Do I need to replace my belts? Lines not stright

-

Hello,

So I put about half a roll of filament through my printer and I've started to notice lines are not quite stright as they were initially.

When going through the initial tuning I printed multiple benchys, calibration cubes, and bed level tests and everything came out square and stright as expected; but now that I've moved onto larger prints I've noticed that prints are bowed.

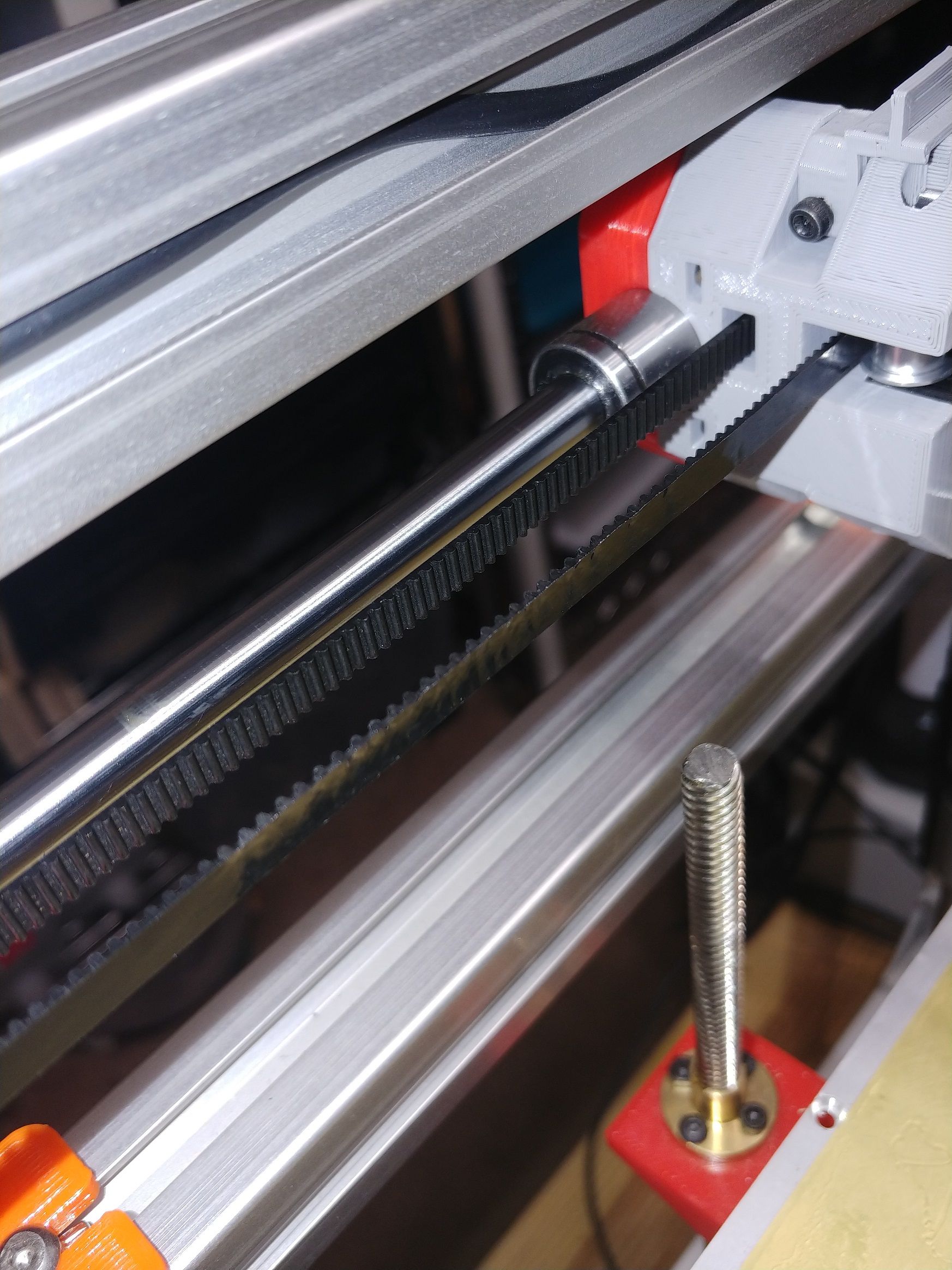

I first found that my belts were super loose almost falling off, so I obviously tightened them again; then I noticed that each belt has a semi-melted part in a section. I assume this melted section and unevenness is the cause for the recent bowing?

