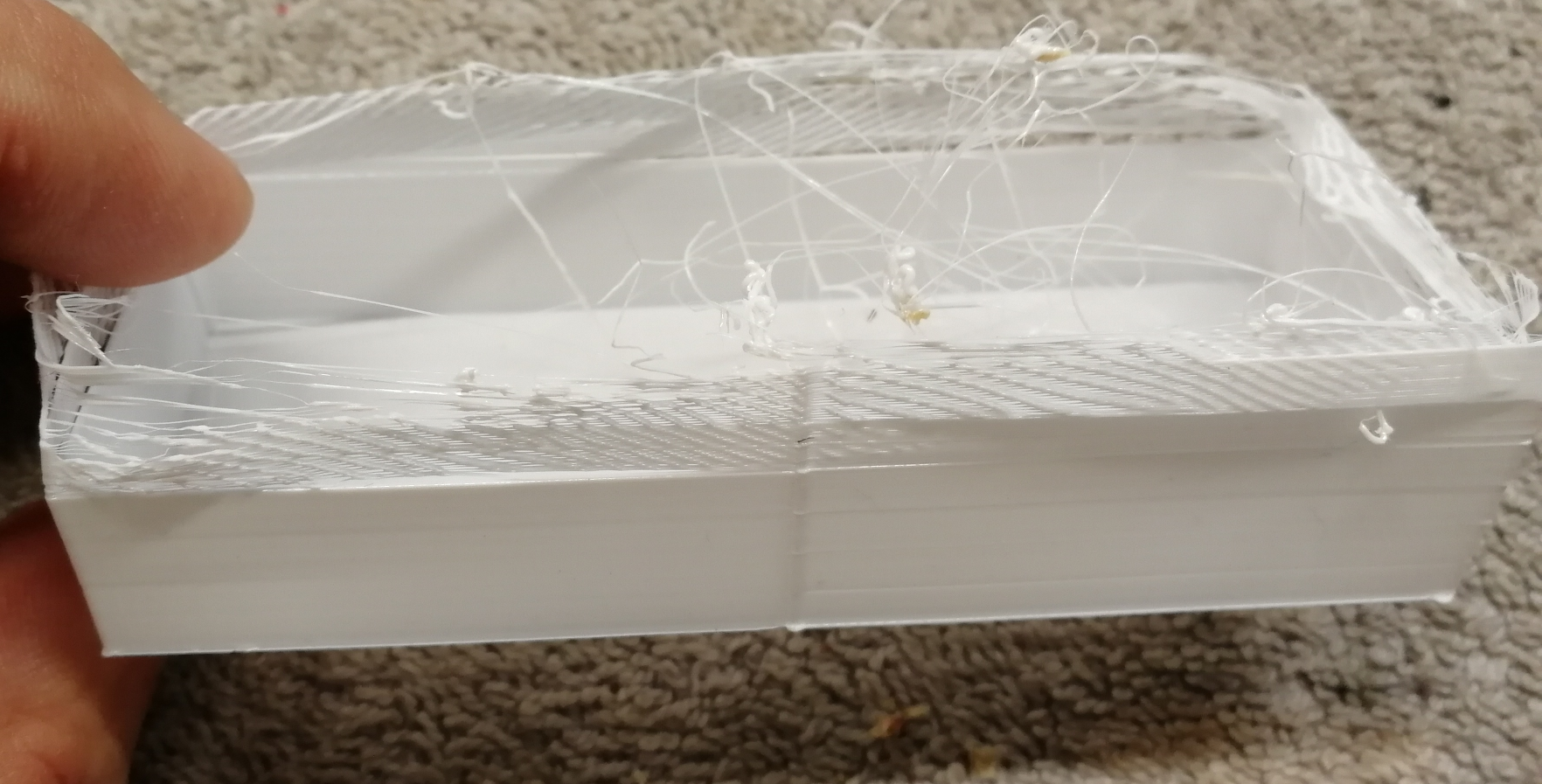

After the last cube I have got the following result (I still can't really see much of a difference, is the seam getting smaller high we go do you feel, if so maybe I just need to take PA up higher, it was 0.7:

![IMG_8789[1].JPG](/assets/uploads/files/1578141600117-img_8789-1-resized.jpg)

![IMG_8790[1].JPG](/assets/uploads/files/1578141629267-img_8790-1-resized.jpg)

Jerk settings were:

M566 X900 Y900 Z60 E1000M122 after this print was:

