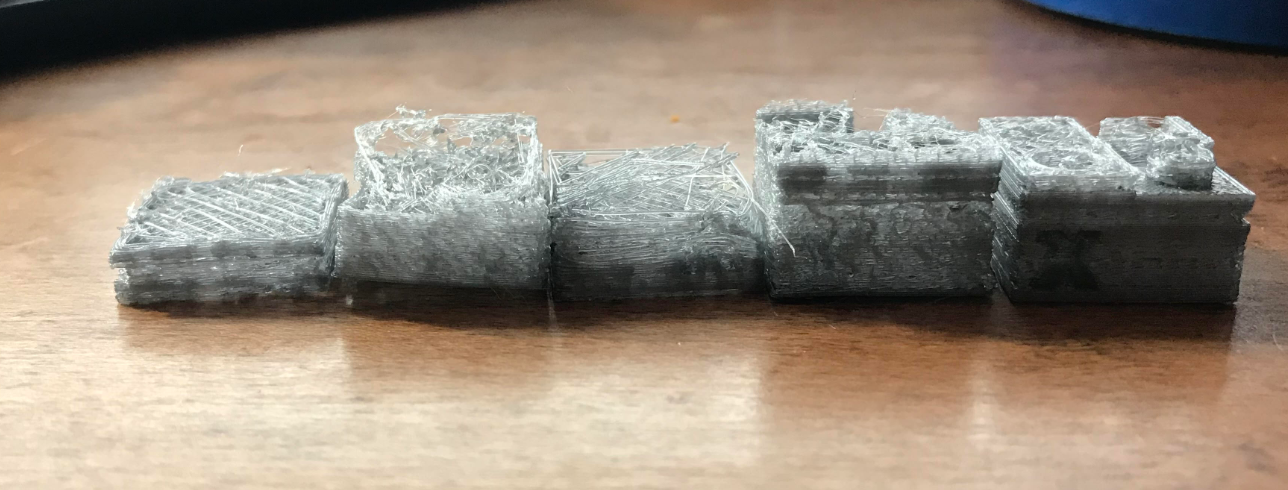

Terrible print

-

Do you happen to have the slicer configured to expect 3mm filament? This sometimes happens with Cura defaulting to 2.85mm filament after an update when you're actually using 1.75mm filament leading to huge under extrusion similar to what you're seeing.

Your screen shot of the speed settings looks like... Simplify3D? What filament diameter do you have configured?

Also, what nozzle size are you using and what size is configured in the slicer? Using a larger nozzle than you think could lead to under extrusion like that as well.

-

@droftarts sure, here is the gcode from the last print. I slowed it down a lot just to rule out print speed.

[0_1583623423559_800 Test_Cube.gcode](Uploading 100%)

-

@Phaedrux I am using Simplify 3d. I confirmed that it is set to 1.75mm filament. the nozzle is 0.4mm. just before my last print I cleaned out the block and changed the nozzle to a fresh, new one.

-

And you've gone through the extruder calibration from that Ender 3 guide?

-

@Phaedrux I have but I can do it again.

-

Can you post a picture of the printer overall and the extruder in particular? Maybe a video of it printing?

Have you tried a different slicer? Might not be a bad idea to try cura or prusa slicer. They have profiles for the Ender 3 and it would be good to see if it's a mechanical issue or a slicer issue.

-

@apex2011 My best guess for what it's worth is that you have terrible under extrusion. I haven't read every post in this thread but it seems that your settings aren't far off. The fact that a manual extrude into air looks OK would rule out any blockage. Which only leaves one thing that I can think of and that is a wiring fault that is making and breaking connection as the hot end moves around. A bad crimp could do that. Try checking by doing a long manual extrude - say 100 mm and wiggle the extruder motor wires while that's happening.

-

@apex2011 said in Terrible print:

@droftarts sure, here is the gcode from the last print. I slowed it down a lot just to rule out print speed.

[0_1583623423559_800 Test_Cube.gcode](Uploading 100%)

Upload didn't work. Try hosting it somewhere else and post a link?

Ian

-

my money is on the bowden gap issue with the terrible pneumatic push fits on an ender, and that the switch to the board is incidental. See https://www.youtube.com/watch?v=30qqKUwviww

-

@droftarts Here is a link to google drive

https://drive.google.com/open?id=1P7hhHLL-JGG3pNmTfgjfTZtHWjeIu3XH

-

So, as many mentioned before it is definitely an extruder issue.