Attached are some example photos.

Machine: Hypercube Evoloution

Type: CoreXY

-

@firex726 said in Do I need to replace my belts? Lines not stright:

for me it looks like a mechanical problem. how big is your print surface? what size have your x/y rods ?

The first thing i would do where to change the belt the old one can make trubble but i don't think that this is your main problem. -

@SIam

Actual print area is around 275x300, the entire bed is closer to 320 squared.

X rods are 8mm, and Y are 10mm. -

have you tried to loosen your belt a bit and tried a test print?

-

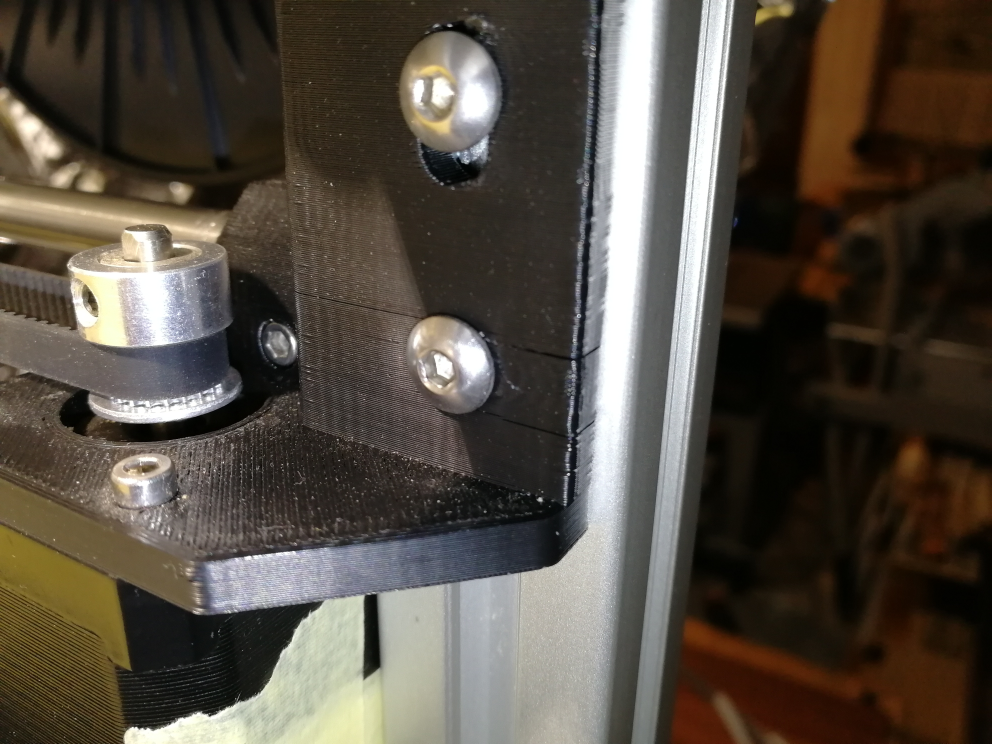

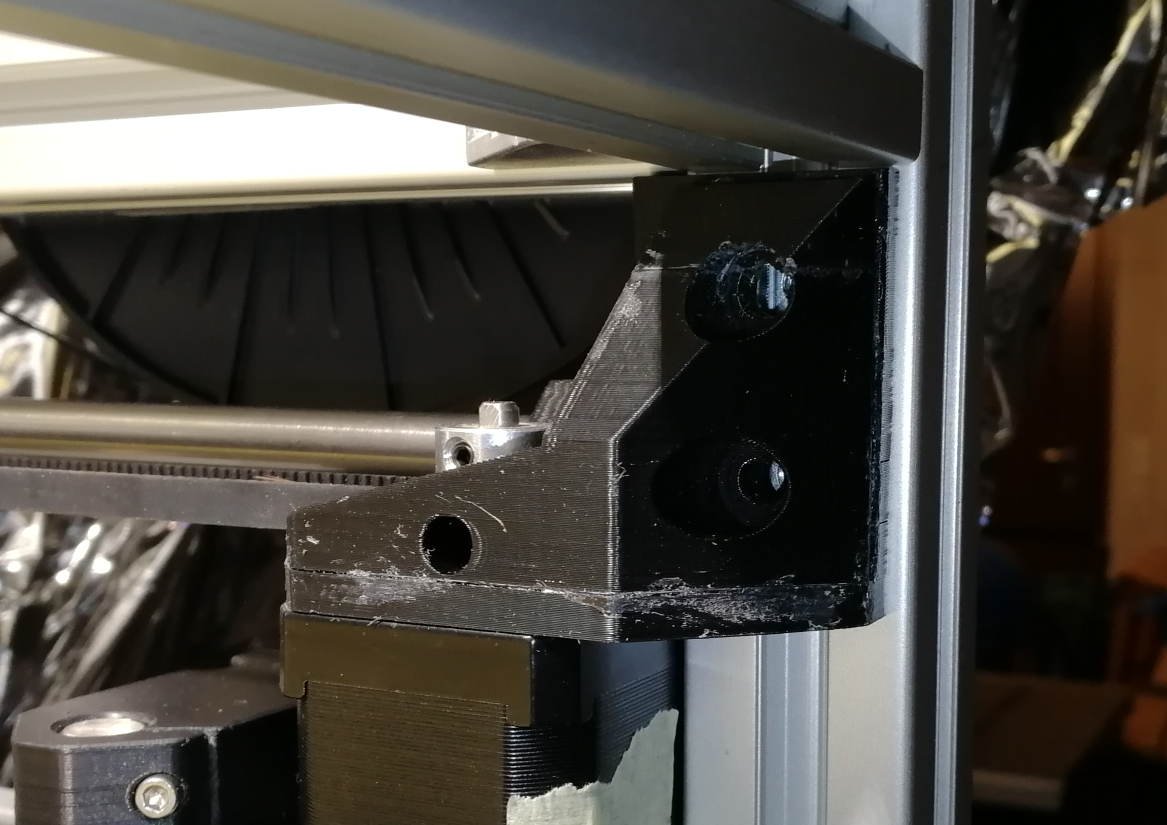

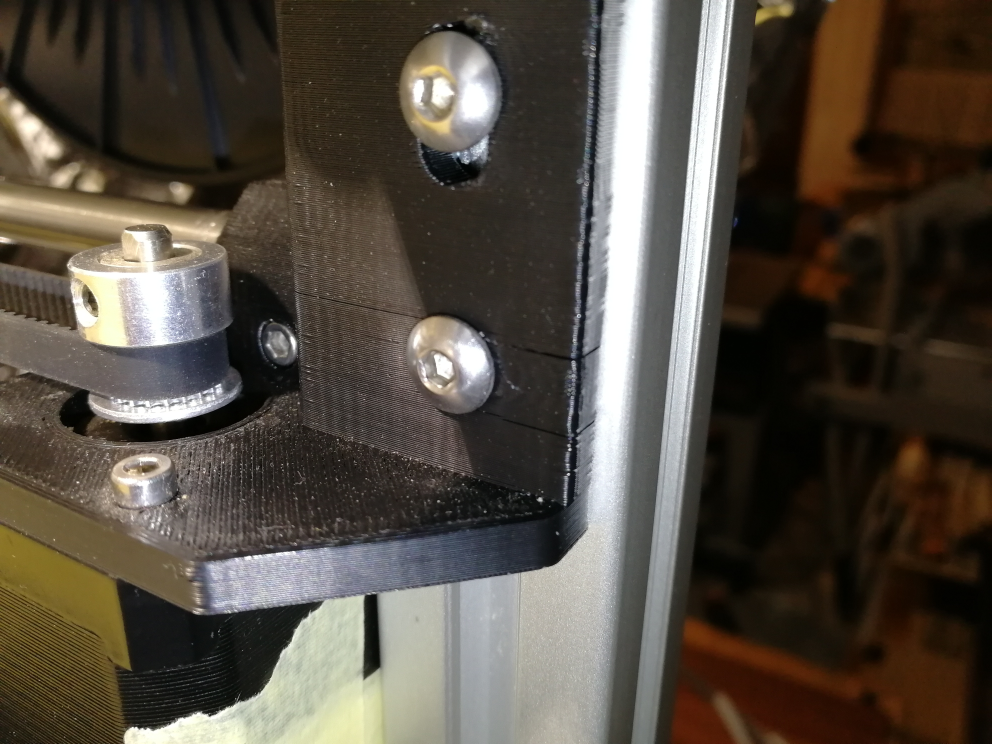

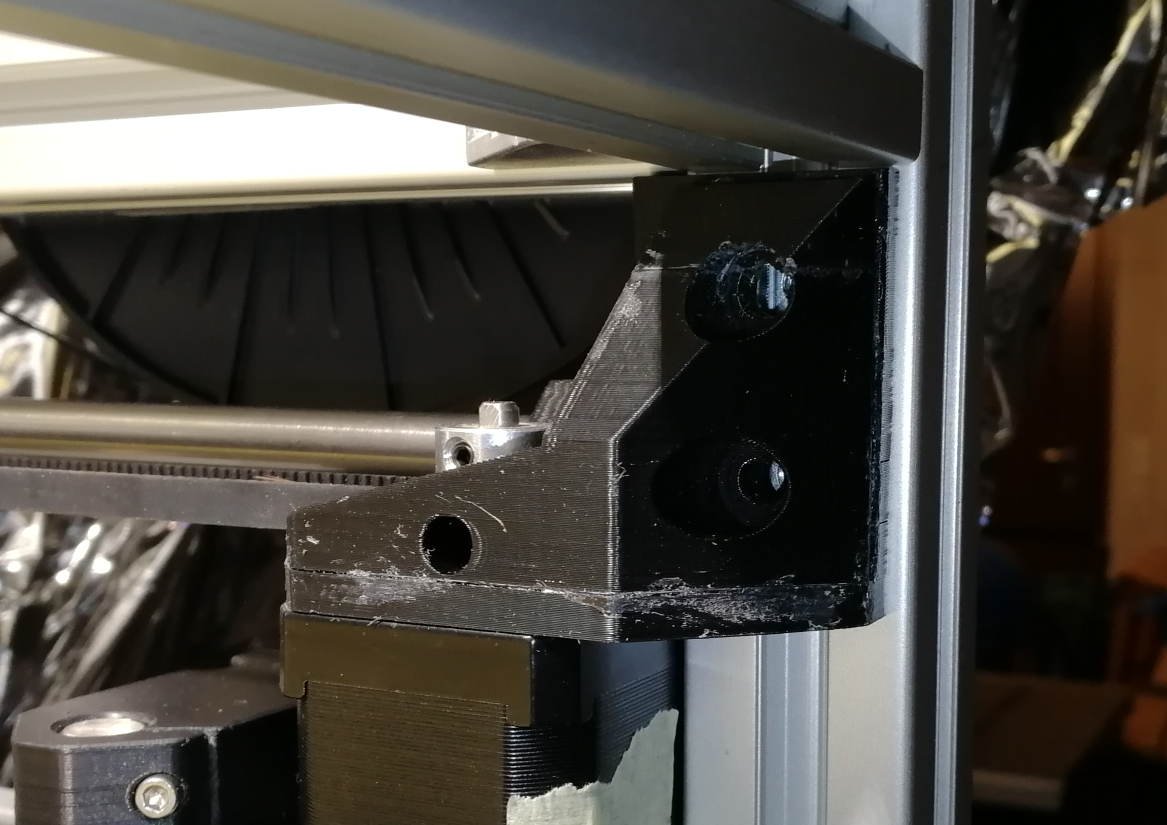

That's a common problem of the Hypercube. Check the motor mounts.