M122 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 2.03 running on Duet WiFi 1.02 or later + DueX5 Board ID: 08DGM-956GU-DJMSN-6J1F4-3SJ6N-1BNBF Used output buffers: 5 of 24 (9 max) === RTOS === Static ram: 25680 Dynamic ram: 94256 of which 308 recycled Exception stack ram used: 540 Never used ram: 10288 Tasks: NETWORK(ready,692) HEAT(blocked,1236) DUEX(suspended,156) MAIN(running,1668) IDLE(ready,160) Owned mutexes: === Platform === Last reset 02:58:13 ago, cause: software Last software reset at 2020-01-04 09:39, reason: User, spinning module GCodes, available RAM 10336 bytes (slot 3) Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d Error status: 0 Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest block write time: 7.2ms, max retries 0 MCU temperature: min 44.1, current 44.4, max 56.6 Supply voltage: min 23.9, current 24.4, max 24.6, under voltage events: 0, over voltage events: 0, power good: yes Driver 0: standstill, SG min/max 0/1023 Driver 1: standstill, SG min/max 0/1023 Driver 2: standstill, SG min/max not available Driver 3: standstill, SG min/max 0/1023 Driver 4: standstill, SG min/max not available Driver 5: standstill, SG min/max 0/271 Driver 6: standstill, SG min/max 0/278 Driver 7: standstill, SG min/max 0/282 Driver 8: standstill, SG min/max 0/288 Driver 9: standstill, SG min/max not available Date/time: 1970-01-01 00:00:00 Cache data hit count 4294967295 Slowest loop: 116.70ms; fastest: 0.07ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Move === Hiccups: 0, FreeDm: 169, MinFreeDm: 149, MaxWait: 165675ms Bed compensation in use: mesh, comp offset 0.000 === DDARing === Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 Heater 0 is on, I-accum = 0.0 Heater 1 is on, I-accum = 0.6 === GCodes === Segments left: 0 Stack records: 4 allocated, 0 in use Movement lock held by null http is idle in state(s) 0 telnet is idle in state(s) 0 file is idle in state(s) 0 serial is idle in state(s) 0 aux is idle in state(s) 0 daemon is idle in state(s) 0 queue is idle in state(s) 0 autopause is idle in state(s) 0 Code queue is empty. === Network === Slowest loop: 39.70ms; fastest: 0.00ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0) HTTP sessions: 1 of 8 - WiFi - Network state is running WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 0 WiFi firmware version 1.23 WiFi MAC address XXXXXXXXXXX WiFi Vcc 3.32, reset reason Turned on by main processor WiFi flash size 4194304, free heap 23208 WiFi IP address XXXXXXXXXXXXXX WiFi signal strength -55dBm, reconnections 0, sleep mode modem Socket states: 0 0 0 0 0 0 0 0 -

You can sent the command directly in DWC

M572 D0 S#.# (#, set the number for the value)

I would recommend to switch every 4-5 mm between PA 0 and current PA value +adding an amount.

Then it's easier to see the difference in direct comparison....

I have done that with a custom code in Prusaslicer.

That are values between 0,6 and 1,4 -

@DIY-O-Sphere - So something like the following:

0-5mm: PA 0

5-10mm: PA 0.2

10-15mm: PA 0.4

15-20mm: PA 0

20-25mm: PA 0.6

25-30mm: PA 0

30-35mm: PA 0.8

35-40mm: PA 0

40-45mm: PA 1I have been doing it just one after another without a 0 between, I see what you mean now, it will enable me to check all the way through the range easily back to original. Thank you, will get that done now.

-

@Samuel235 said in Pressure Advance seems to not be working.:

After the last cube I have got the following result (I still can't really see much of a difference, is the seam getting smaller high we go do you feel, if so maybe I just need to take PA up higher, it was 0.7

I have compared your last result with my first print, where Jerk was too high.

Looks pretty similar. So maybe the jerk is still too high?

In the lower area (PA 0.2-1.0) there is absolutely no visible difference. Then above 1.2 the extrusion begins to fail....

What is the gear ratio of the extruder?

-

@DIY-O-Sphere said in Pressure Advance seems to not be working.:

Then above 1.2 the extrusion begins to fail....

The pressure advance retreat combined with the retraction may have pulled the filament up high enough to get stuck.

-

@DIY-O-Sphere said in Pressure Advance seems to not be working.:

I have done that with a custom code in Prusaslicer.

As a side note, the upcoming PrusaSlicer will make it even easier to set per height configurations.

-

@DIY-O-Sphere - This is a 4:1 ratio extruder

@zapta - That is such an awesome addition to the slicer!

-

@zapta said in Pressure Advance seems to not be working.:

As a side note, the upcoming PrusaSlicer will make it even easier to set per height configurations.

That is exactly the way I have done it ....

-

@DIY-O-Sphere said in Pressure Advance seems to not be working.:

That is exactly the way I have done it ....

And what is also awesome: If you save the project file as 3mf you will be able to take that as template, without setting up all layer changes....

-

Currently trying the print again with Jerk set to 800 rather than 1000

-

I still believe there is something causing PA to not take full effect, i don't believe there is much change on this new cube either. I've lowered my Jerk even more but the fact that I don't see much change at all up the seam, I don't believe its having full effect. Testing another cube now with a Jerk of 400.

-

Lowering the jerk will limit pressure advance even more. Unless you're using a high gear ratio remote direct drive like the Zesty Nimble reducing the jerk isn't really necessary.

I believe you're using the Voron2 Mobius extruder? Which is 4:1?

I would think that a extruder jerk and acceleration in the 3000 to 6000 range should be suitable.

I'm using a 3:1 titan aero with 0.9 degree motor and I use 6000 max speed, and 3000 accel and jerk. Mind you it's direct drive, so my PA value is very low 0.03 to 0.05.

Earlier you said you tried values between 0.5 and 7. Did you mean 0.5 and 0.7?

If you went up to 7 and nothing change something is wrong. If you only went up to 0.7 you haven't gone high enough.

What does the Voron 2 community suggest for extruder value configuration?

-

@Samuel235 I'm facing the similar thing.

My extruder is BMG with 3:1 ratio. Bowden 55cm.

Printed test cube with jerk set to 600 and PA set to 0.2 through 1.0 - got very minor effect.

Previous experiments with python PA test script showed effect with PA set to 1.6-1.65 which made my extruder sing with forward-backward-forward rapid move on every line.

Now i think about trying to set jerk to 0 and raise acceleration, as the formula in doc is: actual_extrusion_speed = requested_extrusion_speed + (K * current_extruder_acceleration), which makes me think the jerk should be minimal while acceleration should be high.