Here's today's progress

Hopefully soon I will have a usable printer again lol

-

@apex2011 I’m pretty sure it’s your Slicer settings. Here’s the first bit from the Gcode you posted:

G90 M82 M106 S0 M140 S60 M190 S60 M104 S230 T0 M109 S230 T0 G28 ; home all axes G1 X5 Y10 Z0.2 F3000 ; get ready to prime G92 E0 ; reset extrusion distance G1 X160 E15 F600 ; prime nozzle G1 X180 F5000 ; quick wipe ; process Process1 ; layer 1, Z = 0.240 T0 G92 E0.0000 G1 E-4.0000 F2400 ; feature skirt ; tool H0.240 W0.600 G1 Z0.240 F1000 G1 X22.029 Y43.415 F4800 G1 E0.0000 F2400 G92 E0.0000 G1 X46.089 Y43.415 E1.2963 F400 G1 X48.959 Y46.285 E1.5151 G1 X48.959 Y70.344 E2.8114 G1 X46.089 Y73.215 E3.0301 G1 X22.029 Y73.215 E4.3265 G1 X19.159 Y70.344 E4.5452 G1 X19.159 Y46.285 E5.8416 G1 X22.029 Y43.415 E6.0603 G92 E0.0000 G1 E-4.0000 F2400 G1 X22.278 Y44.015 F4800 G1 E0.0000 F2400 G92 E0.0000 G1 X45.840 Y44.015 E1.2696 F400 G1 X48.359 Y46.534 E1.4615 G1 X48.359 Y70.096 E2.7311 G1 X45.840 Y72.615 E2.9230 G1 X22.278 Y72.615 E4.1926 G1 X19.759 Y70.096 E4.3845 G1 X19.759 Y46.534 E5.6541 G1 X22.278 Y44.015 E5.8460 G92 E0.0000 G1 E-4.0000 F2400 ; feature inner perimeter G1 X24.959 Y49.215 F4800 G1 E0.0000 F2400 G92 E0.0000 G1 X43.159 Y49.215 E0.9806 F300 G1 X43.159 Y67.415 E1.9613 G1 X24.959 Y67.415 E2.9419 G1 X24.959 Y49.215 E3.9226 ; feature outer perimeter G1 X24.359 Y48.615 F4800 G92 E0.0000 G1 X43.759 Y48.615 E1.0453 F200 G1 X43.759 Y68.015 E2.0906 G1 X24.359 Y68.015 E3.1359 G1 X24.359 Y48.615 E4.1812 ; feature solid layer G1 X42.440 Y49.725 F4800 G92 E0.0000First, you’re using absolute extrusion M82, not relative M83. Then, it seems every retraction is 4mm, but then no unretract of the 4mm, so it’s effectively not extruding for a while. There is a zero E move after each retraction then travel move, which looks like it should be the unretract, but it’s not 4mm. I don’t use S3D, but I’m sure someone can guide you to the settings to correct this

Ian

-

@droftarts Those are indeed absolute extrusion moves but they are preceded by an M82 which should override the M83 that that OP may have in his confg.g should it not? But you are right about the retractions which appear not to have any associated un-retrcat moves. But the G1E-4s are followed by G1 E0.00 so it rather looks like the un-retract move is being inserted but it's been set to zero.

-

@deckingman Ah! I’m wrong. The G1 E0 is the unretract move, as it’s absolute! There’s no E position reset between them.

Yes all the moves are absolute, so M82 is right for this file, but in general relative extrusion works better.

Back to the drawing board...

Maybe disassemble the extruder and check the teeth of the hobbed insert aren’t full of plastic?

Ian

-

@droftarts Of course! G1 E0 absolute is an un-retrcat. I agree that relative extrusion is best - after all the firmware must convert an absolute extrusion value into one that is relative (to the last move) in order to extrude nn mm of filament for a particular move.

Ref the OPs' problem - I still think he's got a bad crimp on the extruder wiring if it works OK statically extruding into air.

-

Some suggestions:

- When it is printing the first layer, does it appear to be extruding smoothly?

- When it is printing, can you see the extruder gear moving smoothly while it is printing a line; or does the motor jerk back sometimes (other than when doing retraction)?

- When it retracts and reprimes, does it look like the extruder is moving back and then forwards by equal amounts?

- Your M201 and M203 E values look rather high. I suspect they may ghe OK for an ungeared extruder, but you could try using half those existing values, in case the problem is that it can't retract or re-prime fast enough.

- I am not familiar with the thermistor characteristics of that machine, but could it be that the M305 P1 parameters are incorrect so that the temperature is lower than reported? What happens if you increase the extruder temperature by 5C or 10C?

-

it looks like it is feeding and retracting properly. here is a video https://drive.google.com/open?id=1tmyHTlHK1n9yKcz9mY-qDMLeeh0X33k5

@dc42 I have tried adjusting m201 and m203 E values, so far no change. I have tried printing at various temps from 205 - 230C

-

@apex2011 can you do a video that shows the actual print? Off hand I’d say that that extruder is moving too slowly, but hard to tell because I can’t see the extrusion. Are you sure you haven’t set filament diameter to 3mm, rather than 1.75mm, in your slicer?

I assume you had the printer working correctly with the original board, before fitting the Duet?

Ian

-

@droftarts I will do a video of the print this morning. I am also trying another slicer. I did verify that the filament is set to 1.75 in both Simplify 3D and now Cura.

Yes, I had the printer working before switching to Duet.

-

@apex2011 have you got the config from the old electronics you can share? Have you changed the extruder motor? I think the assumption has been it’s a 1.8 degree motor, but perhaps it’s a 0.9. Has it got a label on the extruder stepper motor? What does it say?

Did you retune the extrusion distance? See https://duet3d.dozuki.com/Guide/Ender+3+Pro+and+Duet+Maestro+Guide+Part+4:+Calibration/40#s165

Ian