The motor mounts are to weak (or in my case broken).

When they flex the pulleys loose parallelity.

That leads to the belts rubbing the pulley shields.

You can test that pushing against the motors. That should stop the rubbing.You can add a reinforcement or search for stronger ones.

-

@DIY-O-Sphere

Looks like I got some printing to do then... They were on my list of things to remake later. -

@DIY-O-Sphere said in Do I need to replace my belts? Lines not stright:

The motor mounts are to weak (or in my case broken).

Are these made of PETG? Never seen PETG cracking this way.

-

@zapta

Mine were... I had bought them as part of a kit but it was printed so poorly I've basically had to reprint everything; many of which were cracking in the same way while under minimal load. -

@zapta said in Do I need to replace my belts? Lines not stright:

Are these made of PETG

Experience is a hard teacher...

Esun ABS, I hate that material.... Nearly all parts got cracks.

That was my first build and the parts where printed by a friend.

The surface is very smooth, but it's a brittle material.I have switched to M4P ABS and have reprinted most of the parts.

-

@DIY-O-Sphere said in Do I need to replace my belts? Lines not stright:

I have switched to M4P ABS and have reprinted most of the parts.

IIRC the recommended material is PETG. Not sure why.

-

@zapta PETG is probably recommended because PLA will melt if you transport your printer and leave it in a hot car, and most printers can't print ABS very reliably.

What do the belt clamps look like? If you're having to retighten belts over and over there's a good chance that the clamps or belts are failing at the clamps. Are you putting excessive tension on the belts and thereby causing the clamps (and maybe pulley and motor mounts) to fail? Motor and pulley mounts that are designed to look like cast metal parts will not behave like cast metal because they're made of plastic. If you want plastic to be rigid, you have to add bulk.

The belt tension affects squareness of the X and Y rails. When you put the first belt on the machine, don't immediately pull it to final tension. Adding and tensioning the second belt will also tighten the first belt. Tighten the second belt just enough to pull the X axis square with the Y axis. Then, if the first belt seems too loose, tighten it a little, then tighten the second belt again, until the axes are square. Square axes are always the belt tightening endpoint.

If the belts look melted, it should be easy to find the heat source and eliminate it- it's 100% guaranteed that nothing that contacts a belt should be getting hot enough to burn/melt the belt.

-

@DIY-O-Sphere said in Do I need to replace my belts? Lines not stright:

That's a common problem of the Hypercube. Check the motor mounts.

The motor mounts are to weak (or in my case broken).

When they flex the pulleys loose parallelity.

That leads to the belts rubbing the pulley shields.

You can test that pushing against the motors. That should stop the rubbing.You can add a reinforcement or search for stronger ones.

My old eyes might be deceiving me, but that looks like 2 outer wall thicknesses in that bracket print. It should be strong enough in PETG, but I'd want 4x wall thickness, 1mm top/bottom layer and 60% infill for that application.

Actually no....I'd want it machined from aluminium, but the settings above will still be better if your printer is setup correctly. It certainly shouldn't be on there if it's split.

-

@mrehorstdmd said in Do I need to replace my belts? Lines not stright:

The belt tension affects squareness of the X and Y rails. When you put the first belt on the machine, don't immediately pull it to final tension. Adding and tensioning the second belt will also tighten the first belt.

Yes, that correct. Took me some time to realize it. Now I adjust the two belts for the XY to be square. I move the x rail toward the front on the printer until it hits the motor mount on one side and then adjust the belts such that it hits both right and left motor mounts at the same time. I also keep significant tension on both belt, seems to have less backlash that way.